Abstract

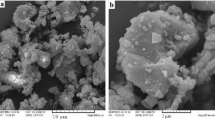

By using calcium carbonate (CaCO3) powder as the blowing agent, Al foams with porosities of ~ 60 to 85% and pore size of ~ 1.5 mm were fabricated via melt-foaming method. Instead of adding a thickening agent to increase Al melt viscosity, a small amount of Mg ingot (5.0 wt%) was added first, and then Al melt was foamed by adding calcium carbonate via the impellor stirring. The effect of Mg addition on the gas release behavior of calcium carbonate in the Al melt was investigated. The compression behavior of fabricated Al foams was examined. The results show that the blowing gas is possibly from the reaction between Mg and calcium carbonate, and this reaction can produce solid oxides with micrometer level size, which leads to increasing the Al melt viscosity and is beneficial for inhibiting pores coarsening. Besides, the micrometer level cracks in the cell walls make the strength of Al foam decrease.

Similar content being viewed by others

References

J. Banhart, Prog. Mater. Sci. 46 (2001) 559–632.

J. Banhart, Adv. Eng. Mater. 15 (2013) 82–111.

S.F. Liu, A. Li, Y.J. Ren, D.F. Li, Z.H. Zhang, J. Iron Steel Res. Int. 24 (2017) 556–560.

S.F. Liu, Z.P. Xi, H.P. Tang, X. Yang, Z.H. Zhang, J. Iron Steel Res. Int. 21 (2014) 793–796.

S. Akiyama, H. Ueno, K. Imagawa, A. Kitahara, S. Nagata, K. Morimoto, T. Nishikawa, M. Itoh, Foamed Metal and Method of Producing Same, European Patent, 0210803, 1989.

S. Akiyama, H. Ueno, K. Imagawa, A. Kitahara, S. Nagata, K. Morimoto, T. Nishikawa, M. Itoh, Foamed Metal and Method of Producing Same, US, 4713277, 1987.

D.H. Yang, J.Q. Chen, H. Wang, J.H. Jiang, A.B. Ma, Z.P. Lu, J. Mater. Sci. Technol. 31 (2015) 361–368.

D.H. Yang, B.Y. Hur, D.P. Hur, S.R. Yang, Mater. Sci. Eng. A 445–446 (2007) 415–426.

D.W. Li, J. Li, T. Li, T. Sun, X.M. Zhang, G.C. Yao, Trans. Nonferrous Met. Soc. China 21(2011) 346–352.

A. Aldoshan, S. Khanna, Mater. Sci. Eng. A 689 (2017) 17–24.

S. Birla, D.P. Mondal, S. Das, A. Khare, J.P. Singh, Mater. Des. 117 (2017) 168–177.

L. Salvo, G. Martin, M. Suard, A. Marmottant, R. Dendievel, J.J. Blandin, C. R. Phys. 15 (2014) 662–673.

F. Von Zepplin, M. Hirscher, H. Stanzick, J. Banhart, Compos. Sci. Technol. 63 (2003) 2293–2300.

N.V.R. Kumar, N.R. Rao, B. Sudhakar, A.A. Gokhale, Mater. Sci. Eng. A 527(2010) 6082–6090.

J.A. Liu, Q.X. Qu, Y.Liu, R.G. Li, B. Liu, J. Alloy. Compd. 676 (2016) 239–244.

S. Kumar, O.P. Pandey, J. Manuf. Process. 20 (2015) 172–180.

D.P. Mondal, N. Jha, B. Gull, S. Das, A. Badkul, Mater. Sci. Eng. A 560 (2013) 601–610.

M.G. Nava, A. Cruz-Ramírez, M.Á.S. Rosales, V.H. Gutiérrez-Pérez, A. Sánchez-Martínez, J. Alloy. Compd. 698 (2017) 1009–1017.

L.E.G. Cambronero, J.M. Ruiz-Roman, F.A. Corpas, J.M.R. Prieto, J. Mater. Process. Technol. 209 (2009) 1803–1809.

V. Gergely, D.C. Curran, T.W. Clyne, Compos. Sci. Technol. 63 (2003) 2301–2310.

Y.R. Luo, S.R. Yu, W. Li, J.A. Liu, M. Wei, J. Alloy. Compd. 460 (2008) 294–298.

A.V. Byakova, S.V. Gnyloskurenko, T. Nakamura, Metals 2 (2012) 95–112.

A.V. Byakova, S.V. Gnyloskurenko, A.I. Sirko, Y.V. Milman, T. Nakamura, Mater. Trans. JIM. 47 (2006) 2131–2136.

D.H. Yang, B.Y. Hur, S.R. Yang, J. Alloy. Compd. 461 (2008) 221–227.

G.Q. Luo, H. Hao, F.Y. Wang, X.G. Zhang, Trans. Nonferrous Met. Soc. China 23 (2013) 1832–1837.

P.F. Li, N.V. Nguyen, H. Hao, Mater. Des. 89 (2016) 636–641.

J. Wang, Z. Zhang, Q. Jiang, X.C. Xia, C.R. Qiu, J. Ding, W.M. Zhao, Mater. Lett. 193 (2017) 187–190.

X.C. Xia, W.M. Zhao, X.Z. Feng, H. Feng, X. Zhang, Mater. Des. 49 (2013) 19–24.

D.H. Yang, Z.Y. Hu, W.P. Chen, J. Lu, J.Q. Chen, H. Wang, L. Wang, J.H. Jiang, A.B. Ma, J. Manuf. Process. 22 (2016) 290–296.

D.H. Yang, J.Q. Chen, W.P. Chen, L. Wang, H. Wang, J.H. Jiang, A.B. Ma, J. Mater. Sci. Technol. 33 (2017) 1141–1146.

D.H. Yang, W.P. Chen, Z.Y. Hu, J.Q. Chen, J.H. Jiang, A.B. Ma, A Powder Metallurgical Method of Fabricating Zinc Alloy Foam, China, ZL201510163987.3, 2015.

D.H. Yang, Z.Y. Hu, W.P. Chen, J.Q. Chen, J.H. Jiang, A.B. Ma, A Powder Metallurgical Method of Fabricating Mg Alloy Foam, China, ZL 201410231349.6, 2014.

Z.L. Song, J.S. Zhu, L.Q. Ma, D.P. He, Mater. Sci. Eng. A 298 (2001) 137–143.

J. Banhart, Adv. Eng. Mater. 8 (2006) 781–794.

Acknowledgements

This work is supported by the Natural Science Foundation of Jiangsu Province of China (Grant No. BK20171437), the Fundamental Research Funds for the Central Universities (Grant No. 2016B06614), the Research Project of University of Science and Technology Beijing (USTB) (Grant No. 2015-Z06). The Guiding Capital for Industrial Development Project of Suqian and National Natural Science Foundation of China (No. 11472098).

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

The fusion heats of Al and Mg are 10.71 and 8.48 kJ/mol, respectively. The reaction enthalpy of Mg + CaCO3 = MgO + CaO + CO↑ is − 136.74 kJ/mol. The mass ratio among Al, Mg and CaCO3 is 100:4.8:20, then the corresponding molar ratio among Al, Mg and CaCO3 is (100/27):(4.8/24):(20/100). Therefore, the ratio between the endothermic value caused by Al and Mg fusion and the exothermic value caused by the liquid–solid reaction of Mg + CaCO3 = MgO + CaO + CO↑ is, [10.71·(100/27) + 8.48·(4.8/24)]:[136.74·(20/100)] ≈ 1.51:1. Consequently, there is no exothermic peak appearing in Fig. 5.

Rights and permissions

About this article

Cite this article

Yang, Dh., Chen, Jq., Wang, L. et al. Fabrication of Al foam without thickening process through melt-foaming method. J. Iron Steel Res. Int. 25, 90–98 (2018). https://doi.org/10.1007/s42243-017-0011-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-017-0011-1