Abstract

UV-curable acrylate-based coatings were modified by copolymerization of base resins with polyhedral oligomeric silsesquioxanes (POSS) containing four methacryloxy and four fluoroalkyl substituents in one molecule (4M4F-POSS), giving hybrid organic–inorganic coatings. Such modifiers are covalently linked to the matrix (by methacryloxy groups) preventing them from exuding onto the surface, and fluoroalkyl substituents (along with the POSS cages) improve scratch resistance and hydrophobicity. Two types of POSS derivatives differing with the length of the fluoroalkyl chain were tested. These compounds were applied in two types of formulations: wood-derived and aluminum substrates. Modification of the coatings led to a substantial increase in the hydrophobicity and enhanced scratch resistance after incorporation of only 1.5 wt% of the modifier. Water contact angle increased by up to 14–160% of the initial value, whereas the scratch hardness for the first surface stripping improved by about 30–170% in the presence of 5 wt% of POSS. The latter can be associated with the increase in the surface sliding properties caused by the presence of fluoroalkyl substituents of the modifier. Better results were obtained for POSS containing shorter fluoroalkyl substituents.

Similar content being viewed by others

Introduction

UV-curable resins have been utilized since the 1960s and are extensively applied in adhesives, inks, electronics, optics, microfabrications, biomedical materials and, more importantly, in coatings on polycarbonate sheets, optical filters, lenses, displays and compact disks.1,2 These types of coatings have high transparency and scratch resistance, but there is still a need to improve some properties such as shrinkage during polymerization, gas barrier properties, abrasion, impact resistance or water contact angle for self-cleaning surfaces.3,4

UV-curing is an efficient method to produce crosslinked materials, due to the very rapid curing rate at ambient temperature, less environmental pollution, low VOC emission, and low costs of the process, including low energy consumption.2,4,5,6

Polyhedral oligomeric silsesquioxanes (POSS) are among the best candidates to improve the physical properties of polymers,3 such as surface hardness, mechanical characteristics, flammability resistance, and oxidation resistance.7,8,9,10 Those nanofillers (size 1–3 nm),9 which represent a class of inorganic–organic hybrid materials, are widely used to modify properties of many polymeric materials like thermoplastics, thermosets and hardened polymers.11 POSS are compounds having a cage structure described by the general formula (RSiO1.5)n (n = 6, 8, 10,…), where R is an organic group and the octahedron (n = 8) is the most typical species.6,12 Various substituents can be introduced into the eight corners, leading to a tunable performance.3 They can be the polar or nonpolar functional nonreactive or reactive groups. Functional groups can make POSS molecules compatible or miscible with monomers and polymers. Reactive groups can bond covalently during the copolymerization with other monomers or graft onto the polymer chain or network, helping to achieve molecular dispersions in the resulting polymer. The presence of these groups in POSS molecules exerts a significant influence on the improvement in thermal stability and mechanical properties of obtained nanocomposites or hybrid polymers.1,4,12,13

It has been reported that incorporation of fluorine-containing POSS compounds into polymers leads to nanocomposites which display low surface energy.14,15,16 The fluorinated POSS can migrate onto the surface of the formulation and decrease the interface energy between UV-curable liquid acrylate resin and air.16

Our earlier work considered the effect of addition of octasubstituted fluoroalkyl POSS derivatives (8F-POSS) on properties of acrylate-based photocurable coatings.17 The effect of this type of modification was compared to the effect of modification with octamethacryloxy derivative (8M-POSS) and the mixture of 8F-POSS and 8M-POSS. All these modifications provided the ability to obtain coatings with improved scratch hardness and hydrophobicity. The best results (synergistic effect) gave mixtures of 8M-POSS and 8F-POSS. However, the problem associated with this kind of modification is that nonreactive POSS with fluoroalkyl groups diffuses to the surface of the coating which results in the formation of an unbound modifier layer on the surface. The best way to eliminate this shortcoming is application of POSS derivatives with two different types of substituents in one molecule, i.e., four substituents containing polymerizable methacryloxy groups and four nonreactive substituents—fluoroalkyl chains. This can enable similar improvement in coating properties (scratch resistance and hydrophobicity) as in the case of the POSS mixture but without sweating of the modifier to the surface. Therefore, the aim of the work was to investigate the effect of coating modification with POSS compounds containing mixed fluoroalkyl and methacryloxy substituents. Two types of formulations were tested: wood-derived and aluminum substrates.

Materials and experimental methods

Reagents

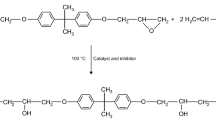

Acrylate resins dedicated to UV-curable coatings on wood and metal substrates: Ebecryl 80 (E80), Ebecryl 81 (E81), Ebecryl 860 (E860) and Ebecryl 168 (E168) were kindly donated by Cytec Industries. The low viscosity monomer used as a reactive diluent, 1,6-hexanediol diacrylate (HDDA) and photoinitiator 2-methyl-4′-(methylthio)-2-morpholinopropiophenone (MTMPF), was purchased from Sigma-Aldrich. Polyhedral oligomeric silsesquioxanes: tetra(methacryloxypropyl)dimethylsiloxy)tetra(octafluorpentyloxypropyl)dimethylosiloxy) octasilsesquioxane (4M4F8-POSS) and tetra(methacryloxypropyl)dimethylsiloxy)tetra-(tetrafluorpentyloxypropyl)dimethylosiloxy)octasilsesquioxane (4M4F4-POSS), were kindly donated by Wielkopolska Centre of Advanced Technologies (synthesized according to procedures described previously18,19,20). These compounds are classified as spherosilicates because the substituents in the investigated compounds were linked to the POSS cage via –Si(CH3)2O– bridges. All these POSS compounds were liquids. The chemicals were used as received. The structures and abbreviations of POSS compounds are shown in Fig. 1.

Coating formulation

The coatings were individually selected for two types of substrates: (1) medium-density fiberboard, MDF board, dimensions 150 × 100 × 6 mm, and (2) aluminum plates: 5251 alloy according to EN standard, dimension 150 × 100 × 2 mm. UV-curable formulations for each substrate had a different composition. The base resin for MDF plates was a mixture of two resins E80 and E81 in the weight ratio 40/60 (denoted as E80/E81) and for aluminum plates—a mixture of E860, E80 and HDDA in the weight ratio 35/35/30 (denoted as E860/E80/HDDA). The base resins were modified with 4M4F4-POSS or 4M4F8-POSS in the concentration of 1.5, 3.0 and 5.0 wt%. The compositions of all the formulations are given in Tables 1 and 2. The photoinitiator content was 3 wt%. The formulations were homogenized first in an ultrasonic bath (30 min, Sonic3, POLSONIC) and then mechanically using an orbital shaker (2000 rpm, 30 min, MS3, IKA).

Coating application and curing

Methods of coating application on the MDF and aluminum substrates as well as the UV-curing process are described in detail in reference (17). Briefly, MDF substrate was sanded (1000 or 1200 grit), cleaned and covered at first with a precoating layer (thickness 30 μm) and then with two coating layers (120 and 80 μm); each layer was cured during passing under UV lamp in DYMAX UVC-5 Conveyor System (metal halide (Fe) bulb, 200–700 nm; light intensity 1, 5 W cm−2 measured with Dymax radiometer ACCU-CAL-50): precoating layer: 3 s, the belt speed 7 m min−1; first and second layer: three passes (3 × 10 s, the belt speed 1.4 m min−1) with 15-s break after each pass.

The aluminum plate, after proper preparation (sanding and purifying by immersion of the plate in various solvents, drying),17 was covered with a layer of adhesion promoter (E168) and irradiated for 3 s (the belt speed 7 m min−1) in DYMAX UVC-5 Conveyor System (conditions as above). Then, two coating layers (80 and 30 μm) were successively applied and cured by three passes (3 × 10 s) under the UV lamp (the belt speed 1.4 m min−1) with 15-s break between each pass.

Characterization of coatings before and after UV-curing

Viscosities of UV-curable formulations

Brookfield Rheometer DV-II+ PRO in a cone-and-plate geometry was used to measure viscosities η of the investigated formulations (at 25°C) in the range of 75–1500 s−1 of the shear rate. The viscosities were found to be independent of the shear rate.

FTIR

Nicolet 5700 FTIR spectrometer (Thermo Electron Scientific Instruments Corporation, USA) equipped with ATR accessory with a ZnSe crystal was used to take infrared spectra. From spectra obtained before and after the photopolymerization, the final double bond conversion pf was determined based on changes in the absorbance (peak height) of the acrylate double bond absorption band at about 812 cm−1. A deconvolution technique was employed to separate overlapping bands in the region of the double bond absorption.

DSC

Calorimetry experiments were conducted using a Mettler Toledo DSC1 instrument. Approximately 5–10 mg of each coating was placed into an aluminum pan, heated at 20°min−1 to 180°C, cooled at 20°min−1 to − 80°C and heated again at 20°min−1 to 180°C. The glass transition temperature (Tg) was determined from the second heating cycle. The Tg values were taken as average values from three measurements.

Scratch hardness

The scratch hardness (first visible scratch HFVS and first surface stripping HFSS) was calculated on the basis on the load and scratch width measurements from the following equation14,21,22:

where x is the parameter specifying the nature of the tip contact with the coating (1 < x < 2 for viscoelastic or viscoplastic deformation, x = 1 for purely elastic contact and x = 2 for plastic deformation), L is the tip load, and w is the scratch width. In this study, the x parameter was taken as 1.

The scratch hardness of investigated coatings was probed by using a commercially available Tester Lineartester 249 (Erichsen GmbH & Co. KG) to follow an PN-EN 15286:2012 standard, method A23 testing protocol. Briefly, investigated coatings on MDF and aluminum substrates were conditioned for seven days at ambient conditions (approx. 25°C). Then coatings were scratched to determine first visible scratch (FVS) and first surface stripping (FSS). The apparatus was equipped with a load from 1.0 to 40.5N with measurement accuracy of 0.5N. The load of the tip (IHD 0842.01.32 for the MDF substrate; ø 0.6 mm or ISO 0208.02.32 for the aluminum substrate; ø 1.0 mm) and width of the scratch were specified. The tip was moving with a speed of 35 mm s−1. The FVS and FSS scratches were observed under a microscope SMZ-143 (Motic Deutschland GmbH). After 24 h, the scratches were stained with a dark marker and their photographs were taken under the microscope. Their widths were determined from the picture obtained in the Motic Images Plus 2.0 software.

Water contact angle

Water contact angle measurements were taken at ambient conditions (about 25°C) by sitting drop method. The contact angle was measured after 5 s from placing the droplet (7 μl) of distilled water on the investigated coating. The measurement was repeated nine times, and the result is the average of these measurements. The coatings were tested 14 days after their curing.

Scanning electron microscopy (SEM)

The morphology of investigated coatings was observed by EVO 40 Series, Carl Zeiss AG scanning microscopy (SEM). The samples were coated with thin layers of gold to make the surface conductive.

Resistance to liquids

The resistance of the investigated coatings to solvents was measured according to PN-EN ISO 2812-324 at ambient conditions (about 25°C). Ethanol (95%), acetone (99.5%), toluene (99.5%), 5% NaOH and 3% H2SO4 solutions in water were used as solvents. The test was carried out on samples after 7 days from their UV-curing using the following procedure: a cotton wool was soaked with the appropriate liquid, applied on the coating and covered with a glass lid. After 2 h, the soaked cotton wool was removed and the sample surface was wiped by dry cotton wool. The changes on the coating surface were evaluated visually.

Results and discussion

Coatings on MDF substrate (based on E80/E81 resin)

Formulation viscosity

The dependence of the formulation viscosity on the modifier content is shown in Fig. 2. Addition of 4M4F-POSS derivatives in very low concentrations (up to 1.5 wt%) causes an increase in the system viscosity. This means that at such low POSS content interactions between the molecules of the resin and the modifier increase, probably as a result of entanglement of long substituents of the POSS cage with the chains of the resin. Further increase in the modifier content (> 1.5 wt%) leads to the reduction in viscosity revealing a lubrication effect of POSS nanoparticles.25,26 At these (still low) concentrations, the modifier is well dispersed and the mobility of chains of the resin (matrix precursor) enhances due to the increase in the free volume caused by the presence of bulky POSS molecules. The viscosity reaches its minimum at ~ 5 wt% of 4M4F-POSS. Further increase in POSS content causes a gradual disappearance of the lubrication effect and strong increase in viscosity. This is associated with POSS agglomeration which imposes a hindrance effect on the oligomer chains. Additionally, the very high initial viscosity of POSS begins to prevail (4M4F4 = 3152 mPa s, 4M4F8 = 1105 mPa s), whereas the viscosity of the mixture of the neat resin E80/E81 is only 289 mPa s. It is worth mentioning that analogous plots for the resin filled with uniformly substituted POSS modifiers, like 8M-POSS, 8F-POSS as well as their mixture, show minima at much lower modifier contents, i.e., 1.5 wt%.17 Thus, for POSS compounds with one type of substituents, regardless of their nature, the minimum of the formulation viscosity occurs at the same content of the modifier. This proves that interactions between the resin molecules and POSS molecules depend not only on the type of substituents but also on the type of substitution (uniform or mixed) which in turn can affect the quality of dispersion (size of aggregates).

Double bond conversion

An important factor influencing coating properties is conversion of double bonds, both on the surface as well as the through-cure. To get this information, the photocured coatings have been removed from the support and the FTIR spectra were taken from both sides: upper (irradiated) and bottom. The results of pf determination are shown in Fig. 3. As can be seen, the difference between the double bond conversion on the top and the bottom of the coating layer is less than 3.5%. It can therefore be assumed that the degree of conversion in the entire sample volume is very similar, and the through-cure is almost unaffected by the light absorption and scattering.

The double bond conversion of the neat base resin does not reach 100% which is mainly associated with two factors: high initial viscosity of the formulation and formation of the network structure during the polymerization. High viscosity causes diffusion constraints of the monomer molecules in the polymerizing medium and reduces their mobility. Moreover, the formation of the polymer network leads to the loss of reactive pendant double bonds due to shielding effects.

Addition of 4M4F4-POSS or 4M4F8-POSS to the resin mixture causes a slight decrease in the double bond conversion by around several percent. Due to the presence of methacryloxy substituents in the molecule, the POSS modifiers act as additional crosslinkers and contribute to higher network density of the polymer being formed which leads in turn to lower conversions. In general, the final conversion depends on the mobility of the polymer network.27 The additional branching points and POSS cages further stiffen the polymer network deepening reduction in conversion. Moreover, it seems that the length of the fluoroalkyl chain has no or very little effect on the double bond conversion, e.g., pf in the presence of 4M4F4-POSS is higher only by about 2% than in the presence of 4M4F8-POSS. It should be emphasized that the average functionality of the investigated systems containing 5 wt% of the modifiers is almost the same, i.e., 2.95/mol for those containing 4M4F4-POSS and 2.98/mol for those containing 4M4F8-POSS (for the neat resin it is 2.93/mol). This indicates that the difference in conversion is not associated with the functionality of the system.

Morphology

SEM images in Fig. 4 show the surface morphology of the cured coatings containing different amounts of the POSS modifiers. The coatings modified with 4M4F4-POSS (Fig. 4a–c) have a smoother surface than those with 4M4F8-POSS (Fig. 4d–f) and contain only small amounts of bigger aggregates. This can indicate that the former modifier is more compatible with the matrix. The size of the visible aggregates ranges approx. between 100 nm and 5 μm. Their distribution in the matrix is rather uniform. Interestingly, the size of the POSS particles seems not to increase with the POSS loading. This can be associated with the tendency of the functionalized POSS nanoparticles to aggregation before the polymerization starts; the POSS molecules inside the aggregate can homopolymerize, but the external molecules copolymerize with the resin, fixing the POSS domains.

Glass transition

Glass transition temperatures for coatings containing 5 wt% (the highest loading level) of the investigated POSS compounds are shown in Fig. 5. The addition of both 4M4F8-POSS and 4M4F4-POSS increases slightly the Tg value of the polymer matrix, which is associated with the additional crosslinking by the modifiers and with the presence of POSS domains which restrict network mobility. On the other hand, the difference in the increase in Tg by the two modifiers results probably from the different plasticizing effect exerted by the long fluoroalkyl substituents; this effect is stronger in the case of the 4M4F8 derivative. Therefore, the value of the glass transition temperature is a function of polymer crosslink density (methacrylate groups), plasticizing effect of the fluoroalkyl groups and stiffening effect of POSS cages. The result—increased Tg—should be more useful than the decrease in Tg observed when the mixture 8M/8F-POSS is used as the modifier; the latter effect is associated with the plasticizing influence of the nonreactive liquid POSS additive.17

Water contact angle

The results of water contact angle measurements are shown in Fig. 6. Introduction of POSS moieties into the polymer matrix causes a strong increase in hydrophobicity of the coatings, by ca. 20–30°, which corresponds to 140–160% of the initial value. The improvement in the hydrophobicity is stronger in the case of 4M4F4-POSS than 4M4F8-POSS. The observed increase in the water contact angle is probably associated with a synergistic combination of the roughness of the material surface and the hydrophobic effect of the long fluoroalkyl side chains.15,28 The roughness represents the microstructure of the coating surface and results from the effect of rigid silicon-oxygen POSS cages and appropriate arrangement of fluoroalkyl chains on the surface of the coating. Modification with 4M4F4-POSS leads to the formation of smaller aggregates (Fig. 4) creating a surface structure that is more beneficial for lowering the contact angle. One can speculate that this beneficial effect of the surface structure is additionally supported by the advantageous arrangement of the shorter fluoroalkyl substituents.

It is interesting that the addition of only 1.5 wt% of POSS modifiers causes a sharp increase in the contact angle value, whereas increasing of POSS concentration above 1.5 wt% has almost no further effect on this parameter. Practical lack of dependence of the contact angle on the POSS content can suggest that the surface structure of the coating (the amount and the arrangement of the POSS molecules on the surface) is very similar for each POSS loading level. This in turn implies that the investigated POSS derivatives diffuse into the surface and their aggregates become fixed during UV-curing with the formation of a compact structure (texture) at relatively small amounts of the additive; at higher POSS concentration, its excess remains in the bulk.

Similar values of water contact angle were also obtained for modification with 8M/8F-POSS mixtures17; the values of water contact angle were always higher when the POSS compound with shorter fluoroalkyl chains was used. Similarity of the results obtained for both types of modifiers (containing mixed substituents or corresponding mixture of those with uniform substituents) suggests that the concentration of their aggregates on the surface is similar—they show similar compatibility with the matrix. However, the superiority of the solution with the use of POSS with mixed substituents is that there is no exudation of the modifier on the surface.

Scratch hardness

The results of the measurements are presented in Fig. 7. The hardness for first visible scratch, HFVS, (Fig. 7a) of the unmodified coating is 75 MPa. Modification with 4M4F4-POSS or 4M4F8-POSS causes an increase in HFVS with somewhat better results for 4M4F4-POSS (shorter fluoroalkyl chain). Moreover, the values of HFVS increase with increasing POSS content in the investigated range of concentration. Our previous study17 showed that the increased crosslink density does not enhance the HFVS values. Therefore, the observed effect must be associated with an increase in the surface sliding properties caused by the presence of the fluoroalkyl substituents of the modifier.

In the case of scratch hardness for the first surface stripping (HFSS), modification with 4M4F8-POSS seems to have no effect (Fig. 7b). On the other hand, an improvement is observed after modification with 4M4F4-POSS. Interestingly, very similar results were obtained for coatings modified with 4M4F8-POSS or 8M/8F8-POSS as well as with 4M4F4–POSS or 8M/8F4-POSS. This indicates the important role of the length of the fluoroalkyl substituent and can suggest better adhesion to the support in the case of the coating containing POSS functionalized with shorter fluoroalkyl chains.

The comparison of the scratch hardness results with results obtained for mixtures of the reactive and unreactive POSS compounds (8M/8F) is difficult because the exudation of the part of fluorine-functionalized unreactive POSS molecules onto the surface of the coating causes the slip of the tester scriber over the surface of the coating, resulting in overstatement of the results.

Resistance to liquids

Addition of functionalized POSS to the base resin did not change the resistance of the UV-cured coatings to solvents. Both the modified and unmodified coatings are resistant to ethanol, acetone and toluene. However, 3 wt% H2SO4 causes swelling and 5 wt% NaOH additional clouding of the samples. Despite this, the complete failure of the coatings was not observed; the changes appeared only on the surface of the samples. This result is analogous to that obtained for the mixture of uniformly substituted POSS.17

To summarize briefly, the results for coatings applied on wood-derived substrate (based on E80/E81 resin) indicate that modification with the investigated POSS compounds leads to the strong increase in water contact angle and to the improvement in the scratch hardness; both parameters are strongly dependent on the length of the fluoroalkyl substituent. Interestingly, the shorter substituents seem to give better results.

Coatings on aluminum plates (based on E860/E80/HDDA resin)

Formulation viscosity

Viscosities of formulations containing 5 wt% of the POSS modifiers are shown in Fig. 8. Viscosity of the base resin E860/E80/HDDA (403 mPa s) is higher than the viscosity of the base resin E80/E81 (289 mPa s) used for coatings on wood-derived supports. Addition of 5 wt% of 4M4F4-POSS or 4M4F8-POSS causes a decrease in viscosity, so the influence of the investigated POSS modifiers is similar to the E80/E81-based systems. However, in this case, a greater impact on the viscosity change exerts 4M4F8-POSS. Explanation of the POSS influence on the coating viscosity is analogous to that described in the “Coatings on MDF substrate (based on E80/E81 resin)” section.

Double bond conversion

The final double bond conversion of the unmodified base resins is rather high (82%, Fig. 9), similar to the case of the E80/E81 resin. Practically no change in double bond conversion is observed for formulations modified with 5 wt% of 4M4F4-POSS or 4M4F8-POSS (from both sides of the coating; difference between the top and bottom was about 1.5%). This result is very interesting because one can expect a reduction in the pf value due to the enhanced crosslinking density (as for E80/E81-based formulation). On the other hand, we should take into account the plasticizing effect exerted by fluoroalkyl substituents attached to POSS cages which can increase system mobility. It seems that in the case of E860/E81/HDDA resin these two opposite effects may counterbalance, and the observed result is practically unchanged final conversion.

Glass transition

Although addition of 4M4F4-POSS or 4M4F8-POSS to the formulation does not affect the final double bond conversion of the E860/E81/HDDA-based formulation, a slight increase in the glass transition of the cured material is observed (Fig. 10). This effect is somewhat stronger when 4M4F4-POSS is used. Qualitatively, the results are similar to the case of the E80/E81 resin. However, it seems that in the case of E860/E81/HDDA-based matrix, the main responsibility for the Tg increase is the stiffening effect of POSS cages.

Somewhat higher increase in Tg than for coatings based on the E80/E81 matrix (Fig. 5) can be associated with the morphology of the material. Figure 11 presents the surface of the coating modified with 4M4F4-POSS and 4M4F8-POSS. Comparison with Fig. 4 shows that these modifiers are more compatible with the E860/E80/HDDA-based matrix than with the E80/E81-based matrix—the number of the observed aggregates and their size are much smaller. Better compatibility of the modifier with the matrix leads to the formation of smaller aggregates, and these in turn better restrict the mobility of polymer chains than the larger aggregates. Again, 4M4F4-POSS seems to be somewhat better dispersed.

Water contact angle

The results are presented in Fig. 12. The water contact angle of the unmodified E860/E80/HDDA-based coating is higher (61°) than in the case of E80/E81-based coating (51°). This parameter increases after modification of the coating with 4M4F4–POSS or 4M4F8–POSS, reaching 73° and 74°, respectively, which corresponds to the increase by 20–21%. As noted previously, the enhancement of the surface hydrophobicity can be explained by the increase in surface roughness due to the presence of POSS cages and by the hydrophobic nature of fluorine atoms in fluoroalkyl substituents. The phenomenon of the lack of dependence of the contact angle on the POSS content is even more pronounced than in the case of the E80/E81-based coating.

Scratch hardness

The results of the first visible scratch hardness, HFVS, are shown in Fig. 13. Its value for the unmodified E860/E81/HDDA-based coating is much higher (260 MPa) than in the case of E80/E81-based coating (75 MPa). Modification with 4M4F4-POSS or 4M4F8-POSS causes ca. twofold increase in HFVS. The effects of the two modifiers seem to be similar, although the scatter of data does not allow it to be stated clearly; this applies in particular to the results for 5 wt% of POSS content.

It should be emphasized that measurements of the scratch hardness for the first surface stripping (HFSS) were not possible. It was due to a very high scratch resistance of the coatings, which were resistant to scratch even at the highest load applied, i.e., 40.5N.

Resistance to liquids

Coatings based on E860/E80/HDDA have better liquid resistance than coatings based on E80/E81. Unmodified coatings and those modified with 4M4F4-POSS are resistant to all the investigated solvents, whereas coatings modified with 4M4F8-POSS are influenced by ethanol and 5 wt% NaOH solution. The latter solvents cause swelling and clouding effects, but do not cause destruction of the coating down to the substrate. This result is also analogous to that obtained for the mixture of uniformly substituted POSS.17

A brief summary of the results obtained for modification of coatings applied on the aluminum substrate (based on E860/E81/HDDA resin) indicates that also in this case a substantial improvement in the water contact angle and scratch hardness was achieved but the differentiating effect of the length of the fluoroalkyl substituent was not as strongly evident.

Conclusions

POSS compounds containing mixed fluoroalkyl and methacryloxy substituents (4M4F4-POSS and 4M4F8-POSS) were investigated as modifiers for acrylate-based UV-curable coatings for wood and aluminum substrates. The use of POSS compounds with mixed substituent was motivated by the fact that such modifiers will be covalently linked with the matrix (through methacryloxy groups) keeping them in the coating, whereas fluoroalkyl substituents will improve scratch resistance and hydrophobicity (along with the effect of POSS cages). Although a similar improvement could be obtained with POSS containing only fluoroalkyl substituents, the main disadvantage in such a case would be exudation of the modifier onto the surface.

The presented results showed that introduction of the modifiers significantly affects formulation properties both before (viscosity) and after the curing (the increases in glass temperature, hydrophobicity and scratch hardness).

The through-cure of the coatings is high and almost unaffected by the light absorption and scattering.

The investigated systems are composites containing POSS aggregates; the distribution of the latter in the matrix is rather uniform. Better compatibility between the components is observed for POSS with shorter fluoroalkyl substituents and for the E80/E81-based matrix.

Very important results are that modification with POSS causes a strong increase in hydrophobicity, even by 140–160% of the initial value (in the case of E80/E81-based matrix).

The scratch hardness for the first surface stripping shows a strong improvement (the increase by about 30–170% in the presence of 5 wt% of the POSS modifiers), which can be attributed to enhancement of the surface sliding properties caused by the presence of fluoroalkyl substituents in the modifier. Resistance to liquids is satisfactory.

In summary, it can be stated that modification of UV-curable coatings with POSS derivatives containing mixed methacryloxy and fluoroalkyl substituents has a potential for practical application in production of scratch resistant and hydrophobic coatings.

References

Lina, HM, Wub, SY, Changa, FC, Yen, YC, “Photo-polymerization of photocurable resins containing polyhedral oligomeric silsesquioxane methacrylate.” Mater. Chem. Phys., 131 393–399 (2011)

Norouzi, S, Mohseni, M, Yahyaei, H, “Preparation and characterization of an acrylic acid modified polyhedral oligomeric silsesquioxane and investigating its effect in a UV curable coating.” Prog. Org. Coat., 99 1–10 (2016)

Chouwatat, P, Nojima, S, Higaki, Y, Kojio, K, Hirai, T, Kotaki, M, Takahara, A, “An effect of surface segregation of polyhedral oligomeric silsesquioxanes on surface physical properties of acrylic hard coating materials.” Polymer, 84 81–88 (2016)

Wanga, X, Wanga, X, Songa, L, Xinga, W, Tanga, G, Hua, W, Hu, Y, “Preparation and thermal stability of UV-cured epoxy-based coatings modified with octamercaptopropyl POSS.” Thermochim. Acta, 568 130–139 (2013)

Zhanga, K, Lia, X, Zhaoa, Y, Zhub, K, Lia, Y, Taoa, C, Yuan, X, “UV-curable POSS-fluorinated methacrylate diblock copolymers for icephobic coatings.” Prog. Org. Coat., 93 87–96 (2016)

Wang, Y, Liu, F, Xue, X, “Morphology and properties of UV-curing epoxy acrylate coatings modified with methacryl-POSS.” Prog. Org. Coat., 78 404–410 (2015)

Li, GZ, Wang, LC, Ni, HL, Pittman, CU, Jr, “Polyhedral oligomeric silsesquioxane (POSS) polymers and copolymers: A review.” J. Inorg. Organomet. Polym., 1 123–154 (2001)

Pan, AZ, Yang, S, He, L, Zhao, X, “Starshaped POSS diblock copolymers and their selfassembled films.” RSC Advances, 4 27857–27866 (2014)

Yang, S, Pan, AZ, He, L, “POSS endcapped diblock copolymers: Synthesis, micelle selfassembly and properties.” J. Colloid Interface Sci., 425 5–11 (2014)

Leea, AS, Joa, YY, Jeona, H, Choia, SS, Baeka, KY, Hwang, SS, “Mechanical properties of thiol-ene UV-curable thermoplastic polysilsesquioxanes.” Polymer, 68 140–146 (2015)

Barczewski, M, Chmielewska, D, Dobrzyńska-Mizera, M, Dudziec, B, Sterzyński, T, “Thermal Stability and Flammability of Polypropylene-Silsesquioxane Nanocomposites.” Int. J. Polym. Anal. Charact., 19 500–509 (2014)

Zucchi, IA, Galante, MJ, Williams, RJJ, “Surface energies of linear and cross-linked polymers based on isobornyl methacrylate and methacryl-heptaisobutyl POSS.” Eur. Polym. J., 45 325–331 (2009)

Ma, Y, He, L, Zhao, L, Pan, A, “POSS-based glycidyl methacrylate copolymer for transparent and permeable coatings.” Soft Matter, 14 253–263 (2016)

Briscoe, BJ, Sinha, SK, “Scratch resistance and localised damage characteristics of polymer surfaces – a review.” Materwiss. Werksttech., 34 989–1002 (2003)

Meuler, AJ, Chhatre, SS, Nieves, AR, Mabry, JM, Cohen, RE, McKinley, GH, “Examination of wettability and surface energy in fluorodecyl POSS/polymer blends.” Soft Materials, 7 10122–10134 (2011)

Dai, LZ, Yang, CJ, Xu, YT, Deng, YM, Chen, JF, Galy, J, Gerard, JF, “Preparation of novel methyl methacrylate/fluorinated silsesquioxane copolymer film with low surface energy.” Sci. China Chem., 53 2000 (2010)

Przadka, D, Marcinkowska, A, Andrzejewska, E, “POSS-modified UV-curable coatings with improved scratch hardness and hydrophobicity.” Prog. Org. Coat., 100 165–172 (2016)

Dutkiewicz, M, Maciejewski, H, Marciniec, B, “Functionalization of polyhedral oligomeric silsesquioxane (POSS) via nucleophilic substitution.” Synthesis, 12 2019–2024 (2009)

Dutkiewicz, M, Maciejewski, H, Marciniec, B, Karasiewicz, J, “New fluorocarbofunctional spherosilicates: Synthesis and characterization.” Organometalics, 30 2149–2153 (2011)

Szubert, K, Marciniec, B, Dutkiewicz, M, Potrzebowski, MJ, Maciejewski, H, “Functionalization of spherosilicates via hydrosilylation catalyzed by well-defined rhodium siloxide complexes immobilized on silica.” J. Mol. Catal. A: Chem., 391 150–157 (2014)

Chu, J, Xiang, C, Sue, HJ, Hollis, RD, “Scratch resistance of mineral-filled polypropylene materials.” Polym. Eng. Sci., 40 944–955 (2000)

Bora, MO, Coban, O, Sinmazcelik, T, Gunay, V, “Effect of fiber orientation on scratch resistance in unidirectional carbon-fiber-reinforced polymer matrix composites.” J. Reinf. Plast. Compos., 29 1476–1490 (2009)

PN EN 15186-2012, Furniture - Assessment of the surface resistance to scratching.

PN-EN ISO 2812-3 2008, Paints and varnishes - Determination of resistance to liquids - Part 3: Method using an absorbent medium.

Yazdaninia, A, Khonakdar, HA, Jafari, SH, Asadi, V, “Influence of trifluoropropyl-POSS nanoparticles on the microstructure, rheological, thermal and thermomechanical properties of PLA.” RSC Adv., 6 37149–37159 (2016)

Joshi, M, Butola, BS, Simon, G, Kukaleva, N, “Rheological and Viscoelastic Behavior of HDPE/Octamethyl-POSS Nanocomposites.” Macromolecules, 39 1839–1849 (2006)

Andrzejewska, E, “Photopolymerization kinetics of multifunctional monomers.” Prog. Polym. Sci., 26 605–665 (2001)

Wang, B, Lin, Q, Shen, C, Han, Y, Tang, J, Chen, H, “Synthesis of MA POSS–PMMA as an intraocular lens material with high light transmittance and good cytocompatibility.” RSC Adv., 4 52959–52966 (2014)

Acknowledgments

This work was supported by the European Regional Development Found under the Innovative Economy Operational Programme for 2007–2013, Priority 1, Action 1.3. [Project No UDA-POIG.01.03.01-30-173/09 Nanosil] and by the Research Project of Poznan University of Technology 03/32/DSPB/0804. The authors thank Dr. Michal Dutkiewicz from Wielkopolska Centre of Advanced Technologies for synthesis of 4M4F4-POSS and 4M4F8-POSS.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Marcinkowska, A., Prządka, D. & Andrzejewska, E. POSS functionalized with mixed fluoroalkyl and methacryloxy substituents as modifiers for UV-curable coatings. J Coat Technol Res 16, 167–178 (2019). https://doi.org/10.1007/s11998-018-0111-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11998-018-0111-2