Abstract

In 2008, the National Research Council published a landmark report on Integrated Computational Materials Engineering (ICME) and defined it as ‘an emerging discipline that aims to integrate computational materials science tools into a holistic system that can accelerate materials development, transform the engineering design optimization process, & unify design and manufacturing’. ICME is becoming a critical enabler for reducing the design/make cycle time and getting complex systems into production more quickly. There are several reasons why this is the case. Firstly, ICME allows materials experts to develop new material systems and methods of manufacture much more quickly. Advanced new materials and their associated manufacturing processes can be tailored to deliver products that meet design requirements quickly and more effectively in terms of cost and performance. Secondly, ICME enables design processes to quantify cause and affect relationships between manufacturing methods and variability, material properties, product geometry, and design requirement margins. In the design phase, material selection itself can impose consideration of material-specific failure modes that are naturally correlated to important attributes such as strength, weight, and geometry. ICME enables designers to quickly understand the complex and probabilistic interactions between the material, manufacturing processes, manufacturing variability, and design. Thirdly, it has been shown that successful account of variability of the manufacturing processes in life calculations leads to improved accuracy in declared low cycle fatigue crack initiation and damage tolerance lives on life limited gas turbine engine components. Furthermore, ICME enables engineers to rapidly explore more effective design and manufacturing solutions for delivering superior products at lower cost, faster but not without challenges. To highlight challenges and progress toward realization of this transformational technology, a survey of recent examples of materials and manufacturing process simulations along with the overarching approach and requirements within ICME to link these simulation capabilities to design and manufacturing methods will be reviewed from a gas turbine engine perspective.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Review

Impetus - why we care

System benefits are lost when communication and technical data does not pass across functional lines. System failures occur when ‘islands’ or ‘silos’ are allowed to persist in product development. Fundamentally, the maturing discipline of Integrated Computational Materials Engineering (ICME) aims to integrate more than 50 years of computational materials and process modeling research into engineering systems to accelerate the design/make process through use of physics-based models and virtual linkage of the manufacturing processes with material structure and design performance. Though historical focus has been on development of digital/virtual toolsets, the success and practical implementation of ICME into product development systems requires and forces the cross-functional information flow and cultural change that is required to realize significant manufacturing benefit and improve competitiveness. Digitally integrating design and manufacture up front for iteration in analysis is much less costly than redesigning and replacement of products in service.Successful integration of ICME into product development systems promises order of magnitude reductions in product development time and cost through use of physics-based models which replace costly experimental iterations for optimizing manufacturing processes and component performance, as illustrated in Figure 1. The magnitude of benefit promised through systems level solutions, ICME, and the necessity for a step change in manufacturing competitiveness has primed industry for the next manufacturing revolution. In addition to the reduction in product development cost and timeline for engine development, life cycle cost benefits can be realized after entry into service.

Figure 2 illustrates the benefits of an improved approach to product development by introducing ICME earlier in the design stage after incorporating all relevant knowledge throughout the product life cycle. It can shorten the time to market and product capability responsiveness and deliver savings through reduction of recurring production and part costs. Improved accuracy in declared lives for life-limited components derived by the application of physics-based modeling of manufacturing processes can provide a significant reduction in cost of operation and maintenance of gas turbine engines. In addition, the application of ICME with Prognostic Health Monitoring (PHM) can also deliver significant business benefit by better informing maintenance decisions and overall fleet risk evaluations. Integration and application of computational materials engineering capability at Rolls-Royce has delivered significant business benefit in a number of ways including, but not limited to the following:

-

Distortion prediction of forged parts resulting in less scrap, fewer concessions (99.98% Right First Time), decreasing forging machining costs (50% cost reduction), and increasing stock-turn.

-

Reduction in casting scrap (> > US$5 M p.a.).

-

Increasing tensile strength (approximately 5% on forged/formed parts).

-

Significant reduction (by 90%) of forming trials (powder HIP process) due to predictive part geometric accuracy.

-

Optimization of parts in furnaces to increase utilization; increasing stock-turn and lowering costs.

-

Shortening development time and time to market for new product introduction and redesign efforts.

The magnitude and opportunity of the benefit afforded by successful integration of ICME into product development systems is substantial. However, the implementation of ICME into product development systems has several significant challenges that must be addressed if bottom line business benefit is to be fully realized.

Scoping the ICME landscape

The integration of computational materials and process modeling into product development systems promises significant benefit for cost reduction, performance improvement, and lead time reduction across many material systems, commodity streams, and products, as well as across the product life cycle itself. As a result, a key challenge exists in appropriately focusing ICME efforts to match the greatest business benefit rather than trying to solve too broad a problem. Manufacturing companies do not sell technology; they sell products. Thus, all prioritization of ICME technology development and implementation efforts must have line-of-sight to bottom line business benefit and delivering superior product to market faster and at lower cost. ICME efforts can fail before they start simply because they have not been scoped for success and the focus falls solely on developing technology and not delivering to customer requirements and business benefit. Initially, internal design and manufacturing functions within the business can be engaged to articulate how ICME methods and toolsets can better deliver to their greatest product improvement needs. This facilitates prioritization of efforts to specific prioritized product benefits, delivered through specific components or sub-systems, and identifies specific design/make stakeholders that will become future business champions if the project is successful. For example, Figure 3 illustrates some general benefits/needs internal sub-system teams might articulate for a gas turbine [1].

In addition to continual customer engagement, it is important to consider several other scoping factors for ICME effort prioritization. The selected effort must be planned to deliver a phased benefit with a series of quick wins early on to maintain business support. This may mean that the selected project may be the one with the greatest business impact, or the project that delivers the largest benefit for an acceptable level of risk. Furthermore, overlap in benefits or needs articulated from customers may highlight efforts that would have a broader impact in areas across the business. Wherever possible, planning to develop once and reuse multiple times will pay big dividends when scaling up the benefit and may highlight a lower risk project that can be selected as a pilot while providing the foundation for future benefit on higher value components and systems. For example, engagement with design, component structural analysis and lifing, and materials and manufacturing functions internally at Rolls-Royce led to grouping ICME’s capability into commodity buckets with similar manufacturing process applicability as highlighted in the tabs of Figures 4 and 5[2].

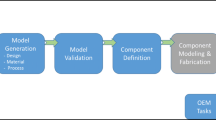

These process modeling maps provide a graphical illustration implying the sequence of ICME models that virtually link design requirements, the manufacturing processes that make up a product’s ‘digital pedigree,’ and the predicted material structures and properties that can predict the component manufacturing yield and design performance. This gives context for key stakeholders to quickly contextualize the larger ICME landscape for a given commodity group and highlights a digital thread for each component that links back to the design requirement articulated from customer engagement.

It is important to note that the integration of ICME into product development systems is not just digital but physical, heuristic, and relational as well. As a gas turbine engine OEM, Rolls-Royce delivers world-class power system and service solutions to our customers… but not on our own. This requires a trusted ICME supply chain and infrastructure of incentivized technology partners that can collaborate to deliver what is best for Rolls-Royce, as an original equipment manufacturer (OEM), and for the product development team as a whole. The interdisciplinary nature of systems engineering underlines the criticality of selecting an appropriate cross-functional team (i.e., design, materials, manufacturing, supply chain, and export control/IP) for program definition up front to ensure that programs are planned to deliver the right information to the right product development team members at the right time.

Though ICME concepts are not new to the aerospace industry [3] and academic work to develop isolated computational material models has been going strong for several decades [4], the competency of the existing supply chain in integration and use of ICME methods and capability is still relatively immature. To facilitate more rapid adoption of this technology across the industry, government and industry must fund, sponsor, and partner in activities aligned to greatest business benefits. To this end, Rolls-Royce continues to invest in developing and deploying new technology through strategic partnerships with a global University Technology Center network, Advanced Manufacturing Research Centers, and public-private partnerships like the Metals Affordability Initiative [5]. An illustration of the strategic partners and development and deployment activities for a healthy ICME supply chain are highlighted in Figure 6.

ICME supply chain for developing, deploying capability for industry consumption[1].

Systems integration

To further scope the ICME opportunity and challenge, it is important to understand that ICME is not and should not be restricted to only design. For example, Rolls-Royce has a vision to embed ICME across the entire product development, introduction, and life cycle management process, including the following:

-

Preliminary design (more analysis at sub-assembly and engine level to eliminate risk early in the design process).

-

Detailed design (use of analysis-based optimization and robust design and manufacture to enable rapid definition at component and sub-system level).

-

System design using high-fidelity virtual engine (more sophisticated, multiphysics analysis to accurately predict engine behavior linking manufacturing variability to component-specific performance).

-

Virtual manufacture (optimization of those aspects of manufacturing that have no impact on the product design but may affect, for example, the cost).

-

Virtual testing (analysis-based test strategy, planning, and correlation to reduce the need for repeat testing).

-

Virtual product validation/certification (rapid certification based on validated analysis, simulation and modeling).

-

Product life cycle analysis (fixed design, probabilistic analysis, and updating of models used during development for improved service and aftermarket decisions involving business risk, such as maintenance and product improvement costs).

-

Process capability analysis (data and knowledge capture for reuse in continuously validated and improved methods, constraints, and rules used above).These describe the elements of larger virtual product development system for faster delivery of superior products to market at lower cost. Figure 7 illustrates a ‘six-stage’ process defining the life cycle of a product and how each of these elements roughly maps onto it.As illustrated by the dashed lines in Figure 7, both legacy and new product development efforts generate significant data and knowledge that can be leveraged in unique and innovative ways at different points in the life cycle to deliver benefit. However, with the addition of more complex analysis, the accompanying large volume of digital data that will be generated out of such complex systems and the pragmatic reality that uncertainty will pervade data and model inputs, the ability to manage risk and effectively utilize these new capabilities to inform engineering decisions requires an appropriate framework and mindset.

Six-stage product life cycle and virtual product development elements[1].

Facilitating engineering decision making: informing decisions under conditions of complexity and uncertainty

Managing the development of complex new systems requires many decisions using combinations of analytical engineering models, experimental data, and expert knowledge. This process is inherently expensive when risks are high and is made even more expensive when risks are not effectively managed throughout the process. Though new systems may ultimately be successful in delivering product to market, the path to success is often far from ideal in terms of the use of models, data, and knowledge to manage risk. Models, data, and knowledge are all valuable resources in their own way but are often pitted against one another inappropriately at key decision points or worse, trusted implicitly or ignored altogether. Decisions must be made, for example, about what to analyze, what to test, what conditions to test, whether a new technology should be inserted, and the level of model fidelity needed.

Significant reduction in the development time and cost depends on quantifying and responding appropriately to risk as early during the process as possible. An error in material selection or manufacturing process definition caught early during design is not nearly as costly as the same error caught later. There are, of course, several reasons such an error might not be caught early. First, the breadth in ramifications may simply not be taken into account. For example, the material may be selected based on a requirement to operate at higher temperatures but other requirements such as corrosion resistance, manufacturability, and inspectability may not be adequately considered or known. Secondly, an understanding of the typical behavior of the material or manufacturing process may be based on relatively small samples or idealized conditions. Later when the true variability becomes apparent, it becomes much more difficult to manage. In both examples, decisions are made under conditions that are unnecessary given many of the tools available today. Physics-based models such as those envisioned under ICME are being used to quantify not only typical behavior but also variability. In addition, today’s access to affordable computational resources is making uncertainty quantification (UQ) for large complex systems possible when addressing the breadth issue.

However, quantification and management of risks associated with complex new systems mean making UQ and decision-making tools and training available to the right people throughout the process. Uncertainty and therefore risk tends to be highest at the onset of development and will be continually managed over time. What is not as well appreciated is the impact of sub-optimal paths on cost. The path used to blend and continually update engineering models, experimental data, and expert knowledge into information useful for decision making is critical to reducing development time and cost.

Finally, the same arguments made for reducing development costs may be advanced for reducing life cycle costs. Despite the enormous investments made to reduce risk and uncertainty prior to production release, a great deal is still learned over the life cycle of the product. New data is gathered on product performance, operational usage, changing economic conditions, for example, which continually present challenges to the decision-making process. Win-win situations can be made for OEMs, suppliers, and customers alike simply through the effective use of updating methods (e.g., Bayesian or otherwise) and decision-making tools.

ICME in context

Successful integration of ICME into next-generation product development systems will involve distributed (i.e., cross-supply chain) problem-solving solutions the ICME supply chain can understand, trust, and use efficiently and effectively to deliver a superior product to market faster and at lower cost.

Understand it

ICME system elements must be developed and delivered in a context and framework that product development teams can understand. Figure 8 highlights some of the key system elements involved in a product development system.During the design process, a cross-functional integrated product development team will exercise these system elements to develop and deliver a product solution. To contextualize how capability is delivered into a digitally integrated design and make system, consider the high-level engineering workflow at the sub-system level of a forged component highlighted in Figure 9. Figure 9 emphasizes the cross-functional and cross-supply chain interfaces that must be managed efficiently and effectively to facilitate truly concurrent engineering earlier in the product development process.

High-level engineering workflow for forged part design[1].

Computational material models and process models deliver predicted component performance in terms of residual stress and location-specific material properties that now enable designers to better understand the impact of manufacturing processes and manufacturing capability on the resulting design space. Digital integration and automation of the engineering workflow enables rapid exploration of feasible design space (based on known material and manufacturing capability) while simultaneously identifying robust methods of manufacture to deliver ‘Right First Time’ solutions that meet the requirements while minimizing or eliminating expensive physical trials. The integration of new ICME capability into workflows for components will require additional work by the engineering function in an environment that already has extreme time pressure to deliver results. Thus, ICME development efforts must address a number of design requirements and needs, or time pressure and frustration will prevent use and realization of benefits associated with the additional capability. To this end, ICME models, methods, and software toolsets must be as follows:

-

Accurate enough Inaccuracy can result in unanticipated life cycle costs, but too much attention to accuracy results in overly high development costs. Both ultimately represent risk that needs to be quantified and managed. This is one area in which uncertainty quantification, ICME, and decision analysis tools become particularly useful. Early in the product life cycle when understanding system, sub-system, and component level requirements is especially challenging, such tools enable key decision makers to quantify what is ‘accurate enough’ to move forward in the development process. Accuracy must be considered both qualitatively and quantitatively. The qualitative component of accuracy (the pattern of behavior) must be consistent with physical reality to appropriately capture trending. Quantitative accuracy depends on several things including, but not limited to, the modeling algorithm, input data accuracy, material/process variations, and measurement accuracy for validation efforts. In some cases, in-process sensing and control can be used to compensate/mitigate quantitative inaccuracy. Model development efforts should be limited to the accuracy needed for the specific product or application of interest. A clear understanding of the requirements up front will define what accuracy is ‘fit for purpose’ and scope development efforts to deliver an appropriately refined engineering solution.

-

Efficient and usable Engineers are fighting a battle against timescales for program delivery, and the inclusion of new capability is asking them to do more with no additional calendar time. Therefore, new capability must be delivered for seamless integration into existing design systems with as little additional computational and/or calendar time as possible.

-

Relevant Though most material models must operate at smaller length scales (micro- or nanoscale) to capture appropriate mechanisms, delivered solutions must be compatible with continuum scale which is where most engineering analysis occurs.

-

Available Export control and intellectual property implications with sharing models and data must be reviewed and planned for up front. This ensures that the developed solution has all required business agreements and export licenses in place for the cross-supply chain product development team while fully complying with export regulations and legal arrangements. Furthermore, a cyber-secure information technology collaboration platform/solution must be available to streamline access to models and data while ensuring export and intellectual property right compliance.

-

Validated Technical and business benefit validation must be considered. Manufacturing variability and uncertainty must be addressed to build confidence and trust in predicted results; however, validation of the ICME capability to deliver bottom line business benefit is what will transition from technology push to business pull.

-

Maintainable Developed solutions must be maintained, version-controlled and updated as improvements are made or system upgrades occur. A competent and robust ICME supply chain is required to support maintenance of developed solutions or they will cease to be useful.

-

Interoperable There are many different product development solutions and software used across the supply chain currently. This poses a challenge for streamlining digital communication between each organization. To this end, ICME efforts must deliver generic, transferrable, and modular solutions that are cross-supply chain compatible and not OEM or supplier specific.

Trust it - verification and validation

Manufacturing variability and uncertainty throughout product development is real and inevitable. Not everything is controlled and/or known which leads to substantial risk if not acknowledged and managed accordingly. In addition to verifying developed solutions to give expected outputs, validation that predicted results line up with reality requires an account of variability and uncertainty inherent to the manufacturing process.In line with best practice robust design and make principles, it is important to identify, prioritize, and quantify sources of variation and uncertainty that impact key process variables (KPVs) in manufacturing, material structure, and ultimately product characteristics and performance in design. Conventional robust design toolsets (e.g., fishbone diagrams, p-diagrams) can be used to help engineering teams identify sources of variability and uncertainty. Expert opinion, available prior knowledge/data, and statistical models and tools can then be used to prioritize key drivers for performance and cost (i.e., Pareto chart, QFD). As is often the case when uncertainty is high, expert opinion needs to be combined carefully with analysis models and available data. This can be done working within a Bayesian statistical framework which then provides a general foundation for incorporating new data, driving toward reduced uncertainty along with verification and validation. The use of ICME toolsets and strategic testing can be leveraged to formally quantify, understand, and reduce variability and uncertainty to improve results to desired customer goal with an acceptable level of confidence. Figure 10 graphically illustrates the general process steps of manufacturing variability and uncertainty quantification and reduction.

General process steps of manufacturing variability and uncertainty quantification and reduction. Illustration of process to (a) acknowledge, (b) identify, (c) prioritize, and (d) quantify manufacturing variability and uncertainty in support of robust design and make processes [1].

Comprehensive implementation of ICME, especially at the engine system level, will require systematic, rigorous, and quantitative verification and validation (V & V) efforts, including targeted demonstrations. Though beyond the scope of this paper, a comprehensive overview of V & V challenges and progress as related to ICME has been captured in a paper by Cowles, Backman, and Dutton [6]. To establish confidence in application of ICME at any system level, an appropriate V & V plan must be established and executed to ensure that the modeling methods have been vetted to the level of accuracy required for the target application.

Use it

To provide specific context for integration of ICME into product development systems, a survey of the opportunities and challenges for use of ICME at different stages in the life cycle will now be reviewed.

Lifecycle integration examples and challenges

Preliminary design

Preliminary design occurs during phases 0 and 1 of the six-stage product life cycle (Figure 7). Stage 0 can occur over an extended period of time as the product requirements and the product attributes are developed simultaneously. In stage 0, product attributes of interest for gas turbine engines are performance, weight, cost, and life. When working closely with a customer, the two questions ‘What can you do for me?’ and ‘What do you need from me?’ are answered.

It is in this stage that the required material properties for a product are identified. ICME becomes integral to the product during this stage of the product life cycle. For example, the differing material properties for the rim of a turbine disc compared to the bore of the same disc are identified. The mathematical identification of these properties enables a robust design solution for product design.

Mathematical methods using design of experiments explore more solutions more thoroughly. The range of solutions establishes a design space where a product design can be selected that is less sensitive to variations. The design solution evolves from a top level solution where the design is established as an overall architecture, to detailed designs of sub-systems and components. This stair-step approach makes for not only effective product design by exploring the design space but also efficient solutions by keeping the solution from going off track. To include detail modeling of each component at the architectural selection phase would create a model too large to run on most computers and take too much time to set up such a model. The human interaction with the models between the levels of optimization needs to be effective in keeping the solution process on track toward a truly optimal product design.The design of a component is a combination of the geometrical features and the material capability. Prior to ICME, the design of material capability was limited to selection of a material from a database with experimentally measured and validated nominal properties. ICME dramatically improves the design of a component by permitting the simultaneous detail design of geometrical and material features (microstructure and properties). By adding material features to the design space, the robustness of the product design is improved with the intent of reducing the chance of in-service issues. Figure 11 illustrates the cost and time benefits of getting a design right at the analysis phase.

Robust design requires mathematical representation of material properties as well as geometrical features and applied loads. ICME provides not only material capability in mathematical terms but also delivers location-specific properties that can be used to design and produce a product with superior attributes.Rolls-Royce has been effective in performing robust design using Isight™ as the integrating framework for a number of programs as illustrated in Figure 12. From the first performance models, Rolls-Royce includes requirements for modules for engine modules and components as well as aircraft-required attributes. The outcome is an optimized, robust design. Numerous solutions are studied with varying requirements and defined optimizations to understand the design space. As the customer and Rolls-Royce gain confidence in the product strategy, the design iterations become more focused on the details of the modules then the details of the design. ICME is integrated with the design approach; first by various validated design allowables early in the process then by detailed process models. The result is an optimized product design.

Materials design

Feasibility evaluation, development, and insertion of new and optimized materials technologies have become heavily dependent on the use of ICME tools and methods, as experimentation and empirical approaches alone cannot keep pace with current advanced aerospace component design cycles. The development and growth of computational tools for materials engineering have historically been hampered by the complexity and diversity of phenomena and properties that must be captured in order to deliver a robust and integrated engineering solution. Fortunately, ICME tools and the computing power required to process complex and simultaneous events during manufacturing and in service are now reaching a level of maturity where they can have a substantial impact if they can be integrated into product development [7].

A common and successful application for ICME tools has been the prediction of multicomponent alloy solidification behavior and phase equilibria in order to more efficiently assess novel compositions for structural materials. For example, innovations in existing nickel-based superalloy compositions and processing routes are required in order to overcome the challenges of usage at higher temperatures in advanced and future aerospace gas turbine engines. The most significant materials limitations for advanced γ/γ′ (γ″) alloys in particular are phase instability above 700°C and mechanical strength reduction from segregation-induced defects. Eutectic γ/γ′-δ alloys (Figure 13) may offer a novel solution due to the additional reinforcing phase δ, which has demonstrated stability in experimental studies up to 1,000°C [8].

Representative micrograph of a γ/γ′-δ eutectic alloy, showing δ-phase plates within a γ/γ′ matrix[8].

The rapid assessment of these potential next-generation alloy concepts has been made possible by the use of ICME tools. A commercially available software, with the incorporated Ni-alloy thermodynamic database, has demonstrated the ability to predict and confirm trends in primary phase volume fraction (Figure 14) and to confirm qualitative trends for phase equilibria and solidification behavior resulting from composition changes in multicomponent γ/γ′-δ alloys (Figure 15) [9]. Comparison to experimentally derived results has shown good agreement in some instances, whereas areas of disagreement between the experimental and predicted metallurgical data highlight gaps in the current thermodynamic database that require further optimization. Even given these current limitations for predictive capability, these particular ICME tools have resulted to a better understanding of the reasonable design space for a ternary γ/γ′-δ alloy system and provides the foundation for future exploration of these novel structural materials.

Experimentally derived and calculated primary phase volume fraction in various alloys. The trend to change from primary γ to δ with increasing Nb content is illustrated [8].

Superimposed liquidus (a) and isothermal (b) projections of Ni-Nb-X ternary phase diagrams. The different trends in the γ to δ eutectic trough and solubility in various alloy systems are illustrated respectively [9].

Detailed design

In today’s highly competitive gas turbine industry, robust multidisciplinary design tools are required early in the design process which links several analyses to achieve aggressive overall system goals. An example of this detailed design process for a critical rotating component is shown in Figure 16. ICME is a relatively new addition to this design iteration loop and is highlighted in orange. A robust tool for sizing a new rotor disc would traditionally link aerodynamic, mechanical, and fluid systems design trades to the resultant heat transfer analysis, structural analysis, and predicted service life of the component. In this manner, design trades are quickly assessed, and the impact to the sub-system is quantified. Linking steps in the analysis allows perturbation of the system by making, for example, a change to a secondary fluid cooling scheme. Such a change would alter the predicted disc temperatures, resultant stress, and life prediction as well as change in blade tip clearance. Linking these types of tools can provide the design team an updated performance, life, and cost prediction indication in minutes.

Generic example of detailed design process for a critical rotor compressor blisk[10].

With the advent of high-performance computing, linking these design tools becomes more attractive and affordable. Recent advances in materials modeling have resulted in analytical tools that package nicely into the design loop described previously. Combining with the traditional design loop, high-performance computing with quantitative material property and residual stress modeling becomes a powerful toolset for advancing the state of the art. Figure 16 shows the ICME modeling capability which are now included in the detailed design process. This approach was recently applied to a legacy LCF spin rig disc experiment. In this historical spin rig study, different initial residual stress profiles were imparted to discs by applying varying degrees of a single pre-spin event prior to cyclic testing. These pre-spin events created regions of local yielding, leading to localized compressive residual stress. Components were cyclically tested to crack initiation and fracture with and without beneficial residual stresses imparted due to pre-spin at critical locations. A 2.8× increase in total life to failure (crack initiation and crack growth) was observed for the pre-spun components compared to the baseline condition. Further details of this experiment are provided in depth by Shen et al. [10]. Application of ICME toolsets was used to predict the component residual stresses by modeling the process of forging, machining, and pre-spinning operations performed prior to testing. Using inelastic stress calculations, the improved total life to failure observed in the spin test study could be predicted through the Rolls-Royce analytical lifing methodologies. Based upon the validation testing conducted previously on Rolls-Royce historical rigs, it has been shown that the accuracy of total life calculations can be improved by accurate account of induced residual stresses. By applying ICME toolsets, the residual stresses that form during the forging and heat treatment process can also be derived for a more accurate description and analysis of the finished component. These calculated residual stresses can then be combined with thermo-mechanical mission stresses for analytical low-cycle fatigue initiation and fatigue crack growth life calculations. Successful control of the manufacturing process allows for tailoring of the final component residual stress and potential for total life improvement in low-cycle fatigue crack initiation and fatigue crack growth.

The work done by Shen et al. [10] opens up the possibility of tailoring the forging shape and/or heat treatment cooling rates to achieve an optimized component solution. Such solution may be minimum weight - a full life component design that meets the sub-system goals. Figure 17 shows the disc used in the previously described spin test with two sample forging shapes. This figure illustrates the variables that can be controlled to tailor the material properties and residual stress of the finished part. Namely, the local heat transfer coefficient (as a function of time) and forging geometry are the key process variables contributing to the resultant predicted service life. This becomes an ideal problem for DOE and/or optimization techniques. Rolls-Royce has recently conducted this type of work for several critical components in recent advanced system demonstrators to maximize service life. This required close working with suppliers to achieve an overall acceptable solution for the program. The result was a specific forging geometry and heat treat fixture that provided acceptable material properties and desired initial residual stress profile. In addition, predicted deflections, obtained by simulating the machining process, were very close to what were observed in manufacturing. Predicted deflections from this modeling were used to guide manufacturing to deliver a complicated component to print without deviation.

The introduction of ICME techniques to the design of gas turbine engines presents a potentially game-changing technique for designing critical engine components for higher life. By considering the residual stress inherent to any forged and heat-treated component allows the designer to make more efficient use of material, weight, life extension, and/or cost design trades. For existing products, this approach can be applied to extend the life of fielded components through alterations to the heat treatment process or forging geometry only, limiting the cost impact to implement changes. Such changes are often warranted later in the design life cycle as engineers gain confidence in how components are actually used and maintained in service. In addition, understanding of the inherent manufacturing process variability can produce a more robust assessment of fielded component risk. This increased understanding can be used by the fleet operators to improve decision making on maintenance and overhaul scheduling in addition to reliability predictions. The benefits of realizing and incorporating this technology are just now beginning to come to fruition. Rolls-Royce is now updating their design methodology to include material and process modeling in the design process. While much work remains to fully benefit from the potentials of including ICME into our design practices, initial work has shown positive trends in capturing additional life and minimizing part weight.

Virtual engine

Detailed design and analysis of individual components and sub-systems alone are not sufficient to fully realize/maximize aero engine performance. Improved design understanding of the entire system is required in order to optimize the final product according to environmental and operational constraints. Significant recent advances in high-performance computational facilities enable analysis of many sub-systems in one ‘product level’ model with sufficient geometric detail and boundary condition definition required to simulate system behavior, such as component movements under steady-state and transient loads. Many of today’s design tools do not sufficiently account for material and manufacturing variability and their impact on component and assembly shape, structural integrity, and performance. For gas turbine design, system level ‘virtual engine’ models incorporating multidisciplinary analysis (i.e., aerodynamics, mechanics, materials, and performance) are giving greater insight to the impact of system variations on overall system performance, cost, weight, and life (Figure 18) [11].

Virtual manufacturing

Manufacturing is traditionally treated as an entirely separate function within the life cycle of a product. Design engineering will perform studies and develop various iterations of a product design then deliver a final definition to manufacturing. This definition may be in drawing or electronic formats. Manufacturing engineers will then determine a method to manufacture the product. In case of a new product design for a machined component, a manufacturing engineer will define a sequence of operations utilizing machine tools, fixturing, cutting tools, and inspection equipment based on available experience and knowledge. Once a method is defined, tooling/fixturing has been designed and built, and NC programs have been written, the process of prove out begins. Each step in the method will be proven out on the production machine tool. If any step in the method does not perform as planned, then modifications are made to the process and tried again. This can become a lengthy and costly loop, especially when there are numerous machining operations. Inherent variations within the process can make troubleshooting of issues very difficult and time consuming. During these prove-out steps, production machine tools are being utilized for development and not for daily production. This reduces operational productivity, disrupts material flow, complicates scheduling and could lead to late deliveries. Furthermore, delay of validation testing of components (required to be conformed to final production processes) may also result in certification delays and additional costs.

The integration of technologies like ICME and model-based definition (MBD) into the product development process facilitates digital integration of manufacturing knowledge, standards, methods, capabilities, and limitations into the design development process. This allows engineering ‘design and make’ teams to predict, optimize, and prove out a components method of manufacture before any step of the manufacturing process is started. The condition of supply definitions can be optimized to minimize variations within a chosen method of machining sequences. Fixturing can be designed to provide the best holding capability and minimized part distortion. NC programs and cutting strategies can be fine-tuned for performance, capability, and robustness. All of these steps can go through numerous iterations virtually to achieve the most optimized process that will perform as predicted, and much of it can be done even before the design is finalized. When fully mature, this approach allows for a new component to be introduced into a production line Right First Time with a process performing at, or better than, the capability of existing processes.

To fully realize this vision, however, integrated tools that span the full supply chain are needed to achieve full capability. Robust modeling tools should be integrated with the Computer Aided Manufacturing systems to allow for full material characteristics prediction and optimization. Challenges arise when an external supply chain is involved, however, since systems that are internal to a company are much more straightforwardly integrated. The overall supply chain needs the ability to integrate their systems and processes to enable true lifecycle integration. IT security, export control and compatibility issues all add to the complexity of a global ‘digital’ supply chain.

Virtual simulation of the machining process exists today in most of the modern CAD/CAM systems and external applications such as Vericut™ by CGTech; however, most current manufacturing process simulations do not integrate available ICME toolsets for prediction of manufacturing process impact on part yield, material properties and/or design performance. Vericut™ for example can simulate the complete kinematics motion of a multiaxis machining center and interaction of the cutting tools and fixtures. Vericut™ can also simulate material removal by cutting tools and compare the cutter path resultant to the original part model. These simulations are valuable for a virtual prove out of the cutter path accuracy and potential interferences between tools/fixtures/machines/parts; however, these simulations are static and will not take into account cutter deflections or part movement from relieving residual stresses as material is cut away. To realize the full potential of an integrated virtual manufacturing system, ability to predict and simulate how the materials interact and react during an operation or process is critical. Fully integrated virtual manufacturing systems could eliminate the costly physical prove-out stages in manufacturing and facilitate Right First Time solutions when integrating known process capability to design-for-manufacture toolsets earlier in the product development process. New products could be introduced into production along with existing products, allowing manufacturing to improve management inventory while maintaining the ‘heartbeat’ of the product flow through the physical manufacturing facility itself.

As integration of virtual manufacturing across the supply chain matures, virtual manufacturing systems at the component level are already delivering substantial business benefit in specific cases. One example is in the virtual modeling of the casting process (Figure 19). Historically, casting process development has been performed through an expensive ‘build and break’ approach [12]. Through the use of casting modeling during product and process development, engineers can evaluate new designs for manufacturability and optimize the manufacturing process before real components are cast, during new product introduction or yield improvement activities. By accurately modeling the heat exchange between the casting, mold, and key parts of the furnace, Rolls-Royce has been able to successfully predict porosity, stray grains, and freckle chain defects. Improvements proposed and rapidly tested by iterating the model can then be validated by selected and highly targeted physical trials, significantly reducing the cost and lead time associated with build-and-break-type process development efforts. Investment casting assemblies now typically contain features that would likely not have been developed without the use of modeling. Rolls-Royce has realized significant business benefit from deployment of process modeling systems to casting facilities and suppliers, which facilitate the use of ICME tools by engineers without requiring a high level of ICME knowledge or skill. Such deployed application of modeling has been applied to modify tooling, process, and product designs to deliver significant cost reduction through reduction of non-conformance and improvements in Right First Time production.

Life prediction and management for life-limited components

While ICME offers powerful new predictive tools, it also embraces the need to quantify uncertainty in predictive capability as seen in the preceding examples. It follows, from a business perspective, the NRC’s vision of ICME as a holistic system that brings together design optimization and manufacturing that encourages further consideration of uncertainties throughout the entire life cycle of a product, not just during development. This is partly due to the nature of optimization and partly to do with the role manufacturing plays in life cycle cost reduction (see Figure 20).

While the objective functions for system design optimization are generally well understood, this is not always true for system boundary conditions. Often, engineers’ understanding of boundary conditions improves as more data is acquired from manufacturing and the product’s usage in service. For the same reason, it may become apparent as a product matures that it satisfies intended requirements but is no longer optimized for the conditions to which it is actually exposed. Further, as such information becomes apparent, tools like ICME will likely be called upon to help improve performance and cost. There are many possible paths toward product improvement and cost reduction to explore. Early use of engineering expertise in ICME along with later in-service data to update models and prior understanding means that ICME fits well within a broader context of Bayesian frameworks and UQ-based decision analysis [13, 14]. Perhaps one of the best examples in the gas turbine industry is in life prediction and management of high-energy discs.

In application to high-energy discs, computational materials science tools must be carefully linked with many other UQ and decision-making tools and data sources to enable the NRC vision [7]. Design optimization and field management of these components require application of a number of complex, inter-related tools, technologies, physics-based models, cost and reliability models, as well as expert decisions. Moreover, referring back to Figure 9, there are many sources of uncertainty associated with discs. Some of these can be quantified early by ICME’s development models such as microstructural characterization, forging, and finished part residual stresses and material properties. Other uncertainties such as operational usage and typical engine performance and deterioration effects must be assumed prior to certification and production. However, in both cases, what are commonly known as Bayesian prior distributions must be assumed. In the case of usage, distributions associated with environment such as ambient conditions or distributions reflecting uncertainty in operator behavior such as pilot decisions to use lower power flex takeoff conditions may be defined. In the case of material uncertainties, the supply chain processing parameters and manufacturing target dimensions may be considered Bayesian priors. Furthermore, these two general sources of uncertainty, developmental and in-service, must be updated and managed jointly in order for safety, performance risks, and costs to be effectively managed throughout the life cycle of the product. This can easily be described by way of a simple example if one considers the correlated effects of inelastic material deformation from speed and temperature with location-specific material characteristics such as yield strength. Bayesian posterior distributions, e.g., LCF life, will therefore be functions of both material properties and usage. As described earlier, ICME then becomes a key part of continual validation and verification. Measureable data such as forging solution temperature, distortion from machining, finished part geometry, and engine air temperatures can be used to update corresponding distributions of quantities that are more difficult to measure in production such as component residual stresses, metal temperatures, and disc stresses. This process of Bayesian updating can be used to generate highly correlated distributions such as disc creep life and damage tolerance capability that naturally follow out of similar prior understandings and data. Furthermore, UQ tools that lend themselves to quantifying system behavior such as Bayesian networks can be used to maintain an updated understanding of these distributions [14]. For discs (and other components), these tools are envisioned to work alongside standard statistical and robust design methods to link ICME into a holistic production system.

Many UQ tools themselves, like Bayesian networks, will be largely invisible to the supply chain. But the outputs, questions, and decisions associated with these networks will be immediately visible and will be easy to explain in terms both an OEM and supplier will understand. In this way, both parties can supply and discuss implications to both non-proprietary and proprietary models and information from new data as it becomes available. The basic Bayesian reasoning process includes simple cause and effect relationships, prior distributions from expert knowledge and data, likelihood models, and approach to updating understanding. This makes it a natural tool for engineers developing complex systems in the context of ICME. ICME models are envisioned as a powerful new way to link design and the manufacturing supply chain. But as with any model, its ultimate utility is seen in how it is used by those who make business risk-related decisions.

Conclusions

Significant work has been done across the industry to develop computational models of materials, manufacturing, and design processes; however, there has been less success at integrating these models into product development processes. Application of these models has delivered both development and production benefits, but mostly in isolated one-off situations. The integration of ICME into design and manufacturing systems, though clearly more challenging, promises order of magnitude benefits in cost and lead time reduction. This review has illustrated and emphasized that integration challenges are not just digital but physical, heuristic, and relational as well. To be successful, ICME initiatives must deliver solutions the entire supply chain understands, trusts, and can use. A review of some of the specific challenges faced by ICME users across the supply chain was presented. Ultimately, the transition from technology push to technology pull for use of ICME across the supply chain will reside in the benefit realized through successful use of the technology to deliver product benefit. In response to already realized business benefit on both legacy and new product introduction, Rolls-Royce is integrating ICME into our product development processes as part of our standard methodology going forward.

References

Matlik JF, Bolcavage A: Integrated computational materials engineering from a gas turbine engine perspective. In Symposium of integrated computational engineering - the customer’s point of view. Pittsburgh, PA: Presentation at the Materials Science & Technology 2012 Conference & Exhibition,; 2012. 8 October 2012 8 October 2012

Glavicic MG, Goetz RL, Shen G, Rasche JA, Ress RA III, Stillinger J: Application of ICME to turbine engine component design optimization. In 52nd AIAA/ASME/ASCE/AHS/ASC structures, structural dynamics and materials conference. Denver; 2011. 4–7 April 2011, AIAA-2011–1738 4–7 April 2011, AIAA-2011-1738

National Research Council: Accelerating technology transition: bridging the valley of death for materials and processes in defense systems. The National Academies Press, Washington, DC; 2004.

Olson GB: Integrated Computational Materials Design: From Genome to Flight. In 54th AIAA/ASME/ASCE/AHS/ASC structures, structural dynamics and materials conference. Boston; 2013. 8–11 April 2013, AIAA-2013–1847 8–11 April 2013, AIAA-2013-1847

Martin R, Evans D: Reducing costs in aircraft: the metals affordability initiative consortium. JOM 2000, 52(3):24–28. 10.1007/s11837-000-0096-y

Cowles B, Backman B, Dutton R: Verification and validation of ICME methods and models for aerospace applications. Integr Mater Manuf Innov 2012, 1: 2. 10.1186/2193-9772-1-2

National Research Council: Integrated computational materials engineering: a transformational discipline for improved competitiveness and national security. The National Academies Press, Washington, DC; 2008.

Huron ES, Reed RC, Hardy MC, Mills MJ, Montero RE, Portella PD, Jack T: Polycrystalline γ (Ni)/γ′ (Ni3A1)-δ (Ni3Nb) eutectic Ni-base superalloys: chemistry, solidification and microstructure. In Superalloys. Edited by: Xie M, Helmink RC, Tin S. Hoboken, NJ: Wiley; 2012:633–642.

Villars P, Okamoto H, Cenzual K (Eds): ASM alloy. ASM International, Phase Diagrams Center, Materials Park, OH; 2007.

Shen G, Cooper N, Ottow N, Goetz R, Matlik J: Integration and automation of residual stress and service stress modeling for superalloy component design. In Superalloys 2012. Edited by: Huron ES, Reed RC, Hardy MC, Mills MJ, Montero RE, Portella PD, Telesman J. Hoboken: Wiley; 2012:129–134.

Keskin A, Saiz A: An integrated design system for optimization of gas turbine components. In 53rd AIAA/ASME/ASCE/AHS/ASC structures, structural dynamics and materials conference. Honolulu; 2012. 23–26 April 2012, AIAA-2013–1408 23–26 April 2012, AIAA-2013-1408

EuroPAM: 16th European conference and exhibition on digital simulation for virtual engineering. Toulouse; 2006. 10–12 October 2006 10–12 October 2006

Azaidan M, Mills A, Harrison R: Bayesian framework for aerospace gas turbine engine prognostics. In IEEE aerospace conference. Big Sky; 2013. 2–9 March 2013 2–9 March 2013

Mahoney S, Stillinger J: Towards a probabilistic framework for integrated computational materials engineering. In 53rd AIAA/ASME/ASCE/AHS/ASC structures, structural dynamics and materials conference. Honolulu; 2012. 23–26 April 2012. AIAA-2013–1529 23–26 April 2012. AIAA-2013-1529

Acknowledgements

Authors would like to express appreciation to Dr. Rollie Dutton and Dr. David Furrer who initially invited a presentation of this work under the same title which was presented during a symposia on ‘ICME - from the customer’s view point’ that Dr. Dutton and Dr. Furrer co-chaired during the 2012 Materials Science & Technology conference in Pittsburgh, PA. Authors would also like to acknowledge contributions from Ben Saunders of Rolls-Royce who supported with images for figure generation and Tony Phipps of Rolls-Royce who supported business benefit articulation. Finally, it is prudent to recognize the purposeful integration efforts being coordinated across several professional societies including TMS, ASM International and AIAA. The lessons learned reported in this paper are collated in part from cross-industry and academia collaboration and feedback regarding the ICME integration efforts of these communities.

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing interests

The authors declare that they have no competing interests.

Authors’ contributions

JM conceived, organized, and integrated all individual author contributions to draft the review. AB contributed to materials design content. PB, DH, and KM contributed to virtual manufacturing content. RC contributed to preliminary design content. NC contributed to detailed design content. CD contributed to the detailed design and life prediction and management content. AK contributed to virtual engine content. GM contributed to uncertainty quantification and robust design content. JS contributed to uncertainty quantification, Bayesian methodology and life prediction and management content. All authors read and approved the final manuscript.

Authors’ original submitted files for images

Below are the links to the authors’ original submitted files for images.

Rights and permissions

This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Bolcavage, A., Brown, P.D., Cedoz, R. et al. Integrated computational materials engineering from a gas turbine engine perspective. Integr Mater Manuf Innov 3, 181–204 (2014). https://doi.org/10.1186/2193-9772-3-13

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1186/2193-9772-3-13