Abstract.

We investigate crack formation in deposition films from drying colloidal suspension drops, by varying the roughness and texture of the substrate. The experimental results indicate that the crack number or crack spacing presents a general dependence on the substrate roughness, despite the orientation of the substrate textures. Interestingly, the crack spacing decreases with the increase of the roughness. Two possible mechanisms are proposed to understand the dependence of the cracks on roughness. Firstly, the concentration reduction of the drying suspension due to collecting colloidal particles from the substrate textures decreases the crack spacing. Secondly, stress concentration resulting from the defects (the notches in textures) in the dried deposition enhances crack formation. However, a quantitative estimation by the calculation of the stress concentrating factors reveals that the notch of the substrate textures dominates crack variation. The results here bring forth a practical method for controlling the crack orientation and suppression, and a potential application to crack-free coatings, films and paintings during the drying of complex fluids.

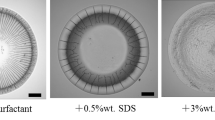

Graphical abstract

Similar content being viewed by others

References

J. Ma, G. Jing, Phys. Rev. E 86, 061406 (2012)

G. Jing, J. Ma, J. Phys. Chem. B 116, 6225 (2012)

W.P. Lee, A.F. Routh, Langmuir 20, 9885 (2004)

M.S. Tirumkudulu, W.B. Russel, Langmuir 21, 4938 (2005)

K.B. Singh, M.S. Tirumkudulu, Phys. Rev. Lett. 98, 218302 (2007)

E. Dufresne, D. Stark, N. Greenblatt, J. Cheng, J. Hutchinson et al., Langmuir 22, 7144 (2006)

M. Lakshmikantha, P.C. Prat, A. Ledesma, Can. Geotech. J. 49, 264 (2012)

P. Xu, A. Mujumdar, B. Yu, Dry Technol. 27, 636 (2009)

R.D. Deegan, Phys. Rev. E 61, 475 (2000)

C. Annarelli, J. Fornazero, J. Bert, J. Colombani, Eur. Phys. J. E 5, 599 (2001)

S. Bohn, J. Platkiewicz, B. Andreotti, M. Adda-Bedia, Y. Couder, Phys. Rev. E 71, 046215 (2005)

H. Colina, S. Roux, Eur. Phys. J. E 1, 189 (2000)

D. Brutin, Colloids Surf., A 429, 112 (2013)

H. Brouwers, Phys. Rev. E 74, 031309 (2006)

S. Mahdavi, F. Akhlaghi, J. Mater. Sci. 46, 7883 (2011)

J.G. Mcgrath, R.D. Bock, J.M. Cathcart, L.A. Lyon, Chem. Mater. 19, 1584 (2007)

V. Lazarus, L. Pauchard, Soft Matter 7, 2552 (2011)

H.M. Gorr, J.M. Zueger, J.A. Barnard, J. Phys. Chem. B 116, 12213 (2012)

J. Bisschop, Int. J. Fract. 154, 211 (2008)

G. Marín, H. Gelderblom, D. Lohse, J.H. Snoeijer, Phys. Rev. Lett. 107, 085502 (2011)

K.I. Dragnevski, A.F. Routh, M.W. Murray, A.M. Donald, Langmuir 26, 7747 (2010)

C.H. Chon, S. Paik, J.B. Tipton, K.D. Kihm, Langmuir 23, 2953 (2007)

F. Boulogne, F. Giorgiutti-Dauphiné, L. Pauchard, Oil Gas Sci. Technol. 69, 397 (2013)

K. Mougin, H. Haidara, Langmuir 18, 9566 (2002)

F. Carle, D. Brutin, Langmuir 29, 9962 (2013)

D. Brutin, B. Sobac, C. Nicloux, J. Heat Transfer 134, 061101 (2012)

I. Kim, K.D. Kihm, Langmuir 28, 9195 (2012)

M. Smith, J. Sharp, Langmuir 27, 8009 (2011)

G. Krishna Darbha, C. Fischer, A. Michler, J. Luetzenkirchen, T. Schäfer et al., Langmuir 28, 6606 (2012)

T. Liu, H. Luo, J. Ma, P. Wang, L. Wang et al., Phys. Lett. A 378, 1191 (2014)

A. Mathur, A.-D. Brown, J. Erlebacher, Langmuir 22, 582 (2006)

A. Horn, H.G. Schoberth, S. Hiltl, A. Chiche, Q. Wang et al., Faraday Discuss. 143, 143 (2009)

K.H. Nam, I.H. Park, S.H. Ko, Nature 485, 221 (2012)

B.C. Kim, T. Matsuoka, C. Moraes, J. Huang, M. Thouless et al., Sci. Rep. 3, 3027 (2013)

D. Nowell, D. Dini, P. Duó, J. Strain Anal. Eng. Des. 38, 429 (2003)

J. Zarzycki, J. Non-Cryst. Solids 100, 359 (1988)

C. Allain, L. Limat, Phys. Rev. Lett. 74, 2981 (1995)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, T., Luo, H., Ma, J. et al. Surface roughness induced cracks of the deposition film from drying colloidal suspension. Eur. Phys. J. E 39, 24 (2016). https://doi.org/10.1140/epje/i2016-16024-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1140/epje/i2016-16024-7