Abstract

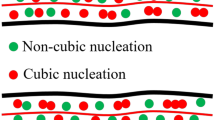

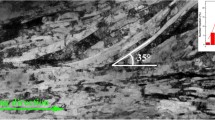

The structure refinement is a challenge for conductors used for the winding of resistive coils producing non-destructive pulsed magnetic fields over 80T. These nanocomposite conductors composed of a conducting multiscale Cu matrix embedding Nb reinforcing nanofilaments are usually manufactured by using a Severe Plastic Deformation (SPD) process based on hot extrusion, accumulative cold drawing and bundling (ADB) steps [Thilly et al. Philos Mag A 82:925, 2002]. Equal-channel angular extrusion (ECAE) is investigated here as an alternative route since it may provide faster refinement to obtain the ultrafine structure needed for optimized electrical and mechanical properties of the conductors. Therefore, copper-niobium specimens obtained by hot extrusion were processed by ECAE at room temperature. The specific die of the ECAE tool used here is constituted by a round channel with three angles corresponding to a total equivalent strain of about 2.5. Deformed samples were examined by optical microscopy and characterized by hardness profiles and x-ray diffraction (texture pole figures). After one ECAE-pass, the shape of the samples is modified but no trace of damage appeared at the Cu-Nb interfaces. An increase of the hardness values localized in the copper matrix is revealed whereas the hardness of the niobium remains unchanged. Prior to ECAE, the hot extrusion process induced a fibre texture for both copper and niobium. Two fibre texture components were observed for copper: <111> and <200>. A single <110> fibre texture component is evidenced for the niobium. After ECAE a significant variation of the texture is observed in relation with the strong shear induced by this process.

Similar content being viewed by others

References

Thilly L, Ludwig O, Véron M, Lecouturier F, Peyrade JP, Askénazy S (2002) Philos Mag A 82:925

Spencer K, Lecouturier F, Thilly L, Embury JD (2004) Adv Eng Mater 6:290

Vidal V (2006) Doct. Thesis, Toulouse University

Vidal V, Thilly L, Van Petegem S, Stuhr U, Lecouturier F, Renault PO, Van Swygenhoven H (2009) Scr Mater 60:171–174

Segal VM, Reznikov VI, Drobyshevskiy AE, Kopylov VI (1981) Russ Metall (Engl Transl) 1:1115

Segal VM (1995) Mater Sci Eng A 197:157

Molodova K, Gottstein G, Winning M, Hellmig RJ (2007) Mater Sci Eng A 460–461:204–213

Lugo N, Llorca N, Cabrera JM, Horita Z (2008) Mater Sci Eng A 477(1–2):366–371

Mishin OV, Gertsman VY, Valiev RZ, Gottstein G (1996) Scr Mater 35(7):873–878

Wu BL, Huang Z, Zhang YD, Bao L, Esling C (2007) Trans Nonferrous Met Soc China 17(3):479–485

French patent N° FR2859928 A1, Sept. 2003

Valiev RZ, Alexandrov IV, Zhu YT, Lowe TC (2002) J Mater Res 17:5

Suzuki S, Utsunimiya H, Nakajima H (2008) Mater Sci Eng A 490:465–470

Baudin T, Etter A, Penelle R (2007) Mater Charact 58(10):947–952

Huang WH, Chang L, Kao PW, Chang CP (2001) Mater Sci Eng A307:113–118

Beyerlein IJ, Tóth LS (2009) Prog Mater Sci 54:427–510

Kocks UF, Tomé CN, Wenk HR (1998) Texture and anisotropy. Cambridge University Press

Montheillet F, Cohen M, Jonas JJ (1984) Acta Metall 32:2077–89

Acknowledgement

This work was carried out with the financial support of the French National Research Agency (ANR) under the ANR-Project “Nanofilmag” (ANR-06-MAPR-0013).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Buet, E., Dubois, JB., Olier, P. et al. Microstructure and texture of copper/niobium composites processed by ECAE. Int J Mater Form 5, 121–127 (2012). https://doi.org/10.1007/s12289-011-1027-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-011-1027-x