Abstract

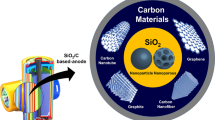

As a promising energy storage device, sodium-ion batteries (SIBs) have received continuous attention due to their low-cost and environmental friendliness. However, the sluggish kinetics of Na ion usually makes SIBs hard to realize desirable electrochemical performance when compared to lithium-ion batteries (LIBs). The key to addressing this issue is to build up nanostructured materials which enable fast Na-ion insertion/extraction. One-dimensional (1D) nanocarbons have been considered as both the anode and the matrix to support active materials for SIB electrodes owing to their high electronic conductivity and excellent mechanical property. Because of their large surface areas and short ion/electron diffusion path, the synthesized electrodes can show good rate performance and cyclic stability during the charge/discharge processes. Electrospinning is a simple synthetic technology, featuring inexpensiveness, easy operation and scalable production, and has been largely used to fabricate 1D nanostructured composites. In this review, we first give a simple description of the electrospinning principle and its capability to construct desired nanostructures with different compositions. Then, we discuss recent developments of carbon-based hybrids with desired structural and compositional characteristics as the electrodes by electrospinning engineering for SIBs. Finally, we identify future research directions to realize more breakthroughs on electrospun electrodes for SIBs.

Reproduced with permission [54]. Copyright 2014, Wiley–VCH. Reproduced with permission [56]. Copyright 2015, Elsevier. Reproduced with permission [59]. Copyright 2017, Elsevier. Reproduced with permission [60]. Copyright 2018, Frontiers S.A. c Photographs, SEM image and application of Na2VTi(PO4)3/CNFs, image illustration and schematic of hierarchical structure of the hybrid nanofiber. Reproduced with permission [61]. Copyright 2017, Royal Society of Chemistry. d SEM image and photographs of NaFePO4/CNFs, galvanostatic charge/discharge profiles at a current density of 20 mA g−1. Reproduced with permission [63]. Copyright 2018, Wiley–VCH

Reproduced with permission [65]. Copyright 2017, Wiley–VCH. b Schematic of the synthetic process and SEM image of NFPO/C and NFPO/rGO/C composites. Reproduced with permission [69]. Copyright 2017, Royal Society of Chemistry. c Schematic illustration for the preparation process and image illustration of Na2+2xFe2−x(SO4)3/porous CNFs hybrid film. Reproduced with permission [71]. Copyright 2016, Royal Society of Chemistry

Reproduced with permission [86]. Copyright 2016, Elsevier. Reproduced with permission [47]. Copyright 2017, Elsevier. b SEM images of N-doped CNFs, N,S-doped CNFs, and P-doped CNFs. Reproduced with permission [102]. Copyright 2018, Elsevier. Reproduced with permission [106]. Copyright 2018, American Chemical Society. c Schematic illustration of the synthetic process and SEM and TEM images of graphene/CNFs. Reproduced with permission [24]. Copyright 2017, Royal Society of Chemistry

Reproduced with permission [107]. Copyright 2013, American Chemical Society. Reproduced with permission [107]. Copyright 2014, Royal Society of Chemistry. Reproduced with permission [108]. Copyright 2014, Elsevier. Reproduced with permission [111]. Copyright 2014, Wiley–VCH. Reproduced with permission [114]. Copyright 2017, American Chemical Society. b Two-step method combined electrospinning with calcination to synthesize porous CNFs combined with alloy nanoparticles, image illustration of SnSb/PCNFs, SnSb/CNFs and Sn nanodots/porous N-doped CNFs. Reproduced with permission [115]. Copyright 2014, Wiley–VCH. Reproduced with permission [116]. Copyright 2015, Royal Society of Chemistry. Reproduced with permission [117]. Copyright 2015, Wiley–VCH

Reproduced with permission [119]. Copyright 2017, Wiley–VCH. Reproduced with permission [118]. Copyright 2017, Elsevier. Reproduced with permission [120]. Copyright 2017, Royal Society of Chemistry. Reproduced with permission [124]. Copyright 2016, Wiley–VCH. c Image illustrations of MnCoNiOx@double-carbon nanofibers, Na2Ti3O7@CNFs, T-Nb2O5@CNFs and MnFe2O4@CNFs; and MnFe2O4 particle size distribution diagram. Reproduced with permission [121]. Copyright 2016, American Chemical Society. Reproduced with permission [122]. Copyright 2017, Wiley–VCH. Reproduced with permission [123]. Copyright 2017, Wiley–VCH. Reproduced with permission [99]. Copyright 2016, American Chemical Society

Reproduced with permission [132]. Copyright 2016, Elsevier. Reproduced with permission [133]. Copyright 2014, Wiley–VCH. Reproduced with permission [134]. Copyright 2018, Elsevier. Reproduced with permission [135]. Copyright 2016, American Chemical Society. Reproduced with permission [136]. Copyright 2017, Elsevier. Reproduced with permission [137]. Copyright 2019, American Chemical Society. Reproduced with permission [138]. Copyright 2018, American Chemical Society. Reproduced with permission [139]. Copyright 2019, Elsevier. b Preparation process of heteroatom-doped CNFs combined with alloy nanoparticles, SEM image of N-doped CNFs@MoS2, SnS/CNTs@S-CNFs, SnS@SNCF-55, SnS2/NSDC nanofibers, and cycle stability of different SnS/C ratio. Reproduced with permission [145]. Copyright 2019, Elsevier. Reproduced with permission [141]. Copyright 2018, Elsevier. Reproduced with permission [143]. Copyright 2018, Elsevier. Reproduced with permission [144]. Copyright 2019, Elsevier

Similar content being viewed by others

References

Chen Y, Liu C, Sun X, Ye H, Cheung C, Zhou L. Recycled diesel carbon nanoparticles for nanostructured battery anodes. J Power Sources. 2015;275:26.

Yabuuchi N, Kubota K, Dahbi M, Komaba S. Research development on sodium-ion batteries. Chem Rev. 2014;114:11636.

Jamesh M-I. Recent advances on flexible electrodes for Na-ion batteries and Li–S batteries. J Energy Chem. 2019;32:15.

Xu ZL, Park J, Yoon G, Kim H, Kang K. Graphitic carbon materials for advanced sodium-ion batteries. Small Methods. 2018;3:1800227.

Kim S-W, Seo D-H, Ma X, Ceder G, Kang K. Electrode materials for rechargeable sodium-ion batteries: potential alternatives to current lithium-ion batteries. Adv Energy Mater. 2012;2:710.

Kim H, Kim H, Ding Z, Lee MH, Lim K, Yoon G, Kang K. Recent progress in electrode materials for sodium-ion batteries. Adv Energy Mater. 2016;6:1600943.

Komaba S, Takei C, Nakayama T, Ogata A, Yabuuchi N. Electrochemical intercalation activity of layered NaCrO2 vs. LiCrO2. Electrochem Commun. 2010;12:355.

Wei Q, Xiong F, Tan S, Huang L, Lan EH, Dunn B, Mai L. Porous one-dimensional nanomaterials: design, fabrication and applications in electrochemical energy storage. Adv Mater. 2017;29:1602300.

Zhang Q, Uchaker E, Candelaria SL, Cao G. Nanomaterials for energy conversion and storage. Chem Soc Rev. 2013;42:3127.

Jin T, Han Q, Wang Y, Jiao L. 1D Nanomaterials: design, synthesis, and applications in sodium-ion batteries. Small. 2018;14:1703086.

Subramanian V, Zhu H, Wei B. High rate reversibility anode materials of lithium batteries from vapor-grown carbon nanofibers. J Phys Chem B. 2006;110:7178.

Cavaliere S, Subianto S, Savych I, Jones DJ, Rozière J. Electrospinning: designed architectures for energy conversion and storage devices. Energy Environ Sci. 2011;4:4761.

Xue J, Xie J, Liu W, Xia Y. Electrospun nanofibers: new concepts, materials, and applications. Acc Chem Res. 1976;2017:50.

Wang Z, Li X, Chen Y, Pei K, Mai Y-W, Zhang S, Li J. Creep-enabled 3D solid-state lithium-metal battery. Chemistry. 2020;6:2878.

Li X, Chen W, Qian Q, Huang H, Chen Y, Wang Z, Chen Q, Yang J, Li J, Mai YW. Electrospinning-based strategies for battery materials. Adv Energy Mater. 2020;11:2000845.

Zhao J, Hu Z, Chen S, Zhang W, Liu X. Electrospinning synthesis of amorphous NiMoO4/graphene dendritic nanofibers as excellent anodes for sodium ion batteries. Nanotechnology. 2020;31:505401.

Zhao W, Ma X, Gao L, Li Y, Wang G, Sun Q. Engineering carbon-nanochain concatenated hollow Sn4P3 nanospheres architectures as ultrastable and high-rate anode materials for sodium ion batteries. Carbon. 2020;167:736.

Zhao W, Ma X, Li Y, Wang G, Long X. Achieving ultrastable cyclability and pseudocapacitive sodium storage in SnSe quantum-dots sheathed in nitrogen doped carbon nanofibers. Appl Surf Sci. 2020;504:144455.

Lu Z, Zhai Y, Wang N, Zhang Y, Xue P, Guo M, Tang B, Huang D, Wang W, Bai Z, Dou S. FeS2 nanoparticles embedded in N/S co-doped porous carbon fibers as anode for sodium-ion batteries. Chem Eng J. 2020;380:122455.

Zhang W, Yue Z, Wang Q, Zeng X, Fu C, Li Q, Li X, Fang L, Li L. Carbon-encapsulated CoS2 nanoparticles anchored on N-doped carbon nanofibers derived from ZIF-8/ZIF-67 as anode for sodium-ion batteries. Chem Eng J. 2020;380:122548.

Luo L, Song J, Song L, Zhang H, Bi Y, Liu L, Yin L, Wang F, Wang G. Flexible conductive anodes based on 3D hierarchical Sn/NS-CNFs@rGO network for sodium-ion batteries. Nano-Micro Lett. 2019;11:63.

Jeong SY, Ghosh S, Kim J-K, Kang D-W, Jeong SM, Kang YC, Cho JS. Multi-channel-contained few-layered MoSe2 nanosheet/N-doped carbon hybrid nanofibers prepared using diethylenetriamine as anodes for high-performance sodium-ion batteries. J Ind Eng Chem. 2019;75:100.

Ma X, Chen L, Ren X, Hou G, Chen L, Zhang L, Liu B, Ai Q, Zhang L, Si P, Lou J, Feng J, Ci L. High-performance red phosphorus/carbon nanofibers/graphene free-standing paper anode for sodium ion batteries. J Mater Chem A. 2018;6:1574.

Liu Y, Fan L-Z, Jiao L. Graphene highly scattered in porous carbon nanofibers: a binder-free and high-performance anode for sodium-ion batteries. J Mater Chem A. 2017;5:1698.

Chen W, Zhang L, Liu C, Feng X, Zhang J, Guan L, Mi L, Cui S. Electrospun flexible cellulose acetate-based separators for sodium-ion batteries with ultralong cycle stability and excellent wettability: the role of interface chemical groups. ACS Appl Mater Interfaces. 2018;10:23883.

Ray SS, Chen S-S, Li C-W, Nguyen NC, Nguyen HT. A comprehensive review: electrospinning technique for fabrication and surface modification of membranes for water treatment application. RSC Adv. 2016;6:85495.

Sill TJ, von Recum HA. Electrospinning: applications in drug delivery and tissue engineering. Biomaterials. 1989;2008:29.

Wang Y, Liu Y, Liu Y, Shen Q, Chen C, Qiu F, Li P, Jiao L, Qu X. Recent advances in electrospun electrode materials for sodium-ion batteries. J Energy Chem. 2021;54:225.

Yarin AL, Koombhongse S, Reneker DH. Taylor cone and jetting from liquid droplets in electrospinning of nanofibers. J Appl Phys. 2001;90:4836.

Lu Z, Sui F, Miao Y-E, Liu G, Li C, Dong W, Cui J, Liu T, Wu J, Yang C. Polyimide separators for rechargeable batteries. J Energy Chem. 2021;58:170.

Xu M, Wang M, Xu H, Xue H, Pang H. Electrospun-technology-derived high-performance electrochemical energy storage devices. Chem Asian J. 2016;11:2967.

Ekabutr P, Klinkajon W, Sangsanoh P, Chailapakul O, Niamlang P, Khampieng T, Supaphol P. Electrospinning: a carbonized gold/graphene/PAN nanofiber for high performance biosensing. Anal Methods. 2018;10:874.

Sun B, Duan B, Yuan X. Preparation of core/shell PVP/PLA ultrafine fibers by coaxial electrospinning. J Appl Polym Sci. 2006;102:39.

Bhardwaj N, Kundu SC. Electrospinning: a fascinating fiber fabrication technique. Biotechnol Adv. 2010;28:325.

Islam MS, Ang BC, Andriyana A, Afifi AM. A review on fabrication of nanofibers via electrospinning and their applications. SN Appl Sci. 2019;1:1248.

Li X, Chen W, Qian Q, Huang H, Chen Y, Wang Z, Chen Q, Yang J, Li J, Mai YW. Electrospinning-based strategies for battery materials. Adv Energy Mater. 2021;11:2000845.

Zhang M, Huang X, Xin H, Li D, Zhao Y, Shi L, Lin Y, Yu J, Yu Z, Zhu C, Xu J. Coaxial electrospinning synthesis hollow Mo2C@C core-shell nanofibers for high-performance and long-term lithium-ion batteries. Appl Surf Sci. 2019;473:352.

Xue J, Wu T, Dai Y, Xia Y. Electrospinning and electrospun nanofibers: methods, materials, and applications. Chem Rev. 2019;119:5298.

Liu C, Shi G, Wang G, Mishra P, Jia S, Jiang X, Zhang P, Dong Y, Wang Z. Preparation and electrochemical studies of electrospun phosphorus doped porous carbon nanofibers. R Soc Chem Adv. 2019;9:6898.

Wu J, Qin X, Miao C, He Y-B, Liang G, Zhou D, Liu M, Han C, Li B, Kang F. A honeycomb-cobweb inspired hierarchical core–shell structure design for electrospun silicon/carbon fibers as lithium-ion battery anodes. Carbon. 2016;98:582.

Chen Z, Yang T, Shi H, Wang T, Zhang M, Cao G. Single nozzle electrospinning synthesized MoO2@C core shell nanofibers with high capacity and long-term stability for lithium-ion storage. Adv Mater Interfaces. 2017;4:1600816.

Shan C, Feng X, Yang J, Yang X, Guan H-Y, Argueta M, Wu X-L, Liu D-S, Austin DJ, Nie P, Yue Y. Hierarchical porous carbon pellicles: electrospinning synthesis and applications as anodes for sodium-ion batteries with an outstanding performance. Carbon. 2020;157:308.

Li W, Zeng L, Yang Z, Gu L, Wang J, Liu X, Cheng J, Yu Y. Free-standing and binder-free sodium-ion electrodes with ultralong cycle life and high rate performance based on porous carbon nanofibers. Nanoscale. 2014;6:693.

Chen Y, Dong J, Qiu L, Li X, Li Q, Wang H, Liang S, Yao H, Huang H, Gao H, Kim J-K, Ding F, Zhou L. A catalytic etching-wetting-dewetting mechanism in the formation of hollow graphitic carbon fiber. Chemistry. 2017;2:299.

Chen Y, Li X, Park K, Zhou L, Huang H, Mai YW, Goodenough JB. Hollow nanotubes of N-doped carbon on CoS. Angew Chem Int Ed Engl. 2016;55:15831.

Chen YM, Yu L, Lou XW. Hierarchical tubular structures composed of Co3O4 hollow nanoparticles and carbon nanotubes for lithium storage. Angew Chem Int Ed Engl. 2016;55:5990.

Chen Y, Li X, Park K, Lu W, Wang C, Xue W, Yang F, Zhou J, Suo L, Lin T, Huang H, Li J, Goodenough JB. Nitrogen-doped carbon for sodium-ion battery anode by self-etching and graphitization of bimetallic MOF-based composite. Chemistry. 2017;3:152.

Li X, Li K, Zhu S, Fan K, Lyu L, Yao H, Li Y, Hu J, Huang H, Mai YW, Goodenough JB. Fiber-in-tube design of Co9S8-Carbon/Co9S8: enabling efficient sodium storage. Angew Chem Int Ed Engl. 2019;58:6239.

Ma M, Yao Y, Wu Y, Yu Y. Progress and prospects of transition metal sulfides for sodium storage. Adv Fiber Mater. 2020;2:314.

Wang L, Yang G, Peng S, Wang J, Yan W, Ramakrishna S. One-dimensional nanomaterials toward electrochemical sodium-ion storage applications via electrospinning. Energy Storage Mater. 2020;25:443.

Chen S, Wu C, Shen L, Zhu C, Huang Y, Xi K, Maier J, Yu Y. Challenges and perspectives for NASICON-type electrode materials for advanced sodium-ion batteries. Adv Mater. 2017;29:1700431.

Xu Y, Wei Q, Xu C, Li Q, An Q, Zhang P, Sheng J, Zhou L, Mai L. Layer-by-layer Na3V2(PO4)3embedded in reduced graphene oxide as superior rate and ultralong-life sodium-ion battery cathode. Adv Energy Mater. 2016;6:1600389.

Liu J, Tang K, Song K, van Aken PA, Yu Y, Maier J. Electrospun Na3V2(PO4)3/C nanofibers as stable cathode materials for sodium-ion batteries. Nanoscale. 2014;6:5081.

Kajiyama S, Kikkawa J, Hoshino J, Okubo M, Hosono E. Assembly of Na3V2(PO4)3 nanoparticles confined in a one-dimensional carbon sheath for enhanced sodium-ion cathode properties. Chemistry. 2014;20:12636.

Li H, Bai Y, Wu F, Ni Q, Wu C. Na3V2(PO4)3/C nanorods as advanced cathode material for sodium ion batteries. Solid State Ionics. 2015;278:281.

Li H, Bai Y, Wu F, Li Y, Wu C. Budding willow branches shaped Na3V2(PO4)3/C nanofibers synthesized via an electrospinning technique and used as cathode material for sodium ion batteries. J Power Sources. 2015;273:784.

Yang L, Wang W, Hu M, Shao J, Lv R. Ultrahigh rate binder-free Na3V2(PO4)3/carbon cathode for sodium-ion battery. J Energy Chem. 2018;27:1439.

Ni Q, Bai Y, Li Y, Ling L, Li L, Chen G, Wang Z, Ren H, Wu F, Wu C. 3D electronic channels wrapped large-sized Na3V2 (PO4)3 as flexible electrode for sodium-ion batteries. Small. 2018;14:1702864.

Li M, Liu L, Wang P, Li J, Leng Q, Cao G. Highly reversible sodium-ion storage in NaTi2(PO4)3/C composite nanofibers. Electrochim Acta. 2017;252:523.

Yu S, Wan Y, Shang C, Wang Z, Zhou L, Zou J, Cheng H, Lu Z. Ultrafine NaTi2(PO4)3 nanoparticles encapsulated in N-CNFs as ultra-stable electrode for sodium storage. Front Chem. 2018;6:270.

Dong J, Zhang G, Wang X, Zhang S, Deng C. Cross-linked Na2VTi(PO4)3@C hierarchical nanofibers as high-performance bi-functional electrodes for symmetric aqueous rechargeable sodium batteries. J Mater Chem A. 2017;5:18725.

Kim J, Seo D-H, Kim H, Park I, Yoo J-K, Jung S-K, Park Y-U, Goddard Iii WA, Kang K. Unexpected discovery of low-cost maricite NaFePO4 as a high-performance electrode for Na-ion batteries. Energy Environ Sci. 2015;8:540.

Liu Y, Zhang N, Wang F, Liu X, Jiao L, Fan L-Z. Approaching the downsizing limit of maricite NaFePO4 toward high-performance cathode for sodium-ion batteries. Adv Func Mater. 2018;28:1801917.

Barker J, Saidi MY, Swoyer JL. A sodium-ion cell based on the fluorophosphate compound NaVPO4F. Electrochem Solid-State Lett. 2003;6:A1.

Jin T, Liu Y, Li Y, Cao K, Wang X, Jiao L. Electrospun NaVPO4F/C nanofibers as self-standing cathode material for ultralong cycle life na-ion batteries. Adv Energy Mater. 2017;7:1700087.

Hu Y, Wu L, Liao G, Yang Y, Ye F, Chen J, Zhu X, Zhong S. Electrospinning synthesis of Na2MnPO4F/C nanofibers as a high voltage cathode material for Na-ion batteries. Ceram Int. 2018;44:17577.

Wang F, Zhang N, Zhao X, Wang L, Zhang J, Wang T, Liu F, Liu Y, Fan LZ. Realizing a high-performance na-storage cathode by tailoring ultrasmall Na2FePO4F nanoparticles with facilitated reaction kinetics. Adv Sci. 2019;6:1900649.

Niu Y, Xu M, Bao SJ, Li CM. Porous graphene to encapsulate Na6.24Fe4.88(P2O7)4 as composite cathode materials for Na-ion batteries. Chem Commun. 2015;51:13120.

Niu Y, Xu M, Dai C, Shen B, Li CM. Electrospun graphene-wrapped Na6.24Fe4.88(P2O7)4 nanofibers as a high-performance cathode for sodium-ion batteries. Phys Chem Chem Phys. 2017;19:17270.

Meng Y, Yu T, Zhang S, Deng C. Top-down synthesis of muscle-inspired alluaudite Na2+2xFe2−x(SO4)3/SWNT spindle as a high-rate and high-potential cathode for sodium-ion batteries. J Mater Chem A. 2016;4:1624.

Yu T, Lin B, Li Q, Wang X, Qu W, Zhang S, Deng C. First exploration of freestanding and flexible Na2+2xFe2-x(SO4)3@porous carbon nanofiber hybrid films with superior sodium intercalation for sodium ion batteries. Phys Chem Chem Phys. 2016;18:26933.

Luo W, Shen F, Bommier C, Zhu H, Ji X, Hu L. Na-ion battery anodes: materials and electrochemistry. Acc Chem Res. 2016;49:231.

Ding J, Wang H, Li Z, Kohandehghan A, Cui K, Xu Z, Zahiri B, Tan X, Lotfabad EM, Olsen BC, Mitlin D. Carbon nanosheet frameworks derived from peat moss as high performance sodium ion battery anodes. ACS Nano. 2013;7:11004.

Hou H, Banks CE, Jing M, Zhang Y, Ji X. Carbon quantum dots and their derivative 3D porous carbon frameworks for sodium-ion batteries with ultralong cycle life. Adv Mater. 2015;27:7861.

Rybarczyk MK, Li Y, Qiao M, Hu Y-S, Titirici M-M, Lieder M. Hard carbon derived from rice husk as low cost negative electrodes in Na-ion batteries. J Energy Chem. 2019;29:17.

Qiu D, Cao T, Zhang J, Zhang S-W, Zheng D, Wu H, Lv W, Kang F, Yang Q-H. Precise carbon structure control by salt template for high performance sodium-ion storage. J Energy Chem. 2019;31:101.

Xu Z-L, Liu X, Luo Y, Zhou L, Kim J-K. Nanosilicon anodes for high performance rechargeable batteries. Prog Mater Sci. 2017;90:1.

Zhang B, Kang F, Tarascon J-M, Kim J-K. Recent advances in electrospun carbon nanofibers and their application in electrochemical energy storage. Prog Mater Sci. 2016;76:319.

Bai Y, Wang Z, Wu C, Xu R, Wu F, Liu Y, Li H, Li Y, Lu J, Amine K. Hard carbon originated from polyvinyl chloride nanofibers as high-performance anode material for Na-ion battery. ACS Appl Mater Interfaces. 2015;7:5598.

Chen T, Liu Y, Pan L, Lu T, Yao Y, Sun Z, Chua DHC, Chen Q. Electrospun carbon nanofibers as anode materials for sodium ion batteries with excellent cycle performance. J Mater Chem A. 2014;2:4117.

Jin J, Shi Z-Q, Wang C-Y. Electrochemical performance of electrospun carbon nanofibers as free-standing and binder-free anodes for sodium-ion and lithium-ion batteries. Electrochim Acta. 2014;141:302.

Guo X, Zhang X, Song H, Zhou J. Electrospun cross-linked carbon nanofiber films as free-standing and binder-free anodes with superior rate performance and long-term cycling stability for sodium ion storage. J Mater Chem A. 2017;5:21343.

Maier J. Nanoionics: ion transport and electrochemical storage in confined systems. Nat Mater. 2005;4:805.

Wang J, Li W, Yang Z, Gu L, Yu Y. Free-standing and binder-free sodium-ion electrodes based on carbon-nanotube decorated Li4Ti5O12 nanoparticles embedded in carbon nanofibers. R Soc Chem Adv. 2014;4:25220.

Wang S, Xia L, Yu L, Zhang L, Wang H, Lou XW. Free-standing nitrogen-doped carbon nanofiber films: integrated electrodes for sodium-ion batteries with ultralong cycle life and superior rate capability. Adv Energy Mater. 2016;6:1502217.

Dirican M, Zhang X. Centrifugally-spun carbon microfibers and porous carbon microfibers as anode materials for sodium-ion batteries. J Power Sources. 2016;327:333.

Zeng L, Li W, Cheng J, Wang J, Liu X, Yu Y. N-doped porous hollow carbon nanofibers fabricated using electrospun polymer templates and their sodium storage properties. R Soc Chem Adv. 2014;4:16920.

Zhu J, Chen C, Lu Y, Ge Y, Jiang H, Fu K, Zhang X. Nitrogen-doped carbon nanofibers derived from polyacrylonitrile for use as anode material in sodium-ion batteries. Carbon. 2015;94:189.

Jin J, Yu B-J, Shi Z-Q, Wang C-Y, Chong C-B. Lignin-based electrospun carbon nanofibrous webs as free-standing and binder-free electrodes for sodium ion batteries. J Power Sources. 2014;272:800.

Wu J, Yu J, Liu J, Cui J, Yao S, Ihsan-Ul Haq M, Mubarak N, Susca A, Ciucci F, Kim J-K. MoSe2 nanosheets embedded in nitrogen/phosphorus co-doped carbon/graphene composite anodes for ultrafast sodium storage. J Power Sources. 2020;476:228660.

Li Y, Chen M, Liu B, Zhang Y, Liang X, Xia X. Heteroatom doping: an effective way to boost sodium ion storage. Adv Energy Mater. 2020;10:2000927.

Zou L, Lai Y, Hu H, Wang M, Zhang K, Zhang P, Fang J, Li J. N/S co-doped 3 D porous carbon nanosheet networks enhancing anode performance of sodium-ion batteries. Chemistry. 2017;23:14261.

Zhang X, Zhu G, Wang M, Li J, Lu T, Pan L. Covalent-organic-frameworks derived N-doped porous carbon materials as anode for superior long-life cycling lithium and sodium ion batteries. Carbon. 2017;116:686.

Yan D, Yu C, Zhang X, Qin W, Lu T, Hu B, Li H, Pan L. Nitrogen-doped carbon microspheres derived from oatmeal as high capacity and superior long life anode material for sodium ion battery. Electrochim Acta. 2016;191:385.

Song H, Li N, Cui H, Wang C. Enhanced storage capability and kinetic processes by pores- and hetero-atoms-riched carbon nanobubbles for lithium-ion and sodium-ion batteries anodes. Nano Energy. 2014;4:81.

Wang M, Yang Z, Li W, Gu L, Yu Y. Superior sodium storage in 3D interconnected nitrogen and oxygen dual-doped carbon network. Small. 2016;12:2559.

Liu C, Hu J, Yang L, Zhao W, Li H, Pan F. Low-surface-area nitrogen doped carbon nanomaterials for advanced sodium ion batteries. Chem Commun. 2018;54:2142.

Fu L, Tang K, Song K, van Aken PA, Yu Y, Maier J. Nitrogen doped porous carbon fibres as anode materials for sodium ion batteries with excellent rate performance. Nanoscale. 2014;6:1384.

Liu Y, Zhang N, Yu C, Jiao L, Chen J. MnFe2O4@C nanofibers as high-performance anode for sodium-ion batteries. Nano Lett. 2016;16:3321.

Chen C, Lu Y, Ge Y, Zhu J, Jiang H, Li Y, Hu Y, Zhang X. Synthesis of nitrogen-doped electrospun carbon nanofibers as anode material for high-performance sodium-ion batteries. Energ Technol. 2016;4:1440.

Xu X, Zeng H, Han D, Qiao K, Xing W, Rood MJ, Yan Z. Nitrogen and sulfur co-doped graphene nanosheets to improve anode materials for sodium-ion batteries. ACS Appl Mater Interfaces. 2018;10:37172.

Bao Y, Huang Y, Song X, Long J, Wang S, Ding L-X, Wang H. Heteroatom doping and activation of carbon nanofibers enabling ultrafast and stable sodium storage. Electrochim Acta. 2018;276:304.

Sun X, Wang C, Gong Y, Gu L, Chen Q, Yu Y. A flexible sulfur-enriched nitrogen doped multichannel hollow carbon nanofibers film for high performance sodium storage. Small. 2018;14:1802218.

Hou H, Shao L, Zhang Y, Zou G, Chen J, Ji X. Large-area carbon nanosheets doped with phosphorus: a high-performance anode material for sodium-ion batteries. Adv Sci. 2017;4:1600243.

Li Y, Yuan Y, Bai Y, Liu Y, Wang Z, Li L, Wu F, Amine K, Wu C, Lu J. Insights into the Na+ storage mechanism of phosphorus-functionalized hard carbon as ultrahigh capacity anodes. Adv Energy Mater. 2018;8:1702781.

Wu F, Dong R, Bai Y, Li Y, Chen G, Wang Z, Wu C. Phosphorus-doped hard carbon nanofibers prepared by electrospinning as an anode in sodium-ion batteries. ACS Appl Mater Interfaces. 2018;10:21335.

Zhu Y, Han X, Xu Y, Liu Y, Zheng S, Xu K, Hu L, Wang C. Electrospun Sb/C fibers for a stable and fast sodium-ion battery anode. ACS Nano. 2013;7:6378.

Wu L, Hu X, Qian J, Pei F, Wu F, Mao R, Ai X, Yang H, Cao Y. Sb–C nanofibers with long cycle life as an anode material for high-performance sodium-ion batteries. Energy Environ Sci. 2014;7:323.

Yin H, Li Q, Cao M, Zhang W, Zhao H, Li C, Huo K, Zhu M. Nanosized-bismuth-embedded 1D carbon nanofibers as high-performance anodes for lithium-ion and sodium-ion batteries. Nano Res. 2017;10:2156.

Jin Y, Yuan H, Lan J-L, Yu Y, Lin Y-H, Yang X. Bio-inspired spider-web-like membranes with a hierarchical structure for high performance lithium/sodium ion battery electrodes: the case of 3D freestanding and binder-free bismuth/CNF anodes. Nanoscale. 2017;9:13298.

Kim J-C, Kim D-W. Synthesis of multiphase SnSb nanoparticles-on-SnO2/Sn/C nanofibers for use in Li and Na ion battery electrodes. Electrochem Commun. 2014;46:124.

Jia H, Dirican M, Chen C, Zhu J, Zhu P, Yan C, Li Y, Dong X, Guo J, Zhang X. Reduced graphene oxide-incorporated SnSb@CNF composites as anodes for high-performance sodium-ion batteries. ACS Appl Mater Interfaces. 2018;10:9696.

Kim J-C, Kim D-W. Electrospun Cu/Sn/C nanocomposite fiber anodes with superior usable lifetime for lithium- and sodium-ion batteries. Chem Asian J. 2014;9:3313.

Mao M, Yan F, Cui C, Ma J, Zhang M, Wang T, Wang C. Pipe-wire TiO2–Sn@carbon nanofibers paper anodes for lithium and sodium ion batteries. Nano Lett. 2017;17:3830.

Ji L, Gu M, Shao Y, Li X, Engelhard MH, Arey BW, Wang W, Nie Z, Xiao J, Wang C, Zhang J-G, Liu J. Controlling SEI formation on SnSb-porous carbon nanofibers for improved Na ion storage. Adv Mater. 2014;26:2901.

Chen C, Fu K, Lu Y, Zhu J, Xue L, Hu Y, Zhang X. Use of a tin antimony alloy-filled porous carbon nanofiber composite as an anode in sodium-ion batteries. R Soc Chem Adv. 2015;5:30793.

Liu Y, Zhang N, Jiao L, Chen J. Tin nanodots encapsulated in porous nitrogen-doped carbon nanofibers as a free-standing anode for advanced sodium-ion batteries. Adv Mater. 2015;27:6702.

Xu Z-L, Yao S, Cui J, Zhou L, Kim J-K. Atomic scale, amorphous FeOx/carbon nanofiber anodes for Li-ion and Na-ion batteries. Energy Storage Mater. 2017;8:10.

Xia G, Gao Q, Sun D, Yu X. Porous carbon nanofibers encapsulated with peapod-like hematite nanoparticles for high-rate and long-life battery anodes. Small. 2017;13:1701561.

Yin H, Cao M-L, Yu X-X, Zhao H, Shen Y, Li C, Zhu M-Q. Self-standing Bi2O3 nanoparticles/carbon nanofiber hybrid films as a binder-free anode for flexible sodium-ion batteries. Mater Chem Front. 2017;1:1615.

Wu L, Lang J, Wang R, Guo R, Yan X. Electrospinning synthesis of mesoporous MnCoNiOx@double-carbon nanofibers for sodium-ion battery anodes with pseudocapacitive behavior and long cycle life. ACS Appl Mater Interfaces. 2016;8:34342.

Zou W, Fan C, Li J. Sodium titanate/carbon (Na2Ti3O7/C) nanofibers via electrospinning technique as the anode of sodium-ion batteries. Chin J Chem. 2017;35:79.

Yang L, Zhu YE, Sheng J, Li F, Tang B, Zhang Y, Zhou Z. T-Nb2O5/C nanofibers prepared through electrospinning with prolonged cycle durability for high-rate sodium-ion batteries induced by pseudocapacitance. Small. 2017;13:1702588.

Wang X, Liu Y, Wang Y, Jiao L. CuO quantum dots embedded in carbon nanofibers as binder-free anode for sodium ion batteries with enhanced properties. Small. 2016;12:4865.

Liu Y, Wang F, Fan L-Z. Self-standing Na-storage anode of Fe2O3 nanodots encapsulated in porous N-doped carbon nanofibers with ultra-high cyclic stability. Nano Res. 2018;11:4026.

Yao S, Cui J, Lu Z, Xu Z-L, Qin L, Huang J, Sadighi Z, Ciucci F, Kim J-K. Unveiling the unique phase transformation behavior and sodiation kinetics of 1D van der Waals Sb2S3 anodes for sodium ion batteries. Adv Energy Mater. 2017;7:1602149.

Hayashi A, Masuzawa N, Yubuchi S, Tsuji F, Hotehama C, Sakuda A, Tatsumisago M. A sodium-ion sulfide solid electrolyte with unprecedented conductivity at room temperature. Nat Commun. 2019;10:5266.

Wu J, Liu J, Cui J, Yao S, Ihsan-Ul-Haq M, Mubarak N, Quattrocchi E, Ciucci F, Kim J-K. Dual-phase MoS2 as a high-performance sodium-ion battery anode. J Mater Chem A. 2020;8:2114.

Wu J, Lu Z, Li K, Cui J, Yao S, Ihsan-ul Haq M, Li B, Yang Q-H, Kang F, Ciucci F, Kim J-K. Hierarchical MoS2/carbon microspheres as long-life and high-rate anodes for sodium-ion batteries. J Mater Chem A. 2018;6:5668.

Wu J, Ihsan-Ul-Haq M, Ciucci F, Huang B, Kim J-K. Rationally designed nanostructured metal chalcogenides for advanced sodium-ion batteries. Energy Storage Mater. 2021;34:582.

Chen YM, Yu XY, Li Z, Paik U, Lou XW. Hierarchical MoS2 tubular structures internally wired by carbon nanotubes as a highly stable anode material for lithium-ion batteries. Sci Adv. 2016;2:1600021.

Chen C, Li G, Lu Y, Zhu J, Jiang M, Hu Y, Cao L, Zhang X. Chemical vapor deposited MoS2/electrospun carbon nanofiber composite as anode material for high-performance sodium-ion batteries. Electrochim Acta. 2016;222:1751.

Zhu C, Mu X, van Aken PA, Yu Y, Maier J. Single-layered ultrasmall nanoplates of MoS2 embedded in carbon nanofibers with excellent electrochemical performance for lithium and sodium storage. Angew Chem Int Ed. 2014;53:2152.

Cui C, Wei Z, Xu J, Zhang Y, Liu S, Liu H, Mao M, Wang S, Ma J, Dou S. Three-dimensional carbon frameworks enabling MoS2 as anode for dual ion batteries with superior sodium storage properties. Energy Storage Mater. 2018;15:22.

Jung J-W, Ryu W-H, Yu S, Kim C, Cho S-H, Kim I-D. Dimensional effects of MoS2 nanoplates embedded in carbon nanofibers for bifunctional Li and Na insertion and conversion reactions. ACS Appl Mater Interfaces. 2016;8:26758.

Zhao C, Yu C, Zhang M, Sun Q, Li S, Norouzi Banis M, Han X, Dong Q, Yang J, Wang G, Sun X, Qiu J. Enhanced sodium storage capability enabled by super wide-interlayer-spacing MoS2 integrated on carbon fibers. Nano Energy. 2017;41:66.

Ni Q, Bai Y, Guo S, Ren H, Chen G, Wang Z, Wu F, Wu C. Carbon nanofiber elastically confined nanoflowers: a highly efficient design for molybdenum disulfide-based flexible anodes toward fast sodium storage. ACS Appl Mater Interfaces. 2019;11:5183.

Li W, Bi R, Liu G, Tian Y, Zhang L. 3D interconnected MoS2 with enlarged interlayer spacing grown on carbon nanofibers as a flexible anode toward superior sodium-ion batteries. ACS Appl Mater Interfaces. 2018;10:26982.

Xia J, Liu L, Jamil S, Xie J, Yan H, Yuan Y, Zhang Y, Nie S, Pan J, Wang X, Cao G. Free-standing SnS/C nanofiber anodes for ultralong cycle-life lithium-ion batteries and sodium-ion batteries. Energy Storage Mater. 2019;17:1.

Chen Z, Chen S, Zhang H, Liu M, Feng Z, Li X, Huang J, Guo D. Exfoliated MoS2@C nanosheets as anode for sodium/potassium storage. Ionics. 2019;26:1779.

Liang J, Wei Z, Wang C, Ma J. Vacancy-induced sodium-ion storage in N-doped carbon Nanofiber@MoS2 nanosheet arrays. Electrochim Acta. 2018;285:301.

Cho E, Song K, Park MH, Nam K-W, Kang Y-M. SnS 3D flowers with superb kinetic properties for anodic use in next-generation sodium rechargeable batteries. Small. 2016;12:2510.

Zhang S, Zhao H, Wang M, Li Z, Mi J. Low crystallinity SnS encapsulated in CNTs decorated and S-doped carbon nanofibers as excellent anode material for sodium-ion batteries. Electrochim Acta. 2018;279:186.

Wang Y, Zhang Y, Shi J, Kong X, Cao X, Liang S, Cao G, Pan A. Tin sulfide nanoparticles embedded in sulfur and nitrogen dual-doped mesoporous carbon fibers as high-performance anodes with battery-capacitive sodium storage. Energy Storage Mater. 2019;18:366.

Xia J, Jiang K, Xie J, Guo S, Liu L, Zhang Y, Nie S, Yuan Y, Yan H, Wang X. Tin disulfide embedded in N-, S-doped carbon nanofibers as anode material for sodium-ion batteries. Chem Eng J. 2019;359:1244.

Gao B, Li X, Ding K, Huang C, Li Q, Chu PK, Huo K. Recent progress in nanostructured transition metal nitrides for advanced electrochemical energy storage. J Mater Chem A. 2019;7:14.

Luo Y, Huang D, Liang C, Wang P, Han K, Wu B, Cao F, Mai L, Chen H. Fe2VO4 hierarchical porous microparticles prepared via a facile surface solvation treatment for high-performance lithium and sodium storage. Small. 2019;15:1804706.

Xu L, Xiong P, Zeng L, Fang Y, Liu R, Liu J, Luo F, Chen Q, Wei M, Qian Q. Electrospun VSe1.5/CNF composite with excellent performance for alkali metal ion batteries. Nanoscale. 2019;11:16308.

Xu L, Xiong P, Zeng L, Liu R, Liu J, Luo F, Li X, Chen Q, Wei M, Qian Q. Facile fabrication of a vanadium nitride/carbon fiber composite for half/full sodium-ion and potassium-ion batteries with long-term cycling performance. Nanoscale. 2020;12:10693.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Li, C., Qiu, M., Li, R. et al. Electrospinning Engineering Enables High-Performance Sodium-Ion Batteries. Adv. Fiber Mater. 4, 43–65 (2022). https://doi.org/10.1007/s42765-021-00088-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42765-021-00088-6