Abstract

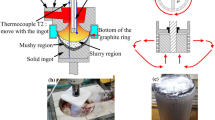

Intensive melt shearing was achieved by a stator–rotor high-shear unit and was used in the sump during direct chill (DC) casting process to investigate the influence of the rotation speed on the as cast structure of an aluminum alloy. It has been demonstrated that intensive melt shearing has a significant effect on achieving a uniform temperature distribution and obtaining a fine and uniform as cast structure. We also found that the intensity of the melt shearing plays an important role in the effect. As the rotation speed increases, the melt around the high-shear unit transformed from a liquid to a semisolid state. At a rotation speed of 3000 rpm, intensive melt shearing can only increase the nuclei through fragmentation in the region close to the solidification front by forced convection. When the rotation speed increases to 6000 rpm, intensive melt shearing can also evidently increase the number of effective nuclei, mainly by increased fragmentation in a large volume around the high-shear unit.

Similar content being viewed by others

References

R. Nadella, D. G. Eskin, Q. Du and L. Katgerman: Prog. Mater. Sci., 2008, vol. 53, pp. 421-480.

Q. F. Zhu, Z.H. Zhao, Y.B. Zuo, X.J. Wang and J.Z. Cui: Int. J. Cast Met. Res, 2013, vol. 25, pp. 93-99.

Y.B. Zhang, J.C. Jie, L. Wu, Y. Fu, M. Li, Y.P. Lu and T.J. Li: Metall. Mater. Trans. A, 2013, vol. 45, pp. 2014-2022.

D.G. Eskin: in Solidification Processing of Metallic Alloys Under External Fields, 1st ed. D.G. Eskin, and J. Mi, eds., Springer, Cham, 2018, pp 1–17.

J.Z. Cui, H.T. Zhang, L. Li, Y.B. Zuo and H. Nagaumi: in Solidification Processing of Metallic Alloys Under External Fields, 1st ed. D.G. Eskin, and J. Mi, eds., Springer, Cham, 2018, pp 119–51.

Y.B. Zuo, J.Z. Cui, Z.H. Zhao, H.T. Zhang, L. Li and Q.F. Zhu: J. Mater. Sci, 2012, vol. 47, pp. 5501-5508.

Z.Y. Fan, Y. Wang, Y. Zhang, T. Qin, X.R. Zhou, G.E. Thompson, T. Pennycook and T. Hashimoto: Acta Mater., 2015, vol. 84, pp. 292-304.

Z.Y. Fan, Y. Wang, M. Xia and S. Arumuganathar: Acta Mater., 2009, vol. 57, pp. 4891-4901.

Z.W. Shao, Q.C. Le, Z.Q. Zhang and J.Z. Cui: Mater. Des., 2011, vol. 32, pp. 4216-4224.

Z.Y. Fan, Y.B. Zuo and B. Jiang: Mater. Sci. Forum, 2011, vol. 690, pp. 141-144.

R. Haghayeghi, E. J. Zoqui, D.G. Eskin and H. Bahai: J. Alloys Compd., 2009, vol. 485, pp. 807-811.

Y.B. Zuo, H.T. Li, M. Xia, B. Jiang, G.M. Scamans and Z. Fan: Scr. Mater., 2011, vol. 64, pp. 209-212.

R. Haghayeghi and L. Nastac: Mater. Lett., 2011, vol. 65, pp. 3230-3233.

H. Men, B. Jiang and Z.Y. Fan: Acta Mater., 2010, vol. 58, pp. 6526-6534.

Y.B. Zuo, B. Jiang and Z.Y. Fan: Mater. Sci. Forum, 2011, vol. 690, pp. 137-140.

H.T. Li, P.Z. Zhao, R.D. Yang, J.B. Patel, X.F. Chen and Z.Y. Fan: Metall. Mater. Trans. B, 2017, vol. 48, pp. 2481-2492.

S. Jones, A.K. Prasada Rao, J.B. Patel, G.M. Scamans, and Z.Y. Fan: in ICAA13 Pittsburgh, H. Weiland, A.D. Rollett, and W.A. Cassada, eds., Springer, Cham, 2016, pp. 91–96.

A.W. Nienow: Chem. Eng. Sci., 1997, vol. 52, pp. 2557-2565.

H.H. Mortensen, F. Innings and A. Håkansson: Chem. Eng. Res. Des., 2017, vol. 121, pp. 245-254.

A.T. Utomo, M. Baker and A.W. Pacek: Chem. Eng. Res. Des., 2008, vol. 86, pp. 1397-1409.

P.E. Smith and W.F. Gunsteren: Chem. Eng. Sci., 1993, vol. 215, pp. 315-318.

Y.L. Sun, M.H. Sun, W.D. Cheng, C.X. Ma and F. Liu: Comput. Mater. Sci., 2007, vol. 38, pp. 737-740.

B.R. Munson, A.P. Rothmayer, T.H. Okiishi and W.W. Huebsch: Fundamentals of fluid mechanics. 7 th ed, Wiley, Hoboken, 2013.

M.H. Sun, H.R. Geng, X.F. Bian and Y. Liu: Mater. Sci. Forum, 2000, vol. 331-337, pp. 337-342.

D.G. Eskin, Q. Du and L. Katgerman: Metall. Mater. Trans. A, 2008, vol. 39, pp. 1206-1212.

H. Vanja, M. Boštjan, K. Nejc and Š. Božidar: Appl Math Model, 2018, vol. 54, pp. 170-188.

I. Tzanakis, G. S. Lebon, D. G. Eskin and K. A. Pericleous: Ultrason. Sonochem., 2017, vol. 34, pp. 651-662.

X.J. Wang, H.T. Zhang, Y.B. Zuo, Z.H. Zhao, Q.F. Zhu and J.Z. Cui: Mater. Sci. Eng. A, 2008, 497, 416-420.

A. N. Turchin, M. Zuijderwijk, J. Pool, D. G. Eskin and L. Katgerman: Acta Mater., 2007, vol. 55, pp. 3795-3801.

D.G. Eskin: Physical Metallurgy of Direct Chill Casting of Aluminum Alloys. first ed, CRC Press, Boca Raton, 2008.

Q. F. Zhu, Z. H. Zhao, J. Z. Cui, Y. B. Zuo and F. Qu: Acta Metall. Sin. 2008, 21, 205-210.

Acknowledgments

This work was supported by the National Natural Science Foundation of China (Grant Numbers 51674078 and 51374067). The authors are grateful to Mrs. Yiyao Kang and Mrs. Yue Lin for their help in the water simulation.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted May 24, 2019.

Rights and permissions

About this article

Cite this article

Liu, X., Zhu, Q., Zuo, Y. et al. Effect of the Intensity of Melt Shearing on the As Cast Structure of Direct Chill Cast 2024 Aluminum Alloy. Metall Mater Trans A 50, 5727–5733 (2019). https://doi.org/10.1007/s11661-019-05452-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-019-05452-1