Abstract

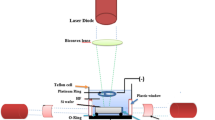

In this work, two configurations (planner and sandwich) structures of (Al/n PSi/n-Si/Al) porous silicon (PSi) gas sensor have been fabricated and tested extensively for CO2 gas molecules. Two laser wavelength infrared and violet of (810 nm) and (405 nm) was used in the laser assisting etching process on the n-type silicon substrate. The gas detection characteristic of planner and sandwich configuration were studied under different condition. The resistance measurement, for the planner and J-V characteristic for sandwich structures, which was analyzed based on the nano-sized silicon, porosity, layer thickness, and the effective dielectric constant of the PSi layer. The SEM image of the PSi layer showed the formation pore-like structure with cylindrical and rectangular pore shape with different dimensions for infrared illuminated PSi and crossed pores-like structure with randomly distributed for violet illuminated PSi. The sensing mechanism for sandwich structure configuration is governed by the porous silicon parameters, while for planer configuration the silicon channel among the pore has a significant role in sensing process.

Article PDF

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

References

Aroutiounian VM (2013) Porous silicon gas sensors. In: Jaaniso R, Tan OK (eds) Semiconductor gas sensors. Wood head Publ. Ltd., Cambridge, pp 408–430

Saha H (2008) Porous silicon sensors-elusive and erudite. Int J Smart Sensing Intell Syst 1:34–56

Miller BL, Fauchet PM, Horner SR, Chan S (2012) Identification of gram negative bacteria using nanoscale silicon microcavities. J Am Chem Soc 123(47):11797–11798

Jeyakumaran N, Natarajan B, Ramamurthy S, Vasu V (2007) Structural and optical properties of n-type porous silicon-effect of etching time. IJNN 3(1):45–51

Soni RK, Bassam GR, Abbi SC (2003) Laser-controlled photoluminescence characteristics of silicon nanocrystallites produced by laser-induced etching. Appl Surf Sci 214–160

Canham LT (1990) Silicon quantum wire array fabrication by electrochemical and chemical dissolution of wafers. Appl Phys Lett 57:1046–1048

Licznerski B (2004) Thick-film gas microsensors based on tin dioxide. Bull Polish Acad Sci Tech Sci 52(1):37–42

Kaneyasu K, Otsuka K, Setoguchi Y, Sonoda S, Nakahara T, Aso I, Nakagaichi N (2000) A carbon dioxide gas sensor based on solid electrolyte for air quality control. Sens Actuators B 66:56–58

Frank J, Meixner H (2001) Sensor system for indoor air monitoring using semiconduction metal oxide and IR-absorption. Sens Actuators B 78:298–302

Herrán J, Mandayo GG, Castaño EJ (2008) Solid state gas sensor for fast carbon dioxide detection. Sens Actuators B 129:705–709

Kayahan E, Bahsi ZB, Oral AY, Sezer M (2014) Porous silicon based sensor for organic vapors. In: Proceedings of the 4th international congress APMAS. Fethiye

Miranda CRB, Baldan MR, Beloto AF (2008) Morphological and optical characteristics of porous silicon produced by anodization process in HF-acetonitrile and HF-ethanol solutions. J Braz Chem Soc 19(4):769–774

Gholami M, Bhar M, Azim-Araghi ME (1986) The preparation of TiO2 nanoparticles and investigation of its electrical properties as CO2 gas sensor at room temperature. Elixir Chem Phys Letter 48: 9626–9628

Alwan AM, Abdulzahra NZ, Ahmed NM, Halim NHA (2009) Influence of rapid thermal oxidation process on the optoelectronic characteristics of PSI devices. Int J Nanoelect Mater 2:157–161

Alwan AM, Jawad MSM (2013) The photolumine-science characteristics of partially and fully (P-N) porous silicon. Eng Tech J 31(3):391–399

Peng C, Hirschmanand KD, Fauchet PM (1996) Carrier transport in porous silicon light-emitting devices. J Appl Phys 80:295–300

Dian J, Chvojka T, Vrkoslav V, Jelínek I (2008) Photoluminescence quenching of porous silicon in gas and liquid phases – the role of dielectric quenching and capillary condensation effects. Phys Stat Sol (C) 2(9):3481–3485

Choi Y-J, Hwang I-S, Park J-G, Choi K-J, Park J-H, Lee J-H (2008) Novel fabrication of a SnO2 nanowire gas sensor with high gas response. Nanotechnology 19:095508

Stievenard D, Deresmes D (1995) Are electrical properties of an aluminium-porous silicon junction governed by Dangling bonds. Appl Phys Lett 67:1570

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Alwan, A.M., Abbas, R.A. & Dheyab, A.B. Study the Characteristic of Planer and Sandwich PSi Gas Sensor (Comparative Study). Silicon 10, 2527–2534 (2018). https://doi.org/10.1007/s12633-018-9787-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-018-9787-2