Abstract

Energy balances are usually aggregated at the level of subsector and energy carrier. While heating and cooling accounts for half the energy demand of the European Union’s 28 member states plus Norway, Switzerland and Iceland (EU28 + 3), currently, there are no end-use balances that match Eurostat’s energy balance for the industrial sector. Here, we present a methodology to disaggregate Eurostat’s energy balance for the industrial sector. Doing so, we add the dimensions of temperature level and end-use. The results show that, although a similar distribution of energy use by temperature level can be observed, there are considerable differences among individual countries. These differences are mainly caused by the countries’ heterogeneous economic structures, highlighting that approaches on a process level yield more differentiated results than those based on subsectors only. We calculate the final heating demand of the EU28 + 3 for industrial processes in 2012 to be 1035, 706 and 228 TWh at the respective temperature levels > 500 °C (e.g. iron and steel production), 100–500 °C (e.g. steam use in chemical industry) and < 100 °C (e.g. food industry); 346 TWh is needed for space heating. In addition, 86 TWh is calculated for the industrial process cooling demand for electricity in EU28 + 3. We estimate additional 12 TWh of electricity demand for industrial space cooling. The results presented here have contributed to policy discussions in the EU (European Commision 2016), and we expect the additional level of detail to be relevant when designing policies regarding fuel dependency, fuel switching and specific technologies (e.g. low-temperature heat applications).

Similar content being viewed by others

Notes

In the EU project ‘Mapping and analyses of the current and future (2020–2030) heating/cooling fuel deployment (fossil/renewables)’ (Fraunhofer ISI, Fraunhofer ISE, TU Wien, TEP Energy, IREES, Observer 2016), a comprehensive analysis has been carried out of the availability of end-use balances in the EU28 + 3, including the residential and tertiary sector as well.

The illustration shows model results for heating and cooling demand presented at the aggregation level also available in energy balances. The actual energy balances include additional electricity for non-heating/cooling uses.

The analysis presented here only comprises one base year, so there is no temporal dimension included. When used in scenario analysis, both the industrial production (IP p, c ) and the energy carrier shares (ShareEC s, ec, c ) may change each year.

It may be unclear, for example, whether this cooling is carried out actively (with additional energy demand or waste heat use) or passively.

The share of energy demand used for heating and cooling (ShareH/C) translates the total energy demand given by the SEC into process heat demand.

The analysis presented here only comprises one base year, so there is no temporal dimension included. When used in scenario analysis, both the employment data (EMP c, s ) and the specific energy demand of the buildings (SEC c, b ) may change each year.

See supplementary data for values.

See supplementary data for values.

See supplementary data for values and details on data origin.

For electrolysis, we included shares of electricity use as process heat, depending on the specific process description. Since, for example, electrolysis in the primary production of aluminium in the Hall–Héroult process requires a temperature of around 950 °C, we assign approx. 2.5-GJ/t electricity use as process heat. While the theoretical minimum would be approx. 0.8 GJ/t, special conditions of the process induce heat losses (US Department of Energy 2008; Nowicki and Gosselin 2012). The distinction between process heat in our definition and process-specific electricity use is therefore not trivial.

Of the 25 processes presented, the ten biggest include eight processes that mainly or exclusively use high-temperature heat above 500 °C.

For example, for 2015, Eurostat’s energy balances (Eurostat 2016b) show 46 ktoe (0.53 TWh) industrial energy demand for Malta, with 36 ktoe (0.42 TWh) of electricity. This proportion is very different from the ones we observe in other economies. The model is not well suited to deal with this, whether the cause is a real difference in economies or a statistical issue.

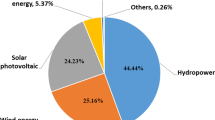

The general distribution of energy carriers can already be derived from Eurostat (2016b). The main difference in these results is that they refer to heating and cooling instead of total energy demand. This does, however, mainly affect electricity, as fuels are assumed to be used for heating uses only.

Smaller countries tend to have a less complete process portfolio. This has the effect of enhancing any errors in the assumptions about processes that do exist. Additionally, outliers of specific energy consumption are accorded higher weight.

Note that Ireland (5) and Estonia (10) have very poor BU-coverage in Fig. 15, indicating inconsistency between the energy balance and production statistics.

The German end-use balance 2012 is not a suitable candidate for comparison as it was compiled with the support of the same model we use here.

Naegler et al. (2015) claim to match the energy balance, too.

Patterson (1996) categorises ‘persistent methodological problems’: value judgements (e.g. what is useful energy), energy quality (e.g. enthalpy vs. exergy), boundaries (e.g. which input is considered to enter the energy balance and in what quality and state?), joint production (e.g. what is the main product of a process with multiple outputs and how to assign its energy use; combined heat and power production is the most popular example) and technical/gross efficiency.

For example, by providing a more detailed picture of waste heat potentials, the use of temperature-dependent technologies like heat pumps and solar thermal systems, or by estimating the effect of differences in industrial structure on heating demand (via a country comparison).

References

Arens et al. (2012). Energy intensity development of the German iron and steel industry between 1991 and 2007. Energy, 45(2012), 786–797.

Arens et al. (2016). Pathways to a low-carbon iron and steel industry in the medium-term—the case of Germany. Journal of Cleaner Production, 2016. https://doi.org/10.1016/j.jclepro.2015.12.097.

Bakhtiari et al. (2010). Opportunities for the integration of absorption heat pumps in the pulp and paper process. Energy, 35(2010), 4600–4606.

Biere et al. (2014). Industry—more than just processes: a combined stock-model approach to quantify the energy saving potential for space heating in European industry. ECEEE industrial summer study proceedings 2014.

Brauer (1996). Handbuch des Umweltschutzes und der Umwelttechnik Band 2: Produktions- und produktintegrierter Umweltschutz, Heidelberg 1996.

BREF Glass (2013). Best available techniques (BAT) reference document for the manufacture of glass. http://eippcb.jrc.ec.europa.eu/reference/. Accessed 3/27/2017, Luxembourg 2013.

BREF Ceramic (2007). Reference document on the best available techniques in the ceramic manufacturing industry. http://eippcb.jrc.ec.europa.eu/reference/. Accessed 3/27/2017, Luxembourg 2007.

Bundesverband der Gipsindustrie (2013). Gips-Datenbuch. Berlin 2013, http://www.gips.de/download/publikationen/buecher/. Accessed 3/28/2017.

Büchel et al. (1999). Industrielle anorganische chemie (3rd ed.). Weinheim (Germany): Wiley-VCH Verlag 1999.

Cembureau (2013). World statistical review 2001–2013. http://www.cembureau.be/world-statistical-review-2001-2013. Accessed 3/29/2017.

Cheeley (1999). Gasification and the MIDREX direct reduction process. Presentation at the 1999 gasification technologies conference, San Francisco 1999.

Department for Business, Energy & Industrial Strategy (2016a). Energy consumption in the UK (ECUK) 2016 data tables. Table 4.04. https://www.gov.uk/government/statistics/energy-consumption-in-the-uk. Accessed 12/19/2016.

Department for Business, Energy & Industrial Strategy (2016b). Digest of United Kingdom Energy Statistics (DUKES) 2016. https://www.gov.uk/government/collections/digest-of-uk-energy-statistics-dukes. Accessed 12/19/2016.

Department for Business, Energy & Industrial Strategy (2016c). Energy consumption in the UK: a user guide. https://www.gov.uk/government/statistics/energy-consumption-in-the-uk. Accessed 12/19/2016.

Dondi et al. (1997). Recycling of industrial and urban wastes in brick production—a review. Tile & Brick International, 13(3), 1997.

ECHA (2016). Registered substances. European chemicals agency: information on chemicals. http://echa.europa.eu/information-on-chemicals/registered-substances. Accessed 4/14/2016.

EuroChlor (2017). Chlorine industry review (2015–2016). Belgium, http://www.eurochlor.org/media/106905/euro_chlor_review_web.pdf. Accessed 3/29/2017.

European Commission (2007). Lot 12 commercial refrigerators and freezers. Final report. Preparatory Studies for Eco-design Requirements of EuPs [TREN/D1/40–2005/LOT12/S07.56644]. Brussels 2007.

European Commission (2011). ENTR-Lot 1 refrigerating and freezing equipment. Preparatory Studies for Eco-design Requirements of EuPs [Contract N° S12.515749]. Brussels 2011.

European Commission (2014). Quality report of European Union energy statistics. http://ec.europa.eu/eurostat/documents/38154/4956233/ESR-Qualityreport-2014.pdf. Accessed 3/24/2017.

European Commission (2016). European commission—fact sheet, http://europa.eu/rapid/press-release_MEMO-16-311_en.htm#_ftnref1. Accessed 8/11/2016.

Fraunhofer ISI, Fraunhofer ISE, TU Wien, TEP Energy, IREES, Observer (2016). Mapping and analyses of the current and future (2020–2030) heating/cooling fuel deployment (fossil/ renewables). https://ec.europa.eu/energy/en/studies. uploaded 3/2017. Accessed 3/20/2017.

European Parliament (2008). Regulation (EC) No 1099/2008 of the European parliament and of the council. http://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex:32008R1099. Accessed 4/14/2016.

Eurostat. (2007). Panorama of energy—energy statistics to support EU policies and solutions. Luxembourg: European Communities.

Eurostat (2016a). Eurostat structural business statistics, annual detailed enterprise statistics for industry (NACE Rev. 2, B-E) (sbs_na_ind_r2). http://ec.europa.eu/eurostat/en/web/products-datasets/-/SBS_NA_IND_R2. Accessed 4/8/2016.

Eurostat (2016b). Database on energy demand/energy balances. http://ec.europa.eu/eurostat/data/database. Accessed 4/14/2016.

Fleiter et al. (2012). Energy efficiency in the German pulp and paper industry—a model-based assessment of saving potentials. Energy, 40(2012), 84–99.

Fleiter et al. (2013). Energieverbrauch und CO2-Emissionen industrieller Prozesstechnologien—Einsparpotenziale, Hemmnisse und Instrumente. Stuttgart 2013.

German Pulp and Paper Association (VDP) (2016). Papierkompass 2014/2015 and older issues. https://www.vdp-online.de/industrie/statistik.html. Accessed 3/29/2017.

Glassglobal (2017): “Glassglobal Plants”, restricted online database, available at: https://plants.glassglobal.com/login/, accessed: 3/29/2017.

Gutierrez, V. (2011). Exergy-based indicators to evaluate the possibilities to reduce fuel consumption in lime production. Energy, 36(2011), 2820–2827.

Hara et al. (1999). Smelting reduction process with a coke packed bed for steelmaking dust recycling. ISIJ International, 40 (2000), (3), 231–237.

ISI (2013). Erstellung von Anwendungsbilanzen für das Jahr 2012 für das verarbeitende Gewerbe mit Aktualisierungen für die Jahre 2009–2011. Karlsruhe, 2013.

Krone (2000). Aluminiumrecycling Vom Vorstoff bis zur fertigen Legierung. Aluminium-Verlag, Düsseldorf 2000.

Laurijssen et al. (2012). Benchmarking energy use in the paper industry: a benchmarking study on process unit level. Energy Efficiency (2013), 6, 49–63.

Lauterbach et al. (2012). The potential of solar heat for industrial processes in Germany. Renewable and Sustainable Energy Reviews, 16(2012), 5121–5130.

Midrex (2013). The MIDREX Process. Company brochure. https://www.midrex.com/assets/user/media/MIDREX_Process-Brochure.pdf. Accessed 3/28/2017.

Naegler et al. (2015). Quantification of the European industrial heat demand by branch and temperature level. International Journal of Energy Research (2015). https://doi.org/10.1002/er.3436.

Nowicki, & Gosselin. (2012). An overview of opportunities for waste heat recovery and thermal integration in the primary aluminum industry. JOM (2012), 64, 990. https://doi.org/10.1007/s11837-012-0367-4.

Pardo et al. (2013). Methodology to estimate the energy flows of the European Union heating and cooling market. Energy, 52, 339–352.

Patil and Khond (2014). Alternative fuels for cement industry: a review. Proceedings of the 2014 international conference on industrial engineering and operations management, 2014.

Patterson. (1996). What is energy efficiency? Concepts, indicators and methodological issues. Energy Policy, 24(5), 377–390.

Rahman et al. (2013). Impact of alternative fuels on the cement manufacturing plant performance. An overview. Procedia Engineering, 56(2013), 393–400.

Primetals (2015). COREX® efficient and environmentally friendly smelting reduction. Company brochure. http://primetals.com/en/technologies/ironmaking/corex%C2%AE. Accessed 3/28/2017.

Statistik Austria 2016a. EEV 2005 bis 2015 nach ET und Nutzenergiekategorien für Österreich (Detailinformationen). http://www.statistik.at/web_de/statistiken/energie_umwelt_innovation_mobilitaet/energie_und_umwelt/energie/nutzenergieanalyse/index.html. Accessed 12/20/2016.

Statistik Austria 2016b. Gesamtenergiebilanz Österreich 1970 bis 2015 (Detailinformation). http://www.statistik.at/web_de/statistiken/energie_umwelt_innovation_mobilitaet/energie_und_umwelt/energie/energiebilanzen/index.html. Accessed 12/20/2016.

SVK, (2012). Elektrizitätsbedarf für Kühlen in der Schweiz - Kampagne effiziente Kälte. Zürich, September 2012.

UBA (2015). Sustainable cooling supply for building air conditioning and industry in Germany. Dessau-Roßlau, April 2015.

UNdata (2017) (FAO). Paper and Paperboard. UNdata viewer presentation of data from FAO (Food and Agriculture Organization). http://data.un.org/. Accessed 3/29/2017.

UNFCCC (2017). Flexible Queries. http://unfccc.int/di/FlexibleQueries.do. Accessed 3/20/2017.

US Geological Survey (2017). Mineral Information. https://minerals.usgs.gov/minerals/pubs/country/europe.html#au. Accessed 3/29/2017.

U.S. Department of Energy (2008). Waste heat recovery: technology and opportunities in U.S. Industry. March 2008.

van Deventer. (1997). Feasibility of energy efficient steam drying of paper and textile including process integration. Applied Thermal Engineering, 17, 1035–1041.

VDMA (2011). Energiebedarf für Kältetechnik in Deutschland - Eine Abschätzung des Energiebedarfs von Kältetechnik in Deutschland nach Einsatzgebieten. Frankfurt am Main, 17.03.2011.

Werner (2006). The new European heating index. 10th international symposium on district heating and cooling (September 3–5, 2006), Section 4 a: Effects on DH from directives, laws and regulations, Hanover.

Werner (2015). European space cooling demands. Energy (2015), 1–9.

Weissermel, Arpe (1998). Industrielle Organische Chemie. 5th Edition, Weinheim (Germany) 1998.

World Steel Association (2016). Steel statistical yearbook (and previous issues). https://www.worldsteel.org/steel-by-topic/statistics/steel-statistical-yearbook-.html. Accessed 3/20/2017.

Winnacker-Küchler (2006). Chemische Technik Prozesse und Produkte, 6a Metalle. Darmstadt, ISBN-13: 978–3–527-31580-2.

Worrell et al. (2008). World best practice energy intensity values for selected industrial sectors. Berkeley, USA 2008.

Acknowledgements

We would like to acknowledge the contribution of the team involved in the ‘Mapping Heat’ project (Fraunhofer ISI, Fraunhofer ISE, TU Wien, TEP Energy, IREES, Observer 2016), Matthias Reuter, who gathered information on European energy and end-use balances, Andrea Herbst, who maintains and updates our database of industrial production and Felix Reitze for his support with process cooling. We would also like to thank the three anonymous reviewers for their helpful comments and patience.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Electronic supplementary material

ESM 1

(XLSX 80 kb)

Rights and permissions

About this article

Cite this article

Rehfeldt, M., Fleiter, T. & Toro, F. A bottom-up estimation of the heating and cooling demand in European industry. Energy Efficiency 11, 1057–1082 (2018). https://doi.org/10.1007/s12053-017-9571-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12053-017-9571-y