Abstract

Industrial wastewater discharged to a municipal sewage system may often be a source of valuable organic substrate for biological processes at a municipal wastewater treatment plant (WWTP). In such situations, the pre-treatment of wastewater at an industrial plant should be minimized, in order to maintain the favourable structure of organic material in influent to a WWTP. A frequent problem is how to determine the maximum industrial pollution load that can be discharged, without compromising the treatment capability of a WWTP. This article presents a method based on computer simulation that can be used for this purpose. As a result, the method produced the permissible industrial pollution load that could be discharged safely, and the relationship between chemical oxygen demand (COD) load and required biomass concentration as a function of process temperature. The method was tested at a fruit-processing plant and municipal WWTP, located in Poland. The results of this study have shown that the bioreactor should be operated at a biomass concentration varying between 3,600 and 5,400 g m−3 in function of the process temperature. Under such operational conditions, the WWTP would be able to accept the permissible industrial COD load of above 9,000 kg COD d−1 for a wide range of temperatures, namely 14–19 °C. If the WWTP was operated at a constant biomass concentration, its permissible industrial COD load would be reduced to 7,500–9,000 kg COD d−1. The method can be applied to other municipal WWTPs with activated sludge that receive industrial effluents.

Similar content being viewed by others

Introduction

Industrial effluents discharged to a sewage system may strongly affect the operation of a municipal wastewater treatment plant (WWTP). A large variability in flow rate, extreme concentrations of pollutants and the possible presence of pollutants that are resistant to biological treatment may disturb technological processes, increase operational costs and deteriorate the quality of the effluent. Industrial wastewater is usually pre-treated before discharge to a sewage system, in order to reduce pollution loads, but even then, treatment processes at a municipal WWTP may be disturbed (Mhlanga et al. 2009; Rédey et al. 2011). The situation is especially difficult when a WWTP applies a multistage activated sludge process, with integrated biological nutrient removal (BNR), that is very sensitive to the varying composition of wastewater (Metcalf and Eddy 2004; Wang et al. 2006). Biological denitrification and enhanced phosphorus removal processes require a constant supply of readily biodegradable organic substrate in an amount that, in practice, may be expressed by BOD5:TN and BOD5:TP ratios being at least 4 and 20, respectively (Janssen et al. 2002). Some types of industrial effluents may contain very high loads of N and P, and therefore, these conditions are sometimes not fulfilled in mixed wastewater, in influent received by a WWTP. Similar situations may arise if organic material, present in high concentrations in industrial effluent, has an unfavourable structure, represented by a high COD:BOD5 ratio (over 1.5–2), suggesting that wastewater is not easily treatable by biological methods, or may even contain some toxic components. On the other hand, some types of industrial wastewater contain organic pollutants that may become a valuable organic substrate for biological treatment processes. In such circumstances, pre-treatment is not necessary or may even be unfavourable from a WWTP operator’s point of view.

The presented situation generates several problems for the WWTP operator. The first is how to determine a permissible industrial pollution load that might be safely accepted at the plant, without exceeding its actual treatment capacity. Another problem is how to adjust the plant’s operational parameters so as not to exceed the effluent standards under a high and variable industrial pollution load. This question can be especially important when external conditions are changing continuously, e.g. wastewater temperature and rainwater flow. In such situations, the operation of biological processes is often based on the experience and intuition of the operator. The main objective of the presented research was to develop a method that can be used to determine the maximum industrial pollution load discharged to a municipal sewage system (called ‘permissible load’) that could be treated effectively at the WWTP. Once determined, this value could be used by a WWTP operator in negotiations with industrial plant operators, as a basis for setting quality standards for industrial effluents discharged to a municipal sewage system. In effect, the benefits would be mutual. On one hand, the industrial plant would save on the construction and operations costs of an on-site pre-treatment facility. On the other hand, the WWTP would receive wastewater with increased organic substrate content and would be able to fully utilize its wastewater treatment and sludge-processing capabilities. The developed method is presented in this article as a case study of Jaslo, a city located in south-eastern Poland. The research/study was carried out at the Institute of Water Supply and Environmental Protection, Cracow University of Technology, during late 2012 and early 2013. Analytical works were performed at the laboratory of the Municipal Public Utilities (MPGK) in Jaslo, Poland.

Materials and methods

Case study description

The fruit-processing plant is a major supplier of industrial wastewater in the city of Jaslo, located in south-eastern Poland. Typically, the effluent from the fruit-processing industry has a high content of organic material, suspended solids and various forms of nitrogen. Nevertheless, it is usually susceptible to biological treatment using anaerobic and aerobic methods (Borja and Banks 1994; Rajagopal et al. 2013). A major problem associated with the treatment of such wastewater is the high seasonal variability of pollutant concentrations and pollution load. In the studied case, the industrial wastewater generated at the fruit-processing plant was discharged directly into the combined sewage system, without any pre-treatment, and it was transported to the treatment plant. While the actual industrial flow rate was moderate, being about 10 % of total inflow to the WWTP, the pollution concentrations were very large reaching 5,000–6,000 g m−3 for COD, 1,500–2,500 g m−3 for TSS, and 80–100 g m−3 for TN (Table 1).

The fruit-processing plant is planning to expand its production capabilities in the near future, which would result in increased volume of wastewater. In this context, two alternative wastewater management options are considered by the plant’s operator. One of them is to encourage the fruit-processing plant operator to construct a new wastewater pre-treatment facility that would reduce the industrial pollution load before it is discharged into the municipal sewage system. However, the concern is that, during pre-treatment, the wastewater composition and the pollutants’ structure might be changed in a way that would be unfavourable for biological treatment processes occurring at the municipal WWTP. The other option assumes that industrial wastewater would continue to be discharged into the sewage system without any pre-treatment, as happens presently. In such a situation, despite the overall reduction in industrial pollutant loads, the efficiency of the technological processes at the WWTP would be affected, and the plant’s operational costs would grow, owing to the increased energy consumption for aeration and the environmental fees for discharged pollution loads. Nevertheless, the WWTP operator favours the latter option, as it expects that an increased supply of readily biodegradable organic substrate in industrial wastewater would be beneficial for biological treatment processes. The purpose of the research/study was to determine the permissible load of industrial pollution that can be accepted at the municipal WWTP, without impairing the plant’s efficiency and process reliability.

Organization

It was planned that the achievement of the project’s objective would require the realization of several subtasks. In the first stage, a detailed characterization of the industrial effluent was necessary to determine its susceptibility for biological treatment and to collect data required for the subsequent computer simulations. The simulations themselves were organized in three steps. During screening simulations, the performance of the WWTP was tested under four distinct operational scenarios that differed in process temperature and rainwater flow. For each scenario, a permissible industrial pollution load for the WWTP was determined. The criterion for the termination of a simulation was the attainment of the plant’s effluent discharge standards and/or the maximum values of the plant’s operational parameters, for example, blowers’ capacity. In the second step, a sensitivity analysis was performed for the operational scenario that was selected as the most likely to occur. Its purpose was to find the system’s response to changing operational parameters. In the third step, the effect of the process temperature in the reactor and the biomass concentration, on the permissible pollution load in industrial wastewater, was determined. The organizational structure of the research/study method is presented in Fig. 1.

Description of the WWTP

The studied WWTP is a middle-sized municipal mechanical–biological plant, situated in the city of Jaslo, in Poland. The plant was commissioned in the mid-1990s. Its design capacity is 95,000 person equivalent (PE), and the design wastewater flow is 20,000 m3 d−1. There are two technological lines in the wastewater treatment train. Mechanical treatment processes are typical and include screening, grit removal in circular grit tanks and primary sedimentation in circular horizontal settlers. In the biological treatment stage, the plant adopts high-effective activated sludge technology with integrated BNR. The biological reactors are designed according to the Johannesburg scheme, with anaerobic, anoxic and aerobic zones, and a separate anoxic zone for the denitrification of nitrates that may occur in the return sludge stream (Van Haandel and Van Der Lubbe 2012). Dissolved oxygen (DO) concentration is measured by one probe in the anoxic zone and two probes in the aerobic zone of each reactor, and controlled by a proportional-integral-derivative (PID) algorithm. Air is supplied to the aerobic part of the activated sludge reactor through fine-bubble tube diffusers, manufactured by OTT System GmbH. Five centrifugal blowers with a total design capacity of 2.3 m3 s−1 are equipped with variable frequency drives. Biomass is separated from wastewater in two horizontal circular secondary clarifiers. Mechanically thickened excess sludge and gravitationally thickened primary sludge are stabilized in a single-stage mesophilic anaerobic digestion process. Biogas is utilized for plant heating and electric energy generation.

In recent years, the plant’s capacity has been underexploited, owing to the significant reduction in water consumption in the area. With an average wastewater flow of 8,055 m3 d−1, only one of the two existing biological reactors is used. At present, industrial effluents constitute about 10–15 % of the wastewater flow in influent to the WWTP, but almost 50 % and even 57 % in terms of COD and BOD5 load, respectively (Table 1). After the planned expansion of the fruit-processing plant’s production capacity, the industrial effluent flow rate may increase up to 1,600 m3 d−1 from its present value of 774 m3 d−1. In this situation, the majority of the pollution load in influent to the WWTP would be of industrial origin. Therefore, it is essential for the WWTP’s operator to determine the permissible industrial pollution load that it can handle effectively.

Modelling tools

Simulations were performed with the GPS-X v.6.1 software package developed by Hydromantis Inc (2011). The model of the WWTP included only wastewater treatment trains, with primary sedimentation, biological reactors and secondary clarification (Fig. 2). Separate influent streams were defined for municipal wastewater and for industrial effluent from the fruit-processing plant. The effect of sludge treatment on the plant operation was considered as a separate inflow of process water from the sludge-processing line. Rainwater was supplied to the influent to the plant as a separate stream, in order to allow for easy modification of its flow rate during simulation. The model included two technological trains, but during simulations two primary settlers with only one biological line were usually used, as this was the operational option preferred by the WWTP’s operator.

Experience showed that a detailed characteristic of influent wastewater was essential for effective model calibration and successful simulations (Xu and Hultman 1996; Mikosz 1999; Pasztor et al. 2009; Mąkinia 2010; Rieger et al. 2010). During the research/study, all influent streams were defined with the ‘tsscod’ influent model, originally developed based on the Activated Sludge Model no. 2d (ASM2d). In this influent model, wastewater composition is defined mainly by COD value, concentrations of TSS and total Kjeldahl nitrogen, and a few state variables. Primary sedimentation and secondary sedimentation were modelled as one-dimensional non-reactive processes (Hydromantis Inc 2011). For the modelling of biochemical processes in the activated sludge reactor, the ASM2d was selected. Both the ‘tsscod’ influent model and ASM2d biochemical model belong to the same process library (CNPLIB) and use a coherent set of state variables. The ASM2d takes account of carbon oxidation, nitrification, denitrification and biological excess phosphorus removal (Henze et al. 1999). Its major advantage is that it describes the role of phosphorus-accumulating organisms in phosphorus utilization under aerobic conditions and in denitrification. A major weakness of the model is that it usually over-parameterized the available data and was difficult to calibrate (Brun et al. 2002; Garcia-Usach et al. 2010; Boontian 2012). Still, in practice, it well describes the processes occurring in multistage integrated biological reactors.

Model calibration

Effective model calibration is essential for successful simulation. Various model calibration protocols have been proposed by different groups, in order to systematize the calibration procedures. Among the best known protocols are BIOMATH, HSG, STOWA and WERF. They all have their strengths and weaknesses, and a comprehensive critical analysis of them is presented by Sin et al. (2009). Besides these formal protocols, there are also other attempts to simplify or automate the typical trial and error calibration procedures (Sin et al. 2008; Lee et al. 2008). Despite various tools and methods that can help in the model calibration, its detail course, extent and required level of accuracy often depend on the experience of a researcher and the specificity of the case. Calibration of the ASM2d is more complicated than the calibration of other activated sludge models, and efforts are undertaken to simplify the calibration procedure and to restrict the range of parameters that need to be adjusted (Brun et al. 2002; Boontian 2012).

The model of the studied WWTP was constructed a few years before this research/study, and since then, it has been used on several occasions. When the model was first developed, it was calibrated according to the typical detailed procedure, which included iterative static and dynamic calibration and model validation. Detailed description is presented in Mikosz (1999). The model usually needs to be checked and recalibrated each time it is used for the optimization of the existing plant, but for many simulation studies, a lower quality of calibration and validation is sufficient (Langergraber et al. 2004). As the model proved to be effective in the past, this time it was only recalibrated statically. The data used for calibration were collected during a measurement campaign in December 2012 (Mikosz 2013). During calibration that was performed for a wastewater temperature of 14.5 °C, it was necessary to adjust only the values of maximum specific growth rate of poly-P accumulating biomass μ PAO from 1.0 to 1.55 d−1, and autotrophic decay rate b A from 0.15 to 0.1 d−1. The values refer to standard process temperature of 20 °C, and the temperature dependence of these parameters is described by an Arrhenius equation, with temperature correction constant θ equal to 1.041 for μ PAO and 1.111 for b A. The final values of the most important kinetic constants after calibration are presented in Table 2, and the comparison of actual measurements and simulated values in effluent before and after model calibration is shown in Table 3.

Results and discussion

Industrial effluent characteristics

A detailed qualitative characteristic of the industrial effluent was essential in the study. As presented in Table 1, the industrial wastewater had a high content of organic matter represented by COD, and a relatively small content of nitrogen and phosphorus. The values of BOD5:TN and BOD5:TP ratios, during the research/study period in 2012, were 34.3 and 645, respectively. This is more than the recommended values of 4 and 20 (Janssen et al. 2002). It should also be noted that these ratios in municipal wastewater in influent to the WWTP were 3.7 and 27.8, respectively, which means there might be a slight deficit of organic carbon for biological treatment processes. At first glance, it seems that the addition of industrial effluent to the municipal wastewater would be advantageous for the WWTP, as the ratio of BOD5:TN would increase to 7.5 and the ratio of BOD5:TP to 60.7. This, however, should be verified with more detailed analyses.

Computer simulation requires a very precise description of influent wastewater composition, especially concerning the structure of organic pollutants, represented by fractions of COD. In the ASM2d, which was used in this research, the total content of organic material in wastewater, represented by total COD (tCOD), includes six major fractions in dissolved (S) and suspended (X) forms (Eq. 1):

The other fractions (e.g. autotrophic nitrifying biomass X AUT, phosphorus-accumulating microorganisms X PAO and internal storage products of phosphorus-accumulating organisms X PHA) are assumed to be less than 1 % of total COD, and usually, they are not measured (Pasztor et al. 2009). The fractions can be quantified with a range of methods, including a combination of physical, analytical (S F), respirometric tests (X H, S S, S I), simulation (X I) and mass balance calculations (X S) (Dulekgurgen et al. 2006; Mhlanga et al. 2009; Mąkinia 2010; Xu and Hultman 1996; Fall et al. 2012). The soluble inert fraction (S I) can also be determined directly by analysis of coagulated and filtered effluent from an activated sludge system (Mamais et al. 1993).

In this research/study, the fractionation of COD was performed on three different samples of industrial wastewater. They were collected in December 2012, as 24-h flow-proportional composite samples. The collected samples were analysed (COD, BOD5, TSS, VSS, TN, ammonia, nitrates, nitrites and TP), according to the standard methods, and the concentration of volatile fatty acids (VFA) was measured with gas chromatography. Then, the collected samples were used to supply a lab-scale activated sludge reactor with extended aeration. Measurements of COD were done in flocculated (ZnSO4) and filtered (0.45 μm) samples collected from influent (CODfin) and effluent (CODfeff). Inert fraction (S I) was calculated as 90 % of CODfeff. Acetate fraction (S A) was equal to concentration of VFA in the collected samples of industrial wastewater. The fermentable fraction (S F) was calculated as CODfin − S A − S I. Heterotrophic biomass fraction (X H) was determined using the typical method of comparing the measured oxygen uptake rate (OUR) to a maximum OUR for active heterotrophic biomass (150 g O2 g VSS−1 h−1) (Xu and Hultman 1996). The slowly biodegradable substrate fraction (X S) was calculated as BOD ultimate − S A − S F, and particulate inert fraction (X I) was calculated as a difference between tCOD and all other fractions (X I = tCOD − S A − S F − S I − X S − X H). The fractionation of municipal wastewater was performed on three different wastewater samples, collected in November 2012. The applied methodology was almost the same as the one for industrial wastewater, but instead of a lab-scale activated sludge reactor, an effluent from the secondary clarifier was used to determine the S I fraction.

The average COD value in industrial wastewater was 5,196 g COD m−3 and standard deviation 2,417 g COD m−3. The research/study showed that the dominating fraction of COD in effluent from the fruit-processing plant was S F (average 3,246 g COD m−3, SD 2,012 g COD m−3) that accounted for about 62 % of total COD. The acetate fraction S A was practically absent in the studied wastewater, with an average concentration of 3.2 g COD m−3. The content of slowly biodegradable substrate X S was 18 % (on average 931 g COD m−3, SD 86 g COD m−3) and particulate inert material X I only 4 % (on average 205 g COD m−3, SD 19 g COD m−3). The remaining 16 % was soluble inert organic material SI (on average 811 g COD m−3, SD 503 g COD m−3). There was practically no heterotrophic biomass in the studied wastewater. The fractionation of municipal wastewater without industrial component was as follows: tCOD = 567 g COD m−3; S F = 348 g COD m−3 (61.4 %); S A = 6.4 g COD m−3 (1.1 %); S I = 39 g COD m−3 (6.9 %); X S = 128 g COD m−3 (22.6 %); X H = 14 g COD m−3 (2.5 %); X I = 31 g COD m−3 (5.5 %). The analyses confirmed that the structure of organic material in industrial effluent was potentially very advantageous for advanced biological treatment, and the major concern was whether the WWTP’s treatment capacity would be sufficient to manage the organic pollution load supplied with industrial effluent.

Simulations

Operational scenarios

During the first stage of the simulations, four different operational scenarios (A–D) were tested, in order to get an overall picture of the WWTP’s performance under a possible increased industrial pollution load. The scenarios were chosen to reflect extreme operational conditions that, in the past, used to affect the WWTP’s operation. While the influent wastewater composition was relatively unvarying in time, the factors that affected the WWTP’s operation the most were increased rainwater flow during prolonged rain periods and process temperature in the biological reactor. Sometimes, these conditions occurred separately and sometimes coincidentally. Thus, two scenarios (A and B) assumed no rainwater flow (called ‘dry weather conditions’) and process temperatures of 18 and 12 °C, respectively. Two other scenarios (C and D) presumed rainwater flow at an average level of 6,000 m3 d−1 (called ‘wet weather conditions’) and process temperatures of 18 and 12 °C, respectively. Scenario A with low flow rate and high process temperature was the most propitious for the WWTP’s operation, while scenario D represented the most unfavourable operational conditions. Rainwater was characterized with a COD value of 281 g COD m−3, TSS of 316 g m−3, TN of 8 g N m−3 and TP of 2.5 g P m−3.

Screening simulations

In the screening simulation results, it was concluded that rainwater flow had relatively little impact on the plant’s capability to accept the increased pollution load. Under wet weather conditions, the WWTP’s permissible capacity was only reduced by 5–12 % (Table 4). The limiting factors were the capacity of blowers installed at the plant (at wastewater temperature 18 °C) and the concentration of total nitrogen in effluent (at temperature 12 °C). Thus, dry weather scenarios (A, B) were selected as the most representative for the planned sensitivity analysis.

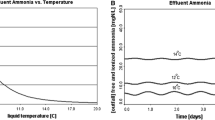

Sensitivity analysis

The developed model was subjected to sensitivity analysis, as presented in Table 5. In the first step, the effect of changing process temperature was tested in the range of 12–20 °C for dry weather and wet weather conditions (Fig. 3a). Biomass concentration was maintained at a constant level of 5,000 g MLSS m−3. The analysis has shown that the largest industrial pollution load of approximately 9,200 kg COD d−1 can be accepted and treated effectively at a process temperature of approximately 15 °C. At lower temperatures, increasing the permissible plant’s loading was limited by the TN concentration in the effluent that reached a permitted value of 15 g N m−3. At temperatures greater than 15 °C, the limiting factor was increased oxygen demand for biological processes, which exceeded the maximum capacity of the blowers installed at the plant. The effect of rainwater flow on the plant’s permissible capacity was small, and only observed practically under low temperature conditions.

The analysis has shown that the form in which organic matter is present in industrial wastewater is important for its effective treatment. As presented in the graph (Fig. 3b), the COD:BOD5 ratio in industrial influent should be kept below 1.25, in order to assure that the COD value in treated wastewater does not exceed the permitted value of 125 g COD m−3. For values of COD:BOD5 ratio larger than 1.25, there is a risk that inert fractions of COD (S I and X I) contained in industrial wastewater might be transferred to the effluent.

In the next step, the effect of the MLSS concentration on the permissible plant treatment capacity under different temperatures was analysed. The industrial flow rate was used as a varied parameter, which can be easily recalculated into the industrial pollution load, assuming an industrial COD value from Table 1 (5,196 g COD m−3). The results have shown that the acceptance of large industrial pollution load would require varying MLSS concentrations in the bioreactor, according to the process temperature. Under low temperature conditions (12 °C), the system should be operated at high MLSS, reaching up to 5,800 g MLSS m−3 (Fig. 3c). A permissible industrial COD load that can be accepted at the plant under these conditions was 7,400 kg COD d−1 (at flow of 1,424 m3 d−1), while a limiting factor was the concentration of TN in effluent (15 g N m−3). Analysis has shown that at a high process temperature (18 °C), biomass concentration should be reduced to 3,800 g MLSS m−3, owing to increased oxygen demand that may exceed the capacity of the blowers installed at the WWTP (equal to 198,700 m3 d−1). The permissible industrial COD load under these conditions was 9,300 kg COD d−1, at flow rate 1,790 m3 d−1 (Fig. 3d).

Permissible industrial pollution load

Results of the sensitivity analysis and the detailed characteristics of industrial effluent became the basis for a series of simulations. For each simulation, a permissible COD load in industrial wastewater was determined, together with its corresponding required biomass concentration. The simulations were repeated for different process temperatures in the range of 12–20 °C. The criteria for the termination of a simulation were either reaching the allowable TN concentration in effluent from the WWTP, or reaching the maximum capacity of the aeration system. The results are presented in Fig. 4. In the graph, the permissible COD load in industrial effluent is associated with the required biomass concentration at a specific process temperature. It can be seen that the WWTP is capable of the effective treatment of the load over 9,000 kg COD d−1, under a wide range of temperatures, 14–19 °C. However, it is necessary that biomass concentration in the bioreactor is adjusted in the range of 3,600–5,400 g MLSS m−3. This is a significant improvement when compared to a situation when the bioreactor is operated at a constant MLSS (Fig. 3a). In practice, in order to assure the required plant’s capacity, the WWTP’s operator should adjust biomass concentration in the bioreactor, according to seasonal changes in process temperature (high MLSS in winter; low MLSS in summer).

Conclusion

Some industrial effluents discharged into municipal sewage systems carry valuable organic substrate that may be favourable for biological treatment processes. Examples of such industries are breweries and fruit-processing plants. In such situations, the pre-treatment of wastewater at an industrial plant should be minimized or even avoided, in order to maintain the favourable structure of organic material in influent to a WWTP. This may, however, result in the delivery of an industrial pollution load that may exceed the treatment capacity of a municipal WWTP. In order to avoid this, a permissible industrial pollution load should be determined for individual municipal WWTPs. This problem was researched as a case study, presented in this article.

The proposed research procedure allowed for determining the permissible industrial COD load for the studied plant. In order to be able to accept the increased industrial pollution load, it was concluded that the activated sludge process at the WWTP should be operated at MLSS that vary in the range of 3,600–5,400 g MLSS m−3, in function of the process temperature. Under such operational conditions, the WWTP would be able to accept the permissible industrial COD load at the level over 9,000 kg COD d−1 for a wide range of temperatures, namely 14–19 °C. If the WWTP was operated at a constant MLSS, its permissible industrial COD load would be reduced to 7,500–9,000 kg COD d−1, depending on the process temperature.

The project was carried out in several steps that include: the detailed characterization of industrial effluent; the development and calibration of the model of a municipal WWTP; the performance of screening simulations; the selection of representative operational scenarios; sensitivity analysis; and a series of final simulations. The result is the relationship of a permissible industrial COD load and a required biomass concentration, as a function of process temperature. This relationship can be presented in the form of a graph and may be used directly during the daily operation of an activated sludge system at a municipal WWTP. However, it should be noted that, in practice, some difficulties with the accurate adjustment of biomass concentration might occur at WWTPs that are not equipped with reliable MLSS control systems.

References

Boontian N (2012) A calibration approach towards reducing ASM2d parameter subsets in phosphorus removal processes. World Acad Sci Eng Technol 64:984–990

Borja R, Banks CJ (1994) Kinetic study of anaerobic digestion of fruit-processing wastewater in immobilized-cell bioreactors. Biotechnol Appl Bioc 20:79–92

Brun R, Kühni M, Siegrist H, Gujer W, Reichert P (2002) Practical identifiability of ASM2d parameters—systematic selection and tuning of parameter subsets. Water Res 36:4113–4127

Dulekgurgen E, Doğruel S, Karaham Ö, Orhon D (2006) Size distribution of wastewater COD fractions as an index for biodegradability. Water Res 40(2):273–282

Fall C, Millán-Lagunas E, Bâ KM, Gallego-Alarcón I, García-Pulido D, Díaz-Delgado C, Solís-Morelos C (2012) COD fractionation and biological treatability of mixed industrial wastewaters. J Environ Manage 113:71–77

Garcia-Usach F, Ribes J, Ferrer J, Seco A (2010) Calibration of denitrifying activity of polyphosphate accumulating organisms in an extended ASM2d model. Water Res 44:5284–5297

Henze M, Gujer W, Mino T, Matsuo T, Wentzel MC, Marais GR, Van Loosdrecht MCM (1999) Activated sludge model No. 2d. Wat Sci Technol 39(1):165–182

Hydromantis Inc (2011) GPS-X version 6.1. Technical Reference. Hamilton, Ontario, Canada

Janssen PMJ, Meinema K, van der Roest HF (2002) Biological phosphorus removal: Manual for design and operation. London, STOWA Report. IWA, London

Langergraber G, Rieger L, Winkler S, Alex J, Wiese J, Owerdieck C, Ahnert M, Simon J, Maurer M (2004) A guideline for simulation studies of wastewater treatment plants. Wat Sci Technol 50(7):131–138

Lee W-Y, Kim M-H, Yoo CK (2008)The model calibration protocol for parameter estimation of activated sludge model. In: Proceedings of the international conference on control, automation and systems, Seoul, pp 2616–2621

Mąkinia J (2010) Mathematical modelling and computer simulation of activated sludge systems. IWA, London

Mamais D, Jenkins D, Pitt P (1993) A rapid physical-chemical method for the determination of readily biodegradable soluble COD in municipal wastewater. Water Res 27(1):195–197

Metcalf and Eddy (2004) Wastewater Engineering, Treatment and Reuse, 4th edn. McGraw-Hill, New York

Mhlanga FT, Brouckaert CJ, Foxon KM, Fennemore C, Mzulwini D, Buckley CA (2009) Simulation of a wastewater treatment plant receiving industrial effluents. Water SA 35(4):447–454

Mikosz J (1999)Application of computer simulation for selection of the best operational strategy of nutrients removal from municipal wastewater (in Polish). Doctoral Dissertation, Cracow University of Technology

Mikosz J (2013) Assessment of the potential of municipal wastewater treatment plant in Jasło to treat industrial effluent from the fruit-processing industry (in Polish). Research report no. ZWK-R/12143/2012, Cracow University of Technology

Pasztor I, Thury P, Pulai J (2009) Chemical oxygen demand fractions of municipal wastewater for modeling of wastewater treatment. Int J Environ Sci Tech 6(1):51–56

Rajagopal R, Torrijos M, Kumar P, Mehrotra I (2013) Substrate removal kinetics in high-rate upflow anaerobic filters packed with low-density polyethylene media treating high-strength agro-food wastewaters. J Environ Manage 116:101–106

Rédey Á, Somogyi V, Ányos J, Domokos E, Thury P, Yuzhakova T (2011) Simulation of the influence of industrial wastewater on a municipal sewage treatment plant—a case study. Environ Sci Pollut R 18(2):192–198

Rieger L, Takacs I, Villez K, Siegrist H, Lessard P, Vanrolleghem PA, Comeau Y (2010) Data reconciliation for wastewater treatment plant simulation studies—planning for high-quality data and typical sources of errors. Water Environ Res 82(5):426–433

Sin G, De Pauw DJW, Weijers S, Vanrolleghem PA (2008) An efficient approach to automate the manual trial and error calibration of activated sludge models. Biotechnol Bioeng 100(3):516–528

Sin G, Van Hulle SWH, De Pauw DJW, van Griensven A (2009) A critical comparison of systematic calibration protocols for activated sludge models: a SWOT analysis. Water Res 39:2459–2474

Van Haandel AC, Van Der Lubbe JGM (2012) Handbook of biological wastewater treatment: design and optimisation of activated sludge systems. IWA, London

Wang X, Peng Y, Wang S, Fan J, Cao X (2006) Influence of wastewater composition on nitrogen and phosphorus removal and process control in A2O process. Bioproc Biosyst Eng 28(6):397–404

Xu S, Hultman B (1996) Experiences in wastewater characterization and model calibration for the activated sludge process. Wat Sci Technol 33(12):89–98

Acknowledgments

The research was financially supported by the Municipal Public Utilities (MPGK) in Jaslo (Poland), grant number ZWK-R/12143/2012.

Author information

Authors and Affiliations

Corresponding author

Appendices

Nomenclature

- ASM2d:

-

Activated Sludge Model no. 2d

- BOD:

-

Biochemical oxygen demand

- COD:

-

Chemical oxygen demand

- MLSS:

-

Mixed liquor suspended solids

- PE:

-

Person equivalent

- TN:

-

Total nitrogen

- TP:

-

Total phosphorus

- TSS:

-

Total suspended solids

- VSS:

-

Volatile suspended solids

List of symbols

- S A :

-

Fermentation products (acetate) [g m−3]

- S F :

-

Fermentable substrates (g m−3)

- S I :

-

Soluble inert organic material (g m−3)

- X S :

-

Slowly biodegradable substrate (g m−3)

- X I :

-

Particulate inert organic material (g m−3)

- X H :

-

Heterotrophic biomass (g m−3)

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Mikosz, J. Determination of permissible industrial pollution load at a municipal wastewater treatment plant. Int. J. Environ. Sci. Technol. 12, 827–836 (2015). https://doi.org/10.1007/s13762-013-0472-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-013-0472-0