Abstract

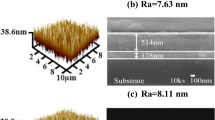

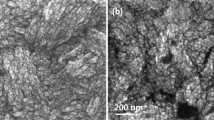

In this study, a bias-enhanced hot filament CVD system with methane and hydrogen as reactant gasses was used to deposit microcrystalline diamond (MCD) and nanocrystalline diamond (NCD) films on Co-cemented tungsten carbide substrates. They were then characterized using FE-SEM, Optical microscopy, XRD, and Raman Spectroscopy. Nanocrystalline diamond coating displays wide carbon peaks near 1350 cm−1 and 1580 cm−1 in Raman Spectroscopy, which correspond to D band and G band of carbon, and a sharp band increase near 1140 cm−1 because of the presence of trans-polyacetylene, confirming the sample as a nanocrystalline diamond. Similarly, the microcrystalline diamond phase was observed at 1350 cm−1 as broadened carbon peaks. The average grain size of the homogenous diamond film was roughly less than 90 nm, several tens of nanometres. The average indentation depths were 45 nm and 63 nm of MCD and NCD coatings and their average hardness values were found 80GPa and 50GPa, respectively. The morphology of the samples was observed using AFM, the average root mean square roughness of the MCD sample in the scanned area was found to be 354.11 nm and of the NCD sample was found to be 142.71 nm this indicates that the nanocrystalline diamond-coated WC was much smoother and had a smaller grain size than microcrystalline diamond coated ones. The values of the coefficient of friction vary from 0.38 to 0.42 for MCD coated sample. In contrast, for the NCD samples, the variations in the coefficient of friction were 0.30–0.36. A low coefficient of friction was observed in NCD as compared to MCD due to the presence of the graphite carbon phase.

Similar content being viewed by others

References

Gopal V, Chandran M, Rao MR, Mischler S, Cao S, Manivasagam G (2017) Tribocorrosion and electrochemical behaviour of nanocrystalline diamond coated Ti based alloys for orthopaedic application. Tribol Int 106:88–100

Henerichs M, Voss R, Harsch D, Kuster F, Wegener K (2014) Tool life time extension with nano-crystalline diamond coatings for drilling carbon-fibre reinforced plastics (CFRP). Procedia CIRP 24:125–129

Dumpala R, Chandran M, Rao MR (2015) Engineered CVD diamond coatings for machining and tribological applications. Jom 67(7):1565–1577

Almeida FA, Soares E, Fernandes AJS, Sacramento J, Silva RF, Oliveira FJ (2011) Diamond film adhesion onto sub-micrometric WC–Co substrates. Vacuum 85(12):1135–1139

Qin F, Hu J, Chou YK, Thompson RG (2009) Delamination wear of nano-diamond coated cutting tools in composite machining. Wear 267(5–8):991–995

Polini R, Barletta M, Cristofanilli G (2010) Wear resistance of nano-and micro-crystalline diamond coatings onto WC–Co with Cr/CrN interlayers. Thin Solid Films 519(5):1629–1635

Wu T, Cheng K (2012) An investigation on the cutting performance of nano-crystalline diamond coatings on a micro-end mill. Proc Inst Mech Eng Part B J Eng Manuf 226(8):1421–1424

Chandran M, Kumaran CR, Dumpala R, Shanmugam P, Natarajan R, Bhattacharya SS, Rao MR (2014) Nanocrystalline diamond coatings on the interior of WC–Co dies for drawing carbon steel tubes: Enhancement of tube properties. Diam Relat Mater 50:33–37

Dumpala R, Chandran M, Kumar N, Dash S, Ramamoorthy B, Rao MR (2013) Growth and characterization of integrated nano-and microcrystalline dual layer composite diamond coatings on WC–Co substrates. Int J Refract Metals Hard Mater 37:127–133

Ma YP, Sun FH, Xue HG, Zhang ZM, Chen M (2007) Deposition and characterization of nanocrystalline diamond films on Co-cemented tungsten carbide inserts. Diam Relat Mater 16(3):481–485

Salgueiredo E, Almeida FA, Amaral M, Fernandes AJS, Costa FM, Silva RF, Oliveira FJ (2009) CVD micro/nanocrystalline diamond (MCD/NCD) bilayer coated odontological drill bits. Diam Relat Mater 18(2–3):264–270

Pengqing Y, Wenzhuang L, Bin Y, Hanfei P, Sen L, Wei F (2016) Multilayer nano/micro crystalline diamond coating on boronizing cemented carbide. Integr Ferroelectr 171(1):186–192

Wei QP, Yu ZM, Ashfold MN, Ye J, Ma L (2010) Synthesis of micro-or nano-crystalline diamond films on WC-Co substrates with various pretreatments by hot filament chemical vapor deposition. Appl Surf Sci 256(13):4357–4364

Dumpala R, Chandran M, Madhavan S, Ramamoorthy B, Rao MR (2015) High wear performance of the dual-layer graded composite diamond coated cutting tools. Int J Refract Metal Hard Mater 48:24–30

Hu J, Chou YK, Thompson RG, Burgess J, Street S (2007) Characterizations of nano-crystalline diamond coating cutting tools. Surf Coat Technol 202(4–7):1113–1117

Dumpala R, Kumar N, Kumaran CR, Dash S, Ramamoorthy B, Rao MR (2014) Adhesion characteristics of nano-and micro-crystalline diamond coatings: Raman stress mapping of the scratch tracks. Diam Relat Mater 44:71–77

Shen B, Sun F (2009) Deposition and friction properties of ultra-smooth composite diamond films on Co-cemented tungsten carbide substrates. Diam Relat Mater 18(2–3):238–243

Chandran M, Kumaran CR, Gowthama S, Shanmugam P, Natarajan R, Bhattacharya SS, Rao MR (2013) Chemical vapor deposition of diamond coatings on tungsten carbide (WC–Co) riveting inserts. Int J Refract Metal Hard Mater 37:117–120

John ST, Klug DD, Gao F (2006) Hardness of nanocrystalline diamonds. Phys Rev B 73(14):140102

Hess P (2012) The mechanical properties of various chemical vapor deposition diamond structures compared to the ideal single crystal. J Appl Phys 111(5):3

Ferrari AC, Robertson J (2004) Raman spectroscopy of amorphous, nanostructured, diamond–like carbon, and nanodiamond. Philos Trans Royal Soc London. Series A Math Phys Eng Sci 362(1824):2477–2512

Naumenko A, Kornienko M (2001) The peculiarities of Raman spectra of carbon materials. AIP Conference Proceedings. American Institute of Physics, College Park, pp 493–495

Lei X, Shen B, Chen S, Wang L, Sun F (2014) Tribological behavior between micro-and nano-crystalline diamond films under dry sliding and water lubrication. Tribol Int 69:118–127

Radhika R, Kumar N, Sankaran KJ, Dumpala R, Dash S, Rao MR, Lin IN (2013) Extremely high wear resistance and ultra-low friction behaviour of oxygen-plasma-treated nanocrystalline diamond films. J Phys D Appl Phys 46(42):425304

Young T (1805) III. An essay on the cohesion of fluids. Philos Trans Royal Soc London 95:65–87

Schrader ME (1995) Young-dupre revisited. Langmuir 11(9):3585–3589

Acknowledgements

We are grateful to the Material Science Research Centre (MSRC) of the Indian Institute of Technology Madras, Chennai, India, for allowing us to use their resources to conduct our experiment. We are also very grateful to Professor M S Ramachandra Rao, Indian Institute of Technology Madras, for his kind guidance and help without which this paper would not have been possible.

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Singla, A., Singh, N.K., Singh, Y. et al. Micro and Nano-Crystalline Diamond Coatings of Co-cemented Tungsten Carbide Tools with Their Characterization. J Bio Tribo Corros 7, 35 (2021). https://doi.org/10.1007/s40735-020-00470-8

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40735-020-00470-8