Abstract

A mechanoluminescent composite layer at the surface of poly(methyl methacrylate) (PMMA) was obtained by liquid-phase incorporation of SrAl2O4 : (Eu2+, Dy3+) phosphor microparticles into the polymer. The photoluminescence spectrum and kinetics of emission from the composite layer have been studied as dependent on the power density of exciting laser radiation pulses. The mechanoluminescence of the composite layer has been studied under the effect of short acoustic pulses and dynamic pressure of a solid stylus sliding over the composite layer surface. A possible mechanism of mechanoluminescence excitation is discussed. It is established that the obtained composite layer is characterized by high efficiency of the mechano-optical conversion and can be used for the detection and visualization of mechanical stresses.

Similar content being viewed by others

Mechanoluminescent materials are drawing the increasing attention of specialists engaged in both the fundamental investigations and applied research related to the properties of materials subjected to various force fields. This interest was stimulated, in particular, by the development of a new direction of research—straintronics, which studies the behavior of physical properties and effects in deformed materials. The mechanoluminescent materials are of interest as the basis for creating devices and elements for detecting, monitoring, imaging, and recording mechanical actions (impacts, vibrations, deformations, etc.) [1–4].

In recent years, a large number of materials have been synthesized possessing high efficiency of the conversion of external mechanical actions into optical emission, in particular, mechanoluminescent materials emitting in various regions of visible and near-IR spectral range. As a rule, these are finely dispersed powderlike dielectric or wide-bandgap semiconductor materials doped with luminescent additives and containing other impurities and defects with energy levels occurring in the bandgap, which can act as electron or hole traps. Activation of these centers under a mechanical action determines the mechanoluminescent properties of these powders. There are two types of mechanoluminescent materials in which deformation-induced luminescence is observed (i) only upon their activation by short-wavelength light and (ii) without preliminary irradiation. In particular, SrAl2O4 : (Eu2+, Dy3+) phosphor exhibits effective mechanoluminescence after preliminary exposure to short-wavelength light with λ < 450 nm [1–3, 5].

In the present work, a mechanoluminescent composite layer with thickness h ≈ 200 μm was obtained by liquid-phase incorporation of SrAl2O4: (Eu2+, Dy3+) phosphor microparticles into the surface layer of poly(methyl methacrylate) (PMMA) matrix. The photoluminescence characteristics of the composite layer were studied as dependent on the power density of exciting laser radiation pulses. The mechanoluminescence from the composite layer was excited by short acoustic pulses and the dynamic pressure of a solid stylus sliding over the composite layer surface.

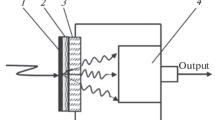

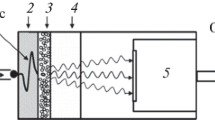

Figure 1a shows a schematic diagram of the experimental setup used for studying the mechanoluminescence in the obtained composite layer excited by short acoustic pulses generated under the action of laser pulses 1 on 100-μm-thick metal plate 2 contacting with the surface of mechanoluminescent composite layer 3. Short (nanosecond) laser pulses (λ = 355 nm, τ = 8 ns, W = 10 mJ) evaporate the plate material and generate the vapor pressure pulse that excites an acoustic pulse in the metal plate. This acoustic pulse propagates trough the metal plate, attains the surface of mechanoluminescent composite layer 3 and, while penetrating through this layer, excites the mechanoluminescence signal detected by photoelectron multiplier 5. Figure 1b presents waveforms of the laser pulse (1), the positive half-period of the acoustic pulse (2), and the mechanoluminescence signal (3).

Figure 2a shows the photoluminescence spectra of SrAl2O4: (Eu2+, Dy3+) phosphor in the composite layer measured at room temperature under the action of laser pulses with different power densities. At a lower power density of I1 ≈ 5 × 106 W/cm2, the spectrum displays a single wide, inhomogeneously broadened band that peaks at λmax ≈ 525 nm. As the laser pulse power density increases to I2 ≈ 7 × 106 W/cm2, this wide band splits into several component bands with maxima at λ = (1) 446, (2) 525, (3) 573, (4) 693, and (5) 755 nm. Note that the emission at λ = 446 nm (band 1, depicted by the dashed line) is only manifested at low temperatures (T < 200 K).

(a) Photoluminescence spectra of the composite layer measured at different laser pulse power densities (I) I1 ≈ 5 × 106 and (II) I2 ≈ 7 × 106 W/cm2 split into component bands 1–5 (see the text for explanation); (b) scheme of the energy levels of Eu2+ luminescent center and traps situated in the composite layer in the vicinity of a dislocation, showing 2 → 3 and 3 → 4 nonradiative transitions.

Based on the obtained results, we propose a scheme of the electron levels and transitions in the luminescent impurity center Eu2+ and traps, which is shown in Fig. 2b. Note that Dy3+ ions play an important role in the generation of phosphorescence and mechanoluminescence of the phosphor. The presence of these ions multiply enhances the intensity and increases the duration of both phosphorescence and mechanoluminescence. Unfortunately, reliable data are not yet available on the positions of energy levels in Dy3+ ions. Indeed, it has been a priori assumed [6] that Dy3+ ions form hole traps and the hole capture makes the Dу3+ + h+ → Dу4+ transition possible, which allowed the hole mechanism of mechanoluminescence involving hole traps to be formulated. However, it was shown later [7] that the aforementioned transition is low probable.

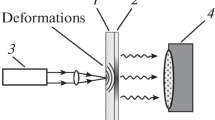

As concerns the mechanism of mechanoluminescence involving electron traps and assuming that Dy3+ ions form these traps, we propose the following mechanism of mechanoluminescence in the system studied. When the phosphor is irradiated by short-wavelength light, electrons absorb these photons and pass from level 1 (Fig. 2b) to the conduction band, where they can be captured by Dy3+ electron traps situated below the conduction band at ΔE ≥ kT. Under the action of an acoustic pulse, polycrystalline phosphor microparticles consisting of a large number of grains (Fig. 3a) are deformed. In polycrystalline materials, the deformation develops mostly by means of intergranular sliding due to the motion of grain-boundary dislocations. It is known [8] that rather high mechanical stresses are present in the vicinity of dislocations, which can lead to curvature (shift) of energy bands and the levels of impurities and defects (Fig. 2b). In the field of dislocation-related stresses, the energy levels of traps shift toward the conduction band as is shown in Fig. 2b. As a result, energy difference ΔE between the levels of Dy3+ traps (levels 5 in Fig. 2b) and the bottom of conduction band decreases. At the same time, the probability of tunneling transitions from filled trap levels 5 to the conduction band sharply increases. This is followed by nonradiative capture of electrons from the conduction band to levels 2 of Eu3+ ions, which results in the appearance of excited Eu2+* ions (Eu3+ → Eu2+*). The mechanoluminescence is caused by the radiative transitions in Eu2+* ions as shown in Fig. 2b. Figure 3b illustrates this experiment by showing the trajectory of solid stylus sliding on the surface of a mechanoluminescent composite (sensor) layer.

In concluding, a mechanoluminescent composite layer was obtained for the first time on the surface of PMMA—a solid material matrix (transparent in the visible spectral range) characterized by high efficiency of the mechano-optical conversion. The spectra and kinetics of photoluminescence and mechanoluminescence from the obtained composite layer have been studied. It has been established that a wide, inhomogeneously broadened photoluminescence band peaking at λmax ≈ 525 nm present in the spectrum of SrAl2O4: (Eu2+, Dy3+) phosphor microparticles splits with increasing power of exciting laser radiation into several spectral bands (with maxima at 573, 693, and 755 nm). A scheme of electron energy levels in the luminescent center of a Eu2+ ion and electron traps in the SrAl2O4: (Eu2+, Dy3+) phosphor is proposed, which is consistent with the observed photoluminescence lines. It is shown that the obtained mechanoluminescent composite layer possesses high sensitivity to pulsed acoustic and dynamic mechanical action and can be used as a sensor element for the detection and visualization of acoustic and mechanical actions.

FUNDING

This work was supported by (i) the Ministry of Education and Science of the Russian Federation in the framework of a state order to the Federal Scientific Research Center Crystallography and Photonics of the Russian Academy of Sciences (in the part of obtaining new nanomaterials and nanostructures for solving topical tasks of micro- and nanoelectronics and nanophotonics) and (ii) the Russian Foundation for Basic Research (project no. 16-29-14003 ofi_m) (in the part of studying deformation-stimulated light emission from nano- and microparticles of phosphor in a polymer matrix).

REFERENCES

N. Terasaki, H. Yamada, and C. N. Xu, Catal. Today 201, 203 (2013).

B. P. Chandra, V. K. Chandra, S. K. Mahobia, P. Jha, R. Tiwari, and B. Haldar, Sens. Actuators, A 173, 9 (2012).

A. A. Banishev, A. A. Lotin, and A. F. Banishev, Int. J. Mod. Phys. B 28, 1450154 (2014).

A. F. Banishev and A. A. Banishev, Phys. Lett. A 375, 2767 (2011).

A. F. Banishev, A. A. Banishev, V. A. Bol’shukhin, Yu. V. Syrov, and A. M. Khort, Fiz. Khim. Obrab. Mater., No. 2, 60 (2010).

T. Matsuzawa, Y. Aoki, N. Takeuchi, and Y. Murayama, J. Electrochem. Soc. 143, 2670 (1996).

P. Dorenbos, J. Electrochem. Soc. 152, H107 (2005).

T. Suzuki, S. Takeuchi, and H. Yoshinaga, Dislocation Dynamics and Plasticity (Springer, Berlin, 1991).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by P. Pozdeev

Rights and permissions

About this article

Cite this article

Banishev, A.F., Banishev, A.A. Mechanoluminescence of a Thin Composite Layer Obtained by Incorporation of SrAl2O4:(Eu2+, Dy3+) Phosphor Microparticles into a Poly(methyl methacrylate) Surface. Tech. Phys. Lett. 45, 475–477 (2019). https://doi.org/10.1134/S1063785019050201

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1063785019050201