Abstract

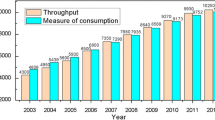

Water consumption in the printing and dyeing industry accounts for a large proportion of the total industrial water consumption. In the industry, there are large wastewater discharge with poor wastewater quality. Water system integration can effectively reduce freshwater consumption and wastewater discharge. The water using system in a printing and dyeing plant is complicated, since there are a large number of water using units, and the water control factors include concentration parameters (suspended solids, SS) and property parameters (pH, chemical oxygen demand (COD), and chromaticity), so that water network optimization is relatively difficult. In this paper, the water using system in a printing and dyeing plant in southeastern China is analyzed. The mathematical programming method is used to determine the optimal water network with the operational cost as the objective function. The optimized water network has reduced the operational cost from 1412.7 $/day to 1173 $/day, freshwater consumption from 2115 to 1480 m3/day, and wastewater discharge from 1915.9 to 1284.4 m3/day.

Similar content being viewed by others

Abbreviations

- Rt :

-

set of regeneration units

- s :

-

set of contaminants

- p :

-

set of properties

- Cost :

-

index for cost

- F :

-

index for flow rate

- c :

-

index for concentration

- \( {\varPsi}_{j,p}^{in,\min } \) :

-

minimum property operator of property p of unit j

- \( {\varPsi}_{j,p}^{in,\max } \) :

-

maximum property operator of property p of unit j

- Cost W :

-

unit cost of freshwater W

- Cost Rt1 :

-

unit cost of first stage regenerated water

- Cost Rt2 :

-

unit cost of second stage regenerated water

- Cost D :

-

unit cost of discharge

- F lb, j :

-

lower bound of unit j’s flow rate

- \( {c}_{j,s}^{in,\max } \) :

-

maximum concentration of contaminant s of unit j’s inlet

- \( {c}_{j,s}^{out,\max } \) :

-

maximum concentration of contaminant s of unit j’s outlet

- \( {p}_{j,p}^{in,\min } \) :

-

minimum property value of property p of unit j’s inlet

- \( {p}_{j,p}^{in,\max } \) :

-

maximum property value of property p of unit j’s inlet

- r Rt :

-

regenerated water production rate of regeneration unit Rt

- Ψ W, p :

-

property operator of property p of industrial water

- \( {\varPsi}_{i,p}^{out} \) :

-

outlet property operator of property p of unit i

- \( {\varPsi}_{j,p}^{in} \) :

-

inlet property operator of property p of unit j

- \( {\varPsi}_{j,p}^{out} \) :

-

outlet property operator of property p of unit j

- \( {\varPsi}_{Rt,p}^{out} \) :

-

outlet property operator of property p of regeneration unit Rt

- \( {\varPsi}_{Rt1,p}^{in} \) :

-

inlet property operator of property p of regeneration unit Rt1

- \( {\varPsi}_{Rt2,p}^{in} \) :

-

inlet property operator of property p of regeneration unit Rt2

- \( {\varPsi}_{Rt2,p}^{out} \) :

-

outlet property operator of property p of regeneration unit Rt2

- F W, j :

-

inlet flow rate of industrial water of unit j, m3/day

- F i, j :

-

flow rate of direct reused water from unit i to unit j, m3/day

- F j, k :

-

flow rate of direct reused water from unit j to unit k, m3/day

- F j, Rt2 :

-

flow rate of water from unit j to regeneration unit Rt2, m3/day

- F Rt, j :

-

flow rate of regenerated water from regeneration unit Rt to unit j, m3/day

- F Rt1, j :

-

flow rate of regenerated water from regeneration unit Rt1 to unit j, m3/day

- F Rt2, j :

-

flow rate of regenerated water from regeneration unit Rt2 to unit j, m3/day

- F Rt2, Rt1 :

-

flow rate of water from regeneration unit Rt2 to regeneration unit Rt1, m3/day

- F Rt, D :

-

flow rate of discharge water of regeneration unit Rt, m3/day

- F Rt1, D :

-

flow rate of discharge water of regeneration unit Rt1, m3/day

- F Rt2, D :

-

flow rate of discharge water of regeneration unit Rt2, m3/day

- F Loss, j :

-

flow rate of water loss of unit j, m3/day

- F steam, j :

-

flow rate of steam used in unit j, m3/day

- \( {F}_j^{in} \) :

-

total flow rate of inlet of unit j, m3/day

- \( {F}_j^{out} \) :

-

total flow rate of outlet of unit j, m3/day

- M j, s :

-

massload of contaminant s of unit j, t/h

- c W, s :

-

concentration of contaminant s of industrial water, mg/L

- c i, s :

-

concentration of contaminant s of unit i, mg/L

- c Rt, s :

-

concentration of contaminant s of regeneration unit Rt, mg/L

- \( {c}_{j,s}^{in} \) :

-

inlet concentration of contaminant s of unit j, mg/L

- \( {c}_{j,s}^{out} \) :

-

outlet concentration of contaminant s of unit j, mg/L

- \( {c}_{Rt2,s}^{in} \) :

-

inlet concentration of contaminant s of regeneration unit Rt2, mg/L

- \( {c}_{Rt2,s}^{out} \) :

-

outlet concentration of contaminant s of regeneration unit Rt2, mg/L

- \( {p}_{j,p}^{in} \) :

-

inlet property value of property p of unit j

- \( {p}_{Rt1,p}^{in} \) :

-

inlet property value of property p of regeneration unit Rt1

- \( {p}_{Rt2,p}^{out} \) :

-

inlet property value of property p of regeneration unit Rt2

- in:

-

inlet

- out:

-

outlet

- min:

-

minimum

- max:

-

maximum

- i/j/k:

-

water using unit i/j/k

- Rt/Rt1/Rt2:

-

regeneration unit Rt/Rt1/Rt2

- W:

-

industrial water

- D:

-

discharge

- Loss:

-

water loss

- steam:

-

steam

References

Bo L et al (2016) Network optimization and performance evaluation of the water-use system in China’s straw pulp and paper industry: a case study. Clean Techn Environ Policy 18:257–268

Cheng W-H, Adi VSK (2018) Simultaneous optimization of non-isothermal design of water networks with regeneration and recycling process. Integr Optim Sustain 2:183–203

Deng C, Jiang W, Feng X (2018a) Deciphering refinery water system design and optimization: superstructure and generalized mathematical model. ACS Sustain Chem Eng 6:2302–2315. https://doi.org/10.1021/acssuschemeng.7b03754

Deng C, Jiang W, Zhou W, Feng X (2018b) New superstructure-based optimization of property-based industrial water system. J Clean Prod 189:878–886

Ding H, Feng X (2018) Graphical targeting approach of water networks with two-stage regeneration recycling. Ind Eng Chem Res 57:9591–9603. https://doi.org/10.1021/acs.iecr.8b01264

Fan XY, Xu DL, Zhu JF, Liu ZY (2016) Targeting of water-using networks involving regeneration with a graphical approach. Clean Techn Environ Policy 18:1–8

Jiang W, Yuan Z, Bi J, Sun L (2010) Conserving water by optimizing production schedules in the dyeing industry. J Clean Prod 18:1696–1702. https://doi.org/10.1016/j.jclepro.2010.07.004

Lin C, Cao P, Xu X, Ye B (2019) Algal-bacterial symbiosis system treating high-load printing and dyeing wastewater in continuous-flow reactors under natural light. Water 11:469

Parand R, Hong MY, Pareek V, Tadé MO (2014) Use of pinch concept to optimize the total water regeneration network. Ind Eng Chem Res 53:3222–3235

Parand R, Yao HM, Foo D, Tadé M (2016) An automated composite table algorithm considering zero liquid discharge possibility in water regeneration–recycle network. Clean Techn Environ Policy 18:1–11

Xu H, Yang B, Liu Y, Li F, Shen C, Ma C, Tian Q, Song X, Sand W (2018) Recent advances in anaerobic biological processes for textile printing and dyeing wastewater treatment: a mini-review. World J Microbiol Biotechnol 34:165. https://doi.org/10.1007/s11274-018-2548-y

Yang L, Salcedo-Diaz R, Grossmann IE (2014) Water network optimization with wastewater regeneration models. Ind Eng Chem Res 53:17680–17695

Yu J, Chen Y, Shao S, Zhang Y, Liu LS, Zhang SS (2014) A study on establishing an optimal water network in a dyeing and finishing industrial park. Clean Techn Environ Policy 16:45–57

Zhang K, Zhao Y, Cao H, Wen H (2017) Optimization of the water network with single and double outlet treatment units. Ind Eng Chem Res 56:2865–2871

Zhang K, Zhao Y, Cao H, Wen H (2018) Multi-scale water network optimization considering simultaneous intra- and inter-plant integration in steel industry. J Clean Prod 176:663–675

Zhou L, Xu K, Cheng X, Xu Y, Jia Q (2017) Study on optimizing production scheduling for water-saving in textile dyeing industry. J Clean Prod 141:721–727. https://doi.org/10.1016/j.jclepro.2016.09.047

Zhu Y, Xu J, Cao X, Cheng Y (2018) Characterization of functional microbial communities involved in different transformation stages in a full-scale printing and dyeing wastewater treatment plant. Biochem Eng J 137:162–171. https://doi.org/10.1016/j.bej.2018.05.026

Funding

Financial support from the National Key R&D Program of China (2016YFC0400509) and the National Natural Science Foundation of China under Grant No. 21736008.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that there is no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ding, H., Feng, X., Wu, Y. et al. Water Network Integration of a Printing and Dyeing Plant. Process Integr Optim Sustain 4, 121–133 (2020). https://doi.org/10.1007/s41660-019-00098-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41660-019-00098-3