Abstract

Considering metal oxide nanoparticles as important technological materials, authors provide a comprehensive review of researches on metal oxide nanoparticles, their synthetic strategies, and techniques, nanoscale physicochemical properties, defining specific industrial applications in the various fields of applied nanotechnology. This work expansively reviews the recent developments of semiconducting metal oxide gas sensors for environmental gases including CO2, O2, O3, and NH3; highly toxic gases including CO, H2S, and NO2; combustible gases such as CH4, H2, and liquefied petroleum gas; and volatile organic compounds gases. The gas sensing properties of different metal oxides nanoparticles towards specific target gases have been individually discussed. Promising metal oxide nanoparticles for sensitive and selective detection of each gas have been identified. This review also categorizes metal oxides sensors by analyte gas and also summarizes the major techniques and synthesis strategies used in nanotechnology. Additionally, strategies, sensing mechanisms and related applications of semiconducting metal oxide materials are also discussed in detail. Related applications are innumerable trace to ultratrace-level gas sensors, batteries, magnetic storage media, various types of solar cells, metal oxide nanoparticles applications in catalysis, energy conversion, and antennas (including microstrip and patch-type optically transparent antennas), rectifiers, optoelectronic, and electronics.

Similar content being viewed by others

1 Introduction

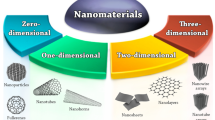

Semiconducting metal oxide-based gas sensors have attracted great attention for its advantages such as fast and sensitive detection portability and low cost, compared to other conventional techniques since their discovery of gas sensing properties in 1960s. The engineered metal oxides nanoparticles (MONPs) are among the widest used manufactured nanomaterials because of their unique properties. The properties that make the nanophase structures indispensable tools in modern nanotechnology are their various nonlinear optical properties, higher ductility at elevated temperatures than the coarse-grained ceramics, cold welding properties, superparamagnetic behaviour, unique catalytic, sensitivity, and selective activity. For example, the melting point of the nanosized material is lower than that of a bulk material with the same composition [1]. At the same time, NPs exhibit unusual adsorptive properties and fast diffusivities and they are not stable in critical conditions [2]. Nanotechnology includes the research and engineering of new materials at the nanoscale level. Several synthetic strategies and techniques were used in nanotechnology. As synthetic strategies are concerned, there are in general two types of approaches for the production of nanomaterials and fabrication of nanostructures.

-

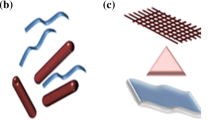

(a)

A bottom-up approach that includes miniaturization of materials components up to atomic level with further self-assembly process (physical forces operating at the nanoscale are used to combine basic units into larger stable structures) leading to the formation of nanostructures. This approach organizes atomic or molecular components in hierarchical nanocomplexes. Such examples are QDs or nanoparticles formed from colloidal dispersion;

-

(b)

Top-down approach rather initiate with macroscopic structures, controlling externally the process of formation of nanostructures. The top-down approach adds or removes thin layers of bulk materials as do ball milling, mask etching, etc.

Figure 1 summarizes the major techniques and synthesis strategies used in nanotechnology. The bottom-up approach for synthesis of nanostructured materials includes physical such as pulse and physical vapour deposition (PVD), chemical vapour deposition (CVD), pulsed laser deposition (PLD), ion implantation (II), atomic layer deposition (ALD), molecular beam epitaxy (MBE), spray pyrolysis (SP), and chemical methods for preparing NPs by an aqueous solution such as hydrothermal, precipitation and microemulsion routes, sol–gel, microwaved, sonochemical electrochemical and photochemical processes [3, 4]. These physical and chemical production methods are typically pricey, labour-intensive and also detrimental to the environment [5].

Recently, a strong focus is placed on green synthesis, where NPs are extracted from fungi, algae, bacteria, and plants (usually terrestrial) in which a variety of metabolites act as reducing agents in NPs synthesis. The advantage of using green synthesis is that they are easily available, safe, and versatile in the type of metabolites that could act as reducing and stabilizing agents. Additionally, different combinations such as plant extracting with the microwave irradiation method that heats the material through its dielectric loss are recently proposed [6]. The obvious increase in the alternatives for the synthesis of NPs and green approaches that use different biological materials is greatly encouraging.

The nanotechnology techniques could be segregated into wet, dry, and computational engineering. Wet nanotechnology deals with the processes taking place in aqua-environments mostly exploiting living systems and components present in the cell, tissue, and organs of living organisms. Dry engineering handles synthesis of inorganic rigid structures and parts with the help of physicochemical methods, whereas computational nanotechnology concerns with the development and use of computer-based quantum and molecular design, modelling, and simulation of the behaviour or properties of systems relevant to nanotechnology.

The variety of methods employed during the fabrication of MONPs can alter the characteristics and control the properties of the obtained nano-oxides. The reaction mechanisms and, therefore, the functionality of nanostructured MOx depend on their composition, crystallographic structure, morphology, surface stoichiometry and geometry, interactions of the phases, etc. For achieving nanostructures with a set of desired properties, it is vital to summarize the existing information for variations in functional properties and characteristics of nanostructured MOx to expand our understanding beyond the existing knowledge. For that reason, this work was aimed at exploring the complications to induce further investigations by summarizing new techniques, benefitting the features of the MONPs and successful studies. The authors present various gas sensors, battery materials, solar cell, antennas, optoelectronic/electronic applications, etc., based on semiconducting MONPs and their composites used in nanotechnology. The many varieties of techniques, types of nano-oxides, and combinations used just confirm the complexity of correlation between changes of nanostructure and composition on the one hand, and on the other hand—the resultant properties of the designed device.

2 Properties of nano-oxides

At present, nanoparticle research is an area of intense scientific activity due to a variety of potential applications in several fields [7]. The electronic structure of nanoparticles can reveal semiconductor, metallic, or insulator character. The unique chemical and physical properties of MONPs are attributed to the high density and limited size of corners and edges on their surface. Potential technological applications of metal oxide nanoparticles play a vital role attracting researchers with considerable interest from the fields of materials chemistry, medicine, agriculture, information technology, biomedical, optical, electronics, catalysis, environment, energy, and sense. Changes in cell parameters due to the size-related structural alterations have been observed, for example, in nanoparticles of CuO, ZnO, SnO2, Al2O3, MgO, ZrO2 AgO, TiO2, CeO2, etc. As the size decreases in the nanoparticles, an increasing number of surface and interface atoms generates strain or stress and adjoining structural perturbations [8]. The specific size of the nanoparticle can alter magnetic, conducting, chemical, and electronic properties [9]. Magnetic metal oxides nanoparticles have gained particular interest as their properties can be tuned based on their size and shape. Magnetic, electronic, and chemical properties of nanoparticles can be dependent on a specific size of the nanoparticle material [10]. Iron oxides, precisely magnetite, are of particular interest to materials scientists as they are connected through series of potential applications, extending from magnetic storage devices (MSD) to magnetic resonance imaging (MRI) contrast agents [11]. Size-dependency was detected in γ-Fe2O3 nanoparticles, where 55 nm particles exhibit ferromagnetic behaviour, while 12 nm nanoparticles exhibit superparamagnetic behaviour without hysteresis [12]. The decrease in particle size will also decrease the total magnetic anisotropy while inducing the change to superparamagnetic [13]. Innovative easy methods of creating required sized metal oxide nanoparticles are essential for attaining all the desired magnetic, electronic, and chemical properties.

Electrical properties (conductance) are strongly dependant on the size of these particles especially using oxides like SnO2, WO3, and In2O3 [14] in gas sensing applications. Electrical/ionic conductivity is a property of TiO2 materials that modulates to find practicality in the area of sensors, optoelectronics, or photovoltaics. TiO2 can be easily reduced at high temperatures, and this assertively impacts conductivity [15]. One-dimensional (1-D) ZnO engaged in both optoelectronic and electronic applications [16] with wurtzite-type structure has tremendous potential in applications from gas sensors to varistors. The long-range effects of the Madelung field, present in the electronic properties of a bulk oxide surface, are either limited or not present in the nanostructured oxide [17].

Germania (GeO2) nanoparticles have many prospective applications for enhancing optical fibres and other optoelectronic fields [18]. Ga2O3 nanoparticles are also used in surface-catalysed systems for new electronic or optical applications [19] specifically at low temperatures. As a material with wider bandgap, it provides a broad range of light emission; β-Ga2O3 is presently being investigated to exploit its potential for optoelectronic applications. As known, the reduced-size nanoparticle enhances the chemical reactivity due to its larger surface area to unit mass ratio. The CuO nanoparticles are used in the microwave irradiation process, also as redox catalyst as well as a catalyst in several oxidation processes, in photoconductive and photothermal applications [20]. MgO nanoparticles are extensively applied in various types of chemical industries as a material for scrubber in eliminating gaseous air pollutants (CO2, CO, NOx, SOx) and also as a catalyst in organic synthesis [21]. The novel structure of Al2O3 is used as a support for active phases in the area of catalysis coated with other materials [22]. ZrO2 nanoparticles are exploited in structural ceramics, as a solid electrolyte, as a catalyst, and also as gas sensing materials [23]. CeO2 nanoparticles are used in areas of catalysis, gas sensing, electrochemistry, biomedical, and material chemistry [24]. TiO2 nanoparticles are applied in various kinds of industrial applications related to photocatalysis for pollutant elimination, solar cells, and also in material science and engineering [25]. ZnO is a wide bandgap semiconductor material extensively studied for its intrinsic properties but with limited industrial use as a UV-blocker in sunscreen creams and lotions, mixed varistors, solar cells, partially as laser sources, optoelectronics, in gas sensors, and also as catalysts for numerous types of organic reactions [26].

All the listed properties and applications of certain MONPs described in the previous sections are closely related to the structure, size, and shape of the nanostructures. It is clear that a large number of factors will influence the structural characteristics and main properties of the functional devices which will affect their performance. When combining two different nano-oxides including the development of p–n junction or modifying them with a dopant, elaboration of a nanostructure with optimal optical or electronic properties becomes a complex task. Moreover, the suitable method for fabrication MONPs with tunable structural parameters and properties should include optimization of all process parameters which could result in adverse alteration of the obtained characteristics. The existence of such a large number of factors influencing the structural characteristics and performance of the functional devices results in difficulties in reproducing the results obtained.

3 Nano-oxides in diverse applications

Presently, sensor technology is one of the important technologies and with continually growing applications, both in government and private sectors it could be on top as a future technology for the coming decades. More and more gas sensors are applied for environmental monitoring, semiconductor, health care, and automobiles. Therefore, the development of ultrafast and highly sensitive gas sensors with very small cross-sensitivity is the focus of the intense research, driven by strategies based on nanoscience and nanotechnology. Nanostructured materials especially nanoparticles with smaller dimensions have demonstrated a greater potential for use as key sensing layers.

3.1 Gas sensors

Developing highly performing, ever reliable gas sensors that can monitor accurately at or close to room temperature (RT) is becoming a priority in the gas sensor research. With some distinguishing advantages, such as larger range of operative parameters to be analysed (rapid fluctuations in light intensity, polarization, wavelength modulation, etc.), selectivity improvement, and easy implementation, MONPs allow better signal transport, in situ monitoring, and potential to be exploited by using surface plasmonic resonance which improves the sensing performance. Traditionally, over the past decades, metal oxide semiconductors (MOS) are the most commonly exploited sensing materials with advantages like a fast response, low cost, ease of handling, a wide range of target gases, and longer lifetimes. However, they also suffer from disadvantages like higher energy consumption and lower selectivities.

Owing more surface active sites, large surface-to-volume ratios, high specific surface areas with very high surface reactivity, and nano-metal oxides are applied towards gas sensing [27, 28]. Usually, a gas sensor that uses MONPs consists of a heating layer or wire (to obtain the optimum working temperature), conducting electrodes (that measure the resistance), and sensing film which changes its resistance upon exposure (Fig. 2). Conductometric gas sensors change their electrical conductivity upon exposure to the target gas. While the transducer function is dependent on the microstructure of the oxide, the receptor function depends on the gas–solid interactions and could be modified by mixing different oxides or adding noble metals. The gas sensing mechanism is defined by the number of reactive surface sites and adsorption of oxygen species that further increase the number of surface reactive sites [29]. The surface conductivity of the metal oxide is very much dependent on the surface stoichiometry because oxygen vacancies increase the surface conductivity, whereas absorbed ions decrease it. Upon adsorption of molecules such as O2 or NO2 at vacancy sites of the oxide, the electrons are flowed out from the conduction band and conductivity decreases, whereas CO or H2 in the oxygen-containing atmosphere react with adsorbed O2 releasing electrons and increasing conductance. The adsorption reactions and abrupt temperature change of the sensor continuously alter the conductance. It follows that the optimum temperature is directly related to the reduction in metal and release of conduction electrons to the conduction band [30]. To have control of the rate-limiting reaction, heating of the gas sensor is used. The sensor response at low temperature is controlled by the speed of chemical reaction and at high temperature—by the speed of molecule diffusion [31]. In optimum temperature, the speed of both processes is equal while the response is setting maximum levels. In conductometric sensors, the heating could be direct or indirect but the latter is preferable due to higher stability and lack of interference with the sensing layer. However, working at higher temperatures not only increases the cost of power consumption and technical complexity of the device, but it could change the oxide properties leading to reduced stability and lifetime of the sensor.

Schematic representation of conductometric gas sensing device and sensing principle. The interaction with the surrounding atmosphere changes the conductivity of metal oxide and because of its transducer function electrical signal is transmitted to the electrode. The indirect heating of the device is used to change its electrical conductivity

The conductivity of a MOx-based sensor depends on the particle size, their interconnected boundary characteristics (barriers, cross sections of the channels, etc.), the spatial organization of the nanoparticles (hierarchical, branched dendritic), p–n junction between the nanocomposites (heterostructures), etc. For nanocomposites, an increase in the conductivity response is usually found near the solubility limit of the second metal where a maximum structural disorder exists depending on the synthesis method and annealing [32]. Usually, the solubility limit of the most metal oxides varies between 1 and 5%. Increasing the surface area of the sensing film, the gas sensing performance increases which give rise to the production of relatively loose film structures or porous nanostructures such as nanotubes, nanospheres, nanowires, nanosheets, etc. [33]. Such hollow structures are usually produced by using anodizing processes, wet chemical methods, hydrothermal, or sol–gel synthesis. Some examples for such structures, their chemical composition, morphology, and sensitivity towards certain gases are summarized in Table 1.

Doping is another concept to change the electrical resistance and enhance the catalytic properties, because of produced smaller-sized doped metal oxides, catalytic activity, formed p–n heterojunctions [65] or obtained higher activity by increasing the density of the functional groups. Introducing the second component (noble or transitional metal, transitional or non-conductive nano-oxide or certain impurity) produces structural disorders of the metal oxide which lead to a significant reduction in the energy gap [32]. Gas sensing is receiving collective consideration in industrial production, biomedical applications, in hospitals and for environmental monitoring [66]. Good performance of a gas sensor is indicated by factors such as high sensitivity, rapid lower response time, low energy consumption, signal stability, long-term monitoring, and good reproducibility [67]. Typical examples of gas sensors for different gases based on semiconductor nano-oxides are discussed in the following sub-sections.

3.1.1 Carbon dioxide gas sensors

Carbon dioxide (CO2) sensors are obligatory in countless fields, from monitoring air quality to hospital indoors and the food packaging industry. The parameters for these sensors in terms of performance, linearity range, the limit of detection and price vary significantly, depending on the field in which it is utilized. CO2 sensors are widely required for many offices indoors, industrial purposes, and environmental monitoring.

Because of their chemical stability, conventional metal and binary metal oxides display low sensitivity to inert gases such as CO2. Different semiconductor nanomaterials have been tested for CO2 detection and most of them indicated ineffectiveness in improving sensor response by doping. It is for this reason that researchers focused on new nanocomposite MOx developed to meet this challenge. Combination of semiconducting oxides CuO–CuxFe3−xO nanocomposite (with 0 ≤ x ≤ 1) was prepared by RF sputtering from a delafossite CuFeO2 and used as a new active layer for CO2 sensing. At different working temperatures (130–475 °C), the response of the sensor in a carbon dioxide atmosphere was measured by varying concentration up to 5000 ppm, and in different frequencies (0.5–250 kHz). The results obtained for a CO2 concentration of 5000 ppm indicate a high response of 50% (\(R_{\text{air}} R_{{{\text{CO}}_{2} }}^{ - 1} = 1.9\)) (at 250 °C and 700 Hz) [68].

BaTiO3–CuO-sputtered thin films were used for carbon dioxide sensing. The BaTiO3–CuO sensor response towards CO2 is due to a reversible reaction based on the presence of BaCO3 in the composite material. Resistance and capacitance changes are closely associated with the work function changes in the p–n heterojunctions between BaTiO3 and CuO [69]. Measuring impedance changes allows monitoring of the variations in CO2 concentrations. The optimal working frequency range was obtained from a frequency response via spatial charge and relaxation phenomena [70].

3.1.2 Carbon monoxide gas sensors

Carbon monoxide (CO) is a toxic, odourless, colourless, and tasteless (therefore, undetectable to human) gas slightly less dense than air. Encountering with ≥ 25 ppm concentrations, normal animal metabolism produces it in very low volumes and CO is thought to have some biological functions. Carbon monoxide is obtained from the partial oxidation of carbon-containing compounds, usually when there is not enough oxygen to completely oxidize and produce carbon dioxide (CO2), as an indoor stove and internal combustion (IC) engine with a confined space.

CO gas sensor is an important primary instrument of detecting the toxic gas. To improve the sensitivity, stability, and response time and to reduce operating temperature, noble metals such as Pd, Au, and Ag are used as dopants in metal oxides gas sensors. For example, SnO2 doped with Pd materials were realized in thick-film technology, stay while sensing CO. Sensing CO with SnO2 sensors in the presence of humidity seems to be very ideal and aid in inferring the basic principles of metal oxide-based gas sensors [71]. However, this sensitivity to humidity makes it not applicable to variable humidity conditions whereas the high cost greatly limits the application of these noble metal-doped gas sensors. Pure SnO2 and In2O3 were also used in detecting toxic CO gas at RT. Materials were produced using DC sputtering in an argon atmosphere (inert condition) by rheotaxial growth and thermal oxidation (RGTO) technique and with a reactive magnetron sputtering (RMS) in Ar and O2 atmospheres, respectively. The sensor showed a linear response within the concentration range of 100–400 ppm of CO [72]. Pt/stabilized zirconia, YSZ/Pt, seems to be highly sensitive to a limited amount of CO in an O2-containing gas stream. The electrochemical measurements carried out by means of steady-state polarization curves in the temperature range of 500–650 °C indicated good CO sensing characteristics in the concentration range of 32–800 ppm of CO in the air [73]. Ag–ZnO/MoS2 ternary nanocomposite CO sensors were fabricated by layer-by-layer self-assembly route and compared with pure ZnO, ZnO/MoS2, and Pt-ZnO/MoS2. Ag–ZnO/MoS2 nanocomposite film showed the highest response among four tested sensors towards CO gas at RT which fact was attributed to the catalytic activity of Ag and synergistic effect of ZnO and MoS2. This nanocomposite sensor had shown an excellent response time, swift response/recovery characteristics, good selectivity, and repeatability [74].

TiO2-reduced graphene oxide (rGO) nanocomposites synthesized in situ via hydrothermal route using graphene oxide (GO), TiCl3, and NH3 solution were also used for CO sensing. The TiO2-rGO nanocomposites showed a linear response for sensing CO gas in the range 100 and 200 ppm [75]. Other authors investigated the sensing properties of copper oxide (CuO)/graphene hierarchical hybrid nanocomposite towards CO gas. The sub-ppm-level CO gas sensor was fabricated by layer-by-layer self-assembly route. The sensor exhibited a high response, good reversibility, fast recovery times, and repeatability for carbon monoxide gas sensing. At RT, CuO/graphene nanocomposite exhibited not only excellent detection abilities but also good stability and selectivity over a wide range (from 0.25 to 1000 ppm) concentration of CO [76]. It seems that the performance of hybrid graphene–nano-oxide nanocomposites indicates the best performance with higher responses to CO at low concentrations and low temperatures.

3.1.3 Oxygen gas sensors

As life-sustaining gas, oxygen sensors are used in numerous fields, for instance, hospitals, in industrial measurements, manufacturing installations, foundries, monitoring, and control of large-sized combustion furnaces. Recent improvements in the development of O2 sensors increased mainly for automotive industries and hospitals. Three existing variants of O2 sensors: say, semiconductor oxides (TiO2 sensors), concentration cell (Zr-based sensors), and electrochemical pumping O2 sensors (based on limiting current), are presently available to control the engines air–fuel ratio. For the purpose of controlling and sensing O2, semiconductor oxide sensors (TiO2 sensors) and solid-state sensors (Zr-sensors) are chosen due to a smaller size, less expensive, outstanding reliability, and high stability.

Oxide materials such as TiO2, CeO2, and Nb2O5 semiconductors have been used as O2 sensors based on the difference in resistance caused by reduction or oxidation of the semiconductor depending on the oxygen partial pressure in the circumvent ambient atmosphere [77]. TiO2 sensor indicated a delay as opposed to that of a ZrO2 sensor for its limited durability and poor accuracy. However, when compared to ZrO2 sensors, TiO2 sensor showed superior tolerance towards oxygen. For that reason, the growth of TiO2-based sensors improved and a few industrial units had adopted these [78]. Sputtered Nb2O5 thin films deposited on an Al2O3 substrate, expended some advantages like swift signal reception and very precise operation close to RT or low temperatures, whereas thin-film Nb2O5 sensor’s response time at ambient conditions in comparison with a ceramic TiO2 sensor (unheated) and a conventional ZrO2 sensor (unheated) was inferior [79]. Few more appropriate metal oxides such as CoO [80], Co1−x, MgxO [81], and SrMgxTi1−xO3 [82] semiconductors were used in monitoring oxygen.

3.1.4 Ozone gas sensors

Ozone (O3) is an oxidizing agent having significant countless real-world usages. Primarily, O3 measurements are required for medical applications, pharmaceutical, biotechnological and chemical processes, food product handling and packing, in research laboratories, water decontamination, etc. However, as a powerful oxidizing reagent, ozone appearance in the ambient atmosphere is very dangerous to the health of humans. It could cause eye irritations, headaches, respiratory problems, and even damage to the lungs. The continuous exposure to 0.1 ppm O3 for 2 h caused a decrease in spirometry (a loss of 20% in breathing capacity) lung function [83]. It follows that the extensive use of O3 creates a strong demand for a simple but highly sensitive method for monitoring the ozone concentration in the atmosphere under many conditions.

A number of approaches for monitoring O3 concentrations that include electrochemical [84], optical [85], resistance method [86], but also other technologies like impedance spectroscopy [87] and photoreduction under UV light [88] were proposed. When introducing ozone to n-type oxide, it fills the vacancies and reduces the MOx which decreases its conductivity. To synthesize cheaper than noble metal-doped sensors, people are trying to explore composite-based semiconductors gas sensors that benefit the sensitivity and response time at room temperature. For the detection of ozone in the air, TiO2–SnO2 sensing materials in different ratios were examined. Working at RT, the 1:4 mixture of TiO2–SnO2 had shown the highest sensor response units of 327. When adding noble metals such as Au (0.5 wt%) to TiO2–SnO2 (1:4) to detect O3 by photoreduction method and to enhance the signal, the ozone response was boosted to 6.6 × 106 (nearly 104 ×), whereas the response signal and recovery times were lessened by 35 and 5 s, respectively [89]. The same research group has studied the carbon nanotubes (SWCNT) incorporation with In2O3 materials for rapid trace detection of ozone with concentration from 25 ppb to 2.5 ppm at RT. The highest sensor response of 13.21 for 1500 ppb O3 was obtained for 2.0 wt% SWCNT-In2O3. The produced SWCNT-In2O3 exhibited reproducibility, stability, excellent reversibility, and selectivity for O3 at RT, which made it one of the best sensing material with promising application in the field of ozone detection [90]. Composite materials containing different weight ratios of TiO2–WO3 and Au-doped TiO2–WO3 was used for the detection of O3 gas while employing a light source of blue LED (460 nm). The 3:1 TiO2–WO3 weight ratio exhibited the highest sensor response that was promoted to 23.8 towards 2.5 ppm O3. Adding Au (0.1 wt%) to 3:1 ratio of TiO2–WO3 elevated the response of the sensor to 64. The sensing properties of O3 were attributed to the mechanism of photoreduction, adsorption and desorption, and surface reactions of O3 [91].

ZnO nanorods grown by CVD method was also subjected to O3 sensing. Among several ZnO nanomaterials, the former displayed interesting and promising results with a fast response time of 1300 and short recovery times of Tr = 60 s and Trec = 5 s, respectively, measured for a concentration of O3 varying from 1 to 2.5 ppm [92]. Photostimulated nano-In2O3-based compact and energy-saving ozone sensors were capable of detecting O3 with a wide dynamical range over four orders of magnitude at RT. By examining the rate of change of resistance, it was found out that the responses to fixed O3 gas concentrations for 5 min, 1 min, and 30 s were uniform and linear in proportion to O3 gas concentration. This linearity continued in a concentration range from 10 ppb to 200 ppm. The cross-sensitivity to CO, CO2, and NO2 of the photostimulated O3 sensor was very low. In addition, the sensing signal was highly reproducible without indicating hysteresis effects during repeated measurements [93].

3.1.5 Methane gas sensors

One of the important natural gas components is methane (CH4), readily found in the environment. Because of its lower explosion limit of 5.0%, methane is used in diverse day-to-day applications [94]. Metal oxides are proved to be potential functional nanomaterials with application in cheap chemical gas sensors. Sensing methane with highly ordered mesoporous In2O3 that replicates the structure of cubic KIT-6 SiO2 and hexagonal mesoporous SBA-15 SiO2 was investigated. Not only the pore sizes and thicknesses of pore walls in the mesoporous materials but also the nanoscopic properties of the sensors correlated to the methane sensitivity. The highest sensitivity to CH4 gas was shown to be in concentrations pertinent for prevention of an explosion. As the high thermal stability is vital for a gas sensor, In2O3 materials turned out to be highly stable methane sensing materials between temperatures of 450 °C and 650 °C [95].

Modifications with Pt or Pd are applied widely for methane monitoring as they exhibit catalytic activity lowering the activation energy for the reaction with gas. For example, in contrast to pristine SnO2, Pd doped SnO2 with 1.5 mol% Pd showed a higher response (75 and 95%) towards LPG at an operating temperature of 50 and 100 °C, respectively. The authors attributed this effect to Pd-enhanced formation of nanospheres at a calcination temperature of 500 °C, a decrease in crystalline size down to 11 nm and the catalytic effect of Pd [96]. Researchers also synthesized a hybrid composite of nanocrystalline zinc oxide (ZnO) and reduced graphene oxide (rGO) by a facile hydrothermal process for sensing methane gas. At an optimal operating temperature of 190 °C, the ZnO–rGO film sensor coated on a ceramic tube with Ni–Cr heater indicated detection of methane from 100 to 4000 ppm together with excellent repeatability, fast response-recovery time and good selectivity [97].

3.1.6 Nitric oxide gas sensors

Nitrogen monoxide (NO) is highly reactive gas that participates in many complex chemical and biochemical reactions. It is a vital messenger molecule, which has been the molecule of interest during the past decades. NO is both beneficial and detrimental. Due to its high reactivity, it is an enormously significant intermediate of the in-process chemical industry and an essential signal molecule, triggering grave toxicity in the mammals’ body.

In nitrous oxide sensing, WO3 is the most widely used oxide material because of its largest response. For improving the performance of WO3-based sensors, various nanocomposites with promising performance have been constructed. For instance, 4:1 (by weight) optimized In2O3–WO3 nanomaterials prepared by sol–gel and calcination methods were used to monitor NO gas at RT (300 K) on gas sensor chips prepared by the screen-printing method. The thin film of nano-In2O3–WO3 composite coated two comb-like inter-digitated gold electrodes with thoroughly platinized edges. We found that this NO gas sensor showed response and recovery times less than 30 and 40 s, respectively, together with very good linearity even in 100–1000 ppb concentration range. The nanocomposite In2O3–WO3 sensor was able to detect ppb to sub-ppb ultratrace levels of NO at RT. It showed sensor response equal to S = 9205, good reversibility (less than 3 s) without shift when purged with nitrogen gas, and extremely high selectivity for a known concentration of 500 ppb NO [98]. In another study, different In2O3–WO3 nanocomposites were synthesized and optimized to a 4:1 ratio which was much better than other compositions towards sensing NO. The metal oxide (4:1) composite and 0.25% Pt-doped In2O3–WO3 (4:1) coated over screen printed gold electrodes acted as RT sensors. Our results showed that the sensor response (S = RNO R −1N2 ) at RT towards 1000 ppm of NO was 23.9 while the response and recovery time were 12.5 and 15.3 min, respectively. Advancing this with an extra 0.25% Pt loading, the response of the sensor was boosted; for 0.1 ppm and 25 ppb, it was 330 and 15.2, respectively. The NO sensor optimal linear range was in the concentration range of 25–100 ppb [99]. It follows that the noble metal doping together with optimizing new nanostructured composite ratio and device design offers new possibilities and address the challenge of significant improvement in sensor performance. The capability of accurate NO sensing in the ppb range provides certainty within the save limit for the human.

3.1.7 Nitrogen dioxide gas sensors

Rapid industrialization, urbanization irregular growth of population, uncontrolled anthropogenic activity, escaping toxic volatile chemicals and gases, from vehicular fuel combustion, excessive use of insecticides, and pesticides in the agricultural sector caused the rise in gaseous pollution levels. This is becoming an alarming threat to the ecological systems present in the biosphere. Nitrogen dioxide (NO2), a reddish-brown pungent oxidizing gas, enters the atmosphere either through natural sources or anthropogenic activities. The second one contributes substantially to reasonably high loads of NO2 gas into our atmosphere. The increasing consumption of fossil fuels in automobiles and industries sends into the atmosphere a large number of NOx. NO2 is considered as a secondary pollutant generated from primary NO source that is produced as a result of internal combustion engines.

Various metal oxide nanoparticles such as SnO2, WO3, TiO2, ZnO, etc., have been subject to NO2 gas sensing. For example, SnO2 nanoparticles synthesized from ethyl hexanoate precursor were directly used as a thick-film NO2 gas sensing. They were extremely crystalline with a low degree of aggregation and 17 nm crystallite size. The drop coating deposited particles indicated a fast and stable response at NO2 concentration below 200 ppb. The flame-pyrolysed SnO2 nanoparticles exhibited high sensitivity and rapid response to both propanal (reducing) and NO2 (oxidizing) gases [100]. Using sol–gel spin coating process, Indium (In)-doped SnO2 thin films with a particle size of about 3 nm and different doping concentrations were deposited on float glass substrates. The selectivity and response of NO2 gas sensor at low operating temperature were improved with In-doping that triggered also a decrease in agglomeration which process could cause lower stability and an increase in response time of the small-sized particles. 10 wt% In-doped SnO2 films demonstrated an extremely high sensor response (~ 7200%) towards 500 ppm of NO2 gas at 150 °C [101].

When evaporating W filament under a low pressure of O2 gas, monoclinic WO3 nanoparticles were obtained. Their size proportionally increased with oxygen pressure and annealing temperature. Comparatively, the decrease in the size of WO3 particles caused an increase in NO2 sensitivity. 36 nm sized WO3 particles displayed the highest sensitivity, 4700 to 1 ppm NO2 gas, at a temperature moderately above RT-50 °C [102]. In another study, reactive gas deposited WO3 porous nanocrystalline films, both pure and activated (doped) were subjected to NO2 gas sensing. Activation was done by co-evaporation of Au or Al with WO3, nanoparticles. With the increase in sintering temperature from 100 to 600 °C, the tetragonal phase changed to monoclinic. As regards to activation, doping with Al was found to be more effective at RT whereas Au was suitable for higher temperatures. The selectivity of the sensors for NO2 was around ppm level with optimum sensing temperature of around 252 °C [103].

Recent studies revealing the gas sensing properties to NO2 of ZnO nanoparticles identify them as promising sensing materials. For example, ZnO nanoparticles with sizes ranging from 5 up to 270 nm were obtained by annealing at four temperatures (200–800 °C, with an increase of 200 °C) a zinc carbonate hydroxide (CH4O5Zn) precursor. The ZnO annealed at 400 °C exhibited the highest selectivity to NO2, good optical properties, quick response time towards NO2 sensing (≤ 30 s) and good recovery (≤ 120 s) [104]. Hydrothermally synthesized ZnO NPs from Zn(OH)2 also showed a good response at RT for NO2 gas of concentration of 5 ppm. In contrast to other tested gases such as CO and ethanol, the response towards NO2 did not increase with the increase in temperature [105]. In another study, neck-based ZnO semiconductor NPs were used for sensing NO2 gas. The necked-ZnO NP sensors response was 100 when subjected to 0.22 ppm of the oxide at a temperature of 200 °C and increased to about 400 when the concentration of NO2 increased to 5 ppm. T90 and Tr90 times for NO2 gas sensor were found to be 13 and 10 s, respectively. Stable response features of the sensor were displayed under repeated studies with NO2 gas with a concentration of 0.4 ppm [106]. Sol–gel-synthesized ZnO films exhibited very high selectivity, sensitivity, and rapid response towards NO2 gas at an operating temperature of 200 °C, but the response towards concentration from 10 to 100 ppm of NO2 varied. The high operating temperature led to high adsorption density of O- and O2 and, therefore, fast gas response (maximum of 75% at 200 °C) and recovery times [107].

Pristine TiO2 anatase nanoparticles and N-doped TiO2 anatase nanoparticles were used to tap and compare the potential of N-doped nanoparticles for sensing and removal of NO2 molecules. The possible orientations of NO2 molecules towards N-doped TiO2 and Van der Waals (VdW) interactions were taken into account to reveal the most geometrically stable NO2–TiO2 complexes. The structural and electronic analysis found out that N-doped particles provided a more stable configuration of the analysed complexes and consequently formed efficient absorption complexes suggesting greater sensitivity [108].

3.1.8 Ammonia gas sensors

With a distinctive pungent odour, ammonia (NH3) is a colourless gas which represents the simplest pnictogen hydride. Very common in nitrogenous waste, mostly among aquatic organisms, it contributes meaningfully for the nourishing demands of surface-dwelling living beings as a precursor to food and chemical fertilizers. For that reason, different MONPs such as ZnO, SnO2, and In2O3 have been examined as NH3 gas sensors. Among them, SnO2 immerged as promising ammonia sensors. For example, cluster matrix of SnO2 NP consisting of thousands of extremely small-sized (~ 3.0 nm) SnO2 NPs and randomly distributed wormhole-like pores interconnecting the oxide NPs was used for sensing ammonia. As previously mentioned, incorporating of noble metal catalyst could improve the sensing properties. Hence, Pt-activated SnO2 NP clusters incorporating the element in two forms—metallic (Pt) and metal oxide (PtO2), were synthesized. Unlike the as-synthesized pure SnO2 nanoparticles by a solvothermal method, Pt-activated clusters demonstrated enhanced gas response from 6.5 to 203.5 towards 500 ppm of NH3. The authors concluded that Pt-doped SnO2 possessed good response–recovery times, selectivity, linear dependency rates, repeatability, extremely high sensitivity, and long-term stability, ascertaining the prospective application of the examined clusters for NH3 sensing [109]. In another study, molybdenum disulphide (MoS2)/tricobalt tetraoxide (Co3O4) nanocomposite film-based sensor was fabricated towards NH3 detection. The MoS2/Co3O4 film sensor enhanced the ammonia sensing properties at RT in ultralow concentrations as opposed to MoS2 and Co3O4 counterparts because of its layered structure, n–p heterojunction formed and synergistic effect of the compounds [110]. The same authors were even able to synthesize a film sensor by hydrothermal and layer-by-layer self-assembly method recognizing and predicting both components in a mixture of two gases—ammonia and formaldehyde. A neural network-based model was used for investigating the sensing properties of MOx/graphene composite towards the mixture of gases such as dynamic response, sensitivity, stability, and recovery time at RT [111].

3.1.9 Hydrogen sulphide gas sensors

Hydrogen sulphide (H2S) is toxic flammable, colourless, explosive, naturally occurring in petroleum rigs, natural and volcanic eruptions, and hot-bath springs. If heated under pressure, it will explode. In contact with the organism, the gas causes inflammation and irritation to eyes and respiratory system. Any process that breaks down organic material without oxygen, produces heavy water or processes food and petroleum, has the potential to create high levels of H2S. Here we have considered the basic limitations of sensor types for quantifying H2S in terms of major operational criteria (e.g. the limit of detection, response time, the common operating range of concentrations, and stability).

Accurate measurement of H2S in real time at low micromolar or nanomolar concentrations has been a long-term challenge. In 2005, researchers from the University of Alabama at Birmingham have developed a novel polarographic H2S sensor that detects rapid changes in the concentration of H2S in biological solutions having a detection limit of 10 nm. [112]. H2S sensor is a metal oxide semiconductor that changes the resistance that is normally produced by desorption and adsorption of H2S in a film. This thin film can be a gold thin film or tin oxide film that is sensitive to hydrogen sulphide. The current response time of H2S sensor ranged from 25 ppb to 10 ppm, which was less than 1 min. Commonly, an ultrahigh sensitive hydrogen sulphide sensor is used currently which employs micromachined nanocrystalline SnO2–Ag. SnO2–Ag nanocomposite was fabricated by a polymeric sol–gel process so that the sensor exhibited outstanding sensing features upon exposure to H2S of just 1 ppm at temperatures of 70 °C (158 °F) while being very less sensitive to gases like C6H14, SO2, HCl, etc. The better sensitivity, as opposed to pristine SnO2, was attributed to the dissemination of AgO at the grain boundaries of SnO2 nanocrystals and the achieved p–n junction. The environmental influence on sensors sensitivity and selectivity indicated a small risk of false alarm [113]. Not only noble dopants but also transitional metals have been also used as an activator for SnO2 NPs subjected to H2S sensing. Vaishampayan et al. (2008) compared H2S sensing performance of 40 nm sized pristine SnO2 and 18 nm sized Fe-doped (1 at%) SnO2 synthesized by a simple modified pechini citrate route. In contrast to the negligible response towards H2S of SnO2, Fe-doped SnO2 was capable to detect even 10 ppm of H2S at RT. Since the high surface-to-volume ratio of NPs, the doped sensor exhibited fast response within 5–15 s with a change of about one order of magnitude in the resistance [114].

The sensitivity of semiconducting SnO2-based gas sensors has been investigated by engineering of the base material and with the incorporation of CuO as an additive. By optimizing the grain size and the amount of CuO loading the sensor elements were sensitive to concentrations of H2S ~ 10 ppm in the air while the operating temperature was reduced down to about 90–100 °C which lowered the energy consumption [115]. It was found that hydrothermally synthesized n-type SnO2 nanorods coated with p-type CuO NPs were particularly sensitive at lower temperatures (60 °C), with the highest sensitivity (9.4 × 106) to 10 ppm H2S [116]. The sensing towards H2S via semiconducting CuO nanoparticles included conversion to metallic CuS, following the reaction:

For n-SnO2/p-CuO heterojunction H2S gas sensor, the exposure to hydrogen sulphide gas led to a chemical transformation of p-CuO into highly conducting Cu2S declining noticeably the barrier height and changing immediately the resistance [117]. The suitability of the proposed modification was further confirmed by the highly selective and sensitive (~ 106 to a few ppm levels) responses of CuO-doped thin film of SnO2 obtained by a thermal evaporation method to H2S in the air. The long-term stability for a period of over 3 years time in response to H2S gas was further assessed at four different operating temperatures [118].

The effectiveness of doping different MONPs with noble metals for enhanced H2S sensing performance was confirmed by other studies. WO3 doped with platinum (Pt), gold (Au) or Au–Pt noble metals were used for H2S sensing. At operating temperature of 220 °C and 1 ppm H2S gas concentration, individual sensitivities of 23 and 5.5 were measured for Pt- and Au–Pt-doped WO3 gas sensors, respectively. Pt- , Au- , and Au–Pt-doped WO3 thin films indicated sensor response times of 30, 8, and 2 s, respectively, whereas the recovery times were about 30, 160, and 30 s, respectively [119]. Doping 0.5 wt% Pd with 5 wt% Al2O3 and mixing with anatase TiO2, outstanding sensitivity was observed for low concentrations of H2S. H2S sensor using TiO2/Al2O3/Pd as sensing materials demonstrated high sensitivity and undesirable cross-sensitivity effects when checked for NO2, LPG, CO, CO2 and H2 gases detection [120].

Performance of α-Fe2O3 NPs produced by post-thermal annealing of a facile Fe3O4 precursor as H2S gas sensing material was examined at different operation temperatures (100–400 °C). At 300 °C, the sensor exhibited the highest sensitivity, reproducibility, and good stability while the limit of detection was measured to be 0.05 ppm with response and recovery time of 30 s and 5 s, respectively [121]. Together with pure iron oxides, various transitional metal ferrites such as CuFe2O4, CoFe2O4, ZnFe2O4, and NiFe2O4 prepared by the citrate process have potential application as gas sensing materials not only for H2S but also for CO, CH4, Cl2, LPG, etc. [122]. Sol–gel auto-combustion technique was used to prepare spinal ferrite CuFe2O4 NPs that were equally sensitive to both H2S and H2, but at low temperatures, they were highly sensitive to H2S detecting concentrations of 25 ppm at 80 °C. In contrast to annealed at 500 and 750 °C nanoparticles with an average size of 36 nm, the 25 nm sized as-prepared NPs were the most suitable for H2S sensing [123].

Recently, except semiconducting (pure, doped, or decorated) MONPs, for monitoring gases in the environment nanocomposites of metal oxides nanoparticles and carbon nanotubes have been tested. For sensing of H2S gas species Co3O4 NPs and Co3O4 single-walled carbon nanotube (SWCNT), nanocomposite structures were explored. Different wt% of Co nanoparticles were introduced into graphite tube to synthesize Co-SWCNTs that were further oxidized at different temperatures. The Co3O4-SWCNT composite structure produced by a co-arc-discharge method displayed improved performance in H2S sensing than the pure Co3O4 nanoparticle structure due to the high defect density in the Co3O4 nanoparticles [124]. The large surface-to-volume ratio, small size, flexibility, and mechanical stability make these MOx-carbon nanotube 3D heterostructures very attractive in ultrahigh sensitive sensors application. However, finding suitable and stable nano-metal dopant with reasonable high integration density and binding energy without affecting the transport and electronic properties of both materials is a challenging task.

3.1.10 Hydrogen gas sensors

The requirement of resources for clean energy towards fuel cells and IC engines can be drawn from hydrogen (H2). Hydrogen energy shall form the infrastructure that will power future societies since it is a clean, cost-effective, and renewable source of energy. Nevertheless, hydrogen, being flammable gas, it has a lower explosion limit of 4% in air meaning that even a small spark can ignite the mixture. Therefore, hydrogen generation, transport and storage can be dangerous if not handled with caution, requiring high precision sensitive gas sensors which are able to detect the smallest leaks fastly. Semiconductor metal oxide gas sensors are an important candidate for the task of a sensor forming an acoustic early warning system, notifying the authorities or provide the signal to a process control system. To accomplish this, an accurate and stable in situ real-time measurement gas sensor is required. Nevertheless, using hydrogen as a fuel source needs innovative ways to store and monitor hydrogen. Reliable, precise hydrogen sensors that are compact and cheap are called for both quantifying the hydrogen concentration in continuously mobile gas streams and also for checking hydrogen gas leaks in ambient air. It is very crucial for the alarm sensors to detect hydrogen below the explosion limits.

A review by Gu et al. [125] gave a complete overview of the hydrogen sensing properties of metal oxides nanostructures, including thin films and 1D nanostructures. The majority of MOx-based gas sensors suffer (a) low sensitivity and (b) lack of selectivity. To solve these, numerous strategies have been applied, such as the sensor’s dynamic response analysis and mixed oxides sensors for gas detection [126]. The addition of noble metals like gold (Au), platinum (Pt) or palladium (Pd), to a semiconducting oxide, which is an effective means to boost detection of specific gases using metal catalysts shall increase the rate of interaction differently for distinct gases [127]. Platinum (Pt) is one of the most effective catalysts for sensing reducing gases, including hydrogen, carbon monoxide, and hydrocarbon, by chemical sensitization or spillover effect [128]. Together with it, several MOx materials like, WO3 [129], ZnO [130], TiO2 [131], MoO3 [132], and Nb2O5 [133] have been used. The newly designed and produced prototype sensor using ZnO–SnO2 composite material was investigated for its gas sensing behaviour at dissimilar concentrations of hydrogen gas at various temperatures. The sensor cross-sensitivities from interfering gases like CH4 and CO were also studied. It displayed very high selectivity, exceptional response times, and very good reproducibility towards hydrogen at 150 °C [134]. A ternary hybrid of palladium-tin oxide-molybdenum disulphide (Pd–SnO2/MoS2) was fabricated towards H2 gas sensing. It indicated excellent sensing properties towards hydrogen at RT in the range 30–5000 ppm explained by the modulation of the potential barrier for electron transfer as well as the synergistic effect of hybrid nanostructure [135]. It could be concluded that in the mixed metal oxides, the combination of two-phase properties and oxygen vacancies contributes to chemical activation not only to H2 but also towards NO, CO2, CH4, H2S, etc.

Out of the studies reviewed, it follows that the elaboration of composite solid-state gas sensors should take into account not only the oxide nanocomposite ratio but also the chemical nature, distribution, size and specific concentration of the additives (modifiers) as well as nano-oxide–matrix pair because semiconductor oxides could change the configuration of d-electrons at the surface when transitional element have been used [136]. However, the optimum concentration on the additive and second component content in the nanocomposite may change depending on the operating temperature and/or humidity. It is, therefore, important to consider the thermodynamic stability of the system in different atmospheres triggering adverse temporal effects. Additionally, in many cases, the improvement in sensing parameters is closely related not only to the composition and operating temperature but also to the nano-oxides morphology and, therefore, optimized technological parameters when developing sensors. It follows that reproducible fabrication processes with precise control over the morphology and composition of the nano-oxides are strongly recommended.

3.2 Batteries

Rechargeable batteries gained noteworthy attention in the past years due to severe environmental concerns. Lithium-ion batteries (LIBs) play a major role in our life by excessively using in the field of portable electric devices, electric vehicles, and hybrid vehicles due to their very high energy density and long life cycles. To enhance the performance of LIBs, researchers gave excessive prominence to develop novel electrode materials with nano-MOx that have been used traditionally for several decades by researchers. Countless TMOs were expansively considered in LIBs as electrode materials. In terms of the reaction mechanisms, TMOs operate on two main principles (a) intercalation/deintercalation and (b) conversion reaction. In batteries, nano-TMOs are appealing anode materials because of their higher theoretical capacities than commercial graphite (372 mA h g−1) [137]. TMOs are able to conduct conversion reactions and even complete phase transformations during charge–discharge cycles. Usually, the size of nanoparticles of conversion materials has a decisive influence on electrochemical properties, since smaller-sized oxides increase the capacity and rate of capability and reversibility. However, some nano-oxide anodes have poor cycling performance or electrical conductivity that could be enhanced by mixing them with electrolytes [138], combining them to form composites [139] or adding a thin layer of conducting polymer [140]. Presently, hierarchically nanostructured TMOs have turned out to be a thrust area of research in the field of LIBs, in which hierarchical architecture provides several available electroactive sites for redox reactions, accommodates the strains due to severe changes in volume throughout cycling, and shortens Li-ion’s diffusion pathway during the process [141]. For instance, because of excellent redox properties and high theoretical capacity, cobalt oxides have drawn tremendous attention as electrode materials in batteries. When used as anode materials in LIBs, superior cycling reversibility and high discharge capacity were demonstrated by Co3O4 nanotubes synthesized on porous-alumina template technique [142].

TMOs are one of the first developed, oldest and quite significant materials for electrodes in SIBs. Many researchers focus their attention towards them for nearly three decades, particularly in the last 5–10-year period [143]. Rechargeable batteries have attracted major attention in recent years because of aggravating environment problems. LIBs play a vital role in our daily life and exclusively used from portable electronic devices to hybrid electric vehicles. Uneven distribution, limitation of lithium resources and their high-cost storage, however, gradually aroused people’s anxiety on LIB sustainability. SIBs have been thought to be next-generation large-scale rechargeable batteries due to the earth abundance, relatively high safety and cost-effectiveness of sodium resources. The vital factor for commercializing the promising SIB rechargeables consists in the development of advanced and cost-effective anode materials. Because of the stable redox potential, high energy density and safety, metal oxides were found to be promising electrode materials for SIB [144].

However, some MOx suffers from large volumetric expansion during electrochemical cycling of SIBs, low conductivity and cycling stability, and unsatisfactory capacity rate. Incorporation of graphene to MOs with the tailored nanostructure, crystal phase, and composition has demonstrated long cycling life, high energy density, and other promising performances as electrodes in SIBs [143]. In a composite, the MOx provides high capacity and activity whereas graphene delivers easy processing and chemical functionality via electron conductive network suppressing agglomeration of the oxide and increasing the available surface for the electrochemical processes. Many MOx/G composites offer unanticipated capacity synergy that helps to escalate storage capacity. For applications in LIBs, nanosized MOx along with graphene are debated more beneficial integrated structure for shortening lithium diffusion pathways and plummeting polarization within the electrode, leading to boosted performance [145].

Recently, researchers focus on the synthesis of multiple (four or five) transitional cationic oxides in equiatomic amounts stabilized in single rock-salt structure or the so-called high entropy oxides (HEOs). They seem to be very promising materials in reversible electrochemical energy storage. In HEOs, only cation sublattice is altered while the oxygen sublattice stays unchanged (Fig. 3). In contrast to the first neighbours, the second near neighbouring atoms in the crystal lattice is different and unusual cation coordination values are present. The random distribution of cations in the solid solution gives stability towards phase separation. The probability of finding a cation on a given lattice site is equal to the atom fraction of the element [146]. Uncertainty in atoms positions could result in an unpredictable and nonlinear synergetic response that comes from an unusual combination of elements and microstructures. This will influence the distribution of lattice site energies, lattice distortions, sluggish diffusion, and the number of equivalent microstates [147]. The random distribution of cation species in their sublattice substantially increases the configurational entropy by composition. HEOs of (Cu, Co, Mg, Ni, Zn) O system are found to have very high dielectric constant [148], whereas the conductivity of Li-doped (Cu, Co, Mg, Ni, Zn) O is found to be orders of magnitude higher than that of the conventional solid electrolyte (LiPON) [149]. Using spray pyrolysis techniques (flame and nebulized spray pyrolysis) and wet chemical technique single phase (Co, Mg, Ni, Zn) O and (Co, Cu, Mg, Ni, Zn) O were directly synthesized in a nanocrystalline form [150]. The reversibility of the phase transformations between a polyphase mixture and homogeneous solid solution of different binary oxides that is proof for the effect of entropy on phase stabilization was confirmed by structural analysis. (Co0.2Cu0.2Mg0.2Ni0.2Zn0.2)O was tested in secondary Li-based cells for complete or partial reduction in metal ions upon lithiation [151]. The cell reached a good capacity of 600 mA h g−1 subsequently increased to 650 mA h g−1 after 70 cycles. The exclusion of one of the elements from the five cation system and turning it to four cation system (Cu0.25Mg0.25Ni0.25Zn0.25)O (medium entropy oxide) significantly decreased the configuration entropy from 1.61 R to 1.39 R which increased the need for post-annealing to obtain single-phase oxide. Co acted as a critically necessary element for HEOs to have a high specific capacity and good cycling stability, whereas Zn or Cu did not substantially influence the reversibility. Removing of Zn changed the oxidation behaviour of the compound from one- to two-step (of NiO and CoO) oxidation process. Therefore, the changes were different for each removed element while the addition of other cations could modulate the electrode performance. Additionally, even in the lithiated condition, the rock-salt was maintained and served as a host structure for the conversion reaction. During lithiation, some cations were reduced and the remaining unreduced cations facilitated the reoccupation of the previously reduced cations to the original sites of the lattice during oxidation. Therefore, during lithiation, the rock-salt structure was preserved and only highly disordered defect-rich regions were present. Upon electrochemical cycling, metal ions were incorporated into the rock-salt structure [151]. This new concept for entropy-stabilized oxides has the potential to gain completely different properties only by combining a number of possible metals. HEOs substantially differ from classic electrode materials and turn to be very promising materials for reversible electrochemical energy storage.

3.3 Solar cells

The main functions of a solar cell include photogeneration of charge carriers in a material that absorbs light and separation of these carriers to conductive materials that transmit the electricity. Most of the carriers are generated near the surface. When a light quantum falls upon a semiconductor, electron–hole pairs are generated which strongly enhances the conductivity. If their recombination is prevented, they could reach the p–n junction where the electric field separates the charges.

Metal oxide semiconductors are environmentally friendly, low cost, and highly stable materials. Over the past decade, they have been applied in photovoltaics (PV) as photoelectrodes in dye solar cells (DSCs) and also used to develop metal oxide p–n junctions [152]. The extraordinary flexible properties and feasibility by modest, low cost and easily scalable methods make metals oxides an exceptional material in new-generation photovoltaics. They have a very large bandgap energy range and are also highly tuneable, thanks to which possibly several metal oxides are more applicable as photo-harvesters. However, silicon (1st generation solar cell) and other III–V semiconductors have factually experienced much more devotion; not entirely but only elite metal oxides have been really studied as photon absorbers. These oxides applied in photovoltaics could be seen as light absorbers, transparent electrodes, transport layers, and special resources with exclusive properties and functionality.

3.3.1 Cu2O solar cells

Among all MOx compounds, the copper oxides (Cu–O) are the most prevalent materials to date. The complete bandgap range in between 1.4 and 2.2 eV [153] can be covered from CuOx by tuning stable binary oxide phases of copper oxides—Cu2O (cuprous oxide), CuO (tenorite or cupric oxide), and Cu4O3 (paramelaconite).

Cuprous oxide (Cu2O) is a p-type semiconductor attractive as photovoltaic material because of its low cost, high absorption coefficient, good mobility, great availability, and nontoxicity. Since 1920, Cu2O was used as an electronic material, peaked up in the early 1970s. As Schottky (heterojunction) solar cells Cu2O power conversion efficiency (PCE) was higher than ~ 8% and it was used as a photocathode in photoelectrochemical cells [154]. Schottky barrier solar cell can be fabricated as a back wall or front wall structures (Fig. 4). A back wall Schottky barrier solar cell that offers a great advantage with its mechanical stability and good sensitivity deposits layers on the top of a metal substrate usually by partial thermal oxidation, sputtering, or spray technology. A thin semiconductor layer is needed for light illumination because of its high absorption coefficient and low diffusion length of carriers. When a metal material (Ag, Au, Cu) or carbon (ohmic contacts) is deposited on the rare of the semiconductive layer front wall-type cell is completed [155]. All Schottky barrier solar cell indicated a major part of the potential drop at the metal/cuprous oxide interface (regardless the type of metal used) and only the electrons that could overcome this high-resistance barrier contribute to the external current of the cell. For that reason, the reported efficiency values were very low. However, by the use of heterojunction, multicomponent oxides based on TCO thin film, in particular, ITO/ZnO/Cu2O solar cell, displayed the best efficiency of above 2% [156] which is much lower than the theoretical maximum efficiency of Cu2O equal to about 19–20%.

Adapted from [155]

Schematic representation of Schottky barrier solar cell: face (rare) and profile of the back wall and front wall cell structures.

Homojunction Cu2O solar cells refer to the structures where the p–n junction is composed exclusively of Cu2O and well-thought-out as one of the methods to enhance the power conversion efficiency of Cu2O solar cells [157]. The electron affinity of Cu2O is low compared to many other semiconducting materials. Because of the lattice matching, the strains at the interface should be reduced. Homojunction Cu2O solar cell had an efficiency of 1.06% because of the high resistivity of p-/n-bilayers [158]. In addition, surface sulphidation of electrodeposited n-Cu2O and the p-Cu2O film was found to be useful for improvement in the film photoactivity [159]. It was found out that on the efficiency of homojunction Cu2O solar cell grain size and crystal orientation had a significant role because of changing the resistivity of the p-type Cu2O [160]. It follows that the methods of synthesis highly influence the performance of the homojunction Cu2O solar cells. Although prepared by simple methods (such as electrodeposition or spray pyrolysis) using cheap and available materials, Cu2O films still demonstrate low electrical power conversion efficiency.

3.3.2 Binary heterojunction solar cells

In the p–n junction (heterojunction) of two semiconducting materials where one of them displays a higher affinity to electrons whereas the other—to holes, local electric field increasing excitation and current is created. As doping of n-type Cu2O is persistently hindered, a relevant bilayer ZnO oxide either planar [161] or nanostructured [162] was used as oxide window for Cu2O absorbers. ZnO and Ga2O3 display tailored band edge offset applied to Cu2O. Among n-type windows, ZnO is characterized by low-temperature synthesis, inherently low-cost methodology, high electron mobility (~ 120 cm2 V−1s−1), and wide direct bandgap (~ 3.37 eV) [163]. Electrodeposited Cu2O layers still demonstrate a lower-power conversion efficiency of 1.43% compared to Cu2O/ZnO solar cells. ZnO (transparent window layer)/Cu2O solar cell indicated that the dominant current flow mechanism across the heterojunction is the diffusion of holes against the barrier established by the band bending to recombine with electrons trapped in interfacial states [164]. Compared with ZnO, Ga2O3/Cu2O delivered an enhanced performance of 3.97% and 5.38% depending on the deposition method (ALD and PLD, respectively) [165, 166].

The all-transparent solar cell can be attained by the heterojunction MOx material with a wide energy bandgap for power generation (with visible light transmittance and UV photon absorption). p-type NiO/n-type ZnO is transparent heterojunction materials that could be obtained by a solid-state sputtering method. A unit cell was responsible to give a record-high conversion efficiency of 6% with a very high current density (2.7 mA cm−2) and open-circuit voltage of 532 mV. This outstanding transparent solar power is duly credited to the complete UV absorption inducing the considerable excitonic effect for ZnO/NiO heterojunction [167]. All the emerging oxides are being thoroughly examined as light absorbers including cobalt (Co–O) and iron (Fe–O) oxides [168]. However, because of the heterojunction, there are always concerns about the existence of lattice mismatch between the layers with different crystal structures or other defects that could induce lower solar cell performance.

3.3.3 Thin-film solar cells

A thin-film (TF) solar cell (second-generation solar cell) is made by depositing photovoltaic material as several thin layers or monolayer on different substrates such as glass, plastic, or metal. Compared to conventional semiconductors, ferroelectric solar cells demonstrate several orders of magnitude higher photovoltaic voltage than the corresponding bandgap of the material and ability to regulate the photovoltaic characteristics by electric field [169] Dharmadhikari reported the first thin-film solar cell based on ferroelectrics in 1982 [170]. Barium titanate (BaTiO3 or BTO) is the most important ferroelectric material for a wide range of applications. Nonetheless, until recent times, the oxygen octahedra ferroelectric thin film from the PZT (Pb(Zr,Ti)O3) family was extensively studied. Many ferroelectric materials such as Pb(Zr1−xTix)O3 and LiNbO3 also exhibit photoelectric and photovoltaic effects under the illumination of visible and near ultraviolet light; but the magnitude of photocurrent and voltage obtained for the device application are far below the photo-electronics requirements.

BaTiO3 thin films have been extensively studied ferroelectric material over the years because of the wide range of applications. Using RF sputtering BaTiO3 layers/films condensed over (100) p-Si achieved a thickness of 0.3–0.5 μm. At temperatures above 500 °C, crystalline BaTiO3 films with a tetragonal structure were obtained. The polarization–electric field (P–E) hysteresis loops and a broad peak in the dielectric constant versus temperature curve at Curie point indicate that BaTiO3 films were ferroelectric. An anomalous photovoltaic effect was observed in these thin films which were related to the remnant polarization of the material. The results on open-circuit and short-circuit measurements provide an important basis for a better understanding of the role of the photovoltaic field, photovoltaic current, and the pyroelectric properties in photoferroelectric domain switching [170]. Although eco-friendly material, BaTiO3 suffers from low thermal stability and loses ferroelectricity at a temperature of about 130 °C because of phase transformation and strain relaxation. When pores were introduced that induced anisotropic strains or heterointerfaces into the nanocomposites of BaTiO3 and SrTiO3, the ferroelectric phase of BTO was stabilized [171]. In another study, to decrease the bandgap of BTO material, Nd-doped BaTiO3 thin films with single tetragonal perovskite phase were sol–gel deposited. When doping with 2 at% Nd, the average grain size slightly increased and after that up to 5 at% Nd the grain sizes decreased with increasing Nd content. The open-circuit photovoltage, power conversion efficiency, and short-circuit photocurrent density reached maximum values at 2 at% Nd because of a change in bandgap and residual polarization [172]. In addition to the history of over 40 years of research, there is still a need for a deeper understanding of the enhanced photo-response and requirement for developing new materials with improved conductivity, thermal stability, together with reduced bandgap and thickness.

3.3.4 Indium tin oxide

Indium tin oxide (ITO) is one of the most commonly used transparent conducting oxides owing to its two main properties: optical transparency and electrical conductivity. It has high conductivity, hardness, chemical inertness, high work functions (~ 4.8 eV) [173], and transmission of over 80% in the visible range of the solar spectrum. ITO films exhibit also anti-reflection properties and good spectral response in the blue visible region [174]. Like in most transparent conducting films a compromise was made between conductivity and transparency, since increasing both thickness and charge carriers concentration might surge conductivity, but optical transparency drops. For that reason, the thickness of the transparent electrode ITO films ranges from 150 up to 700 nm while below 150 nm the film resistivity increases [175]. Depending on the oxygen content ITO behaved as an alloy or a ceramic but its typical composition is oxygen-saturated containing 74% In, 18% O2, and 8% Sn by weight. The unsaturated compositions were labelled as oxygen-deficient ITO, which showed to be very transparent and colourless as a thin layer, while its bulk form turned yellowish to grey in colour. In the infrared (IR) region, it performs as a metallic mirror.

ITO is an n-type transparent conductive oxide where tin is a dopant in indium oxide lattice. Because of the complex structure of crystalline In2O3, it was thought that the factors that determine the high conductive mechanism and lead to a low resistivity were unclear [176]. Recently, it was found that ITO could both donate and accept electrons in dye-coated ITO films when photoinduced charge transfer occurred [177]. When ITO was modified with elements such as Mg, Ca, Yb, etc., the electrodes maintained their electrical characteristics but increased their ambient stability [178]. This optoelectronic material is broadly applied both in research and industry as a thin film in photovoltaics, gas sensors, polymer-based electronics, antennas, and for glass windows to conserve energy [179]. Conventionally used ITO electrodes have a drawback of low resistivity, high transmittance, and high process temperatures for crystallization [180]. Apart from the high cost and energy that vacuum deposition techniques consume, ITO production requires volatile indium incorporation. The film usually indicates brittle nature and low thermal expansion coefficient. As alternatives to ubiquitous ITO, metals, metal oxides, nanomaterial, and polymers are used. ITO/metal/ITO electrodes on plastic or glass substrates are promising candidates for new-generation solar cells that offered the same performance as ITO and more stable mechanical and electric properties while reducing the amount of ITO by four [181].

3.3.5 Amorphous indium–zinc oxide

To lessen indium composition, expurgate working difficulties, and increase electrical homogeneity, amorphous transparent conducting oxides have been developed. Indium zinc oxide (IZO) has some analogous properties to ITO [182]. It is a hole transporting TCO with high work function (5.2 eV) [183]. Warasawa et al. discovered that at a thickness greater than 40 nm, the electrical properties of RF sputtered IZO was independent on film thickness [184]. The crystallization of an amorphous indium zinc oxide is disturbed by the difference in the ratio of oxygen to metal atoms between In2O3 and ZnO. The amorphous structure remains unchanged even at 500 °C, thus containing vital processing phases usually seen in organic solar cells. The enhancement within homogeneity improves the usage capability in case of organic solar cells. Additional benefits of IZO are good etchability and higher crystallization temperature than amorphous ITO [185]. By using ALD technique, flexible IZO was fabricated on polyimide substrate by repeated cycles of In2O3 and ZnO deposition at three different temperatures—150, 175, and 200 °C. The thin film did not perform degradation, showing great potential to be used for flexible applications [186]. Moreover, together with ITO, doped ZnO films are potential candidates for plasmonic applications [187].

3.3.6 Dye-sensitive solar cells

It was revealed in the late 1960s that organic dyes upon illumination produce electricity at the oxide electrodes in electrochemical cells [188]. A dye-sensitized solar cell (DSSC or DSC, belonging to third-generation solar cell) contains a thick film of semiconductor nanoparticles, a monolayer of organic dye molecules adsorbed to the nanostructured layer, liquid electrolyte (redox shuttle I3−/I−), and counter electrode (Fig. 5). The photoexcited electron in the dye is injected into the conduction band of the semiconducting material (n-type DSSC such as TiO2) and by hopping between the particles, the electron diffuses to the anode. When hopping, the electron could recombine with the electrolyte. When photoexcitation is followed by a hole injection into the conductive band of the semiconductor, the solar cell is p-type (for example with NiO electrode material). The recombination limits the efficiency of the DSSC. Usually, p-type DSSCs had lower performance than n-type DSSCs because of lack of suitable wide bandgap semiconductor with good charge transport properties and sufficient transparency [189]. A later version of a dye solar cell was known as Grätzel cell.

Scheme of the structure and operating principle of a DSSC device. The electrode nano-oxide layer is covered by dye molecules that absorb solar energy. TCO facilitates charge transfer to the counter electrode layer usually made by Pt or C. Iodide electrolyte supplies electrons to dye molecules that have delivered electrons to nano-oxide particles when being excited