Abstract

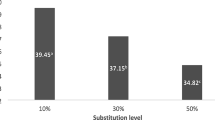

The citrus juice industry produces a significant amount of peel residues; it can represent between 18 and 30% of the total weight of the fruit. In recent years, there has been an increase in its use as a source of fiber. The objective of this study was to evaluate the Tahiti lemon peel flour (Citrus latifolia Tanaka) as a fat mimetic (10, 20 and 30%) in a cake. The chemical and nutritional characterization of the lemon peel, the determination of the drying conditions to obtain the flour of the lemon peel, and the physical, chemical, and nutritional characterization of the lemon peel flour and cake was evaluated. A high content of dietary fiber for Tahiti lemon peel (89.15 ± 0.00 g/100 g) and flour (85.30 ± 0.06 g/100 g) was obtained. For the drying conditions to obtain the lemon peel flour, a temperature of 60 °C during 16 h was selected. The cake with greater acceptability had a 10% fat replacement with lemon peel flour, which presented a reduction of 19.16% in the fat content and an approximately double increase in the dietary fiber content. This study suggests that the flour obtained from Tahiti lemon flavedo can be used as a mimetic of fat in cakes, contributing to the nutritional characteristics of the food in which it is included.

Similar content being viewed by others

References

Abou-Arab AA, Mahmoud MH, Abu-Salem FM (2016) Bioactive compounds content of citrus peel as affected by drying processes. World Acad Sci Eng Technol Int J Biol Biomol Agric Food Biotechnol Eng 10:240–243. https://doi.org/10.5281/zenodo.1126375

Al-Sayed Hanan MA, Ahmed Abdelrahman R (2013) Utilization of watermelon rinds and sharlyn melon peels as a natural source of dietary fiber and antioxidants in cake. Ann Agric Sci 58:83–95. https://doi.org/10.1016/j.aoas.2013.01.012

AOAC International (2012) Official methods of analysis of AOAC international, 19th edn. Gaithersburg, Maryland

Ares G, Tarrega A, Luis I, Jaeger S (2014) Investigation of the number of consumers necessary to obtain stable sample and descriptor configurations from Check-All-That-Apply (CATA) questions. Food Qual Prefer 31:135–141. https://doi.org/10.1016/j.foodqual.2013.08.012

Badillo MD (2011) Estudio comparativo del potencial nutritivo del limon persa (Citrus latifolia Tanaka) deshidratado en secador de bandejas y en microondas. Escuela Superior Politécnica de Chimborazo. https://dspace.espoch.edu.ec/bitstream/123456789/1577/1/56T00258.pdf. Accessed 20 Aug 2018

Chang R, Li C, Shiau S (2015) Physico-chemical and sensory properties of bread enriched with lemon pomace fiber. Czech J Food Sci 33:180–185. https://doi.org/10.17221/496/2014-CJFS

Ciriminna R, Fidalgo A, Scurria A, Sciortino M, Lino C, Meneguzzo F, Ilharco LM, Pagliaro M (2020) The case for a lemon bioeconomy. Adv Sustain Syst 2000006:6. https://doi.org/10.1002/adsu.202000006

De Moraes T, Jablonski A, De Olivera A, Rech R, Hickman S (2013) Dietary fiber from orange byproducts as a potential fat replacer. LWT Food Sci Technol 53:9–14. https://doi.org/10.1016/j.lwt.2013.02.002

Demirok E, Kolsarici N, Cicek N, Salman G, Akoglu I, Kasko Y (2015) The comparative effect of carrot and lemon fiber as a fat replacer on physico-chemical, textural, and organoleptic quality of low-fat beef hamburger. Korean J Food Sci Anim Resour 35:370–381. https://doi.org/10.5851/kosfa.2015.35.3.370

Dewanto V, Wu X, Liu RH (2002) Processed sweet corn has higher antioxidant activity. J Agric Food Chem 50:4959–4964. https://doi.org/10.1021/jf0255937

Dias PGI, Sajiwanie JWA, Rathnayaka RMUSK (2020) Chemical composition, physicochemical and technological properties of selected fruit peels as a potential food source. Int J Fruit Sci. https://doi.org/10.1080/15538362.2020.1717402

Díaz L, Puelles J, Retto P, Valverde L, Rodríguez K, Valderrama C (2014) Effect of pressure and concentration of solutions of honey in mass transfer and sensory acceptability of orange peel (Citrus sinensis) variety "Huando" impregnated vacuum. Agroind Sci 4:95–107. https://doi.org/10.17268/agroind.science.2014.02.06

Egbuonu ACC, Osuji CA (2016) Proximate compositions and antibacterial activity of Citrus sinensis (sweet orange) peel and seed extracts. Eur J Med Chem Plants 12(3):1–7. https://doi.org/10.9734/EJMP/2016/24122

Elleuch M, Bedigian D, Roiseux O, Besbes S, Blecker C, Attia H (2011) Dietary fibre and fibre-rich by-products of food processing: characterisation, technological functionality and commercial applications: a review. Food Chem 124:411–421. https://doi.org/10.1016/j.foodchem.2010.06.077

Figuerola F, Hurtado M, Estevez A, Chiffelle I, Asenjo F (2005) Fiber concentrates from apple pomace and citrus peel as potential fiber sources for food enrichment. Food Chem 91:391–405. https://doi.org/10.1016/j.foodchem.2004.04.036

Food and Agriculture Organization of the United Nations (FAO) (2012) Global food losses and food waste—extent, causes and prevention. https://www.fao.org/3/a-i2697s.pdf. Accessed 21 Oct 2018

Garcia-Amezquita LE, Tejada-Ortigoza V, Campanella OH, Welti-Chanes J (2018) Influence of drying method on the composition, physicochemical properties, and prebiotic potential of dietary fibre concentrates from fruit peels. J Food Qual 2018:1. https://doi.org/10.1155/2018/9105237

García-Méndez S, Martinez-Flores H, Morales E (2011) Effect of extrusion parameters on some properties of dietary fiber from lemon (Citrus aurantifolia Swingle) residues. Afr J Biotechnol 10:16589–16593. https://doi.org/10.5897/AJB11.1582

Gómez C, Colina J (2019) Formulation of gluten-free cupcake with hydrocolloids for people with Celiac disease. Bioact Comp Health Dis 2:134–148. https://doi.org/10.31989/bchd.v2i6.630

Grigelmo-Miguel N, Martín-Belloso O (1999) Comparison of dietary fiber from by-products of processing fruits and greens and from cereals. LWT 32:503–508. https://doi.org/10.1006/fstl.1999.0587

Gutiérrez E, Pascual G (2016) Characterization of mandarin (Citrus reticulata) peel powder and inclusion in bread making. Agron Colomb 1:776–778. https://doi.org/10.15446/agron.colomb.sup.2016n1.57938

Hodges R, Buzby J, Bennett B (2011) Postharvest losses and waste in developed and less developed countries: opportunities to improve resource use. J Agric Sci 149:37–45. https://doi.org/10.1017/S0021859610000936

Huang YL, Ma YS (2016) The effect of extrusion processing on the physicochemical properties of extruded orange pomace. Food Chem 192:363–369. https://doi.org/10.1016/j.foodchem.2015.07.039

Kiran B, Neetu S (2017) Physicochemical and texture evaluation of biscuits and muffins for old age. Int J Food Sci Nutr 2(6):161–1640 ISSN: 2455-4898

Lario Y, Sendra E, García-Pérez J, Fuentes C, Sayas-Barberá E, Fernandez-López J, Pérez-Álvarez J (2004) Preparation of high dietary fiber powder from lemon juice by-products. Innov Food Sci Emerg Technol 5:113–117. https://doi.org/10.1016/j.ifset.2003.08.001

Larrauri JA (1999) New approaches in the preparation of high dietary fiber powders from fruit by-products. Trends Food Sci Technol 10:3–8. https://doi.org/10.1016/S0924-2244(99)00016-3

Londoño-Londoño J, Rodrigues V, Lara O, Gil A, Crecsynsky T, Arango G, Pineda J (2010) Clean recovery of antioxidant flavonoids from citrus peel: optimizing and aqueous ultrasound-assisted extraction method. Food Chem 119:81–87. https://doi.org/10.1016/j.foodchem.2009.05.075

Londoño J, Sierra J, Álvarez R, Restrepo AM, Passaro C (2012) Aprovechamiento de los subproductos citrícolas. In: Garcés LF, Pássaro C (ed) Cítricos: cultivo, poscosecha e industrialización, Corporación Universitaria Lasallista, pp 307–342

López-Marcos MC, Bailina C, Viuda-Martos M, Perez-Alvarez JA, Fernández-López J (2015) Properties of dietary fibers from agroindustrial coproducts as source for fiber-enriched foods. Food Bioprocess Technol 8(12):2400–2408. https://doi.org/10.1007/s11947-015-1591-z

Lundberg B, Pan X, White A, Chau H, Hotchkiss A (2014) Rheology and composition of citrus fiber. Food Chem 125:97–104. https://doi.org/10.1016/j.jfoodeng.2013.10.021

Luoa X, Arcot J, Gill T, Louie J, Rangan A (2019) A review of food reformulation of baked products to reduce added sugar intake. Trends Food Sci Technol 86:412–425. https://doi.org/10.1016/j.tifs.2019.02.051

Lupi FR, Puoci F, Bruno E, Baldino N, Marino R, Gabriele D (2020) The effects of process conditions on rheological properties of functional citrus fibre suspensions. Food Bioprod Process 121:54–64. https://doi.org/10.1016/j.fbp.2020.01.018. (0960-3085)

Mercali G, Jaeschke B, Tessaro I, Marczak L (2012) Study of vitamin C degradation in acerola pulp during ohmic and conventional heat treatment. LWT 47:91–95. https://doi.org/10.1016/j.lwt.2011.12.030

Napier K (1997) Fat replacers. The cutting edge of cutting calories, American Council on Science and Health, New York

O’Shea N, Ktenioudaki A, Smyth TP, McLoughlin P, Doran L, Auty MAE, Arendt E, Gallagher E (2015) Physicochemical assessment of two fruit by-products as functional ingredients: apple and orange pomace. J Food Eng 153:89–95. https://doi.org/10.1016/j.jfoodeng.2014.12.014

Peerajit P, Chiewchan N, Devahastin S (2012) Effects of pretreatment methods on health-related functional properties of high dietary fiber powder from lime residues. Food Chem 132(4):1891–1898. https://doi.org/10.1016/j.foodchem.2011.12.022

Torres JD, González KJ, Acevedo D, Jaimes JC (2016) Efecto de la utilización de harina de Lens culinaris como extensor en las características físicas y aceptabilidad de una salchicha. Tecnura 20(49):15–28. https://doi.org/10.14483/udistrital.jour.tecnura.2016.3.a01

Valiente C, Esteban RM, Molla E, López-Andréu FJ (1994) Roasting effects on dietary fiber composition of cocoa beans. J Food Sci 76(7):T163–T172. https://doi.org/10.1111/j.1365-2621.1994.tb06914.x

Vegas-Gálvez A, Di Scalab K, Rodríguez K, Lemus-Mondaca R, Miranda M, López J, Perez-Wona M (2009) Effect of air-drying temperature on physico-chemical properties, antioxidant capacity, colour and total phenolic content of red pepper (Capsicum annuum, L. var. Hungarian). Food Chem 117:647–653. https://doi.org/10.1016/j.foodchem.2009.04.066

Welti-Chanes J, Serna SO, Campanella OH, Tejada-Ortigoza V (2020) Science and technology of fibers in food systems. Springer Nature, Basel

Willemsen K, Panozzo A, Moelants K, Wallecan J, Hendrickx M (2020) Towards improved understanding of the viscoelastic properties of functionalized lemon peel fibers in suspension based on microstructure, hydration value and swelling volume. J Food Eng 278:109950. https://doi.org/10.1016/j.jfoodeng.2020.109950

Zhang Y, Liao J, Qia J (2020) Functional and structural properties of dietary fiber from citrus peel affected by the alkali combined with high-speed homogenization treatment. LWT Food Sci Technol 128:109397. https://doi.org/10.1016/j.lwt.2020.109397

Acknowledgements

The authors are grateful to the Fundación Universitaria Agraria de Colombia, Bogotá for the financing of the project.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflicts to interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jiménez Nempeque, L.V., Gómez Cabrera, Á.P. & Colina Moncayo, J.Y. Evaluation of Tahiti lemon shell flour (Citrus latifolia Tanaka) as a fat mimetic. J Food Sci Technol 58, 720–730 (2021). https://doi.org/10.1007/s13197-020-04588-y

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-020-04588-y