Abstract

Purpose of Review

Graphene is introduced in dentistry as a material to be used in the fabrication or coating of dental implants due to its biocompatibility, ability to physically interact with biomolecules and very high surface area. This review highlights the current knowledge on the general properties of graphene, potential benefits especially when used in zirconia-based implants, as composite materials and coatings.

Recent Findings

The literature reviewed showed a growing body of evidence supporting the use of graphene-based material, associated with titanium or zirconia as a coating or composite material that helps in cell viability, differentiation and proliferation, improving the bioactivity, osseointegration, physical, chemical and mechanical properties particularly zirconia. Graphene-based materials present great potential for biomedical applications especially when used in the form of nanostructured biological coatings that can be obtained through reproducible and economical processes.

Summary

The use of graphene as a composite implant material or coating may have great potential for osseointegration and bone regeneration, providing that, features including hydrophilicity, protein adsorption capacity, oxygen content and effect of external parameters such as temperature, pH and ionic strength need further elucidations before they can be implemented as a coating or composite material for dental implants.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Zirconia-based materials are being increasingly used in the production of dental implants due to their biocompatibility and high chemical stability, preventing the release of toxic products to the surrounding tissues [1, 2]. In addition, as a result of its favourable mechanical and optical properties, zirconia is also commonly indicated for the fabrication of monolithic crowns, prosthetic frameworks and implant abutments, further expanding their clinical applications [3]. The use of zirconia as an implant material reduces bacterial adhesion and local biofilm accumulation, leading to a low risk of inflammatory reactions in peri-implant tissues [4, 5]. Previous studies reported similar osseointegration rates when zirconia implants were compared to those of titanium-based ones after 12 weeks of implantation [5, 6].

Due to the large alterations in pH and constant temperature fluctuations in the oral cavity, titanium-based implants are, however, subjected to corrosion which becomes critical, especially at the implant/bone interface [7]. Thus, different physicochemical surface coating methods have been suggested in order to inhibit the corrosion process, consequently improving the interaction between the implant surface and bone tissues. Among such coating methods, those composed of silica, magnesium and graphene stand out [8,9,10,11] with or without bioactive molecules, where the latter is used to assist the local biological processes [12].

Graphene and graphene-based materials have received more attention during the last two decades especially in the biomedical fields due to favourable properties such as biocompatibility, electrical conductivity, excellent aqueous processability and surface functionality [13]. Furthermore, their excellent mechanical, tribological properties and resistance to corrosion corroborate their use as implant surface coatings [13].

The aim of this review is to highlight the current knowledge on the general properties of graphene, potential benefits and limitations especially when used in zirconia-based implants, as coatings or composite materials.

History of Graphene

Carbon is a chemical element known since prehistoric civilizations. Records show that coal, diamond and graphite were employed by several European cultures, and graphite, in particular, was used to paint vases and ceramic pieces over 6000 years BC [14•]. The term “graphite” is derived from the Greek word “graphein”, which means “to write” as it was widely used to mark sheep in the 1700s [15]. Since then, graphite became the most commonly used material in the production of pencils. During writing, when the graphite in a pencil is in contact with the paper surface, as a result of mechanical friction between both objects and its layered structure, graphite flakes are delaminated and fixed onto the paper surface [14•].

The analysis of the graphite layers indicated that one single layer of carbon with a graphite structure was the final component of these multiple layers. The term graphene was then used to name this specific carbon layer [16]. In order to isolate this layer, in 1999, graphite was micromechanically exfoliated into thin lamellae using a method that employed lithographic standardization combined with oxygen plasma corrosion [15]. However, only in 2004, with a similar micromechanical approach, followed by repeated peeling of graphite flakes with adhesive tapes, the fundamental structure of graphene was completely separated from the two-dimensional graphene to the multilayered graphite and characterized by optical microscopy and electronics [17••], proving that the graphene sheets in the graphite crystal were independent and highly stable. Further observations indicated that the existing connections between the graphene structure were difficult to be broken which in fact contributed greatly to its durability and ability to stretch (20–25% of its initial length) [18, 19]. This discovery of Andre Geim and Kostya Novoselov, from the University of Manchester resulted in their Nobel Prize in 2010 [14•].

Currently, it is possible to state that graphene is the name given to planar carbon compounds that are present in the form of monolayers arranged in a hexagonal structure, that is, a thin two-dimensional layer formed by hexagonal carbon structures [19, 20]. Due to its excellent electronic, mechanical and thermal properties, graphene has been used in paints, water desalinates, transistors, batteries, sensors and displays, among many others. It also offers a large surface area that can be chemically functionalized, which is very favourable for biological applications [19, 21, 22]. The excellent surface activity resulting from the presence of many functional groups on its surface may reveal adsorption capacity for drugs [23], growth factors [24] and other biomolecules, while the high specific surface area may also enable them as platforms for several biological interactions, bringing important benefits related to therapies using tissue engineering [25].

Graphene-based Materials

Pure graphene can be obtained through different processing routes, such as micromechanical graphite exfoliation, chemical vapour deposition (CVD) and epitaxial growth on silicon carbide (SiC) [26]. However, obtaining pure graphene requires a defect-free hexagonal carbon arrangement in a monolayer, which requires expensive procedures for its large-scale production [19]. Furthermore, the excess free surface energy in this material results in instability, generating agglomeration and folding of the layers [27]. Thus, graphene derivatives, such as graphene oxide (GO) and reduced graphene oxide (rGO), have been obtained as alternatives to pure graphene utilizing less costly chemical methods [28, 29].

GO is a graphene-based monolayer material with high oxygen content. Being chemically similar to oxidized graphite, GO has graphite structures consisting of a layer of graphene functionalized with epoxy, hydroxyl, carboxylic and carbonyl groups [30, 31], which can be used to combine GO with several biomolecules and biomaterials [32]. While the presence of these polar and reactive groups reduces the thermal stability of the material, it also promotes interaction and compatibility with polar solvents or polymeric matrices [14•, 33]. The various oxidation groups in the composition help in the physiological solubility and stability, allowing the GO to be biocompatible and not inducing oxidative stress, as catalyst agents are not involved in the synthesis process [22]. Furthermore, due to the presence of oxidative groups, a wide range of organic and inorganic molecules may interact with GO, through covalent, non-covalent (π-π or hydrophobic) and/or ionic interactions [22, 34]. Thus, GO has been shown to be an interesting alternative to improve the mechanical properties and bioactivity of biomaterials, biomolecule carriers and different drugs for biological applications [22, 30].

Reduced graphene oxide (rGO) on the other hand, can be obtained by removing the oxygenated groups present in graphene oxide (GO), using processes that can be chemical, photochemical, thermal or photothermal [32]. Although this removal results in a material that resembles pure graphene, oxygen-containing groups and defects in different proportions are found on the surface of rGO [29].

Carbon Nanotubes

Carbon nanotubes were developed using an arc-discharge evaporation method, making the graphitic sheets (layers) arranged as coaxial tubes with an internal diameter in the nanometer scale. The number of sheets in a nanotube may vary from 2 to 50 [35]. Soon after their creation, studies on carbon nanotubes (CNT) were found to demonstrate a wide variety of interesting properties such as high capillarity in open tubes, excellent electronic properties and high mechanical strength [36, 37]. In 1993, with the evolution and better understanding of the processing methods for manufacturing CNTs, such nanotubes could even be produced in one layer only [38]. Currently, the nomenclature used refers to the number of layers present in a CNT. Therefore, nanotubes may be called either single-wall carbon nanotubes or multi-wall carbon nanotubes [39].

Due to their inert nature, CNTs often need to go through some kind of surface functionalization in order to perform well in different applications such as in materials engineering, interaction with living tissues or applications in nanobiotechnology. Surface properties play an important role in the performance of CNT [40] since CNTs do not disperse well in their pure state, tending to form agglomerates [41]. The functionalization of CNTs consists of a process of modifying their surface through polymer chains that involve the nanotubes or through coating with different types of surfactant molecules that are adsorbed onto their surface [42].

The nanoscale dimensions ensure a large surface area for CNTs, and as a result, the aggregates have high attraction forces. In this way, it is possible to achieve the entanglement of CNTs which results in low dispersion of the nanotubes in a suspension or matrix [43, 44]. The presence of functional groups on the surface of the CNTs such as COOH, OH and NH2, among others, helps in the dispersion and allows interaction of the CNTs with the precursors of the surrounding matrix, producing materials with improved properties [45,46,47]. The functionalization of CNTs can be attained in different ways but the most common ones are the covalent functionalization, polymeric functionalization and functionalization by surfactants [48] where the last two are characterized as non-covalent functionalization [49]. Covalent functionalization occurs through aggressive oxidative processes, generating defects on the side walls and tips of the tubes. These defects, however, will serve as anchor groups that will be sites for chemical bonds [48]. Non-covalent functionalization on the other hand, has the advantage of not destroying or damaging the side walls of the CNTs so that structural properties of the final material are not compromised. In this type of functionalization, aromatic compounds, surfactants or polymers are used through hydrophobic interactions where the groups present in the surface-active compounds are adsorbed by the surfaces of the CNTs [49].

Toxicity of Graphene

With the increase in the applications of graphene in the dental field, there is also a growing concern regarding the risk of unintentional exposure to this material due to its potential toxicity potential [50]. Graphene commonly enters the human body through inhalation, intratracheal instillation, oral swallowing or subcutaneous injection [51, 52]. Since graphene has nanometric dimensions, they are able to cross physiological barriers (blood organ) and thus deposit in substantial quantities, resulting in the formation of fibrosis and granulomas [53, 54].

Although graphene is currently being used for drug delivery applications, in which there is a direct introduction of this material into the human body, the safety profile and toxicity mechanism of this material have not yet been clarified. To date, studies have shown that graphene presents an inflammatory response when present in the organism, which can lead to local necrosis, damage to the cellular DNA, triggering mechanisms of cellular apoptosis or autophagy [55, 56]. Although in dentistry there is no direct insertion of isolated graphene into the body, one can accidentally release weakly bound graphene from the surface of implants [57] or even swallow or inhale graphene disconnected from the surfaces of dental materials [58,59,60]. However, all the injuries described are directly related to the accumulated exposure of graphene concentration, dimension, surface structure (whether it has sharp edges or not) and functionalization state [61].

The graphene applied in implant dentistry, in general, is strongly linked to the structure of the metallic alloy of the implant or prosthetic abutment [57]. Therefore, its absorption by the body will be practically null by the most common route reported in the literature, which is inhalation. Yet, there is a possibility that the graphene released from implant structures may reach the bloodstream and be retained in different organs. Due to its nanometric size and the ability to pass through physiological barriers, there is a possibility that the material will accumulate in the liver or spleen serous regions [62]. Nonetheless, such deposition will only be dangerous to the organism if it occurs in large amounts.

Zirconia-based Implants

Zirconia is a biocompatible ceramic material, and due to its excellent resistance to corrosion and wear, high flexural strength (700–1500 MPa), modulus of elasticity (220–240 GPa), fracture toughness (4.4 to 9.4 MPa·m1/2), hardness (~ 12 GPa), Weibull modulus (10–16), radiopacity, low thermal conductivity and colour similar to dental tissues, it has been increasingly used as a dental implant material [63,64,65,66]. The biocompatibility of zirconia is recognized by favourable indices of osseointegration, being similar to those observed for titanium implants [5, 6], or for surface treatments [67, 68]. Local or systemic cytotoxic effects, as well as adverse reactions, have not been observed with zirconia implants [69]. In addition, poor bacterial adhesion is reported on zirconia surfaces compared to titanium surfaces in vitro [70] and in vivo [71], contributing to the health and maintenance of peri-implant tissues.

Clinical studies reported 100% survival and success rates for zirconia implants 6 months after surgery, with marginal bone losses of around 2.1 mm after 1 year of follow-up [72]. Success rates of 95.8% were reported after 2 years in 52 patients with single-tooth gaps in the posterior mandible or maxilla who received a two-piece zirconia implant system [46] but the survival decreased to 77.3% after 7 years of follow-up [73]. In that study, the authors found a mean bone loss of 0.97 mm (± 0.07) in 161 implants placed in 61 patients [74]. In a more recent study in 60 patients with 71 implants, after 5 years of function, the overall survival rate was reported as 98.4% with an overall mean marginal bone loss of 0.7 mm (± 0.6) [75]. Payer et al. also found significant similarity between zirconia and titanium implants as regard to marginal bone loss which was about 1.43 mm (± 0.67) for titanium implants and 1.48 mm (± 1.05) for zirconia implants after 24 months of follow-up [76].

Most of today’s zirconia implants are sold in one piece, which eliminates the need for screw-on abutments. However, the impossibility of making corrections for surgical misalignments, as well as the fact that the prosthetic solution will always involve cementation, is inherent limitations to these systems [77]. Following critical planning, using this type of ceramic implant requires careful placement of the implant, use of precise surgical guides and radiographic evaluation of the ideal positioning of the implant.

Using Graphene for Zirconia-based Implants

Composite materials and coatings for both titanium and zirconia implants have been developed and suggested in the literature in order to increase the antibacterial potential and bioactivity that are fundamental for osseointegration [78]. Among them, materials based on silica, magnesium and graphene stand out [8,9,10,11]. The use of graphene in implants is mainly because of its ability to physically interact with biomolecules, such as enzymes, proteins or peptides [79], high biocompatibility, good stimulation and differentiation of stem cells [80] and long-term durability [81]. One other important feature of graphene is the presence of a highly specific surface area, which is important for further bio-functionalization [34]. Furthermore, by the addition of graphene-based nanomaterials in zirconia coating, an enhancement in the wear resistance [8] has been reported. An additional improvement in the toughness has been also noted when graphene-based nanomaterials are incorporated into zirconia [82].

Indeed, the use of graphene, carbon nanotubes and fullerenes in conjunction with titanium implants has been controversially discussed in the literature [57]. In vitro studies reported different applications of graphene sheets associated with titanium [83], such as titanium substrates coated with GO and loaded with bone morphogenetic protein-2 (BMP-2) [24], commercially pure Ti (CP Ti) modified with reduced graphene oxide (RGO) [84], multipass caliber-rolled Ti alloy of Ti13Nb13Zr (MPCR-TNZ) modified with reduced graphene oxide (RGO) and loaded with osteogenic dexamethasone [85], ternary graphene oxide-chitosan-hydroxyapatite (GO-CS-HA) composite coating on Ti substrate [86], and GO coated on pure titanium using dopamine [87], among others. These studies report favourable results on cell formation and inhibition of biofilm formation when graphene-based coatings are used on titanium substrates via different techniques for graphene deposition, such as spin coating, electrophoretic deposition and layer by layer assembly [57]. However, studies on the association of these materials with zirconia-based substrates are still scarce.

In 2013, Kou et al. produced functionalized multiwalled carbon nanotubes (fMWCNTs) and used them as a coating material for zirconia surfaces [88]. Cell proliferation, viability, morphology and attachment of an osteoblast-like cell were evaluated in this study, where the results showed that fMWCNT-coated zirconia discs did not cause any acute toxicity and presented good proliferation of Saos-2 cells with a better attachment of osteoblast-like cells. Subsequently, in 2014, Li et al. fabricated the zirconia/graphene nanosheets (ZrO2/GNs) as composite coatings using a plasma spraying technique [8]. The authors investigated the microstructure and tribological properties of this composite applied to Ti-6Al-4 V substrates where microscopic observations showed that the GN additives were homogeneously distributed in the ZrO2 matrix. In addition, a GN-rich transfer layer was observed on the wear track of ZrO2/GN coating, contributing to the improvement in wear resistance and reduction in friction coefficient, which led to a superior tribological performance. Then in 2022, Rodriguez et al. [89] have produced composites made of yttria stabilized zirconia (YSZ) with a few layers of graphene (sample named as ‘FLG’) and commercialized YSZ with exfoliated graphene nanoplatelets (sample named as ‘e-GNP'). The results show that following the grain refinement effect on YSZ, the composite including exfoliated graphene performs (‘e-GNP') higher resistance to low-temperature degradation than that of the monolithic zirconia. Moreover, the benefits of using surface-functionalized carbon nanotubes with zirconia have been also reported. The bridging and the pull-out effects of nanotubes on the fractured surface are believed to increase the fracture toughness, and the surface functionalization is expected to enhance the surface roughness as well as the efficacy against bacteria which may retard the aging effect, eventually [90,91,92].

On the production side, to manufacture zirconia-based graphene-containing composites, a homogeneous precursor powder should be formed beforehand, then the powder is compacted and baked [93,94,95,96]. Different approaches including mixing graphite and zirconia via ball milling, planetary mixing or mechanical agitator in a dry or wet (solvent) environment have been utilized to obtain a homogeneous precursor. The ultrasonic mixing could be also combined with mechanical mixing for obtaining more efficient homogenous dispersion of graphene and/or exfoliation of graphene oxide [97] with zirconia. Alternatively, a colloidal system could be used where zirconia-containing suspension with negative surface charge is treated with grapheme-containing suspension (i.e. GrO-water suspension) that has positive surface charge. The electrostatic interaction between these oppositely polarized particles leads to stable agglomeration of constituents. It is also possible to use sol–gel method where graphene-containing suspension (i.e. GrO-water suspension) is mixed with soluble zirconia-rich compound. Finally, alkoxide pyrolysis could be also utilized in the production of composites. For compacting and baking, spark plasma sintering (SPS) is widely used but hot (isostatic) pressing, pressureless sintering in vacuum or in air have been also studied [98,99,100].

The positive effect of SPS on the microstructure of the fully dense yttria-stabilized zirconia (YSZ) ceramics reinforced with reduced graphene oxide (rGO) [97] leads to higher electrical, thermal and mechanical properties. Also, thermal diffusivity increased by 12% and fracture toughness increased from 4.4 to 5.9 MPa1/2 after the addition of rGO, while hardness slightly decreased. Another study that used the same technique, investigated the microstructure, mechanical properties and toughening mechanisms of the 3Y-ZrO2-based composites with addition of 0–0.3 wt% GO [101] which easily dispersed homogeneously within the zirconia. The addition of only 0.09 wt% GO in zirconia resulted in an increase of 75% in fracture toughness when GO-doped Y-TZP powder was pressed to obtain green samples which were further sintered at a temperature range of 1200 °C to 1500 °C [102]. Furthermore, the addition of GO to the Y-TZP powder improved the density, densification and mechanical properties of the composite. However, the presence of GO was not effective in suppressing aging-induced monoclinic phase formation in specimens sintered above 1300 °C and exposed to hydrothermal aging in superheated steam at 180 °C/10 bar for up to 200 h.

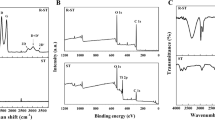

In 2019, a ZrO2/rGO powder was produced by a hydrothermal synthesis technique that used the hydrolysis process of the ZrOCl2 solution to positively charge zirconia ions that were collected on a surface of negatively charged GO sheets due to electrostatic attraction [103]. Scanning electron microscopy (SEM), transmission electron microscopy (TEM), X-ray diffraction (XRD), Raman spectroscopy, X-ray photoelectron spectroscopy (XPS) and Fourier-transform infrared spectroscopy (FTIR) were performed to characterize the structure of the obtained materials, confirming that the zirconia nanoparticles were successfully bonded to grapheme-oxide sheets. The synthesis route used in this study allowed the efficient production of uniform zirconia/graphene nanopowders, in an economical and practical way.

In 2020, Zhang et al. fabricated a hot-pressed yttria-zirconia/multilayer graphene-oxide composite (3YZrO2/GO) and investigated its mechanical and wetting properties [104]. The authors observed increases in flexural strength and fracture toughness values in the range of 41 to 200% and a slight increase in Vickers relative density and hardness. The fracture toughness gradually increased when the GO content increased to 0.1 wt%, but the fracture toughness tended to decrease with the increase in the number of GO sheets. The addition of GO sheets increased the hydrophilicity, presenting smaller contact angle which was attributed to a large amount of hydroxyl groups (OH–), which could be uniformly deposited as a thin film on the porous surface of ZrO2 ceramic. In another similar study, the effect of graphene-oxide (GO) concentrations on the tribological behaviour of 3Y-ZrO2 based composites were evaluated using the same technique with favourable the results on the friction coefficient, wear rate and surface roughness [105]. Accordingly, it was concluded that the addition of GO changes the wear behaviour of composites from a severe to mild state owing to the self-lubricating properties. Continued research results in 2021, employing the dip-coating technique to obtain a thin, homogeneous and stable graphene-oxide film applied on zirconia substrates confirmed the presence, transparency, integrity and homogeneity of the GO film using SEM, AFM, XPS and contact angle measurements [106••]. In the same study, the zirconia substrates were modified with silane in order to enable the immobilization of GO. After a period of 24 days in double distilled water (ddH2O) and phosphate-buffered saline solution, the GO film remained intact, proving to be hydrolytically stable. The immobilized GO film was also shown to be biocompatible for L929 mouse fibroblasts and for osteogenic differentiation in human mesenchymal stem cells. According to the authors, as GO contains hydroxyl and carboxyl groups, biological agents, such as growth factors, can be immobilized on the zirconia coated with GO, further enhancing osseointegration.

One other interesting effect of graphene oxide (GO) deposition on the zirconia surface is on bacterial adhesion and osteoblast activation using an atmospheric pressure plasma generator [107]. When plasma was rotated and switched simultaneously from one side to the other from a distance of 25 mm between the specimens, a uniform GO layer could be deposited on the zirconia surface. The adhesion of Streptococcus mutans to the surfaces of the zirconia specimens and the evaluation of adhesion, proliferation and differentiation of MC3T3-E1 osteoblasts were subsequently performed with the results showing significant reduction in biofilm formation on the GO-coated surfaces compared to that of the uncoated control group. According to the authors, this was due to the increased antibacterial activity of GO, which was also observed on titanium surfaces when coated with GO [108, 109]. Graphene has also been proven to inhibit the growth of other dental pathogens, such as Porphyromonas gingivalis and Fusobacterium nucleatum [110, 111] and that GO reduces the thickness of the biofilm formed, separating it from the material surface [112]. Regarding cell adhesion, proliferation and differentiation, the authors did not find statistically significant difference between the groups with and without GO coating, although proliferation and differentiation increased in the Zr-GO group [107]. This can be explained by the good hydrophobic and electrostatic interaction with the GO.

The studies mentioned above indicate that the presence of graphene-based nanomaterials along with zirconia is important as they may improve the mechanical, tribological, electrical and thermal properties of zirconia based composites (i.e. Y-TZP). Reduction in biofilm thickness [112], antimicrobial effects [97] and bone activation [109] are significant findings reported so far. To date, the most commonly accepted antibacterial mechanism of GO is based on physical destruction of the cell membrane and oxidative stress damage, which would harm bacterial cells, resulting in antibacterial action [113]. Likewise, due to the hydrophobic properties of GO, the adhesion of bacterial cells is prevented, and the hydrophobic interaction can destroy the bacterial membrane, resulting in better antibacterial action [107, 114]. However, further studies are essential to understand the mechanisms of cell adhesion and interaction with graphene-coated surfaces along with their antibacterial activity and long-term stability and performance.

Concluding Remarks

Composite materials and coatings have been proposed in the literature to improve the interaction between the dental implant materials such as zirconia and titanium and the bone tissues, improving their bioactivity and osseointegration. Graphene-based materials have a great potential for biomedical applications especially when used in the form of nanostructured biological coatings due to their excellent physical, chemical and mechanical properties, which also can be obtained through reproducible and economical processes. These techniques allow for controlled chemical composition and film thickness, as well as the deposition of homogeneous films that adhere to the substrate, particularly to complex substrates such as dental implants. However, it is imperative to highlight that despite the favourable physical, chemical and mechanical results as previously reported, further investigations are needed on the promotion of cell behaviour, including fixation, growth, proliferation and differentiation, when graphene-based materials are used as coatings on implant materials. When graphene is used in combination with zirconia, aspects including hydrophilicity, protein adsorption capacity, oxygen content and effect of external parameters such as temperature, pH and ionic strength needs further elucidations before they can be implemented as a coating or composite material.

References

Papers of particular interest, published recently, have been highlighted as: • Of importance •• Of major importance

Rodriguez AE, Monzavi M, Yokoyama CL, et al. Zirconia dental implants: a clinical and radiographic evaluation. J Esthet Restor Dent. 2018;30:538–44.

Afrashtehfar KI, Del Fabbro M. Clinical performance of zirconia implants: a meta-review. J Prosthet Dent. 2020;123:419–26.

Larsson C, Wennerberg A. The clinical success of zirconia-based crowns: a systematic review. Int J Prosthodont. 2014;27:33–43.

Scarano A, Di Carlo F, Quaranta M, et al. Bone response to zirconia ceramic implants: an experimental study in rabbits. J Oral Implantol. 2003;29:8–12.

Kohal RJ, Schwindling FS, Bächle M, et al. Peri-implant bone response to retrieved human zirconia oral implants after a 4-year loading period: a histologic and histomorphometric evaluation of 22 cases. J Biomed Mater Res Part B Appl Biomater. 2016;104:1622–31.

Gahlert M, Roehling S, Sprecher CM, et al. In vivo performance of zirconia and titanium implants: a histomorphometric study in mini pig maxillae. Clin Oral Implants Res. 2012;23:281–6.

Asri RIM, Harun WSW, Samykano M, et al. Corrosion and surface modification on biocompatible metals: a review. Mater Sci Eng C Mater Biol Appl. 2017;77:1261–74.

Li H, Xie Y, Li K, et al. Microstructure and wear behavior of graphene nanosheets-reinforced zirconia coating. Ceram Int. 2014;40:12821–9.

Pardun K, Treccani L, Volkmann E, et al. Magnesium-containing mixed coatings on zirconia for dental implants: mechanical characterization and in vitro behavior. J Biomater Appl. 2015;30:104–18.

Pardun K, Treccani L, Volkmann E, et al. Mixed zirconia calcium phosphate coatings for dental implants: tailoring coating stability and bioactivity potential. Mater Sci Eng C Mater Biol Appl. 2015;48:337–46.

Schienle S, Al-Ahmad A, Kohal RJ, et al. Microbial adhesion on novel yttria-stabilized tetragonal zirconia (Y-TZP) implant surfaces with nitrogen-doped hydrogenated amorphous carbon (a-C:H:N) coatings. Clin Oral Investig. 2016;20:1719–32.

Laranjeira MS, Carvalho A, Pelaez-Vargas A, et al. Modulation of human dermal microvascular endothelial cell and human gingival fibroblast behavior by micropatterned silica coating surfaces for zirconia dental implant applications. Sci Technol Adv Mater. 2014;15:025001.

Geim AK. Graphene: status and prospects. Science. 2009;324(5934):1530–4.

Singh V, Joung D, Zhai L, et al. Graphene based materials: past, present and future. Prog Mater Sci. 2011;56:1178–271. This comprehensive literature review presents the structural, thermal, optical, electrical properties of graphene, its toxicological effects and discusses its impact on the environment.

Dreyer DR, Ruoff RS, Bielawski CW. From conception to realization: an historial account of graphene and some perspectives for its future. Angew Chemie Int Ed. 2010;49:9336–44.

Boehm HP, Setton R, Stumpp E. Nomenclature and terminology of graphite intercalation compounds. Pure Appl Chem. 1994;66:1893–901.

Novoselov KS, Geims AK, Morozovd SV, et al. Electric field effect in atomically thin carbon films. Science. 2004;306:666–9. This article presented the fundamental structure of graphene for the 1st time.

Wilson M. Electrons in atomically thin carbon sheets behave like massless particles. Phys Today. 2006;59:21–3.

Geim AK, Novoselov KS. The rise of graphene. Nat Mater. 2007;6:183–91.

Whitener KE, Sheehan PE. Graphene synthesis. Diam Relat Mater. 2014;46:25–34.

Bunch JS, Verbridge SS, Alden JS, et al. Impermeable atomic membranes from graphene sheets. Nano Lett. 2008;8:2458–62.

Shen H, Zhang L, Liu M, et al. Biomedical applications of graphene. Theranostics. 2012;2:283–94.

Goenka S, Sant V, Sant S. Graphene-based nanomaterials for drug delivery and tissue engineering. J Control Release. 2014;173:75–88.

La WG, Park S, Yoon H-H, et al. Delivery of a therapeutic protein for bone regeneration from a substrate coated with graphene oxide. Small. 2013;9:4051–60.

Pruna A, Pullini D, Soanca A 2017 Graphene-based coatings for dental implant surface modification Carbon-related mater recognit Nobel Lecture by Prof Akira Suzuki ICCE. Springer International Publishing 103–116

Xie H, Cao T, Rodríguez-Lozano FJ, et al. Graphene for the development of the next-generation of biocomposites for dental and medical applications. Dent Mater. 2017;33:765–74.

Allen MJ, Tung VC, Kaner RB. Honeycomb carbon: a review of graphene. Chem Rev. 2010;110:132–45.

Dreyer DR, Park S, Bielawski CW, et al. The chemistry of graphene oxide. Chem Soc Rev. 2010;39:228–40.

Pei S, Cheng HM. The reduction of graphene oxide. Carbon. 2012;50:3210–28.

Edwards RS, Coleman KS. Graphene synthesis: relationship to applications. Nanoscale. 2013;5:38–51.

Nanda SS, Papaefthymiou GC, Yi DK. Functionalization of graphene oxide and its biomedical applications. Crit Rev Solid State Mater Sci. 2015;40:291–315.

Compton OC, Nguyen ST. Graphene oxide, highly reduced graphene oxide, and graphene: versatile building blocks for carbon-based materials. Small. 2010;6:711–23.

Huang X, Yin Z, Wu S, et al. Graphene-based materials: synthesis, characterization, properties, and applications. Small. 2011;7:1876–902.

Feng L, Liu Z. Graphene in biomedicine: opportunities and challenges. Nanomedicine. 2011;6(2):317–24.

Iijima S. Helical microtubules of graphitic carbon. Nature. 1991;354:56–8.

Robertson DH, Brenner DW, Mintmire JW. Energetics of nanoscale graphitic tubules. Phys Rev B. 1992;45:12592–5.

Ajayan PM, Ebbesen TW, Ichihashi T, et al. Opening carbon nanotubes with oxygen and implications for filling. Nature. 1993;362:522–5.

Bethune DS, Klang CH, de Vries MS, et al. Cobalt-catalysed growth of carbon nanotubes with single-atomic-layer walls. Nature. 1993;363:605–7.

Ando Y. Carbon nanotube: the inside story. J Nanosci Nanotech. 2010;10:3726–38.

Jagadeesan D, Eswaramoorthy M. Functionalized carbon nanomaterials derived from carbohydrates. Chem-Asian J. 2010;5:232–43.

Vaisman L, Wagner HD, Marom G. The role of surfactants in dispersion of carbon nanotubes. Adv Colloid Interface Sci. 2006;128–130:37–46.

Dyke CA, Tour JM. Unbundled and highly functionalized carbon nanotubes from aqueous reactions. Nano Lett. 2003;3:1215–8.

Thess A, Lee R, Nikolaev P, et al. Crystalline ropes of metallic carbon nanotubes. Science. 1996;273:483–7.

Lourie O, Cox DM, Wagner HD. Buckling and collapse of embedded carbon nanotubes. Phys Rev Lett. 1998;81:1638–41.

Zhu J, Kim J, Peng H, et al. Improving the dispersion and integration of single-walled carbon nanotubes in epoxy composites through functionalization. Nano Lett. 2003;3:1107–13.

Ramanathan T, Fisher FT, Ruoff RS, et al. Amino-functionalized carbon nanotubes for binding to polymers and biological systems. Chem Mater. 2005;17:1290–5.

Li L, Xing Y. Pt−Ru Nanoparticles supported on carbon nanotubes as methanol fuel cell catalysts. J Phys Chem C. 2007;111:2803–8.

Di Crescenzo A, Ettorre V, Fontana A. Non-covalent and reversible functionalization of carbon nanotubes. Beilstein J Nanotech. 2014;5:1675–90.

Ma P-C, Siddiqui NA, Marom G, et al. Dispersion and functionalization of carbon nanotubes for polymer-based nanocomposites: a review. Compos Part A: Appl Sci Manuf. 2010;41:1345–67.

Lee JH, Han JH, Kim JH, et al. Exposure monitoring of graphene nanoplatelets manufacturing workplaces. Inhal Toxicol. 2016;28:281–91.

Yang K, Gong H, Shi X, et al. In vivo biodistribution and toxicology of functionalized nano-graphene oxide in mice after oral and intraperitoneal administration. Biomaterials. 2013;34:2787–95.

Wen KP, Chen YC, Chuang CH, et al. Accumulation and toxicity of intravenously-injected functionalized graphene oxide in mice. J Appl Toxicol. 2015;35:1211–8.

Sanchez VC, Jachak A, Hurt RH, et al. Biological interactions of graphene-family nanomaterials: an interdisciplinary review. Chem Res Toxicol. 2012;25:15–34.

Su WC, Ku BK, Kulkarni P, et al. Deposition of graphene nanomaterial aerosols in human upper airways. J Occup Environ Hyg. 2016;13:48–59.

Van Goethem F, Lison D, Kirsch-Volders M. Comparative evaluation of the in vitro micronucleus test and the alkaline single cell gel electrophoresis assay for the detection of DNA damaging agents: genotoxic effects of cobalt powder, tungsten carbide and cobalt-tungsten carbide. Mutat Res. 1997;392:31–43.

Singh N, Manshian B, Jenkins GJ, et al. NanoGenotoxicology: the DNA damaging potential of engineered nanomaterials. Biomaterials. 2009;30:3891–914.

Park C, Park S, Lee D, et al. Graphene as an enabling strategy for dental implant and tissue regeneration. Tissue Eng Regen Med. 2017;14:481–93.

Schinwald A, Murphy FA, Jones A, et al. Graphene-based nanoplatelets: a new risk to the respiratory system as a consequence of their unusual aerodynamic properties. ACS Nano. 2012;6:736–46.

Li B, Yang J, Huang Q, et al. Biodistribution and pulmonary toxicity of intratracheally instilled graphene oxide in mice. NPG Asia Mater. 2013;5:e44-e.

Tonelli FM, Goulart VA, Gomes KN, et al. Graphene-based nanomaterials: biological and medical applications and toxicity. Nanomedicine. 2015;10:2423–50.

Ou L, Song B, Liang H, et al. Toxicity of graphene-family nanoparticles: a general review of the origins and mechanisms. Part Fibre Toxicol. 2016;13:57.

Kurantowicz N, Strojny B, Sawosz E, et al. Biodistribution of a high dose of diamond, graphite, and graphene oxide nanoparticles after multiple intraperitoneal injections in rats. Nanoscale Res Lett. 2015;10:398.

Liu SY, Chen IW. Fatigue of yttria-stabilized zirconia: fatigue damage, fracture origins, and lifetime prediction. J Am Ceram Soc. 1991;74:1197–205.

Luthardt RG, Holzhüter M, Sandkuhl O, et al. Reliability and properties of ground Y-TZP-zirconia ceramics. J Dent Res. 2002;81:487–91.

Guazzato M, Albakry M, Ringer SP, et al. Strength, fracture toughness and microstructure of a selection of all-ceramic materials Part II Zirconia-based dental ceramics. Dent Mater. 2004;20:449–56.

Taskonak B, Yan J, Mecholsky JJ, et al. Fractographic analyses of zirconia-based fixed partial dentures. Dent Mater. 2008;24:1077–82.

Bormann K-H, Gellrich N-C, Kniha H, et al. Biomechanical evaluation of a microstructured zirconia implant by a removal torque comparison with a standard Ti-SLA implant. Clin Oral Implants Res. 2012;23:1210–6.

Hoffmann O, Angelov N, Zafiropoulos GG, et al. Osseointegration of zirconia implants with different surface characteristics: an evaluation in rabbits. Int J Oral Maxillofac Implants. 2012;27:352–8.

Covacci V, Bruzzese N, Maccauro G, et al. In vitro evaluation of the mutagenic and carcinogenic power of high purity zirconia ceramic. Biomaterials. 1999;20:371–6.

Roehling S, Astasov-Frauenhoffer M, Hauser-Gerspach I, et al. In vitro biofilm formation on titanium and zirconia implant surfaces. J Periodontol. 2017;88:298–307.

Scarano A, Piattelli M, Caputi S, et al. Bacterial adhesion on commercially pure titanium and zirconium oxide disks: an in vivo human study. J Periodontol. 2004;75:292–6.

Borgonovo AE, Censi R, Vavassori V, et al. Zirconia implants in esthetic areas: 4-year follow-up evaluation study. Int J Dent. 2015;2015:415029.

Becker J, John G, Becker K, et al. Clinical performance of two-piece zirconia implants in the posterior mandible and maxilla: a prospective cohort study over 2 years. Clin Oral Implants Res. 2017;28:29–35.

Roehling S, Woelfler H, Hicklin S, et al. A retrospective clinical study with regard to survival and success rates of zirconia implants up to and after 7 years of loading. Clin Implant Dent Relat Res. 2016;18:545–58.

Balmer M, Spies BC, Kohal R, et al. Zirconia implants restored with single crowns or fixed dental prostheses: 5-year results of a prospective cohort investigation. Clin Oral Implants Res. 2020;31:452–62.

Payer M, Heschl A, Koller M, et al. All-ceramic restoration of zirconia two-piece implants - a randomized controlled clinical trial. Clin Oral Implants Res. 2015;26:371–6.

Cionca N, Hashim D, Mombelli A. Zirconia dental implants: where are we now, and where are we heading? Periodontol. 2000;2017(73):241–58.

Schünemann FH, Galárraga-Vinueza ME, Magini R, et al. Zirconia surface modifications for implant dentistry. Mater Sci Eng C. 2019;98:1294–305.

Chung C, Kim YK, Shin D, et al. Biomedical applications of graphene and graphene oxide. Acc Chem Res. 2013;46:2211–24.

Kim J, Kim Y-R, Kim Y, et al. Graphene-incorporated chitosan substrata for adhesion and differentiation of human mesenchymal stem cells. J Mater Chem B. 2013;1:933–8.

Shin SR, Li YC, Jang HL, et al. Graphene-based materials for tissue engineering. Adv Drug Deliv Rev. 2016;105:255–74.

Jianan Su, Chen Y, Huang Q. Graphene nanosheet-induced toughening of yttria-stabilized zirconia. Appl Phys A. 2017;123:10.

Rojas MI, Leiva EPM. Density functional theory study of a graphene sheet modified with titanium in contact with different adsorbates. Phys Rev B. 2007;76:155415.

Jung HS, Choi Y, Jeong J, et al. Nanoscale graphene coating on commercially pure titanium for accelerated bone regeneration. RSC Adv. 2016;6:26719–24.

Jung HS, Lee T, Kwon IK, et al. Surface modification of multipass caliber-rolled Ti alloy with dexamethasone-loaded graphene for dental applications. ACS Appl Mater Interfaces. 2015;7:9598–607.

Shi YY, Li M, Liu Q, et al. Electrophoretic deposition of graphene oxide reinforced chitosan-hydroxyapatite nanocomposite coatings on Ti substrate. J Mater Sci Mater Med. 2016;27:48.

Su J, Du Z, Xiao L, et al. Graphene oxide coated titanium surfaces with osteoimmunomodulatory role to enhance osteogenesis. Mater Sci Eng C. 2020;113:110983.

Kou W, Akasaka T, Watari F, et al. An in vitro evaluation of the biological effects of carbon nanotube-coated dental zirconia. ISRN Dent. 2013;2013:296727.

Rodríguez AM, González-Orellana C, et al. Ageing-resistant zirconia/graphene-based nanostructures composites for use as biomaterials. J Eur Ceram Soc. 2022;42:1784–95.

Echeberria J, Rodríguez N, et al. Hard and tough carbon nanotube-reinforced zirconia-toughened alumina composites prepared by spark plasma sintering. Carbon. 2012;50:706–17.

Teixeira-Santos R, Gomes M, et al 2021 Antimicrobial and anti-adhesive properties of carbon nanotube-based surfaces for medical applications: a systematic review ISCIENCE. 33490909.

Zheng Y, Bashandeh K, et al. Review of dental tribology: current status and challenges. Tribol Int. 2022;166:107354.

Gallardo-López Á, Muñoz-Ferreiro C, et al. Critical influence of the processing route on the mechanical properties of zirconia composites with graphene nanoplatelets. Materials. 2021;14:108.

Rani S, Kumar M, Sharma S, et al. Role of graphene in structural transformation of zirconium oxide. J Sol-Gel Sci Technol. 2014;71:470–6.

Rincón A, Moreno R, et al. Colloidal processing of fully stabilized zirconia laminates comprising graphene oxide-enriched layers. J Eur Ceram Soc. 2016;36(7):1797–804.

Glukharev AG, Konakov VG. Synthesis and properties of zirconia-graphene composite ceramics: a brief review. Rev Adv Mater Sci. 2018;56:124–38.

Shin JH, Hong SH. Fabrication and properties of reduced graphene oxide reinforced yttria-stabilized zirconia composite ceramics. J Eur Ceram Soc. 2014;34:1297–302.

Obradović N, Kern F, et al. Properties of 3Y-TZP zirconia ceramics with graphene addition obtained by spark plasma sintering. Ceram. 2018;44:16931–6.

López-Pernía C, Muñoz-Ferreiro C, et al. Optimizing the homogenization technique for graphene nanoplatelet/yttria tetragonal zirconia composites: influence on the microstructure and the electrical conductivity. J Alloys Compd. 2018;767:994–1002.

Echeberria J, Ollo J, et al. Sinter and hot isostatic pressing (HIP) of multi-wall carbon nanotubes (MWCNTs) reinforced ZTA nanocomposite: microstructure and fracture toughness. Int J Refract Hard Met. 2010;28:399–406.

Zeng Z, Liu Y, Chen W, et al. Fabrication and properties of in situ reduced graphene oxide-toughened zirconia composite ceramics. J Am Ceram Soc. 2018;101:3498–507.

Ramesh S, Khan MM, Alexander Chee HC, et al. Sintering behaviour and properties of graphene oxide-doped Y-TZP ceramics. Ceram Int. 2016;42:17620–5.

Smirnov A, Solís Pinargote NW, Peretyagin N, et al. Zirconia reduced graphene oxide nano-hybrid structure fabricated by the hydrothermal reaction method. Materials (Basel). 2020;13:687.

Zhang C, Jiang Z, Zhao L, et al. Synthesis and characterization of multilayer graphene oxide on yttria-zirconia ceramics for dental implant. J Mater Res. 2020;35:2466–77.

Zhang C, Jiang Z, Zhao L. Mechanical properties and tribological behaviors of yttria-zirconia ceramics with additions of graphene oxide by hot-press sintering for dental implants. Surf Topogr Metrol Prop. 2020;8:035010.

Desante G, Labude N, Rütten S, et al. Graphene oxide nanofilm to functionalize bioinert high strength ceramics. Appl Surf Sci. 2021;566:150670. The authors developed a technique to immobilize GO film on the surface of zirconia, allowing osteogenic differentiation

Jang W, Kim HS, Alam K, et al. Direct-deposited graphene oxide on dental implants for antimicrobial activities and osteogenesis. Int J Nanomed. 2021;16:5745–54.

Qiu J, Geng H, Wang D, et al. Layer-number dependent antibacterial and osteogenic behaviors of graphene oxide electrophoretic deposited on titanium. ACS Appl Mater Interf. 2017;9:12253–63.

Liu M, Hao L, Huang Q, et al. Tea polyphenol-reduced graphene oxide deposition on titanium surface enhances osteoblast bioactivity. J Nanosci Nanotechnol. 2018;18:3134–40.

Ruiz ON, Fernando KAS, Wang B, et al. Graphene oxide: a nonspecific enhancer of cellular growth. ACS Nano. 2011;5:8100–7.

Zhao C, Pandit S, Fu Y, et al. Graphene oxide based coatings on nitinol for biomedical implant applications: effectively promote mammalian cell growth but kill bacteria. RSC Adv. 2016;6:38124–34.

Fallatah H, Elhaneid M, Ali-Boucetta H, et al. Antibacterial effect of graphene oxide (GO) nano-particles against Pseudomonas putida biofilm of variable age. Environ Sci Pollut Res. 2019;26:25057–70.

Zou X, Zhang L, Wang Z, et al. Mechanisms of the antimicrobial activities of graphene materials. J Am Chem Soc. 2016;138:2064–77.

Liu S, Zeng TH, Hofmann M, et al. Antibacterial activity of graphite, graphite oxide, graphene oxide, and reduced graphene oxide: membrane and oxidative stress. ACS Nano. 2011;5:6971–80.

Funding

Open access funding provided by University of Zurich

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Human and Animal Rights and Informed Consent

This article does not contain any studies with human or animal subjects performed by any of the authors.

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This article is part of the Topical Collection on Dental Restorative Materials

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Özcan, M., Volpato, C.A.M., Hian, L. et al. Graphene for Zirconia and Titanium Composites in Dental Implants: Significance and Predictions. Curr Oral Health Rep 9, 66–74 (2022). https://doi.org/10.1007/s40496-022-00310-3

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40496-022-00310-3