Abstract

Environmental concerns about carbon emissions coupled with the oil industry’s need to secure additional CO2 for enhanced oil recovery (CO2-EOR) projects have sparked interest in the potential that CO2-EOR may have in jumpstarting carbon capture and sequestration (CCS). However, existing studies on the viability of coupling CO2-EOR with CCS have generally placed more focus on either the engineering or economic aspects of the problem. Most engineering studies focus on the technical aspects of the CO2-EOR project to produce the maximum amount of oil, while simultaneously storing the most CO2 during the production process with the economics as an afterthought, while most economic studies found have focused on a singular aspect of the issue such as impacts of exogenously varying injection rates. Furthermore, modelling efforts have stopped at the end of the productive life of the field. We build a unique two-stage dynamic optimization model, which simultaneously addresses engineering and economic policy aspects, to study the viability of coupling CO2-EOR transitioning into CCS. Our model includes a carbon tax for emissions, which becomes a subsidy for full scale sequestration after oil production has ceased; this allows us to explore the transition from CO2-EOR, our first stage, to sole CO2 sequestration in our second stage for a single field. We maximize the operator’s profits across both stages, while tracking the responsiveness of oil production and total carbon movements to both price and policy changes. We pair our optimization model with a reservoir simulation model, allowing us to mimic actual field behavior, giving our work a more realistic representation of both production and sequestration profiles. Our results suggest that small increases in the level of carbon tax can have large and discontinuous impacts on net sequestration. This stems from the observed transition from limited natural sources of CO2 to more expensive captured CO2 resulting from the implemented policy. With appropriate taxes, total volumes of captured CO2 sequestered across both stages are equivalent to 30 to 40% of the emissions from the use of the oil produced. With the credits oil producers receive from sequestering CO2, which equate to the tax, relatively high carbon taxes incentivize additional sequestration without significantly impacting the supply of oil. This, alongside maintaining a steady stream of profits, is a win-win situation for energy security and the climate.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

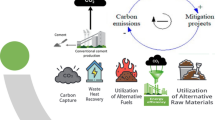

The International Energy Agency (IEA) asserts that emissions from continued use of fossil fuels at current rates of consumption could increase average global temperature by almost 4.0 °C by 2100, while carbon capture and sequestrations’ (CCS) technical viability and capability of abating immense amounts of this CO2 per year make it a strong contender in mitigating these emissions. Yet, commercial deployment of CCS has been stunted from the lack of any significant carbon price coupled with the prohibitive cost of implementation, technological uncertainties in performance for large-scale stationary sources, and the absence of guaranteed storage sites. At the same time, the oil industry’s infrastructure, expertise, and decades of experience in separating, transporting, injecting, and sequestering CO2 in underground oil reservoirs make it a logical partner in improving commerciality of CCS (IEA 2017).

The one study found, Leach et al. (2011), which addresses how the producer will co-optimize oil recovery and CO2 sequestration in a dynamic optimization framework, has not considered multiple sources of CO2 and also stopped at the end of the productive life of the field. Their model maximizes the producer’s profits subject to a policy that penalizes the producer for every unit of CO2 emitted and credits them for every unit of CO2 sequestered. Their stylized model of a CO2 for enhanced oil recovery (CO2-EOR) project is constructed in an optimal control framework and makes use of numerical simulations to solve for the resulting time paths. Although their findings are sound qualitatively, van’t Veld et al. (2014) suggest use of Leach et al.’s dynamic optimization model in conjunction with a reservoir simulation model. We follow their suggestion to better represent how production and sequestration profiles respond to injection.

Shifting to a world where atmospheric disposal of CO2 is no longer free, policy makers, who will be influencing CO2 prices, and oil companies, which will be reacting to them, all need more knowledge of the potential role that CO2-EOR transitioning to full scale CCS might play. As such, there exists an opportunity for a CO2 market to develop where carbon capture facilities supply the CO2 to EOR projects. Then, CO2, typically considered a negative externality, which needs to be regulated, would have a market that values it as an input in production. In this paper, we explore this potential transition on a single field level, building on the limited previous work, via the coupling of a reservoir simulation model with a two-stage dynamic optimization model that captures this transition.

Given that the reservoir’s storage capacity for CO2 is dependent on historical production activities, our two-stage dynamic optimization allows us to evaluate the producer’s tradeoff between oil production and CO2 sequestration capacity. The producer must balance the amount of oil they produce and how they produce it against how much CO2 they would be able to sequester during and beyond oil production activities. In our model, the government introduces market forces with a carbon tax for emissions and use of CO2 from natural accumulations as well as a carbon subsidy for sequestration. Our model identifies and quantifies relevant factors that lead to the transition from CO2-EOR to CCS. It also enables us to evaluate the producer’s responsiveness to oil price and imposed policy while they manage their three non-renewable resources which also represent our state variables: oil stock, natural CO2 stock, and CO2 sequestration capacity. We also track the usage and sequestration of all CO2 during the two stages from both natural reservoirs of CO2 and anthropogenic sources.

These simulations allow us to generate the time paths of both injection and production for a range of oil prices and carbon taxes. The major findings relate to these optimal time paths, the time of switch from one stage to the next, total volumes of captured CO2 sequestered, total oil produced, when to terminate the project, and how these outputs are influenced by the interaction between geological, technical, and market conditions. Our results inform oil producers and policy makers on the optimal design and response to a market for CO2 and shed light on how inherent physical production and reservoir constraints impact the producer’s response to market mechanisms (e.g., prices and tax levels).

In the reservoir

The evaluation is conducted from the perspective of a profit maximizing EOR producer to study the factors that influence the management of their oil stock and CO2 sequestration capacity that are interdependent. We model an individual field to develop an appropriate base with the potential to scale up the evaluation to a regional or even an international level. We start with a reservoir simulation model to help us develop technical equations for oil production and sequestration in both stages: CO2-EOR and CCS. These technical equations, developed from and calibrated to the reservoir simulation output, are then entered into our two-stage dynamic optimal control model. The complexity of our resulting optimization equations makes it challenging to analyze our dynamic optimization model theoretically. As such, we conduct a series of numerical simulations of our dynamic optimization model using GAMS software.

Leach et al. (2011) use a field level optimal control model to evaluate how a CO2-EOR producer can maximize the net present value (π) of an EOR project through the choice of the optimal rate of CO2 injection (\( {q}_i^c(t) \)), constrained by a fixed oil stock (R(t)). They include a tax policy where the producer pays a tax (τ) for a produced barrel of oil according to the amount of CO2 emitted when the oil they produce is consumed and credits them for each unit of CO2 they sequester. Their model determines the economic productive field life along with the optimal CO2 injection, oil production, and sequestration profiles. In doing so, Leach et al. endogenize oil production decline as well as the optimal time to terminate the project.

We build on the Leach et al. model not only adopting their notation and parameter values, wherever possible, but also extending it in several ways. We track usage of CO2 from natural accumulations of CO2 and from captured anthropogenic sources. We also optimize on a single oil field with initial reserves set at one million barrels, but we add a second stage to the dynamic optimization by modelling sequestration activities after oil production stops. This enables us to evaluate the transition to only CCS and the producer’s responsiveness to the price of oil and the carbon tax/subsidy policy. We use a reservoir simulation model to help us achieve more realistic representations of injection, production, and sequestration profiles across both stages of our dynamic optimization model.

During the primary or initial stage of production from a reservoir, we generally observe unassisted flow from wells as the reservoir is sufficiently pressurized to drive the oil to the surface. Oil wells usually reach the height of their production shortly after they are brought on-stream and soon thereafter experience production decline, at a rate we represent as (δ), mainly resulting from falling pressure drive. This yields an oil production rate in barrels at time (t) of q p o(t) = δR(t), where R(t) is remaining oil reserves. Then, our equation of state for our reserves stock is as follows:

To mitigate the loss in pressure drive as reserves fall, producers inject fluids, at a rate of q i (t), into the reservoirs to provide the necessary pressure support and help sweep oil remaining in the reservoir. Our resulting decline rate then becomes a function of total injection δ(q i (t)) with our oil production function (q p o( t ) = δ(q i (t)) × R(t)). (Donaldson et al. 1985; Fetkovich et al. 1996).

During the CO2-EOR stage, an injection process called water alternating gas (WAG) is gaining significant popularity for improving oil recovery. The alternating injection of our injected fluids CO2 ((\( {q}_i^c(t) \))Footnote 1 and water \( \Big({q}_i^w(t) \)) to enhance oil recovery has the advantage of coupling the improved microscopic displacement efficiency of gas flooding with the improved macroscopic sweep efficiency of water injection. The result is an improvement in recovery compared to separate gas or water injection schemes. Water flooding sweeps most of the reservoir leaving a smaller amount of oil behind compared to CO2 which can finger around some of the oil leaving it behind. On the other hand, CO2 dissolves into the oil reducing its viscosity and allowing for easier mobility of the oil in the reservoir and subsequently to the surface. In our modelling efforts, we emulate a WAG recovery technique. As such, our production decline function will be dependent on the injection of both water and CO2. It should be noted that injected volumes of both fluids will either be produced with the oil or fill available pore space in the reservoir.

During the production stage of the model, the following material balance requirement must hold. Total injection must equal total production. Thus, CO2 \( \left({q}_i^c(t)\right) \)and H2O \( \left({q}_i^w(t)\right) \)injected must equal CO2 \( \left({q}_p^c(t)\right) \), H2O \( \left({q}_p^w(t)\right) \), and oil produced (\( {q}_p^o(t) \)). Note that all CO2 volumes are converted from tonnes (tCO2) to reservoir barrels (rb) at a rate of 9.5 rb/tCO2. Material balance is coupled with the requirement of maintaining a minimum level of pressure within the reservoir (minimum miscibility pressure) to allow the CO2 to dissolve in the oil guaranteeing the success of the CO2-EOR operation. Miscibility occurs when both the displacing and displaced fluid mix in all proportions without interference leading to higher and more efficient recovery of oil. Maintaining this minimum pressure level requires a constant overall injection rate, which is achieved by injecting alternating volumes of CO2 and water. The volumes injected of each will vary depending on technical and economic conditions. Fluctuation in the rate of CO2 injection necessitates fluctuation in the rate of water injection to meet the total injection rate required to achieve the minimum miscibility pressure.

To simulate the CO2-EOR process and determine the constant overall injection rate as well as how the mix of CO2 and water affect the oil production decline rate, how much CO2 and water are produced, and how much are left in the reservoir, we turn to Schlumberger’s eclipse reservoir simulator. We input all necessary reservoir parameters (pressure, porosity, permeability, and total reserves) for a typical carbonate reservoir and use the output to help us determine how total injection, q i (t), for our designed WAG process, impacts both our oil production \( \left({q}_p^o(t)\right) \) and CO2 sequestration rates \( \left({q}_s^c(t)\right) \). The simulator indicates the constant overall injection amount per period to maintain minimum miscibility is 1 million rb/year. Coincidentally, this is equal to our chosen reserves stock which equals 1 million rb for our modelled field. Given this injection rate, we can summarize material balances of injected fluids equal to produced fluids for each unit of time as:

Given the total amount of fluids we need to inject, we still need to refine the model a bit more. Combining our reservoir simulation model results with the functional form in Leach et al., \( \delta \left({q}_i(t)\right)=\delta \left({q}_i^c(t)\right)={\delta}_w+{\delta}_1{q}_i^c(t)-{\delta}_2{q}_i^c{(t)}^2 \) with δ′(0) > 0 > δ′(1). δ w represents the impact of a water flood on oil recovery. If we are injecting only water, the decline rate equals δ(0) = δ w , and if we are injecting purely CO2, the decline rate equals δ(1) = δ1 − δ2. Oil production is then determined by the following function:

Multiple sensitivity runs of the reservoir model were performed to help us establish the response of oil production to different ratios of CO2 in the injection stream. From these results, we developed δ w , δ1, and δ2 to be used as parameters in our dynamic simulation model.

During the oil production stage, material balances determine that the CO2 sequestered is the portion of the injected CO2 that has not dissolved in the oil and has occupied available pore space in the reservoir. Every reservoir barrel of oil displaced will potentially allow for an equivalent volume of CO2 and water, also measured in rb, to occupy the freed pore space. The volume of oil displaced by each of the injected fluids is proportional to the fraction of each fluid in the total injection stream. Our resulting rate of CO2 sequestration becomes the product of the fraction of CO2 in the total injection stream and oil production. Thus sequestration becomes \( {q}_s^c(t)=\frac{q_i^c(t)}{q_i(t)}\times {q}_p^o(t) \)). Given that q i (t) = 1 million rb/year to satisfy the minimum miscibility pressure and our decline curve from above, our rate of sequestration becomes as follows:

This established rate of sequestration also represents the change in total sequestrated CO2 or how much total reservoir storage capacity is taken up with CO2 in each period:

Using Eqs. (3) and (4), we graph the resultant oil production and CO2 sequestered as a function of CO2 injection rate for a value of R equals 1 million rb in Fig. 1.

Incremental oil production and CO2 sequestration as a function of CO2 injection rate. Source: Equations created from simulations in Schlumberger’s eclipse reservoir simulator of WAG process. Note: Units are millions of reservoir barrels per year with total reserves equal to 1 million rb and injection rate 1 million rb per year. Multiply by remaining reserves to get the production and sequestration rates for other time periods of the model

For our reservoir, there is an increase in incremental oil production as we increase CO2 injection up to a critical rate of around 0.5 million rb/year before decreasing. This is a common pattern although this critical rate will change depending on a reservoir’s characteristics (Verma 2015). Increasing CO2 continually increases CO2 sequestration, first at a slightly increasing rate until around 0.32 and then at a slightly decreasing rate.

In stage 2, the total injection rate of one million barrels continues, but the fluid is all CO2. To ensure the integrity of the reservoir with no leakage, we do not exceed the original reservoir pressure. Since CO2 is compressible and the minimum miscible pressure is below the initial reservoir pressure, we can still force more CO2 into the reservoir. The reservoir model indicates that the ultimate capacity for this reservoir if all the oil has been produced is the amount sequestered in period 1 plus an additional 1.2 million barrels (1.2 times oil produced).

Notice that at this point, our control variable CO2 injection \( {q}_i^c(t) \) dictates oil production and carbon sequestered subject to our state variables, which at this point are (R) and (S) with the following end point conditions at t = 0 and T1 (the end of oil production to be chosen by the model):

Our next challenge is to use the above outputs from the reservoir simulation model and our other constraints to pick the source and amount of CO2 to inject to maximize the producer’s joint profits from oil production and sequestration for this field over its productive life.

Dynamic profit maximization model

In the first stage, the producer has oil initial reserves of R and at least that much potential pore space to sequester CO2 if all the oil is vacated. The producer buys CO2 and sells oil subject to a carbon tax and sells sequestration for this same tax amount. Now let us further explore the sources of injected CO2. We include three sources in our model: recycled\( \left({q}_R^c\right) \), natural CO2 captured from underground reserves (\( {q}_{NR}^c\Big) \), and CO2 captured from industrial processes (\( {q}_{CAP}^c\Big). \)The cost for each of these sources in increasing order is as follows: w R < w NR < w CAP . So, we represent total CO2 injection as \( {q}_i^c(t)={q}_R^c(t)+{q}_{NR}^c(t)+{q}_{CAP}^c(t) \). This injected CO2 is either sequestered or produced (\( {q}_i^c(t)={q}_s^c(t)+{q}_p^c(t) \)). The CO2 produced with the oil can either be discarded or recycled (\( {q}_R^c \)). Since recycled CO2 is the cheapest source, all produced CO2 is recycled \( \left({q}_p^c(t)={q}_R^c(t)\right) \). Adding a tax on produced CO2 would further re-enforce this choice. Substituting the recycled result into the previous two equalities relating to injections yields an additional constraint: \( {q}_i^c(t)={q}_R^c(t)+{q}_{NR}^c(t)+{q}_{CAP}^c(t)={q}_s^c(t)+{q}_R^c(t)\to {q}_{NR}^c(t)={q}_s^c(t)-{q}_{CAP}^c(t) \).

We consider available reserves of natural CO2, X, as another state variable. This leads us to the equation of state for our natural CO2 stock:

As in Leach et al. (2011), all other costs not related to the purchase, handling and transport of the CO2 are designated by the fixed variable F1. The producer is taxed for each unit of CO2 emitted in the combustion of a barrel of oil produced or each rb equivalent of natural CO2 purchased and credited for each rb equivalent of CO2 sequestered. This yields the following first-stage objective function, subject to the above seven equations, and transversality condition with a free terminal time (T1):

For consistency, all volumes have been converted to rb and our tax is represented in $/rb. The β in the above equation is taken from Leach et al. It represents the EPA estimate on the amount of CO2 emitted with the combustion of a barrel of oil combined with an estimate of the producer’s burden of the tax incidence. We also assume with Leach et al. that the incidence of the CO2 tax/subsidy in the CO2 market falls on the oil producer.

The second stage (T1 to T2) involves simulating CO2 sequestration beyond oil production activities during which all production wells are suspended and CO2 is injected into the reservoir with no physical outlet. The operator maximizes profits from sequestering at a price that equals the carbon tax (τ) at their optimal CO2 injection rate (still = 1 million rb/year) such that \( {q}_i^c(t) \)=\( {q}_s^c(t)=1 \) million rb/year. Our equation of state for our sequestration capacity becomes as follows:

The sequestration capacity constraint in this stage is a function of cumulative oil production resulting from our first stage as well as ensuring that our total injection does not produce pressure that might fracture the reservoir and allow leakage. The technical constraint from the EOR process for S(T1) is shown above in Eq. (6). With compression, we can still insert an additional 120% over the amount of oil extracted yielding the constraint:

We represent all costs related to the handling and transport of CO2 in this stage as w INJ while we treat non-CO2 related operational costs as fixed at F2. This leads to the setup of our second stage, sequestration after CO2-EOR. It should be noted that the terminal conditions during this stage are also based on having free terminal time (T2) which our model solves for. Adding the second stage profits to the first yields our objective function as follows:

subject to the constraints in Eqs. 1–7 and 9–10.

The first integral in the objective function represents profits from CO2-EOR, while the second represents profits generated by CCS. We assume that the transition from one stage to the next does not require any additional capital cost outside of shutting in producing wells. We solve our two-stage dynamic optimization problem by making use of Pontryagin’s maximum principle. The resulting optimality conditions, also presented and discussed in the Appendix, are set up in GAMS software in a mixed complementarity programming framework. GAMS allows us to numerically solve for the optimal time paths of our injection, production and sequestration profiles as well as the timing of the switch from one stage to the next and the termination time of the project. Solving for our time paths using a numerical solver is necessary to deduce the direction of the time path of our variables as well as achieving quantitative results. Table 1 defines the variables and parameters used in the GAMS modelling.

We considered all prices, costs, and tax levels to be exogenous and remain constant over the life of the project. The simulations are run for several scenarios that include oil price levels varying from $50 to $200 per reservoir barrel of oil (rb) and for carbon tax levels varying from $0 to $120 per tonne of CO2 (tCO2). To ensure consistent units in running our numerical simulations, all volumes, prices, and taxes are in reservoir barrels. It is also important to note that the oil and natural CO2 stocks are separate accumulations in different reservoirs.

The initial stocks of both oil and natural CO2 could theoretically carry any value; we assume an initial value of one million reservoir barrels for each. Given the current distribution of CO2 supply, we assumed that the cost used by Leach et al. was a reasonable estimate of costs related to the handling of natural CO2 (w NR ) and also carried through the same estimate of recycling CO2 (w R ). Rubin et al. (2015) estimate cost of a tonne of CO2 from postcombustion capture from a supercritical pulverized coal plant to range from $45 to $70 per tonne of CO2 captured with a representative value of $63. This converts to a cost of $6.33/rb. We round this value down to $6, assuming that technical progress will reduce costs. By the end of production, we assume that the costs of capturing and injecting CO2 (w INJ ) have fallen back to $4/rb.

F i represents annual non-CO2 related costs in stage i, which are based on implementing CO2-EOR in a field of comparable size from Leach et al. We carried though this value for our non-CO2-related costs to our second stage. Our β parameter taken from Leach et al. absorbs the conversion reflecting the amount of CO2 emitted in the combustion of a barrel of oil, allowing us to account for the induced tax liability transferred to the producer from a $1 increase in the carbon tax.

Simulation results and discussion

We start with a business as usual (BAU) case with no tax or subsidy and oil price of $100/rb. The simulated optimal time paths in stage 1 for CO2 injection (\( {q}_i^c \)), oil production (\( {q}_p^o(t) \)), and CO2 sequestered (\( {q}_s^c \)) are shown in Fig. 2. Optimal injection starts at about 75,000 rb/year and declines to zero by the beginning of year 5. This decline reflects the decrease in marginal product of CO2 as a result of the necessary decline in both oil production, seen in Eq. (3) and reserves as seen in Eq. (1). Thereafter, the producer defaults to a pure water flood until we reach the economic limit for our first stage. Oil production starts at about 58,600 barrels a day and declines through the end of year 54 at which point the producer no longer finds it economical to produce. We find, with the CO2 prices given and no tax incentives, that there is no use of captured anthropogenic CO2 and therefore no associated sequestration. With this scenario, the producer depletes about 95% of the oil reserves. The producer is able to sequester close to 10,000 rb equivalent of CO2 during the first 5 years, all of which comes from natural sources of CO2. With no tax or subsidy, of course, there is no stage 2. Compared to the Leach et al. model, the coefficients from the reservoir model suggest slightly more oil production but significantly less sequestered CO2.

At a lower price of $50 per barrel of oil, the oil production curve follows the same shape as in Fig. 2, we reach our economic limit faster. Oil production stops after 43 years, and slightly more oil is left in the reservoir. No EOR with natural CO2 or otherwise is profitable. As the price of oil increases above $100/rb, we produce for a longer period of time, more ultimate oil is produced, and the use of natural CO2 increases. Captured CO2 is never competitive without a tax even at oil prices of $200, and much natural CO2 is left in the ground. Values of the state variables at the end of each stage with a comparison to Leach et al. for selected scenarios with no carbon tax are shown in the first four result rows in Table 2.

Next, we add a tax/subsidy in the model. At our chosen range of prices, a tax level of $20/tCO2 ($2.01/rb of CO2) is needed to induce the use of captured anthropogenic sources. After that threshold tax, no natural CO2 is used at any oil price level. The general shapes of the optimal model trajectories given in Fig. 2 are maintained. Mirroring the results of Leach et al. in our first stage, we observe that higher oil prices induce the need for higher oil production making it optimal to increase CO2 injection levels over the productive life of the project. But with higher tax rates, our results differ from that of Leach et al., as we also observe a shift outward in our CO2 injection profile over the productive life of the project. These higher CO2 injection rates observed at higher price and tax levels will induce higher oil production rates early in the life of the project. But, unlike Leach et al., we do not observe the accelerated switch to a pure water flood.

The increases in CO2 injection rates as a result of increases in both oil price and tax levels have a positive impact on cumulative sequestration. In effect, the producer sacrifices incremental oil output and revenues in return for higher sequestration revenues by injecting CO2. Total volumes of captured CO2 sequestered across both stages are equivalent to 30 to 40% of the emissions from the use of the oil produced. For oil that is 85% carbon by weight. as in Pyrolyseum (2018), an estimate of its emission of CO2 per rb when burned is 0.85 × 44/12 = 3.12 rb. At an oil price of $100 and a tax of $20, the amount sequestered divided by the amount emitted when the oil is burned over both stages is 997,456/(1,179,989 × 0.85 × 44/12) = 0.38.

Our evaluation of the change in resulting injection and production profiles with changes in price and tax levels, unlike the Leach et al. paper, suggests that under our modified policy, CO2 injection and sequestration are more responsive to carbon tax than to oil price. The implication is that policies could induce an increase in magnitudes of CO2 sequestration with the minimal impact on oil production are a win-win situation for both the producer and the environment.

Let us consider more closely the total CO2 use and the switch from natural to captured CO2 at different price and tax levels. We make use of the equations established for our first stage to compute cumulative use of CO2 from each source in stage 1. First, consider what happens when only price changes. If oil price of $50 per barrel were to prevail indefinitely, EOR would not be profitable even with natural CO2 in stage 1 as shown in the Fig. 3 for τ equal 0. At our BAU, price of $100 total natural usage jumps to about 10,000 rb. As all the CO2 is recycled, there is no increase in atmospheric emissions, but neither is there any net new sequestration. An oil price of $200 roughly doubles the total BAU use of natural CO2. However, in no scenario is captured CO2 ever used for EOR nor is the 1 million rb of natural CO2 ever used up. It should be noted that an increase in tax by $1 per tCO2 equals $0.11 per rb of CO2 and results in a net reduction in net price received by the producer of $0.23/barrel of oil.

Adjusting the Leach et al. policy to penalize the producer for every unit of natural CO2 used is effective in encouraging the producer to transition from sole use of natural CO2 to sole use of captured CO2 in stage 1. Under the assumption that CO2 from both sources are perfect substitutes, the tax threshold above which the producer switches from natural to captured CO2 is equal to the difference in price between captured and natural CO2 of $20 per tCO2. Figure 3 also shows this switch and the change in total usage as the tax rate increases. Total natural CO2 usage declines with increases in tax levels up to the tax threshold because the credit they receive for sequestering CO2 gets negated by the tax they have to pay for every unit of natural CO2 they use. Above the threshold, no natural CO2 is used, and captured CO2 usage increases with higher tax levels. The revenues accrued to the producer from CO2 sequestration provide the needed incentive to increase CO2 usage, which will positively impact sequestration.

We consequently see a significant jump in net sequestration in stage 1 above the tax threshold, which increases with higher oil prices and higher tax levels as shown in Fig. 4. The jump in sequestration of captured CO2 at tax levels above the threshold is attributed to the transition to sole use of captured CO2 at those tax levels. Model results suggest that the amount of captured CO2 sequestered in the EOR process, stage 1, is on the order of hundreds of thousands of barrels which equates to tens of thousands of tonnes. As highlighted earlier, higher rates of CO2 injection result in increases in incremental oil production, up to a critical value beyond which the resulting magnitude of the incremental production declines. Nonetheless, at higher tax rates, we observe the producer injecting CO2 at rates higher than the critical rate. In effect, the producer sacrifices incremental oil output and revenues in return for higher sequestration revenues by injecting more CO2.

The amount of CO2 we can sequester in our second stage is a function of cumulative oil production resulting from our first stage as shown in Eq. (10). As expected, total volumes of sequestered CO2 across stage 2 will also increase with higher tax rates and oil prices. Even though we do not make use of captured CO2 in our first stage below the tax threshold, there is still economic incentive to switch in stage 2 for continued sequestration.

Oil price and tax levels will also influence the timing of the switch from our first stage to the second. We find that at fixed price levels, but increasing tax rates, the time of switch from one stage to the next is accelerated. Increased tax has a negative effect on oil production in the first stage, induces an accelerated switch to the second stage where the operator can accrue greater profits from just sequestration. On the other hand, at fixed tax levels, but increasing prices, the time of the switch from stage one to two is delayed. Higher oil prices encourage longer production periods coupled with the volumes of oil produced and CO2 sequestered outweigh potential benefits from our second stage for longer periods of time.

Results from applying the model to a single field show that sequestration of captured CO2 across both stages is on the order of 30 to 40% of the emissions from the use of the oil produced. These results are from a single field, but when aggregated across all fields on a national or global level could be significant relative to annual CO2 emissions. Quantifying impacts of implemented policy are necessary in establishing that CO2-EOR will have a positive role in promoting carbon capture and sequestration with minimal impact on oil production and associated economic activity.

Future work

The results of the modelling work done on this particular field indicate that given the appropriate economic environment, CO2-EOR can contribute to the promotion of CCS. Although the tax rates required are rather high, they do promote a significant amount of sequestration. The model, although stylized, developed values for CO2 emissions and a structure to measure the tradeoff between production and sequestration. This modelling work can benefit from greater depth and breadth. Although we bring better technical representation of the reservoir, significant effort is being focused on sequestration technology. We want to continue with more research on sequestration technology and the potential for cost reduction as well as other parameters in the model. Although oil in carbonate formations is quite prevalent, we will also test the robustness of our model results on other reservoir types. Our aim is to continue bridging the gap between engineering and economic policy aspects while providing an easy to use tool that allows for evaluating the practicality of wide-scale implementation of CCS when partnered with CO2-EOR.

We hope to expand this modelling work focusing on the nuances of how the producers co-manage both oil production activities and sequestration resulting from the impacts of varying both market and reservoir parameters (i.e. reservoir maturity, size, and quality). We assume a regional modelling effort or analysis will inform us on how to allocate both natural and captured CO2 volumes across a portfolio of hydrocarbon producing assets allowing us to evaluate the dynamics between both the oil and CO2 markets now tied together by pore volume management. This future study includes the evaluation of the mechanics of supply and demand of CO2 on a regional and global scale providing the basis for creating an international CO2 market.

The possible investigations addressed above highlight the flexibility of the model constructed. The potential studies suggested go beyond quantifying CO2-EOR’s contribution to CCS. Those studies allow us to investigate whether there is sufficient storage capacity on a global scale to allow for the capture and sequestration of enough CO2 to sustain current and future levels of human and industrial activity. The research highlights the importance of using existing knowledge and infrastructure in the pursuit of our environmental objectives. Significant technical and engineering study, in addition to data collection, will be required to investigate these possibilities and formulate the functional forms of the equations in the model.

Notes

CO2 behaves like a fluid at reservoir temperatures and pressures (Leach et al. 2011).

References

Donaldson EC, Chilingarian GV, Yen TF 1985 Enhanced oil recovery, I, volume 17A. Developments in Petroleum Science

Fetkovich MJ, Fetkovich EJ, Fetkovich MD 1996 Useful concepts for decline curve forecasting, reserve estimation, and analysis. Society of Petroleum Engineers

IEA (2017). World energy outlook 2017. Available at: http://www.iea.org/bookshop/750-World_Energy_Outlook_2017

Leach A, Mason CF, van’t Veld K (2011) Co-optimization of enhanced oil recovery and carbon sequestration. Resour Energy Econ 33:892–912

Pyrolysium (2018) How much CO2 produced by burning one barrel of oil. https://pyrolysium.org/how-much-co2-produced-by-burning-one-barrel-of-oil/ last accessed 20 Jan 2018

Rubin ES, Davidson JE, Herzog HJ (2015) The cost of carbon capture. Int J Greenhouse Gas Control 40:378–400. https://www.cmu.edu/epp/iecm/rubin/PDF%20files/2015/Rubin_et_al_ThecostofCCS_IJGGC_2015.pdf. https://doi.org/10.1016/j.ijggc.2015.05.018

van’t Veld K, Wang X, Alvarado V (2014) Economic co-optimization of enhanced oil recovery and CO2 sequestration. Paper SPE-170880-MS presented at the 2014 SPE AT&CE, The Netherlands

Verma MK 2015 Fundamentals of carbon dioxide-enhanced oil recovery (CO2-EOR)—a supporting document of the assessment methodology for hydrocarbon recovery using CO2-EOR associated with carbon sequestration. U.S. Geological Survey Open-File Report 2015–1071

Author information

Authors and Affiliations

Corresponding author

Additional information

We thank Editor Magnus Ericsson for the invitation to contribute to this special issue and to the anonymous referee for valuable comments that substantially helped us clarify our exposition in the paper. The views in this paper are solely those of the authors and do not reflect the views of Saudi Aramco, the Colorado School of Mines, or Luleo Technical University.

The authors of this article are pleased to pay tribute to Dr. Marian Radeztki, an icon in the field of Mineral Economics. As homo economicus, we humans have learned to rip and suck mineral and energy resources from the Earth to make our lives more productive and comfortable. Marian has spent a lifetime studying this process. His wit and sarcastic turn of phrase, his institutional and technical knowledge, and his well-reasoned and supported arguments entertain and enlighten us about how these resource markets work. With each bout of “We are running out.” Marian, ever the myth buster, responds with “No—we aren’t.” We thank him for his past insights and wish him many more years of being right.

Appendix: Model Setup and Optimality Conditions

Appendix: Model Setup and Optimality Conditions

The ordinary control theory formulation does not consider dynamic problems with more than a single optimization phase. The challenge arises in our two-stage setup in the selection of the transition point from one stage to the next, in addition to the selection of the optimal paths for the control and state variables in each stage of the optimization. We now present the setup and optimality conditions of our two-stage model that considers a price-taking producer that seeks to maximize the present value of profits with respect to a policy that could potentially make sole sequestration profitable. Our first integral in the objective function represents profits from CO2-EOR, while the second represents profits generated by CCS. We assume that the transition from one stage to the next does not require any additional capital cost outside of shutting in producing wells. Our objective function (Eq. 11 from the text), associated constraints, and optimality or first-order conditions are listed below:

Objective function:

Substituting in the relationships between oil production and CO2 injection and sequestration yields:

Subject to the following constraints that will differ across each stage:

Transversality conditions for our first stage:

Moving to our second stage:

The upper bound on sequestration for S(T2) in Eq. 25 serves as our terminal conditions with free terminal time (T2) and eliminates the need to identify transversality conditions for our second stage. This upper bound on sequestration also provides the link between the first and second stage of the model.

Modelling stage 1

The current value Hamiltonian for period 1 is as follows:

Optimality conditions for stage 1

with

Substituting in for \( \frac{\partial {H}_1(t)}{\partial R(t)} \), we get the following:

The above expression suggests that the user cost for oil is a complicated expression depending on the interactions of price, tax, CO2 injection, and the shadow values of the other constraint. Our simulations show that the user cost falls.

For our natural CO2, its shadow value follows:

We will see a growth in the shadow value of our natural CO2 stock until it reaches the switch point to captured sources. The switch point to captured sources occurs at the difference in price between both sources. As such, we will see a growth in λX(t) at the rate of r until it reaches a value equal to the difference in price of both captured and natural sources of CO2 (λX(0)erT = w CAP − (w NR + τ)). After this point, λX(t) will remain constant as we no longer make use of natural CO2 and make sole use of CO2 from captured sources. Captured sources can be viewed as a backstop technology. Since our prices and costs are held constant, we will observe our shadow price rise to the value that induces a switch from one source to the next.

Similarly, the shadow price for sequestration is as follows:

We will see a growth in the shadow value of our sequestration capacity until it equals the marginal cost of sequestration in our second stage.

Modelling stage 2

The current value Hamiltonian for period 2 is as follows:

Optimality conditions for stage 2

The marginal cost of sequestration at the beginning of our second stage is \( {\lambda}^{S_2}(0){e}^{rt}={w}_{INJ}-\tau \). This value grows as pore space increases until we hit the capacity constraint of the reservoir.

The complementarity model includes Eqs. 28 and 30 and discretized versions of Eqs. 31–33 and 35–37 for stage 1 and Eq. 39 and discretized versions of Eqs. 40 and 41 for stage 2.

Rights and permissions

About this article

Cite this article

Abdulbaqi, D.M., Dahl, C.A. & AlShaikh, M.R. Enhanced oil recovery as a stepping stone to carbon capture and sequestration. Miner Econ 31, 239–251 (2018). https://doi.org/10.1007/s13563-018-0151-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13563-018-0151-1