Abstract

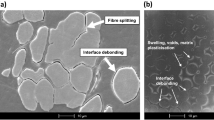

Layered material systems are widely seen in various engineering applications such as thin films circuit boards in electronic engineering, lipid bilayer in biological engineering, and adhesive bonding in aerospace and civil engineering applications. However, the durability of the material interface can be seriously affected due to the prolonged exposure to water. Although the experimental studies have shown the reduction in terms of ultimate bond strength and fracture toughness for material interface, the shift in failure mode found in experiment cannot be explained using conventional fracture theory, which is related to the interaction between the water and material interface. To understand the debonding mechanism from a fundamental and comprehensive aspect and bridge knowledge from the atomistic scale to continuum scale, multiscale modeling approach has been proposed to study the debonding behavior of material interface under moisture effect. A number of studies have been conducted using multiscale modeling approach to investigate the debonding of material interface, and it is necessary to summarize these studies to understand the role of water molecules in weakening and diffusing at the material interface using different atomistic models, force fields and upscaling techniques. This paper provides a comprehensive review on the multiscale modeling of interfacial and delamination behavior of layered material system under moisture attack with the focus on the molecular dynamics simulation and finite element modeling. The FRP bonded concrete system is used as a representative to demonstrate the approach of multiscale modeling. The future research direction is recommended, which involves the consideration of roughness of substrate and structural voids at interface for the better understanding of durability issue for interface in layered material system under different environmental conditions.

Similar content being viewed by others

References

V.M. Karbhari, M. Engineer, D.A. Eckel II, On the durability of composite rehabilitation schemes for concrete: use of a peel test. J. Mater. Sci. Springer 32(1), 147–156 (1997)

J.R. Cromwell, K.A. Harries, B.M. Shahrooz, Environmental durability of externally bonded FRP materials intended for repair of concrete structures. Constr. Build. Mater. 25(5), 2528–2539 (2011)

D. Lau, Q. Qiu, A. Zhou, et al., Long term performance and fire safety aspect of FRP composites used in building structures. Constr. Build. Mater. 126, 573–585 (2016)

O. Büyüköztürk, D. Lau, C. Tuakta, Durability and long-term performance modelling of Frp-concrete systems. in The 6th International Conference on FRP Composites in Civil Engineering , pp. 13–15 (2012)

R. Qin, D. Lau, D, L.H. Tam, et al., Experimental Investigation on Interfacial Defect Criticality of FRP-Confined Concrete Columns. Sensors, 19(3), 468 (2019)

R. Sen, Developments in the durability of FRP-concrete bond. Constr. Build. Mater. 78, 112–125 (2015)

S. Amidi, J. Wang, Direct measurement of traction–separation law of concrete-epoxy interfaces subjected to moisture attack under mode-I Loading. J. Compos. Constr. 21(5), 4017028 (2017)

S. Amidi, J. Wang, Deterioration of the FRP-to-concrete interface subject to moisture ingress: effects of conditioning methods and silane treatment. Compos. Struct. 153, 380–391 (2016)

S. Amidi, J. Wang, Subcritical debonding of FRP-to-concrete bonded interface under synergistic effect of load, moisture, and temperature. Mech. Mater. 92, 80–93 (2016)

L. Gautier, B. Mortaigne, V. Bellenger, Interface damage study of hydrothermally aged glass–fibre–reinforced polyester composites. Compos. Sci. Technol. 59(16), 2329–2337 (1999)

A. Chateauminois, B. Chabert, J.P. Soulier et al., Hygrothermal ageing effects on the static fatigue of glass/epoxy composites. Composites 24(7), 547–555 (1993)

Allred, The effect of temperature and moisture content on the flexural response of Kevlar/epoxy laminates. I. [0/90] filament orientation. J. Compos. Mater. 15, 100–116 (1981)

A. Pandian, M. Vairavan, W.J. Jebbas Thangaiah et al., Effect of moisture absorption behavior on mechanical properties of basalt fibre reinforced polymer matrix composites. J. Compos. 2014, 1–8 (2014)

L.C. Bank, T.R. Gentry, A. Barkatt, Accelerated test methods to determine the long-term behavior of FRP composite structures: environmental effects. J. Reinf. Plast. Compos. 14(6), 559–587 (1995)

A. Zhou, C. L. Chow, D. Lau, Structural behaviour of GFRP reinforced concrete columns under the influence of chloride at casting and service stages. Compos. B Eng. 136, 1–9 (2017)

O. Büyüköztürk, O. Gunes, E. Karaca, Characterization and modeling of debonding in Rc beams strengthened with Frp composites. in Proceedings of the 15th ASCE Engineering Mechanics Conference: 1–8 (2002)

C. Au, O. Büyüköztürk, Peel and shear fracture characterization of debonding in FRP plated concrete affected by moisture. J. Compos. Constr. 10(1), 35–47 (2006)

C. Au, Moisture degradation in FRP bonded concrete systems: an interface fracture approach.PhD Thesis. Massachusetts Institute of Technology (2005)

O. Büyüköztürk, M.J. Buehler, D. Lau et al., Structural solution using molecular dynamics: fundamentals and a case study of epoxy–silica interface. Int. J. Solids Struct. 48(14–15), 2131–2140 (2011)

D. Lau, R.H.W. Lam, Atomistic prediction of nanomaterials: introduction to molecular dynamics simulation and a case study of graphene wettability. IEEE Nanatechnol. Mag. 6(1), 8–13 (2012)

Y.L. Yaphary, Z. Yu, R.H.W. Lam et al., Molecular dynamics simulations on adhesion of epoxy-silica interface in salt environment. Compos. B Eng. 131, 165–172 (2017)

Y. Mishin, M. Asta, J. Li, Atomistic modeling of interfaces and their impact on microstructure and properties. Acta Mater. 58(4), 1117–1151 (2010)

M.J. Buehler, Atomistic modeling of materials failure (Springer, 2008)

D. Lau, Moisture-induced debonding in concrete–epoxy interface. HKIE Trans Hong Kong Inst Eng 19(3), 33–38 (2012)

H. Salahshoor, N. Rahbar, Nano-scale fracture toughness and behavior of graphene/epoxy interface. J. Appl. Phys. 112(2) (2012)

D. Lau, K. Broderick, M.J. Buehler et al., A robust nanoscale experimental quantification of fracture energy in a bilayer material system. Proc. Natl. Acad. Sci. U.S.A. 111(33), 11990–11995 (2014)

O. Gunes, D. Lau, C. Tuakta et al., Ductility of FRP-concrete systems: investigations at different length scales. Constr. Build. Mater. 49, 915–925 (2013)

E. Lidorikis, M. Bachlechner, R. Kalia, Coupling of length scales: hybrid molecular dynamics and finite element approach for multiscale nanodevice simulations. MRS Online Proc. Library Arch., 653 (2001)

B. Shiari, R.E. Miller, D.D. Klug, Multiscale simulation of material removal processes at the nanoscale. J. Mech. Phys. Solids 55(11), 2384–2405 (2007)

S. Ogata, E. Lidorikis, F. Shimojo et al., Hybrid finite-element/molecular-dynamics/electronic-density-functional approach to materials simulations on parallel computers. Comput. Phys. Commun. 138(2), 143–154 (2001)

A. Nakano, M.E. Bachlechner, R.K. Kalia et al., Multiscale simulation of nanosystems. Comput. Sci. Eng. 3(4), 56–66 (2001)

C.R. Dandekar, Y.C. Shin, Modeling of machining of composite materials: a review. Int. J. Mach. Tools Manuf. 57, 102–121 (2012)

S.W. Chang, Y.-P. Liao, C.-S. Chen et al., Energy and force transition between atoms and continuum in quasicontinuum method. Interact. Multiscale Mech., 7(1), 543–561 (2014)

Z. Wu, H. Yuan, H. Niu, Stress transfer and fracture propagation in different kinds of adhesive joints. J. Eng. Mech. 128(5), 562–573 (2002)

M.J. Chajes, W.W. Finch, T.F. Januszka et al., Bond and force transfer of composite material plates bonded to concrete. ACI Struct. J. 93(2), 208–217 (1996)

B. Täljsten, Strengthening of beams by plate bonding. J. Mater. Civ. Eng. 9(4), 206–212 (1997)

U. Neubauer, F. S. Rostasy, Design aspects of concrete structures strengthened with externally bonded CFRP-plates. in Proceedings of the Seventh International Conference on Structural Faults and Repair, pp. 109–118 (1997)

A. Khalifa, W.J. Gold, A. Nanni et al., Contribution of externally bonded FRP to shear capacity of RC flexural members. J. Compos. Constr. 2(4), 195–202 (1998)

X.Z. Lu, J.F. Chen, L.P. Ye et al., RC beams shear-strengthened with FRP: stress distributions in the FRP reinforcement. Constr. Build. Mater. 23(4), 1544–1554 (2009)

J.F. Chen, J.G. Teng, Anchorage strength models for FRP and steel plates bonded to concrete. J. Struct. Eng. 127(7), 784–791 (2001)

H.A. Rasheed, Strengthening design of reinforced concrete with FRP. (CRC Press, 2014)

ACI 440.2R-08. Guide for the design and construction of externally bonded FRP systems for strengthening existing structures. ACI committee 440 (2008)

M.Y. He, J.W. Hutchinson, Kinking of a crack out of an interface. J. Appl. Mech. Am. Soc. Mech. Eng. 56(2), 270–278 (1989)

J. Hutchinson, Z. Suo, Mixed-mode cracking in layered materials. Adv. Appl. Mech. 29, 63–191 (1992)

C. Tuakta, O. Büyüköztürk, Deterioration of FRP/concrete bond system under variable moisture conditions quantified by fracture mechanics. Compos. B Eng. 42(2), 145–154 (2011)

P. S and J. K, Computer simulation of liquids. J. Mol. Liquids 38(3–4), 267 (1988)

B.J. Alder, T.E. Wainwright, Phase transition for a hard sphere system. J. Chem. Phys. 27(5), 1208–1209 (1957)

E. Chiessi, A. Lonardi, G. Paradossi, Toward modeling thermoresponsive polymer networks: a molecular dynamics simulation study of N-isopropyl acrylamide co-oligomers. J. Phys. Chem. B 114(25), 8301–8312 (2010)

V. Varshney, S.S. Patnaik, A.K. Roy et al., A molecular dynamics study of epoxy-based networks: cross-linking procedure and prediction of molecular and material properties. Macromolecules 41(18), 6837–6842 (2008)

P.V. Komarov, Y.T. Chiu, S.M. Chen et al., Highly cross-linked epoxy resins: an atomistic molecular dynamics simulation combined with a mapping/reverse mapping procedure. Macromolecules 40(22), 8104–8113 (2007)

Q. Wang, N.S. Suraweera, D.J. Keffer et al., Atomistic and coarse-grained molecular dynamics simulation of a cross-linked sulfonated poly(1,3-cyclohexadiene)-based proton exchange membrane. Macromolecules 45(16), 6669–6685 (2012)

J.D. Monk, J.B. Haskins, C.W. Bauschlicher et al., Molecular dynamics simulations of phenolic resin: construction of atomistic models. Polymer (United Kingdom) 62, 39–49 (2015)

S.H. Min, S.K. Kwak, B.-S. Kim, Atomistic simulation for coil-to-globule transition of poly(2-dimethylaminoethyl methacrylate). Soft Matter 11(12), 2423–2433 (2015)

G. Paradossi, I. Finelli, F. Natali et al., Polymer and water dynamics in poly(vinyl alcohol)/poly(methacrylate) networks. A molecular dynamics simulation and incoherent neutron scattering investigation. Polymers 3(4), 1805–1832 (2011)

P.H. Lin, R. Khare, Molecular simulation of cross-linked epoxy and epoxy− POSS nanocomposite. Macromolecules 42(12), 4319–4327 (2009)

A. N. Rissanou, V. Harmandaris, Structure and dynamics of poly(methyl methacrylate)/graphene systems through atomistic molecular dynamics simulations. J. Nanoparticle Res. 15(5) (2013)

D.R. Heine, G.S. Grest, C.D. Lorenz et al., Atomistic simulations of end-linked poly(dimethylsiloxane) networks: structure and relaxation. Macromolecules 37(10), 3857–3864 (2004)

D.C. Doherty, B. N. Holmes, P. Leung, et al., Polymerization molecular dynamics simulations. I. Cross-linked atomistic models for poly(methacrylate) networks. Comput. Theor. Polym. Sci. 8(1–2), 169–178 (1998)

Z. Yu, D. Lau, Flexibility of backbone fibrils in α-chitin crystals with different degree of acetylation. Carbohyd. Polym. 174, 941–947 (2017)

Z. Yu, D. Lau, Development of a coarse-grained α-chitin model on the basis of MARTINI force field. J. Mol. Model. 21(5), 128 (2015)

Z. Yu, D. Lau, Molecular dynamics study on stiffness and ductility in chitin–protein composite. J. Mater. Sci. 50(21), 7149–7157 (2015)

J.A. Zimmerman, D.J. Bammann, H. Gao, Deformation gradients for continuum mechanical analysis of atomistic simulations. Int. J. Solids Struct. 46(2), 238–253 (2009)

R.E. Miller, E.B. Tadmor, Hybrid continuum mechanics and atomistic methods for simulating materials deformation and failure. MRS Bull. 32(11), 920–926 (2007)

V.B. Shenoy, R. Miller, E.B. Tadmor et al., Quasicontinuum models of interfacial structure and deformation. Phys. Rev. Lett. 80(4), 742 (1997)

G. Scocchi, P. Posocco, A. Danani, et al., To the nanoscale, and beyond! Multiscale molecular modeling of polymer–clay nanocomposites. Fluid Phase Equilibria 261(1–2), 366–374 (2007)

C. Zhang, J. Hankett, Z. Chen, Molecular level understanding of adhesion mechanisms at the epoxy/polymer interfaces. ACS Appl. Mater. Interfaces. 4(7), 3730–3737 (2012)

X. Periole, S.J. Marrink, The martini coarse-grained force field. Methods Mol. Biol. 924, 533–565 (2013)

C.J. Dickson, B.D. Madej, Å.A. Skjevik et al., Lipid14: the amber lipid force field. J. Chem. Theory Comput. 10(2), 865–879 (2014)

S.J. Marrink, H.J. Risselada, S. Yefimov et al., The MARTINI force field: coarse grained model for biomolecular simulations. J. Phys. Chem. B 111(27), 7812–7824 (2007)

A.C.T. Van Duin, S. Dasgupta, F. Lorant et al., ReaxFF: a reactive force field for hydrocarbons. J. Phys. Chem. A 105(41), 9396–9409 (2001)

K. Vanommeslaeghe, E. Hatcher, C. Acharya et al., CHARMM general force field: a force field for drug-like molecules compatible with the CHARMM all-atom additive biological force fields. J. Comput. Chem. 31(4), 671–690 (2010)

T.A. Halgren, Merck molecular force field. J. Comput. Chem. 17(5–6), 490–519 (1996)

W. Jian, L.H. Tam, D. Lau, Atomistic study of interfacial creep behavior in epoxy–silica bilayer system. Compos. B Eng. 132, 229–236 (2018)

R. Berruet, E. Vinard, A. Calle et al., Mechanical properties and biocompatibility of two polyepoxy matrices: DGEBA-DDM and DGEBA-IPD. Biomaterials 8(3), 162–171 (1987)

D.G.D. Galpaya, J.F.S. Fernando, L. Rintoul et al., The effect of graphene oxide and its oxidized debris on the cure chemistry and interphase structure of epoxy nanocomposites. Polymer (United Kingdom) 71, 122–134 (2015)

K. Li, Y. Li, Q. Lian et al., Influence of cross-linking density on the structure and properties of the interphase within supported ultrathin epoxy films. J. Mater. Sci. 51(19), 9019–9030 (2016)

B. Qi, Q.X. Zhang, M. Bannister et al., Investigation of the mechanical properties of DGEBA-based epoxy resin with nanoclay additives. Compos. Struct. 75(1–4), 514–519 (2006)

A. Shokuhfar, B. Arab, The effect of cross linking density on the mechanical properties and structure of the epoxy polymers: molecular dynamics simulation. J. Mol. Model. 19(9), 3719–3731 (2013)

M. Tackie, G.C. Martin, The polymerization mechanism and kinetics of DGEBA with BF3-MEA. J. Appl. Polym. Sci. 48(5), 793–808 (1993)

L. Tam, D. Lau, A molecular dynamics investigation on the cross-linking and physical properties of epoxy-based materials. RSC Adv. 4(62), 33074–33081 (2014)

A. Zhou, L.H. Tam, Z. Yu et al., Effect of moisture on the mechanical properties of CFRP-wood composite: an experimental and atomistic investigation. Compos. B Eng. 71, 63–73 (2015)

R.J.M. Pellenq, H. Van Damme, Why does concrete set? The nature of cohesion forces in hardened cement-based materials. MRS Bull. 29(05), 319–323 (2004)

E.J. Garboczi, D.P. Bentz, Computer simulation of the diffusivity of cement-based materials. J. Mater. Sci. 27(8), 2083–2092 (1992)

J.R. Maple, U. Dinur, A.T. Hagler, Derivation of force fields for molecular mechanics and dynamics from ab initio energy surfaces. Proc. Natl. Acad. Sci. U.S.A. 85(15), 5350–5354 (1988)

P. Dauber-Osguthorpe, V.A. Roberts, D. J. Osguthorpe, et al., Structure and energetics of ligand binding to proteins: Escherichia coli dihydrofolate reductase-trimethoprim, a drug–receptor system. Proteins Struct. Funct. Bioinf. 4(1), 31–47 (1988)

M.J. Hwang, T.P. Stockfisch, A.T. Hagler, Derivation of class II force fields. 2. Derivation and characterization of a class II force field, CFF93, for the alkyl functional group and alkane molecules. J. Am. Chem. Soc. 116(6), 2515–2525 (1994)

A.T. Hagler, C.S. Ewig, On the use of quantum energy surfaces in the derivation of molecular force fields. Comput. Phys. Commun. 84(1–3), 131–155 (1994)

H. Heinz, T.J. Lin, R. Kishore Mishra et al., Thermodynamically consistent force fields for the assembly of inorganic, organic, and biological nanostructures: the INTERFACE force field. Langmuir 29(6), 1754–1765 (2013)

S.L. Mayo, B.D. Olafson, W.A. Goddard, et al., DREIDING: a generic force field for molecular simulations. J. Phys. Chem. 101, 8897–8909 (1990)

R.T. Cygan, J.-J. Liang, A.G. Kalinichev, Molecular Models of hydroxide, oxyhydroxide, and clay phases and the development of a general force field. J. Phys. Chem. B 108(4), 1255–1266 (2004)

D. Lau, O. Büyüköztürk, M.J. Buehler, Characterization of the intrinsic strength between epoxy and silica using a multiscale approach. J. Mater. Res. 27(14), 1787–1796 (2012)

D. Xin, Q. Han, Adhesion reliability of the epoxy-cu interface by molecular simulations. J. Adhes. 91(5), 409–418 (2014)

H. Mei, Y. Pang, R. Huang, Influence of interfacial delamination on channel cracking of elastic thin films. Int. J. Fract. 148(4), 331–342 (2007)

W. Xie, S.K. Sitaraman, Investigation of interfacial delamination of a copper–epoxy interface under monotonic and cyclic loading: modelling and evaluation. IEEE Trans. Adv. Packag. 26(4), 441–446 (2003)

H. Fan, M. M. F. Yuen, A multiscale approach for interfacial delamination in solid-state lighting. in Solid State Lighting Reliability: Components to Systems, pp. 305–316 (2013)

O. Hölck, J. Bauer, T. Braun, et al., Transport of moisture at epoxy–SiO2 interfaces investigated by molecular modeling. in Microelectronics Reliability, pp. 1111–1116 (2013)

M. H. Shirangi, B. Michel, Mechanism of moisture diffusion, hygroscopic swelling, and adhesion degradation in epoxy molding compounds. in Moisture Sensitivity of Plastic Packages of IC Devices, (Springer, USA, 2010), pp. 29–69

H. Sun, P. Ren, J.R. Fried, The COMPASS force field: parameterization and validation for phosphazenes. Comput. Theor. Polym. Sci. 8(1–2), 229–246 (1998)

H. Sun, COMPASS: an ab initio force-field optimized for condensed-phase applications overview with details on alkane and benzene compounds. J. Phys. Chem. B 102(38), 7338–7364 (1998)

O. Hölck, J. Bauer, O. Wittler et al., Comparative characterization of chip to epoxy interfaces by molecular modeling and contact angle determination. Microelectron. Reliab. 52(7), 1285–1290 (2012)

A. Laio, F.L. Gervasio, Metadynamics: a method to simulate rare events and reconstruct the free energy in biophysics, chemistry and material science. Rep. Prog. Phys. 71(12), 126601 (2008)

A. Laio, M. Parrinello, Escaping free-energy minima. Proc. Natl. Acad. Sci. U.S.A. 99(20), 12562–12566 (2002)

P. Tiwary, M. Parrinello, A time-independent free energy estimator for metadynamics. J. Phys. Chem. B 119(3), 736–742 (2015)

P. Tiwary, M. Parrinello, From metadynamics to dynamics. Phys. Rev. Lett. 111(23) (2013)

A. Barducci, M. Bonomi, M. Parrinello, Metadynamics (Computational molecular science, Wiley Interdisciplinary Reviews, 2011)

S. Keten, M.J. Buehler, Asymptotic strength limit of hydrogen-bond assemblies in proteins at vanishing pulling rates. Phys. Rev. Lett. 100(19) (2008)

S. Yang, F. Gao, J. Qu, A molecular dynamics study of tensile strength between a highly-crosslinked epoxy molding compound and a copper substrate. Polymer (United Kingdom) 54(18), 5064–5074 (2013)

C. K. Y. Wong, S. Y. Y. Leung, R. H. Poelma, et al. Molecular dynamics study of the traction-displacement relations of epoxy-copper interfaces. In: 2011 12th Int. Conf. on Thermal, Mechanical and Multi-Physics Simulation and Experiments in Microelectronics and Microsystems, EuroSimE (2011)

H. Sun, Ab initio calculations and force field development for computer simulation of polysilanes. Macromolecules 28(3), 701–712 (1995)

K.-S. Chang, T. Yoshioka, M. Kanezashi et al., A molecular dynamics simulation of a homogeneous organic-inorganic hybrid silica membrane. Chem. Commun. 46(48), 9140–9142 (2010)

J.L. Asensio, M. Martin-Pastor, J. Jimenez-Barbero, The use of CVFF and CFF91 force fields in conformational analysis of carbohydrate molecules. Comparison with AMBER molecular mechanics and dynamics calculations for methyl α-lactoside. Int. J. Biol. Macromol. 17(3–4), 137–148 (1995)

G.C. Sih, Multiscaling in molecular and continuum mechanics: interaction of time and size from macro to nano (Springer, Dordrecht, 2007)

N. Iwamoto, M.M.F. Yuen, H. Fan, Molecular modeling and multiscaling issues for electronic material applications, vol. 57 (Springer, London, 2012)

X. W. Zhou, N. R. Moody, R. E. Jones, et al. Molecular dynamics study of interfacial cohesive zone law: elastic constant effects. In: ICF12, pp. 1–7 (2009)

X.W. Zhou, N.R. Moody, R.E. Jones et al., Molecular-dynamics-based cohesive zone law for brittle interfacial fracture under mixed loading conditions: effects of elastic constant mismatch. Acta Mater. 57(16), 4671–4686 (2009)

Z.H. Jin, C.T. Sun, Cohesive zone modelling of interface fracture in elastic bi-materials. Eng. Fract. Mech. 72, 1805–1817 (2005)

A. Zhou, R. Qin, L. Feo et al., Investigation on interfacial defect criticality of FRP-bonded concrete beams. Compos. B Eng. 113, 80–90 (2017)

R. Qin, A. Zhou, D. Lau, Effect of reinforcement ratio on the flexural performance of hybrid FRP reinforced concrete beams. Compos. B Eng. 108, 200–209 (2017)

E.K.L. Chan, H. Fan, M.M.F. Yuen, Effect of interfacial adhesion of copper/epoxy under different moisture level. in 7th International Conference on Thermal, Mechanical and Multiphysics Simulation and Experiments in Micro-Electronics and Micro-Systems, EuroSimE (2006)

N. Iwamoto, Molecularly derived mesoscale modeling of an epoxy/Cu interface: interface roughness. in Microelectronics Reliability, pp. 1101–1110 (2013)

N. Burger, A. Laachachi, M. Ferriol, et al., Review of thermal conductivity in composites: mechanisms, parameters and theory. Prog. Polym. Sci. 61, 1–28 (2016)

Z. Yu, D. Lau, Evaluation on mechanical enhancement and fire resistance of carbon nanotube (CNT) reinforced concrete. Coupled Syst. Mech. 6(3), 335–349 (2017)

D. Lau, Z. Yu, O. Büyüköztürk, Mesoscale modeling of cement matrix using the concept of building block. in Materials Research Society Symposium Proceedings, pp. 13–19 (2015)

Z. Yu, A. Zhou, D. Lau, Mesoscopic packing of disk-like building blocks in calcium silicate hydrate. Sci. Rep. 6(1), 36967 (2016)

R. Qin, H. Hao, T. Rousakis et al., Effect of shrinkage reducing admixture on new-to-old concrete interface. Compos. B Eng. 167, 346–355 (2019)

L. Tam, D. Lau, Effect of structural voids on mesoscale mechanics of epoxy-based materials. Multiscale Multiphys. Mech. 1(2): 127–141 (2016)

Z. Yu, D. Lau, Nano- and mesoscale modelling of cement matrix. Nanoscale Res. Lett. 10(1), 173 (2015)

Acknowledgements

The authors are grateful to the support from the Research Grants Council (RGC) in Hong Kong through the General Research Fund (GRF) with the Grant no. 11255616.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Qin, R., Lau, D. Evaluation of the Moisture Effect on the Material Interface Using Multiscale Modeling. Multiscale Sci. Eng. 1, 108–118 (2019). https://doi.org/10.1007/s42493-018-00008-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42493-018-00008-8