Abstract

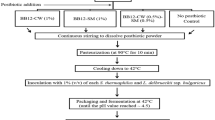

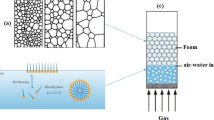

Yoghurt powder is widely used in industries of confectionery and baking. The production of yoghurt powder can be made by several drying methods, including freeze, spray, microwave vacuum, convective and foam-mat. In this study, the effect of varying concentrations of egg albumin (EA) on foam and powder characteristics of yoghurt were determined. Besides, microwave-assisted foam-mat drying of yoghurt was carried out to examine the effects of three microwave output powers (100, 180 and 300 W) on powder properties of yoghurt. Increased in EA concentration resulted in an increase in foam expansion and decrease in foam density. Higher foam stability (after 120 min.) was observed for foams containing 10 and 15% EA (both found as 88.24%). As powder properties, wettability and solubility times were significantly decreased with the addition of EA, while water holding capacity was increased. Change in EA concentration was significantly (p ≤ 0.05) effective on all powder properties dried at 100 W. Carr Index and Hausner Ratio values were in the range of 0.99–13.89 and 1.01–1.17, respectively. Microwave powers were significantly (p ≤ 0.05) effective on the flowability of powders containing 0, 5 and 10% EA. Yoghurt powders showed mostly excellent flow characteristics (for all concentrations of EA and microwave output powers).

Similar content being viewed by others

Data Availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Abbasi E, Azizpour M (2016) Evaluation of physicochemical properties of foam mat dried sour cherry powder. Lwt-Food Sci Technol 68:105–110. https://doi.org/10.1016/j.lwt.2015.12.004

Affandi N, Zzaman W, Yang TA, Easa AM (2017) Production of Nigella sativa beverage powder under foam mat drying using egg albumen as a foaming agent. Beverages. https://doi.org/10.3390/beverages3010009

AOAC (1990) Official methods of analysis, 15th edn. Arlington, VA, USA

Asokapandian S, Venkatachalam S, Swamy GJ, Kuppusamy K (2016) Optimization of foaming properties and foam mat drying of muskmelon using soy protein. J Food Process Eng 39:692–701. https://doi.org/10.1111/jfpe.12261

Azizpour M, Mohebbi M, Khodaparast MHH (2016) Effects of foam-mat drying temperature on physico-chemical and microstructural properties of shrimp powder. Innov Food Sci Emerg 34:122–126. https://doi.org/10.1016/j.ifset.2016.01.002

Carvalho MJ, Perez-Palacios T, Ruiz-Carrascal J (2017) Physico-chemical and sensory characteristics of freeze-dried and air-dehydrated yogurt foam. Lwt-Food Sci Technol 80:328–334. https://doi.org/10.1016/j.lwt.2017.02.039

ÇalışkanKoç G (2020) The effect of different drying techniques and microwave finish drying on the powder properties of the red pepper powder (Capsicum annuum L). J Food SciTechnol. https://doi.org/10.1007/s13197-020-04496-1

Çalışkan Koç G, Dirim SN (2018) Spray dried spinach juice: powder properties. J Food Meas Charact 12:1654–1668. https://doi.org/10.1007/s11694-018-9781-9

Dehghannya J, Pourahmad M, Ghanbarzadeh B, Ghaffari H (2018) Heat and mass transfer modeling during foam-mat drying of lime juice as affected by different ovalbumin concentrations. J Food Eng 38:164–177. https://doi.org/10.1016/j.jfoodeng.2018.06.014

Dehghannya J, Pourahmad M, Ghanbarzadeh B, Ghaffari H (2019) Heat and mass transfer enhancement during foam-mat drying process of lime juice: impact of convective hot air temperature. Int J Therm Sci 135:30–43. https://doi.org/10.1016/j.ijthermalsci.2018.07.023

Durian DJ (1995) Foam mechanics at the bubble scale. Phys Rev Lett 75:4780–4783. https://doi.org/10.1103/PhysRevLett.75.4780

Falade KO, Adeyanju KI, Uzo-Peters PI (2003) Foam-mat drying of cowpea (Vigna unguiculata) using glyceryl monostearate and egg albumin as foaming agents. Eur Food Res Technol 217:486–491. https://doi.org/10.1007/s00217-003-0775-3

Fang Y, Selomulya C, Chen XD (2008) On measurement of food powder reconstitution properties. Dry Technol 26:3–14. https://doi.org/10.1080/07373930701780928

Freudig B, Hogekamp S, Schubert H (1999) Dispersion of powders in liquids in a stirred vessel. Chem Eng Process 38:525–532. https://doi.org/10.1016/S0255-2701(99)00049-5

Goula AM, Adamopoulos KG (2008) Effect of maltodextrin addition during spray drying of tomato pulp in dehumidified air: II. Powder Prop Dry Technol 26:726–737. https://doi.org/10.1080/07373930802046377

Hayaloglu AA, Karabulut I, Alpaslan M, Kelbaliyev G (2007) Mathematical modeling of drying characteristics of strained yoghurt in a convective type tray-dryer. J Food Eng 78:109–117. https://doi.org/10.1016/j.jfoodeng.2005.09.006

Hnin KK, Zhang M, Devahastin S, Wang B (2020) Combined infrared freeze drying and infrared drying of rose-flavored yogurt melts-effect on product quality. Food Bioprocess Tech 13:1356–1367. https://doi.org/10.1007/s11947-020-02486-x

Karim AA, Wai CC (1999) Foam-mat drying of starfruit (Averrhoa carambola L.) puree. Stability and air drying characteristics. Food Chem 64:337–343. https://doi.org/10.1016/S0308-8146(98)00119-8

Khamjae T, Rojanakorn T (2018) Foam-mat drying of passion fruit aril. Int Food Res J 25:204–212

Kim SS, Bhowmik SR (1994) Moisture sorption isotherms of concentrated yogurt and microwave vacuum dried yogurt powder. J Food Eng 21:157–175

Koç B, Sakin-Yılmazer M, Kaymak-Ertekin F, Balkır P (2014) Physical properties of yoghurt powder produced by spray drying. J Food Sci Technol 51:1377–1383. https://doi.org/10.1007/s13197-012-0653-8

Kumar P, Mishra HN (2004) Yoghurt Powder—A Review of Process Technology, Storage and Utilization. Food Bioprod Process 82:133–142. https://doi.org/10.1205/0960308041614918

Malik M, Sharma A (2019) Optimisation of foam-mat drying of yoghurt and properties of powdered yoghurt. Int J Dairy Technol 72:381–387. https://doi.org/10.1111/1471-0307.12594

Mckinley MC (2005) The nutrition and health benefits of yoghurt. Int J Dairy Technol 58:1–12. https://doi.org/10.1111/j.1471-0307.2005.00180.x

Ng ML, Sulaiman R (2018) Development of beetroot (Beta vulgaris) powder using foam mat drying. Lwt-Food Sci Technol 88:80–86. https://doi.org/10.1016/j.lwt.2017.08.032

Qadri OS, Srivastava AK (2017) Microwave-assisted foam mat drying of guava pulp: drying kinetics and effect on quality attributes. J Food Process Eng 40:e12295. https://doi.org/10.1111/jfpe.12295

Ratti C, Kudra T (2006) Drying of foamed biological materials: opportunities and challenges. Dry Technol 24:1101–1108. https://doi.org/10.1080/07373930600778213

Say D, Soltani M, Guzeler N (2015) Dried yoghurts: Kurut and Kashk. Pamukkale U J Eng Sc 21:428–432. https://doi.org/10.5505/pajes.2015.47048

Shaari NA, Sulaiman R, Rahman RA, Bakar J (2018) Production of pineapple fruit (Ananas comosus) powder using foam mat drying: effect of whipping time and egg albumen concentration. J Food Process Preserv 42:e13467. https://doi.org/10.1111/jfpp.13467

Sharma NK, Arora CP, Mital BK (1992) Influence of concentration of milk solids on freeze-drying rate of yoghurt and its quality. J Food Process Eng 15:187–198. https://doi.org/10.1111/j.1745-4530.1992.tb00151.x

Stone AK, Karalash A, Tyler RT, Warkentin TD, Nickerson MT (2015) Functional attributes of pea protein isolates prepared using different extraction methods and cultivars. Food Res Int 76:31–38. https://doi.org/10.1016/j.foodres.2014.11.017

Varhan E, Elmas F, Koc M (2019) Foam mat drying of fig fruit: optimization of foam composition and physicochemical properties of fig powder. J Food Process Eng. https://doi.org/10.1111/jfpe.13022

Funding

The author received no financial support for the research, authorship, and/or publication of this article.

Author information

Authors and Affiliations

Contributions

ANY carried out literature survey and experiments, analyzed the data and wrote the manuscript.

Corresponding author

Ethics declarations

Conflicts of interest

The author declares no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yüksel, A.N. Development of yoghurt powder using microwave-assisted foam-mat drying. J Food Sci Technol 58, 2834–2841 (2021). https://doi.org/10.1007/s13197-021-05035-2

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-021-05035-2