Abstract

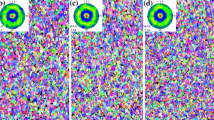

Al2O3/Cu composite films, useful for film resistors, were successfully fabricated at room temperature via aerosol deposition (AD). Microstructures of the Al2O3/Cu composite films were analyzed to understand the correlations between the surface morphologies and Al2O3/Cu ratio. A scratch test was carried out by gradually increasing the load applied to the Al2O3/Cu composite films. We also evaluated the adhesion ability by measuring the tensile strength between Al2O3/Cu composite films and Al2O3 substrate. The results confirmed that the adhesive properties of Al2O3/Cu composite films were strongly influenced by two adhesive mechanisms: mechanical interlocking and anchoring bonds between the films and Al2O3 substrate. When a powder mixture containing 50 wt% of Al2O3 and Cu was deposited on the substrate, high mechanical properties and suitable resistivity were simultaneously achieved at approximately 8.02 MPa and 85.2 mΩ cm, respectively due to effective mechanical interlocking and anchoring bonds. The results further suggest that room-temperature AD method is highly favorable to fabricate heterogeneous composite films for application to film resistors.

Graphical Abstract

Similar content being viewed by others

References

Bhattacharya, S.K., Tummala, R.R.: Integral passives for next generation of electronic packaging: application of epoxy/ceramic nanocomposites as integral capacitors. Microelectron. J. 32(1), 11–19 (2001)

Chahal, P., Tummala, R.R., Allen, M.G., Swaminathan, M.: A novel integrated decoupling capacitor for MCM-L technology. IEEE Trans. Compon. Packag. Manuf. Technol. Part B: 21(2), 184–193 (1998)

Tummala, R.R.: SOP: what is it and why? A new microsystem-integration technology paradigm-Moore’s law for system integration of miniaturized convergent systems of the next decade. IEEE Trans. Adv. Packag. 27(2), 241–249 (2004)

Bhattacharya, S.K., Tummala, R.R.: Next generation integral passives: materials, processes, and integration of resistors and capacitors on PWB substrates. J. Mater. Sci. Mater. Electron. 11(3), 253–268 (2000)

Lin, R.C., Lee, T.K., Wu, D.H., Lee, Y.C.: A study of thin film resistors prepared using Ni–Cr–Si–Al–Ta high entropy alloy. Adv. Mater. Sci. Eng. 2015, 1–7 (2015)

Lai, L., Zeng, W., Fu, X., Sun, R., Du, R.: Annealing effect on the electrical properties and microstructure of embedded Ni–Cr thin film resistor. J. Alloys Compd. 538, 125–130 (2012)

Vinayak, S., Vyas, H.P., Muraleedharan, K., Vankar, V.D.: Ni–Cr thin film resistor fabrication for GaAs monolithic microwave integrated circuits. Thin Solid Films 514(1–2), 52–57 (2006)

Vinayak, S., Vyas, H.P., Vankar, V.D.: Microstructure and electrical characteristics of Ni–Cr thin films. Thin Solid Films 515(18), 7109–7116 (2007)

Rolke, J.: Nichrome thin film technology and its application. Electrocompon. Sci. Technol. 9(1), 51–57 (1981)

Jacq, C., Maeder, T., Ryser, P.: High-strain response of piezoresistive thick-film resistors on titanium alloy substrates. J. Eur. Ceram. Soc. 24(6), 1897–1900 (2004)

Ma, E., Anderson, W.A.: Mechanism of stabilizing RuO2/Ta2N double layer thin film resistors. Mater. Sci. Eng., B 47(2), 161–166 (1997)

Wang, C.M., Hsieh, J.H., Fu, Y.Q., Li, C., Chen, T.P., Lam, U.T.: Electrical properties of TaN–Cu nanocomposite thin films. Ceram. Int. 30(7), 1879–1883 (2004)

Berg, S., Nyberg, T.: Fundamental understanding and modeling of reactive sputtering processes. Thin Solid Films 476(2), 215–230 (2005)

Vygranenko, Y., Wang, K., Chaji, R., Vieira, M., Robertson, J., Nathan, A.: Stability of indium-oxide thin-film transistors by reactive ion beam assisted deposition. Thin Solid Films 517(23), 6341–6344 (2009)

Yan, Z., Ma, Y., Deng, P., Yu, Z., Liu, C., Song, Z.: Ag–N doped ZnO film and its p–n junction fabricated by ion beam assisted deposition. Appl. Surf. Sci. 256(7), 2289–2292 (2010)

Smidt, F.A.: Use of ion beam assisted deposition to modify the microstructure and properties of thin films. Int. Mater. Rev. 35(1), 61–128 (1990)

Pyun, M.W., Kim, E.J., Yoo, D.H., Hahn, S.H.: Oblique angle deposition of TiO2 thin films prepared by electron-beam evaporation. Appl. Surf. Sci. 257(4), 1149–1153 (2010)

Yao, J.K., Huang, H.L., Ma, J.Y., Jin, Y.X., Zhao, Y.A., Shao, J.D., He, H.B., Yi, K., Fan, Z.X., Zhang, F., Wu, Z.Y.: High refractive index TiO2 film deposited by electron beam evaporation. Surf. Eng. 25(3), 257–260 (2009)

Wang, Y., Lin, Z., Cheng, X., Xiao, H., Zhang, F., Zou, S.: Study of HfO2 thin films prepared by electron beam evaporation. Appl. Surf. Sci. 228(1–4), 93–99 (2004)

Ramasamy, K., Malik, M.A., O’Brien, P.: The chemical vapor deposition of Cu2ZnSnS4 thin films. Chem. Sci. 2(6), 1170–1172 (2011)

Wei, Y.Y., Eres, G., Merkulov, V.I., Lowndes, D.H.: Effect of catalyst film thickness on carbon nanotube growth by selective area chemical vapor deposition. Appl. Phys. Lett. 78(10), 1394–1396 (2001)

Alguero, M., Ricote, J., Torres, M., Amorin, H., Alberca, A., Iglesias-Freire, O., Nemes, N., Holgado, S., Cervera, M., Piqueras, J., Asenjo, A., Garcia-Hernandez, M.: Thin film multiferroic nanocomposites by ion implantation. ACS Appl. Mater. Interfaces. 6(3), 1909–1915 (2014)

Shi, W., Zhang, H., Zhang, G., Li, Z.: Modifying residual stress and stress gradient in LPCVD Si3N4 film with ion implantation. Sens. Actuators A Phys. 130–131, 352–357 (2006)

Akedo, J.: Aerosol deposition method for fabrication of nano crystal ceramic layer. Mater. Sci. Forum 449–452, 43–48 (2004)

Lee, J.H., Kim, H.K., Lee, S.H., Choi, K., Lee, Y.H.: Effect of Zn filler for percolative BaTiO3/Zn composite films fabricated by aerosol deposition. Ceram. Int. 41(9), 12153–12157 (2015)

Lee, W.H., Kim, H.J., Lee, D.W., Jeong, M.G., Lim, D.S., Nam, S.M.: Al2O3-nanodiamond composite coatings with high durability and hydrophobicity prepared by aerosol deposition. Surf. Coat. Technol. 206(22), 4679–4684 (2012)

Cho, M.Y., Lee, D.W., Kim, I.S., Lee, W.H., Yoo, J.W., Ko, P.J., Koo, S.M., Choi, Y.K., Oh, J.M.: Formation of silver films for advanced electrical properties by using aerosol deposition process. Jpn. J. Appl. Phys. 57(11S), 11UF05 (2018)

Lee, D.W., Shin, M.C., Kim, Y.N., Oh, J.M.: Brushite ceramic coatings for dental brace brackets fabricated via aerosol deposition. Ceram. Int. 43(1), 1044–1051 (2017)

Kim, C.W., Choi, J.H., Kim, H.J., Lee, D.W., Hyun, C.Y., Nam, S.M.: Effects of interlayer roughness on deposition rate and morphology of aerosol-deposited Al2O3 thick films. Ceram. Int. 38(7), 5621–5627 (2012)

Lee, D.W., Kwon, O.Y., Cho, W.J., Song, J.K., Kim, Y.N.: Characteristics and mechanism of Cu films fabricated at room temperature by aerosol deposition. Nanoscale Res. Lett. 11(1), 162 (2016)

Kim, H.J., Nam, S.M.: Powder preparation in aerosol deposition for Al2O3-polyimide composite thick films. Electron. Mater. Lett. 8(1), 65–70 (2012)

Kim, J.H., Kim, H.K., Lee, S.H., Lee, S.G., Kim, J.S., Kim, J.S., Lee, Y.H.: Dielectric properties of percolative BaTiO3/Ni composite film fabricated by aerosol deposition process. J. Mater. Sci. Mater. Electron. 27(8), 8567–8572 (2016)

Cho, M.Y., Park, S.J., Kim, S.M., Lee, D.W., Kim, H.K., Koo, S.M., Moon, K.S., Oh, J.M.: Hydrophobicity and transparency of Al2O3-based poly-tetra-fluoro-ethylene composite thin films using aerosol deposition. Ceram. Int. 44(14), 16548–16555 (2018)

Lee, D.W., Cho, M.Y., Kim, I.S., Kim, Y.N., Lee, D., Koo, S.M., Park, C., Oh, J.M.: Experimental and numerical study for Cu metal coatings at room temperature via powder spray process. Surf. Coat. Technol. 353, 66–74 (2018)

Nouri, A., Hodgson, P.D., Wen, C.: Effect of ball-milling time on the structural characteristics of biomedical porous Ti–Sn–Nb alloy. Mater. Sci. Eng., C 31(5), 921–928 (2011)

Hanft, D., Exner, J., Schubert, M., Stocker, T., Fuierer, P., Moos, R.: An overview of the aerosol deposition method: process fundamentals and new trends in materials applications. J. Ceram. Sci. Technol. 6(3), 147–182 (2015)

Kim, H.J., Yoon, Y.J., Kim, J.H., Nam, S.M.: Application of Al2O3-based polyimide composite thick films to integrated substrates using aerosol deposition method. Mater. Sci. Eng. B Solid State Mater. Adv. Technol. 161(1), 104–108 (2009)

Fu, K., Sheppard, L., Chang, L., An, X., Yang, C., Ye, L.: Comparative study on plasticity and fracture behavior of Ti/Al multilayers. Tribol. Int. 126, 344–351 (2018)

Azhar, A.Z.A., Mohamad, H., Ratnam, M.M., Ahmad, Z.A.: The effects of MgO addition on microstructure, mechanical properties and wear performance of zirconia-toughened alumina cutting inserts. J. Alloys Compd. 497(1–2), 316–320 (2010)

Chaudhri, M.M.: Subsurface strain distribution around Vickers hardness indentations in annealed polycrystalline copper. Acta Mater. 46(9), 3047–3056 (1998)

Hench, L.L., Splinter, R.J., Allen, W.C., Greenlee, T.K.: Bonding mechanisms at the interface of ceramic prosthetic materials. J. Biomed. Mater. Res. 5(6), 117–141 (1971)

Krupicka, A., Johansson, M., Hult, A.: Use and interpretation of scratch tests on ductile polymer coatings. Prog. Org. Coat. 46(1), 32–48 (2003)

Miranda-hernandez, J.G., Moreno-guerrero, S., Soto-guzman, A.B., Rocha-rangel, E.: Production and characterization of Al2O3-Cu composite materials. J. Ceram. Proc. Res. 7, 311–315 (2006)

Cho, M.Y., Lee, D.W., Kim, W.J., Kim, Y.N., Koo, S.M., Lee, D., Moon, K.S., Oh, J.M.: Fabrication of TiO2/Cu hybrid composite films with near zero TCR and high adhesive strength via aerosol deposition. Ceram. Int. 44(15), 18736–18742 (2018)

Acknowledgements

This present Research has been conducted by the Research Grant of Kwangwoon University in 2018. And, this work was supported by the National Research Foundation of Korea (NRF) funded by Korean government (MSIP; Ministry of Science, ICT and Future Planning) (No. 2018R1D1A1B07045295) and the High Level Track of Power Semiconductor Technology for Renewable Energy and Electrical Vehicle (No. 20174010201290) of the Korea Institute of Energy Technology Evaluation and Planning (KETEP).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Cho, MY., Lee, DW., Ko, PJ. et al. Adhesive Mechanism of Al2O3/Cu Composite Film via Aerosol Deposition Process for Application of Film Resistor. Electron. Mater. Lett. 15, 227–237 (2019). https://doi.org/10.1007/s13391-018-00111-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13391-018-00111-w