Abstract

In order to address risks associated with nanotechnology, there needs to be improved understanding of potential sources of engineered nanomaterials (ENMs) into the environment. Nano-enabled products (NEPs) are amongst such sources, and the current study identified NEPs sold in South Africa as a means of examining their potential to emit ENMs into the environment. Two hundred and sixty-four products were identified, mainly from the health and fitness category (66.7%), followed by electronics and computers (15.2%), home and garden (10.6%), appliances (3.8%), automotive (2.7%) and food and beverage category (1.1%). The chemical identity of ENMs was reported in 62.8% of those products with the top five most common being ENMs (in the descending order) Ti, C, Ag, Si and bisoctrizole. Determining the NEPs environmental exposure potential indicated that 63.6% exhibited high exposure potential comprising predominantly health and fitness, personal care, cosmetics and clothing products. The priority NEPs in terms of environmental exposure were sunscreens, hair relaxers, moisturising lotions, eye creams, cosmetic sera and socks. Assessed through analytical examination, NEPs were found to contain ENMs with length and width ranges of 15–350 and 8–185 nm, respectively. Our study suggests that most NEPs sold in South Africa pose a high potential for nanopollution, with water resources as the highest risk. Mandatory labelling of NEPs is recommended in order to better estimate the extent of nanopollution arising from usage of the NEPs.

Similar content being viewed by others

1 Introduction

The concerns raised regarding human and environmental safety aspects of nanotechnology [5, 19, 23] are being addressed at a slow pace relative to their development and commercialisation rate, and hence pose a threat to the sustainability of nanotechnology [3, 11, 30]. The lack of robust data on sources and environmental exposure characteristics of engineered nanomaterials (ENMs) [19, 31] coupled with the ENMs’ toxicity potential [18, 26, 27, 29] hamper risk assessment efforts that can inform decision-making to mitigate or manage their associated risks. Large data sets that currently exist are generated predominantly from studies with pristine ENMs and therefore do not compare well to those applied in products and processes, and thus are inadequate to support meaningful risk assessment tasks. There have been rising calls to examine various life cycle phases involved in nanotechnology applications to assist in addressing the persistent lag in nanotechnology risk assessment efforts.

Nano-enabled products (NEPs) constitute potential sources of ENMs release into the environment (nanopollution), and there have been initiatives to characterise such products as a means of examining potential implications for environmental health (http://www.nanotechproject.org/cpi; http://nanodb.dk; [12, 35, 40]). The project of emerging nanotechnologies (PEN), the oldest initiative initiated in 2005, has recorded 1827 NEPs that are available in certain countries in North and South America, Europe, Asia and Australia (http://www.nanotechproject.org/cpi). The data being generated by these initiatives are valuable in supporting efforts for risk assessment of NEPs. However, findings are not easily applicable between international regions because differences in socio-economic factors (e.g. GDP, population size, market diversity and dynamics) and other aspects that affect the rate of NEPs application, disposal patterns and waste management [8, 16, 37] can influence the extent of nanopollution arising from usage of NEPs. Furthermore, different NEPs exhibit different potentials to emit ENMs into the environment (exposure potential) based on their design, use and disposal. For instance, the incorporation and location state of ENMs in the product influence the ease and rate at which these are released from the product [10, 13, 14]. The exposure potential between human and environmental recipients also differs. Moreover, different ENMs have different physico-chemical and toxicological properties; therefore, such basic information needs to inform the classification and prioritisation of NEPs for environmental risk profiling. The current study is unique in that NEPs in local markets were not only identified and categorised according to their environmental exposure potential, but also examined using a suite of analytical techniques for hazard identification; currently no study has adopted such a detailed approach.

South Africa has taken initiatives to evaluate the risks associated with nanotechnology, although so far such efforts have been poorly coordinated and not harmonised for a common national objective. As a result, calls have been raised for the development of a coordinated national nanotechnology health, safety and environment (HSE) research strategy [23] that aims to: (1) identify principal sources of exposure and exposure routes, (2) investigate physico-chemical properties that affect the environmental transportation and behaviour of ENMs and (3) investigate various environmental factors that affect the environmental transformation of ENMs. The present study was undertaken as a response to local Nanotechnology HSE initiatives, viz. to identify sources of nanopollution and exposure routes in the environment. It provides the first scientific record of NEPs in South Africa and the African continent, hence widening the global profiling of nanotechnology environmental implications. The study undertook physico-chemical characterisation of the hazard (ENMs) in the identified NEPs and examined the NEPs’ environmental exposure potential. “Priority” NEPs cases were identified based on their high ENMs’ environmental exposure potential, and the priority NEPs should be the focus of risk estimation in the future; the current study did not extend to risk calculation. However, our research group has already started examining the environmental exposure release of ENMs during the life cycle of some priority NEPs identified inhere [25]; such a tiered approach will be useful to identify candidates for dose–response evaluation within the risk assessment pathway.

2 Materials and methods

2.1 Identification of NEPs

The inclusion of products in the present study was limited to products which contained ENMs in its formulation as shown by the labelling on the package or ingredients list. Locally sold NEPs were identified through online searches of manufacturers’ and store/retailer’s websites (limited to .za domain) as well as physical store visitations for identification on the shelves.

2.2 Evaluation of environmental exposure potential

Once a NEP was identified, the incorporated ENMs chemical type, location and claimed function/property (if provided), as well as product-use category, were recorded. Briefly, the ENMs location refers to the position of the ENMs in the NEPs or how it is incorporated; the different categories are provided in Table S1. The product-use categorisation (health and fitness, home and garden, electronics and computers, food and beverages, automotive and appliances) and the classification of the ENMs location of Hansen et al. [14] were used in the present study. Commonly, the function of the ENMs was not provided by the manufacturers, and therefore, further literature consultation was conducted to determine its potential function. A qualitative procedure to assess the NEPs environmental exposure potential was adopted and informed by the following parameters: the location of ENMs in the NEP, intended product use, estimated ENM concentration, usage patterns and the release factor.

The first step in this assessment involved using the location of ENMs in a given NEP to estimate the exposure potential (i.e. likelihood to release ENMs) to the environment, and the outcome can either be low, medium or high exposure potential (Table S1). To illustrate: for the “suspended in solid” category, products can be assigned either a high or low release potential. A solid nanocomposite such as those used in tennis/hockey rackets is assigned low exposure potential, whereas powdered products are assigned a high exposure potential. In addition to the assessment based on the ENMs location in NEPs, the NEPs with medium or high exposure potential were further evaluated by incorporating additional exposure assessment parameters, namely the estimated ENMs concentration in the NEP, NEP usage rate and release factor (RF). The RF refers to the fraction of ENMs that can be released in comparison with the amount of product used, which in turn is influenced by how the product is used. Various assumptions were made when assigning concentration and usage rate values. Firstly, the concentration of ENMs in a given NEP will be the same across countries as such products are largely manufactured by multi-national companies, and secondly the published data on the usage rate of a given NEP are globally homogenous. Each input value (concentration and usage rate) was then assigned a weight rating which was in turn used to determine the overall environmental exposure potential. The rating was both qualitative (very low to high) and numerical (1–4), as illustrated in Table 1. The higher the numerical score, the higher the exposure potential, and each exposure assessment parameter was ranked separately. For example, a given NEP can be rated low in terms of concentration but has a medium rating in terms of usage rate.

2.3 Characterisation of ENMs in NEPs

A selection of NEPs that exhibited high environmental exposure potential, and thus considered as a likely source of nanopollution posing high environmental exposure, were characterised to confirm the presence of ENMs and their characteristics. The products included three sunscreens containing TiO2 (Sun 1–3), a moisturising cream with ZnO (MC 1), and an eye cream with SiO2 (MC 2).

2.3.1 Extraction of ENMs from NEPs

n-Hexane, hydrofluoric acid (HF) (47-51%), nitric acid (HNO3) (≥ 65%) and hydrogen peroxide (H2O2) (35%) were obtained from Sigma-Aldrich (South Africa). Ethanol (99%) was obtained from Merck (South Africa). Acetone and boric acid (H3BO3) were obtained from Associated Chemical Enterprise (South Africa). Calibration and internal standards for ICP-MS were obtained from De Bruyn Spectroscopic Solutions (South Africa) and are traceable to NIST reference materials.

Solvent extraction was applied in order to preserve the incorporated ENMs in their (nano) particulate form. The ENMs were extracted by weighing 2 g of the NEP sample into a 50 mL centrifuge tube; 30 mL of n-hexane was then added, and the mixture vortexed for 30 s and bath sonicated (ultrasonic cleaner 705; Scientech) for 20 min. The mixture was shaken at 120 rpm for 12 h in a shaker at 25 ± 2 °C before centrifugation (Centrifuge refrigerated Z 326K, Hermle) at 6000 rpm for 30 min. The supernatant was discarded, and 30 mL ethanol was added to the pellet and centrifuged, as previously described. After centrifugation, the supernatant was discarded and 10 mL of acetone was added to the pellet, vortexed for no less than 30 s and centrifuged at 6000 rpm for 30 min. This step was repeated, and the residue of the remaining solvent was evaporated in oven at 80 °C under vacuum and then ground into a powder which was analysed as described in the section that follows (Sect. 2.3.2).

2.3.2 Characterisation

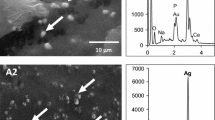

For scanning electron microscopy (SEM), the dried powders were immobilised on double-sided carbon-coated tape, and imaged with a Zeiss Auriga Cobra FEGSEM at an accelerating voltage of 5 kV. Energy-dispersive spectroscopy (EDS) was used to determine the elemental composition of the sample. For high-resolution transmission electron microscopy (HRTEM), 60 mg of the extracted powder was dispersed in 10 mL of ethanol ultra-sonicated for 30 min, before mounting on carbon-coated copper grids and drying at room temperature. The samples were examined with a JEOL JEM 2100 HRTEM coupled with EDS at 200 kV. Multiple images of each sample were taken for subsequent particle-size analysis with Image J software.

Nanoparticle tracking analysis (NTA) was performed on a NanoSight NS500 (Software 3.0) as a rapid screening tool for the presence of ENMs in the samples irrespective of their shape and chemical nature. Fifty milligrams of the dried powder was mixed with 10 mL of deionised water and sonicated for 30 min. The suspension was filtered using a 0.45 µm syringe filter and sonicated for a further 10 min before analysis. Analysis was conducted in triplicate, and each replicate was analysed by recording three 30-s videos. If the sample was too concentrated, further dilution was undertaken. The X-Ray diffraction (XRD) analysis was undertaken to determine the crystalline structure of TiO2 in sunscreens. A Rigaku Ultima IV X-ray diffractometer was operated using Cu Kα radiation under the following conditions: 40 kV and 30 mA, 2θ range of 5°–90° with step size of 0.01 and a 2°/min scan speed.

The elemental concentration of the metal was determined with ICP-MS following sample dissolution of the metal-oxide nanoparticles using microwave-assisted acid digestion. For this purpose, the NEP sample was used instead of the extracted sample. A NEP sample of 0.2 g was weighed into a Teflon vessel, and then, 4 mL of HNO3, 2 mL of H2O2 and 1 mL of HF were added. The samples where digested with microwave (Multiwave Pro, Anton Paar) under the following conditions: ramp to 500 W for 5 min, hold at 500 W for 20 min. After cooling, 6 mL of 4% (w/w) H3BO3 was added to each sample to complex the excess HF. This was achieved by ramping the microwave power to 400 W for 15 min, and then held at 400 W for 10 min. The contents of the tube were decanted and diluted to 50 mL with deionised water. Total elemental concentration was determined with ICP-MS (iCAP Q) using 45Sc (for Zn) and 73Ge (Ti and Si) as internal standards. The examination of the method’s recovery efficiency was undertaken by spiking the cream matrix with a known amount of TiO2 and then digested as before.

3 Results and discussion

3.1 Nano-enabled products

Two hundred and sixty-four (264) NEPs were identified spreading across six product-use categories, namely: health and fitness, electronics and computers, home and garden, appliances, automotive and food beverages (Fig. 1; Table S2). The health and fitness category dominated, making up 66.7% of the identified products, followed by the electronics and computer at 15.2%, home and garden at 10.6%, appliances at 3.8%, automotive at 2.7%; and the least proportion was in the food and beverage category, which accounted for just 1.1%.

In the health and fitness category, most NEPs were personal care and cosmetic products (52.8%), followed by sunscreens (29.5%), sporting goods (11.9%) and least proportion was clothing (5.7%). The electronics and computer category consisted mainly of television sets and camera lenses. The home and garden category consisted of cleaning and maintenance products (67.9%) and paints and coatings (28.6%). In the appliances category, the products were refrigerators and air conditioners. The products in the automotive category were mostly cleaning and maintenance products. All the products in the food and beverage category were supplements. The dominance by the health and fitness NEPs is similar to trends reported in Singapore [40], Europe [12] and the Consumer Product Inventory (CPI) nanodatabase [35]. The number of NEPs identified in South Africa is considerably lower than that in the CPI and The Nanodatabase which stand at 1827 and 3037 NEPs, respectively. However, an increase locally is anticipated in the future as indicated by the trends observed in both the CPI and The Nanodatabase over the years.

The chemical type of ENMs incorporated was stated in 62.8% of the identified products, whilst for the rest it was either not declared or poorly defined (e.g. “nano-coating”) (Fig. 2). The most frequently used ENMs in the identified products were TiO2, carbon-based materials, Ag and SiO2. It is noteworthy that the chemical identity of ENMs was not declared in any product from the home and garden category. The application of TiO2 ENMs was predominantly in sun protection and cosmetic products, probably in pursuit of UV absorptive capacity, similarly for bisoctrizole and ZnO. Carbon-based ENMs were used in sporting goods (53.1%) such as rackets, probably as carbon nanotubes (CNTs) and other carbon derivatives and in cosmetics (46.9%) as a colourant. Silver ENMs were used as antimicrobial agents in hair-care products (66.7%), filtration membranes (18.5%) and in clothing (11.1%). Indium selenide quantum dots were used in display-screen products such as televisions, whilst Au ENPs were used in cosmetic products for anti-oxidant and soothing properties. The chemical identity of ENMs was not stated or poorly defined in 37% of the NEPs, and such lack of information is one of the factors that hamper progress in performing robust exposure assessment, hazard evaluation and ultimately risk assessment of NEPs. Calls have been raised for mandatory declaration of the type of ENMs in NEPs, and in some cases, mandatory labelling is exclusive to certain product categories, for instance personal care products in the USA (http://nanotechia.org/news/nanomaterials-us-science-scorecard-personal-care). In South Africa, there are currently no requirements for manufacturers to declare NEPs for local markets and it is assumed that most products identified in this study are produced by multinational companies and packaged for international markets where the declaration of NEPs is mandatory or encouraged. However, even in the regions where the declaration of NEPs is required, the chemical identity of ENMs and other properties may still not be reported. For instance, the European Cosmetic Directive stipulates mandatory declaration for nano-enabled cosmetics (Regulation EC 1223/2009) [6] although in about 50% of cosmetics identified in The Nanodatabase the chemical type of ENMs was not reported [12]. Thus, local enforcement for NEPs declaration can enhance the identification of NEPs of concern pertaining environmental risks.

3.2 Assessment of environmental exposure potential

Amongst the identified NEPs, the location of the ENMs was determined to be in the following categories: suspended in liquid, suspended in solid, airborne, surface-bound and nano-structured surface (Fig. 3). The ENMs were found to be predominantly suspended in liquid, and the products were mostly health and fitness NEPs such as personal care products, cosmetics and sunscreens. In almost all the NEPs (96.4%) in the home and garden category, the ENMs were suspended in liquid and thus possessed high likelihood to release ENMs into the environment. The proportion of products with ENMs suspended in solid was 14.4%, and these were mostly health and fitness products such as sporting goods (50%), personal care and cosmetics (28.9%). The products with nano-structured surfaces were predominantly electronics and computer products, for instance coated lenses. Airborne ENMs were used only in the appliances category, specifically air conditioners. The products with surface-bound ENMs made up 12.9% of the identified NEPs, 85.3% of which were health and fitness products, and 14.7% were clothing and appliances.

The outcomes of the environmental exposure potential in the identified products are illustrated in Fig. 4. Of the identified NEPs, 63.6% were found to possess high potential for ENMs environmental exposure. This was predominantly for NEPs with ENMs suspended in liquid (88.1%), but there were also cases of ENMs suspended in solid (7.1%), airborne (2.9%) and surface-bound (1.8%). With respect to product-use category, the high exposure potential NEPs were health and fitness products, personal care, cosmetics and clothing. All NEPs in the automotive and food–beverages category had high exposure potential, viz. cleaning and surface protection liquids and supplements, respectively. Medium environmental exposure potential was identified in 23.5% of the identified NEPs, mostly with surface-bound ENMs and those that are nano-structured at the surface. Only 12.9% of the NEPs exhibited low environmental exposure potential and were made up of those with nano-structured surfaces and ENMs suspended in solid.

The dominance of NEPs with medium and high ENMs environmental exposure potential observed for South Africa is similar to other international findings [12, 35, 40]. The low-tier assessment of environmental exposure undertaken was meant to guide the identification and prioritisation of cases of concern for nanopollution. We then proceeded to further examine exposure potential of the identified medium and high environmental exposure NEPs whose chemical type of ENMs was known. The assessment indicated that personal care NEPs such as hair relaxers, moisturising lotions and sunscreens present a high priority case as likely sources of nanopollution, as they exhibited high exposure score and release factors for ENMs (Table 2).

The environmental exposure assessment based on the ENMs’ loci in NEPs adopted in the present study at a low tier was valuable in identifying priority NEPs nanopollutants in South Africa, considering no previously published information existed to guide such an assessment. However, it is important to caution that a different outcome can be observed when other exposure assessment factors are considered. For instance, eyeshadows and sunscreens exhibited high exposure potential based on the location of ENMs; but when usage rate and RF were considered in the assessment, a different exposure rating was observed for the two products (Table 2). The inclusion of the RF in this study was important because it relates to the likelihood of ENMs release during the actual use of the NEPs. For instance, the RF of the nutritional supplements to the environment is low because oral uptake is the main route of exposure, and ENMs such as Ag and ZnO are expected to be dissolved in the acidic environment of the intestinal tract [40]. Their eventual release is expected to be reduced due to potential biotransformation, uptake and excretion processes. For most of the cosmetics (e.g. concealers and eyeshadows), the RF to water was relatively lower when compared to sunscreens and moisturising lotions because of the assumption that in the former most of the products remain in facial cotton wool after being wiped off and therefore disposed as solid waste [40]. For sunscreens and moisturising lotions, however, the RF was above 90% because of high likelihood of the product being released into water systems during bathing and swimming.

Overall, the current findings indicate that most identified NEPs, especially those in the health and fitness category, are expected to release ENMs into environment with relative ease, with water resources being the most likely immediate recipients, and thus are a priority for South Africa. This will require rigorous scientific examination in order to closely estimate the environmental implications. Similarly, there is likelihood for ENMs being released during use even for NEPs with medium exposure potential. For products with low environmental exposure potential, the ENMs are usually deeply embedded in the matrix; and whilst the likelihood of them being released during use is negligible, exposure from such products is expected to occur during their manufacturing, disposal and recycling. Higher tier assessments, such as modelling of ENMs’ volumes released during product usage, are still necessary to generate robust quantitative data, providing in-depth information regarding the extent of nanopollution from the use of NEPs in South Africa.

3.3 Characterisation of the physico-chemical properties

A sample of NEPs that exhibited high environmental exposure potential were then experimentally examined to obtain the characteristics of the incorporated ENMs, being three sunscreens and two moisturising creams (Table 3). The ENMs were detected in all the NEPs samples examined, thus confirming the manufacturers’ nano-claim (Figs. 5, 6; Table S3), and the ENMs size ranges obtained were comparable to other studies [1, 21, 22] Additionally, the presence of TiO2 and SiO2 ENMs in Sun 1–3 and MC 2, respectively, was confirmed (Figures S1–S2). However, for MC 1 no Zn was detected by either EDS or ICP-MS, although Ti was detected instead, suggesting rather the presence of TiO2 ENMs. The findings suggested that either the claim by the manufacturer for MC 1 was incorrect or the ZnO ENMs concentration was below the lower detection limits of the equipment utilised. Erroneous ENMs reporting by manufacturers has been observed previously [1]. Electron microscopy showed that the ENMs were predominantly agglomerated with variable size and shape. The Sun 1 and Sun 2 samples contained a mixture of rectangular, rod-like TiO2 particles with sizes ranging 8–34 nm in width and 20–121 in length. Sample Sun 3 contained spherical-like-to-oval-shaped ENMs, ranging 15–86 nm in width and 15–105 nm in length. The particles in MC 1 were mostly near spherical with some being hexagonal, exhibiting a wide size distribution, ranging from 50 to 350 nm. Whilst there was an overlap in the size distribution of the particles determined by TEM and NTA, the modal size value determined with NTA was greater than the ones determined with TEM. This may be due to the fact that NTA cannot distinguish agglomerates and individual particles, whilst TEM allows for measurement of individual particles. Nonetheless, NTA can be used as a valuable rapid screening tool for ENMs in samples prior to more detailed analysis with electron microscopy. The size distribution and modal values determined by NTA and TEM are summarised in Table S3. The acquired XRD patterns of the extracted particles from TiO2-containing samples (Fig. 7) were compared to the known XRD patterns of TiO2 in literature [33, 39]. It was found that the TiO2 ENMs in Sun 1–2 and MC 1 were rutile (the most common natural form of TiO2), whereas Sun 3 contained anatase (a common modification of TiO2) with small amount of rutile. The preferable use of rutile over anatase in sunscreens arises from the lower toxicity of the former due to its lower photocatalytic activity [7, 15]. Even when TiO2 in sunscreens are coated with layers of Al and Si hydroxides, they are subjected to degradation by environmental factors such as sunlight, and can thus expose bare TiO2 [20, 36]. The properties of TiO2 ENMs in sunscreens observed in this study have been observed by others [1, 4, 21, 22] (Fig. 7).

Detecting the inorganic elemental concentrations of the ENMs with ICP-MS was successful as a recovery rates were 73.4 and 91.97% for Si and Ti respectively; thus illustrating the efficiency of the digestion process which was comparable to another study [28]. The percentage weights of Ti were 2.14 ± 0.074, 1.56 ± 0.012, 1.23 ± 0.045 and 0.34 ± 0.052% for Sun 1, 2, 3 and MC 1, respectively, and that of Si was 0.87 ± 0.034% for MC 2. However, these were within ranges reported elsewhere as generally the elemental content of ENMs is often no more than 10% wt of the NEPs in which they are found [4, 38]. The very low concentrations of ENMs in NEPs have been raised as a hindrance to risk estimations, as commonly insufficient mass can be extracted or released to undertake robust experimental examination such as toxicity testing [24]. The issue is further complicated by the challenging and time-consuming extraction of ENMs from NEPs, which can influence the quality of data generated with ICP-MS and electron microscopy. For instance, incomplete elution of the organic matrix can limit the sizing of ENMs (Figure S3). Standardised protocols are urgently needed in this regard.

It is important to highlight that whilst the current section presents characteristics of the ENMs extracted from NEPs, ENMs are not necessarily released into the environment in a “pure” state. For instance, the ENMs are embedded in complex product matrices mostly of organic nature (Figure S3), and therefore not released immediately to the environment as free entities. Instead, it is the complex ENMs-containing matrix that is initially released and which must then undergo environmental physico-chemical transformations before the ENMs are subsequently released (nanopollution). Hence, a more realistic picture of the physico-chemical properties of ENMs in the environment is obtainable from release studies rather than from extraction studies. The physico-chemical nature of such ENMs is influenced by the product life cycle, as well as ageing and transformation processes in the receiving environment [24]. Therefore, we raise the call for more release studies with the priority source NEPs identified in this study as a basis for more quantitative data.

3.4 Concluding remarks

This is the first study in South Africa, and the African continent, that identified commercial NEPs and prioritised them based on their likelihood to emit ENMs into the environment. It is anticipated that the present study not only advances scientific knowledge with respect to the environmental implications of NEPs, but also has relevance to the general public debate, and environmental regulation in South Africa regarding steps towards government policy development..

The study identified 264 NEPs available in the South African market and examined their potential to release ENMs into the environment.

-

Health and fitness products in the form of personal care and cosmetics and sunscreens were the dominant proportion of the identified NEPs.

-

There was high occurrence of products for which the chemical identity of their ENMs was not reported by the manufactures, presenting an information gap with respect to robust identification of ENMs sources into the environment. Experimentally, no NEP in this category was examined; however, from the sample that was examined by ICP-MS and EDS, the manufacturer-provided ENMs elemental information was mostly correct, suggesting relatively high reliability of manufacturer information; but low levels of incorrect reporting can be expected.

-

It is concerning that the majority of NEPs identified exhibited medium and high ENMs exposure potential for the environment, indicative of current potential nanopollution of water resources although the extent is yet to be estimated.

-

The health and fitness as well as home and garden NEPs were observed to exhibit elevated ENMs exposure potential for the environment. We identified these to include sunscreens, hair relaxers, moisturising lotions, eye creams, cosmetic sera and socks to be priority sources of ENMs into water resources. We propose that local studies investigate exposure potential and effects of ENMs in the environment (mostly water resources) arising from NEPs focus on this priority list. Such efforts should include release studies, life cycle assessments and environmental mass flow estimations of ENMs from NEPs. In that way, more valuable data would be generated as a means of shedding more insights into the extent of ENMs environmental pollution, more so because ENMs have been identified as an emerging case of concern for water resource quality in South Africa [9].

-

We relied fully on the manufacturers’ “nano” claim, in identifying NEPs and as such there is a likelihood of additional NEPs that were missed in the current study due to the lack of mandatory declaration in South Africa, or even erroneous declaration. Thus, we propose that government authorities consider establishing a requirement for manufacturers to declare and label NEPs sold in South Africa as nano-enabled including chemical type of incorporated ENMs. This will help in collecting locally relevant information in order to understand the extent of nanopollution and whether or not regulation is necessary.

References

Bairi VG, Lim J-H, Fong A, Linder SW (2017) Size characterization of metal oxide nanoparticles in commercial sunscreen products. J Nanopart Res 19:256

Benn TM, Westerhoff P (2008) Nanoparticle silver released into water from commercially available sock fabrics. Environ Sci Technol 42(11):4133–4139

Besley J (2010) Current research on public perceptions of nanotechnology. Emerg Health Threats J 3:7098

Botta C, Labille J, Auffan M, Borschneck D, Miche H, Cabié M, Masion A, Rose J, Bottero J-Y (2011) TiO2-based nanoparticles released in water from commercialized sunscreens in a life-cycle perspective: structures and quantities. Environ Pollut 159:1543–1550

Bowman DM, Hodge GA (2007) A small matter of regulation: an international review of nanotechnology regulation. Columbia Sci Technol Law Rev 8:1–32

Buzek J, Ask B (2009) Regulation (EC) No 1223/2009 of the European Parliament and of the Council of 30 November 2009 on cosmetic products

Clément L, Hurel C, Marmier N (2013) Toxicity of TiO2 nanoparticles to cladocerans, algae, rotifers and plants—effects of size and crystalline structure. Chemosphere 90:1083–1090

Dumont E, Johnson AC, Keller VDJ, Williams RJ (2015) Nano silver and nano zinc-oxide in surface waters—exposure estimation for Europe at high spatial and temporal resolution. Environ Pollut 196:341–349

DWA (2013) National Water Resources Strategy: water for an equitable and sustainable future. Department of Water Affairs, Republic of South Africa, 145 p

Foss Hansen S, Larsen BH, Olsen SI, Baun A (2007) Categorization framework to aid hazard identification of nanomaterials. Nanotoxicology 1:243–250

Grassian VH, Haes AJ, Mudunkotuwa IA, Demokritou P, Kane AB, Murphy CJ, Hutchison JE, Isaacs JA, Jun Y-S, Karn B et al (2016) NanoEHS—defining fundamental science needs: no easy feat when the simple itself is complex. Environ Sci Nano 3:15–27

Hansen SF, Heggelund LR, Besora PR, Mackevica A, Boldrin A, Baun A (2016) Nanoproducts—what is actually available to European consumers? Environ Sci Nano 3:169–180

Hansen SF, Jensen KA, Baun A (2014) NanoRiskCat: a conceptual tool for categorization and communication of exposure potentials and hazards of nanomaterials in consumer products. J nanopart Res 16:1–25

Hansen SF, Michelson ES, Kamper A, Borling P, Stuer-Lauridsen F, Baun A (2008) Categorization framework to aid exposure assessment of nanomaterials in consumer products. Ecotoxicology 17:438–447

Jin C, Tang Y, Yang FG, Li XL, Xu S, Fan XY, Huang YY, Yang YJ (2011) Cellular toxicity of TiO2 nanoparticles in anatase and rutile crystal phase. Biol Trace Elem Res 141:3–15

Keller AA, Lazareva A (2013) Predicted releases of engineered nanomaterials: from global to regional to local. Environ Sci Technol Lett 1:65–70

Keller AA, Vosti W, Wang H, Lazareva A (2014) Release of engineered nanomaterials from personal care products throughout their life cycle. J Nanopart Res 16:2489

Klaine SJ, Alvarez PJJ, Batley GE, Fernandes TF, Handy RD, Lyon DY, Mahendra S, McLaughlin MJ, Lead JR (2008) Nanomaterials in the environment: behavior, fate, bioavailability, and effects. Environ Toxicol Chem 27:1825–1851

Klaine SJ, Koelmans AA, Horne N, Carley S, Handy RD, Kapustka L, Nowack B, von der Kammer F (2012) Paradigms to assess the environmental impact of manufactured nanomaterials. Environ Toxicol Chem 31:3–14

Labille J, Feng J, Botta C, Borschneck D, Sammut M, Cabie M, Auffan M, Rose J, Bottero J-Y (2010) Aging of TiO2 nanocomposites used in sunscreen. Dispersion and fate of the degradation products in aqueous environment. Environ Pollut 158:3482–3489

Lewicka ZA, Benedetto AF, Benoit DN, William WY, Fortner JD, Colvin VL (2011) The structure, composition, and dimensions of TiO2 and ZnO nanomaterials in commercial sunscreens. J Nanopart Res 13:3607

Lu P-J, Huang S-C, Chen Y-P, Chiueh L-C, Shih DY-C (2015) Analysis of titanium dioxide and zinc oxide nanoparticles in cosmetics. J Food Drug Anal 23:587–594

Musee N, Brent AC, Ashton PJ (2010) A South African research agenda to investigate the potential environmental, health and safety risks of nanotechnology. S Afr J Sci 106:1–6

Nowack B, Mitrano DM (2018) Procedures for the production and use of synthetically aged and product released nanomaterials for further environmental and ecotoxicity testing. NanoImpact 10:70–80

Nthwane YB, Tancu Y, Maity A, Thwala M (2019) Characterisation of titanium oxide nanomaterials in sunscreens obtained by extraction and release exposure scenarios. SN Appl Sci 1(4):312

Oberdörster G, Oberdörster E, Oberdörster J (2005) Nanotoxicology: an emerging discipline evolving from studies of ultrafine particles. Environ Health Perspect 113:823

Oberdörster G, Stone V, Donaldson K (2007) Toxicology of nanoparticles: a historical perspective. Nanotoxicology 1:2–25

Peters RJB, van Bemmel G, Herrera-Rivera Z, Helsper HPFG, Marvin HJP, Weigel S, Tromp PC, Oomen AG, Rietveld AG, Bouwmeester H (2014) Characterization of titanium dioxide nanoparticles in food products: analytical methods to define nanoparticles. J Agric Food Chem 62:6285–6293

Podila R, Brown JM (2013) Toxicity of engineered nanomaterials: a physicochemical perspective. J Biochem Mol Toxicol 27:50–55

Reed RB, Faust JJ, Yang Y, Doudrick K, Capco DG, Hristovski K, Westerhoff P (2014) Characterization of nanomaterials in metal colloid-containing dietary supplement drinks and assessment of their potential interactions after ingestion. Acs Sustain Chem Eng 2:1616–1624

Selck H, Handy RD, Fernandes TF, Klaine SJ, Petersen EJ (2016) Nanomaterials in the aquatic environment: a European Union-United States perspective on the status of ecotoxicity testing, research priorities, and challenges ahead. Environ Toxicol Chem 35:1055–1067

Taufikurohmah T, Sanjaya IGM, Syahrani A (2011) Nanogold synthesis using matrix mono glyceryl stearate as antiaging compounds in modern cosmetics. J Mater Sci Eng A 1(6A):857

Thamaphat K, Limsuwan P, Ngotawornchai B et al (2008) Phase characterization of TiO2 powder by XRD and TEM. Kasetsart J(Nat Sci) 42:357–361

Tiede K, Westerhoff P, Hansen FS, Fern GJ, Hankin SM, Aitken RJ, Chaudhry Q, Boxall A (2011) Review of the risks posed to drinking water by man-made nanoparticles. Food and Environment Research Agency, Yorkshire, DWI 70/2/246

Vance ME, Kuiken T, Vejerano EP, McGinnis SP, Hochella MF Jr, Rejeski D, Hull MS (2015) Nanotechnology in the real world: redeveloping the nanomaterial consumer products inventory. Beilstein J Nanotechnol 6:1769–1780

Virkutyte J, Al-Abed SR, Dionysiou DD (2012) Depletion of the protective aluminum hydroxide coating in TiO2-based sunscreens by swimming pool water ingredients. Chem Eng J 191:95–103

Wang Y, Nowack B (2018) Dynamic probabilistic material flow analysis of nano-SiO2, nano iron oxides, nano-CeO2, nano-Al2O3, and quantum dots in seven European regions. Environ Pollut 235:589–601

Weir A, Westerhoff P, Fabricius L, Hristovski K, Von Goetz N (2012) Titanium dioxide nanoparticles in food and personal care products. Environ Sci Technol 46:2242–2250

Yan J, Wu G, Guan N, Li L, Li Z, Cao X (2013) Understanding the effect of surface/bulk defects on the photocatalytic activity of TiO2: anatase versus rutile. Phys Chem Chem Phys 15:10978–10988

Zhang Y, Leu Y-R, Aitken RJ, Riediker M (2015) Inventory of engineered nanoparticle-containing consumer products available in the Singapore retail market and likelihood of release into the aquatic environment. Int J Environ Res Public Health 12:8717–8743

Acknowledgements

We acknowledge the review comments of Bettina Genthe and those of anonymous reviewers.

Funding

The study was funded by the Department of Science and Technology in South Africa under the Nanotechnology Health, Safety and Environment Risk Research Platform, Reference: 0085/2015.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Moeta, P.J., Wesley-Smith, J., Maity, A. et al. Nano-enabled products in South Africa and the assessment of environmental exposure potential for engineered nanomaterials. SN Appl. Sci. 1, 577 (2019). https://doi.org/10.1007/s42452-019-0584-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-019-0584-3