Abstract

The first step in transformer design optimization is to solve a non-linear optimization task. Here, not only the physical and technological requirements, but the economic aspects are also considered. Large number of optimization algorithms have been developed to solve this task. These methods result the optimal electrical parameters and the shape of the core and winding geometry. Most of them model the windings by their copper filling factors. Therefore the transformer designer’s next task, to find out the detailed winding arrangement, which fits to the optimization results. However, in the case of large power transformers, the calculation of some parameters like: winding gradients, short-circuit stresses etc., needs the knowledge of the exact wire dimensions and winding arrangement. Therefore, an other optimization task should be solved. This paper shows how this sub-problem can be formulated and solved as a generalized geometric program.

You have full access to this open access chapter, Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

It is well known that the transformer design optimization is a complex, nonlinear optimization task, due to the nature of the interaction of several physical fields encountered during the design of an electrical machine [1]. Therefore, in practice, this design process is split into more sub-optimization tasks and design stages. The first design stage is the preliminary or tendering design stage, where not only the physical and technological requirements, but the economical aspects are also considered [2]. Large number of optimization algorithms have been published in the literature to solve this task [3]. These methods are using simplified transformer models to calculate the optimal electrical parameters and the shape of the core and windings with adequate precision in a very short time. These approaches generally model the windings by a copper filling factor to obtain the optimal key design parameters. This simplification is widely used in the industry, and gives accurate results for the electrical parameters [4]. Moreover, FEM calculations also use this replacement [5].

In the case of large power transformers, the calculation of some parameters like winding gradients, short-circuit stresses etc., requires deeper knowledge of the exact wire dimensions and winding arrangement. Therefore, the transformer designer’s next task is to find out the detailed winding arrangement which fits the optimized winding shape and their electrical parameters. This is another optimization task that should be performed Fig. 1. This design stage is often time consuming and usually needs huge expertise and manual interaction from the designer.

This paper demonstrates how this design step can be solved with introducing a novel sub-problem. This sub-problem assumes that the geometrical and electrical parameters of the winding are known from a copper filling factor based transformer optimization. Its application is denonstrated on a case-type winding. It can be generalized for every other type of windings and it can be integrated into the metaheuristic based solution to replace copper filling factor based approximation [6]. A generalized geometric programing can be formulated and solved, which guarantees that the global optimum is found in no time [7].

2 Relationship to Smart Systems

The smart system environments will arise new challenges regarding to total cost of ownership, which is the base of the hereby presented optimization process. “The increasing proliferation of renewable energy resources and new size-able loads like electric vehicle (EV) charging stations has posed many technical and operational challenges to distribution grids” [8]. Therefore the conventional passive system design have to be replaced by an active concept resulting in a change of the emphasis of cost efficient design.

3 Generalized Geometric Programming

A geometric program is a type of the non-linear mathematical optimization problem characterized by the objective and constraint functions given in the following special form [7, 9]:

where \( x = (x_{1} ,x_{2} , \ldots ,x_{n} ) \) is a vector containing the optimization variables, \( f_{0} , \ldots ,f_{m} \) are the posynomial functions, and \( g_{0} , \ldots ,g_{m} \) are the monomial functions. All the elements of x must be positive. The monomial function \( g(x) \) can be expressed as

where \( {\text{c}}_{\text{g}} \,2\,{\text{R}},\_{\text{i}}\, 2\,{\text{R}}, \), and \( {\text{c}}_{\text{g}} > 0 \). This definition of monomial term is similar, but differs from the standard definition of the monomial used in algebra, where the exponents must be non-negative integers and the coefficient c is 1.

The posynomial function is the linear combination of monomials

We can introduce the generalized posynomials such that a function \( f \) of positive variables \( x_{1} , \ldots ,x_{n} \) is a generalized posynomial if it can be formed from posynomials using the operations of addition, multiplication, positive (fractional) power, and maximum.

Geometric programing \( ({\text{GP}}) \) problems, in general, are not convex optimization problems, and the main trick in the solution of a \( {\text{GP}} \) is a transformation to a convex optimization task. This transformation, which is a simple logarithmic change in the variables, is automatically performed by the solver. The \( {\text{GP}} \) modeler only knows the formal rules defined in 1.

There are many major advantages of \( {\text{GP}} \) modeling. First, the \( {\text{GP}} \) formalism guarantees that the solver finds the globally optimal solution, and if the problem is infeasible, this provides that no feasible point exists. Second, the major advantage of this formulation is the great efficiency of this special class of optimization problems. Finally, these interior-pointbased \( {\text{GP}} \) solvers are also very robust [6, 7, 9].

4 The Optimization Sub-process

4.1 Input Parameters

The main purpose of the optimization sub-process is to determine additional input parameters for the preliminary design optimization. These methods, which employs copper filling factors, are suitable to determine the leakage magnetic field distribution inside the core working window. Even a finite element methods are also applicable for greater accuracy [5]. This calculation yields the maximum value of the radial and axial magnetic flux inside the winding area. These important parameters will be our additional input parameter next to the winding dimensions. Than we can prescribe an optimization problem that minimize the load loss in the desired winding area. In our example we focus on disc type winding arrangement consisting of single conductors.

The following input values are come from the previous sub-optimization process:

-

t w radial thickness of the winding,

-

h w axial height of the winding,

-

r m mean radius of the winding,

-

n number of turns,

-

B rad radial flux density,

-

B ax axial flux density,

-

ff copper filling factor.

The input parameters taken from the requirement specification:

-

f frequency,

-

I phase current,

-

t rad minimum value of radial insulation thickness,

-

t ax minimum value of axial insulation thickness.

-

The goal of the main optimization process is to obtain the following values:

-

n ax axial number of turns,

-

nrad radial number of turns,

-

nc number of conductors in a turn,

-

Acu copper area in a turn,

-

Vcu copper volume,

-

w width of a condutor,

-

h height of a condutor.

The optimization algorithm requires support parameters describing the physical constraints:

-

P0 heat flow density,

-

ρ specific resistance,

-

α ratio of total and exposed surface area,

-

kc heat conductivity of the insulation paper,

-

Ploss total load loss,

-

βhor, βver horizontal, vertical heat flow ratio;

-

θshor, θsver horizontal, vertical temperature rise above cooling oil,

-

θphor, θpver vertical temperature rise above cooling oil.

4.2 Winding Geometry

The following posynomial inequality and monomial constraints describe the winding arrangement, this is a disc winding with normal conductors in the examined case:

4.3 Loss Calculations

The Ploss is minimized in this optimization task, which consist of the ohmic losses and the eddy losses. The eddy loss calculation takes into account the axial and radial components of the magnetic flux. It is assumed that the magnetic field is not modified by the field of the eddy currents [5]:

4.4 Thermal Model

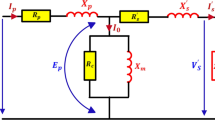

The applied calculation method of the temperature gradient uses an electrical analogy of heat-exchange, to solve the 2D-Poisson equation of the steady-state heat-flow [10]. It implies the decomposition of the whole winding into simplified components (cooling blocks), where the heat flow possible only in the axial or the radial directions (Fig. 2) [11,12,13]. Here, the axial and the radial component of the heat-flow density is owing through the effective thermal resistance of the insulation and the oil boundary layer (Fig. 2). The heat-flow density value defined by the following monomial expression:

The effective insulation thickness in the axial (vertical) and the radial direction are the following:

To calculate the ratio of the radial and axial heat-flow density, between the cooling surfaces the loss ratio parameters are introduced by [11] (β parameters). However, the calculation method of these parameters, which presented in [11] not fulfills the GGP formalism. Therefore a monomial function is fitted in βhor and βver (Fig. 3). Using this formulation, the horizontal and vertical heat-flows and the temperature gradients through the insulation can be formulated by the following monomial expressions:

Temperature gradient through the oil boundary layer, in the case of ON or OF cooling:

Where, the auxiliary parameter a = 1 in the case of zig-zag cooling. Regardless of the used formula, the incorporated constant C depends on the established cooling mechanism. Potential interpretations are shown in [11, 13].

The gradient is defined by the following generalized posynomial:

The min() function is not a valid generalized posynomial inequality, but it can be handled by a replacement [9].

5 Results

The winding sub-optimization method has been tested on an inner winding of a three-phase, 10 MVA, 33/6.9 kV, star/star Volts/turn = 46.87, Z = 7.34% transformer. The transformer data is presented in [14], and the optimization is based on this real life example transformer. This example gives us the following input parameters: tw = 35 mm, hw = 1100 mm, n = 89, rm = 495/2 mm, I = 836 A, f = 50 Hz. As we consider disc type winding, all oil cooling ducts are considered to be 3 mm wide. The minimal thickness of the insulation of the single conductor is 0.5 mm, this value was chosen taking into account of the voltage level. The transformer specification and relevant design details of the source [14] are:

-

LV conductor: thickness = 2.3 mm, insulation between conductors = 0.5 mm, area of one conductor = 22:684 mm 2

-

Total conductor area = 12 × area of one conductor = 272.21 mm 2

-

LV winding volume for 3 phases = 0.1079 m 3

-

P eddy = 489.55 W (only radial flux considered)

-

P dc = 21.885 kW

-

copper filling factor 60%

-

the winding temperature rise is undocumented

After the optimization our results for this transformer are the following:

-

LV conductor: thickness = 1.8 mm, insulation between conductors = 0.5 mm, area of one conductor = 21.6 mm 2

-

Total conductor area = 12 × area of one conductor = 237:6 mm 2

-

LV winding volume for 3 phases = 0.0986 m 3

-

P eddy = 850.27 W (includes the axial and radial ux too)

-

P dc = 21.6 kW

-

copper filling factor 55%

-

the winding temperature rise above oil is 14.1 K

6 Conclusions

Finding a cost efficient transformer design is a complex, non-linear optimization task. Therefore, the transformer design process is separated into several, independent sub-problems and design stages. This paper deals with the preliminary design stage, where numerous algorithms has been applied to find the key design parameters with minimal total owning cost. However, most of these methods are modeling the windings by their copper filling factors - a simplification widely used in the industry with good accuracy - this approach is not appropriate to take into account the numerous possible winding arrangement. The transformer optimization sub-problem is presented and solved in this paper, with the method of generalized geometric programming. The results are shown a good agreement with the realized transformer winding’s parameters. The presented model can be generalized to any type of winding arrangements and various type of conductors, for example case of continuously transposed cables.

References

Del Vecchio, R.M., Poulin, B., Feghali, P.T., Shah, D.M., Ahuja, R.: Transformer Design Principles: With Applications to Core-Form Power Transformers. CRC Press, Boca Raton (2010)

Orosz, T., Sőrés, P., Raisz, D., Tamus, Á.Z.: Analysis of the green power transition on optimal power transformer designs. Period. Polytech. Electr. Eng. Comput. Sci. 59(3), 125–131 (2015)

Olivares-Galvan, J., Georgilakis, P., Fofana, I., Magdaleno-Adame, S., Campero-Littlewood, E., Esparza-Gonzalez, M.: A bibliographic analysis of transformer literature 2001–2010. In: 8th Mediterranean Conference on IET Power Generation, Transmission, Distribution and Energy Conversion (MEDPOWER 2012), pp. 1-6 (2012)

Georgilakis, P.S.: Spotlight on Modern Transformer Design. Springer, Heidelberg (2009)

Andersen, O.W.: Transformer leakage flux program based on the finite element method. IEEE Trans. Power Appar. Syst. 92(2), 682–689 (1973)

Orosz, T., Sleisz, Á., Tamus, Z.Á.: Metaheuristic optimization preliminary design process of core-form autotransformers. IEEE Trans. Magn. 52(4), 1–10 (2016)

Boyd, S., Vandenberghe, L.: Convex Optimization. Cambridge University Press, New York (2004)

Andresen, M., Costa, L.F., Buticchi, G., Liserre, M.: Smart transformer reliability and efficiency through modularity. In: 2016 IEEE 8th International Power Electronics and Motion Control Conference (IPEMC-ECCE Asia), pp. 3241–3248, May 2016

Boyd, S., Kim, S.-J., Vandenberghe, L., Hassibi, A.: A tutorial on geometric programming. Optim. Eng. 8(1), 67–127 (2007)

Orosz, T., Kleizer, G., Iváancsy, T., Tamus, Z.Á.: Comparison of methods for calculation of core-form power transformer’s core temperature rise. Period. Polytech. Electr. Eng. Comput. Sci. 60(2), 88–95 (2016)

Dankó, G., Imre, L.: A method for determining the steady-state temperature distribution in the windings discs of oil-cooled transformers. Period. Polytech. Electr. Eng. 20(4), 89–103 (1976)

Ryan, H.M.: High Voltage Engineering and Testing, 3rd Edition, no. 32. IET (2013)

Ryder, S., et al.: A simple method for calculating winding temperature gradient in power transformers. IEEE Trans. Power Deliv. 17(4), 977–982 (2002)

Kulkarni, S.V., Khaparde, S.: Transformer Engineering: Design and Practice, vol. 25. CRC Press, Boca Raton (2004)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 IFIP International Federation for Information Processing

About this paper

Cite this paper

Orosz, T., Nagy, T., Tamus, Z.Á. (2017). A Generalized Geometric Programming Sub-problem of Transformer Design Optimization. In: Camarinha-Matos, L., Parreira-Rocha, M., Ramezani, J. (eds) Technological Innovation for Smart Systems. DoCEIS 2017. IFIP Advances in Information and Communication Technology, vol 499. Springer, Cham. https://doi.org/10.1007/978-3-319-56077-9_36

Download citation

DOI: https://doi.org/10.1007/978-3-319-56077-9_36

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-56076-2

Online ISBN: 978-3-319-56077-9

eBook Packages: Computer ScienceComputer Science (R0)