Abstract

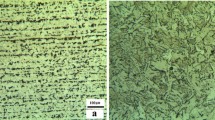

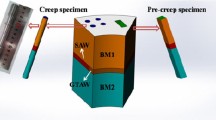

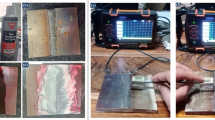

Based on a series of stress rupture tests at 620 °C under 110 to 170 MPa and at 650 °C under 80 to 110 MPa, the relationship between the stress and rupture time was obtained to evaluate the long-term performance of the welded joint (WJ). At 620 °C, the stress rupture occurred in the base metal of 9 pct Cr steel (9 pct Cr-BM), with the stress ranging from 130 to 170 MPa, yet the failure shifted to the heat-affected zone (HAZ) of 9 pct Cr steel (9 pct Cr-HAZ) with the stress ranging from 110 to 120 MPa. This failure behavior was observed at 650 °C with the turning point of 110 MPa. In particular, a ductile-to-brittle transition was determined when the rupture location shifted from 9 pct Cr-BM to 9 pct Cr-HAZ. Moreover, both the Laves phase adjacent to the M23C6 and the independent phases could be detected in the 9 pct Cr-HAZ after the stress rupture test, while only M23C6-type carbides could be found in the 9 pct Cr-BM. The appearance of the microhardness turning point and the formation of the Laves phase in the 9 pct Cr-HAZ are considered as the crucial factors resulting in the transition of the failure mode.

Similar content being viewed by others

References

1.X.Z. Zhang, X. Wu, J.R. Liu, J. Liu, and M.X. Yao: Mater. Sci. Eng. A, 2017, vol. 706, pp. 279–86.

2.P. Yan, Z.D. Liu, H.S. Bao, Y.Q. Weng, and W. Liu: Mater. Des., 2014, vol. 54, pp. 874–79.

3.I. Hajiannia, M. Shamanian, and M. Kasiri: Mater. Des., 2013, vol. 50, pp. 566–73.

4.K. Mo, G. Lovicu, X. Chen, H.-M. Tung, J.B. Hansen, and J.F. Stubbins: J. Nucl. Mater., 2013, vol. 441, pp. 695–703.

5.F.G. Lu, P. Liu, H.J. Ji, Y.M. Ding, X.J. Xu, and Y.L. Gao: Mater. Charact., 2014, vol. 92, pp. 149–58.

6.R.L. Klueh and D.J. Alexander: J. Nucl. Mater., 1998, vols. 258–263, pp. 1269–74.

7.A. Zieliński, J. Dobrzański, H. Purzyńska, and G. Golański: Arch. Metall. Mater., 2016, vol. 61, pp. 957–64.

A.C. Pandey, M.M. Giri, and A. Mahapatra: Mater. Sci. Eng. A, 2016, vol. 664, pp. 58–74.

9.X. Liu, Z.P. Cai, X.L. Deng, and F.G. Lu: J. Mater. Res., 2017, vol. 32, pp. 3117–27.

10.K.H. Lee, J.Y. Suh, S.M. Hong, J.Y. Huh, and W.S. Jung: Mater. Charact., 2015, vol. 106, pp. 266–72.

11.X. Liu, F.G. Lu, R.J. Yang, P. Wang, X.J. Xu, and X. Huo: J. Mater. Eng. Perform., 2015, vol. 24, pp. 1434–40.

12.J. Bugge, S. Kjær, and R. Blum: Energy, 2006, vol. 31, pp. 1437–45.

13.A.K. Roy, M.H. Hasan, and J. Pal: Mater. Sci. Eng. A, 2009, vol. 520, pp. 184–88.

14.X.Q. Song, L.Y. Tang, Z. Chen, and R.C. Zhou: J. Mater. Sci., 2017, vol. 52, pp. 4587–98.

15.X.L. Deng, F.G. Lu, H.C. Cui, X.H. Tang, and Z.G. Li: Mater. Sci. Eng. A, 2016, vol. 651, pp. 1018–30.

16.Q. Guo, F.G. Lu, H.C. Cui, R.J. Yang, X. Liu, and X.H. Tang: J. Mater. Process. Technol., 2015, vol. 226, pp. 125–33.

17.C.D. Shao, F.G. Lu, X.F. Wang, Y.M. Ding, and Z.G. Li: J. Mater. Sci. Technol., 2016, vol. 33, pp. 1610–20.

18.W. Liu, F.G. Lu, Y.H. Wei, Y.M. Ding, P. Wang, and X.H. Tang: Mater. Des., 2016, vol. 108, pp. 195–206.

19.M. Taneike, K. Sawada, and F. Abe: Metall. Mater. Trans. A, 2004, vol. 35A, pp. 1255–62.

20.Q.F. He, Y.F. Ye, and Y. Yang: J. Phase Equilib. Diff., 2017, vol. 38, pp. 416–25.

21.L. Tan, D.T. Hoelzer, J.T. Busby, M.A. Sokolov, and R.L. Klueh: J. Nucl. Mater., 2012, vol. 422, pp. 45–50.

22.L. Tan, Y. Yang, and J.T. Busby: J. Nucl. Mater., 2013, vol. 442, pp. S13–S17.

23.S.S. Wang, D.L. Deng, L. Chang, and X.D. Hui: Mater. Des., 2013, vol. 50, pp. 174–80.

24.H. Wang, W. Yan, S.V. Zwaag, Q.Q. Shi, W. Wang, K. Yang, and Y.Y. Shan: Acta Mater., 2017, vol. 134, pp. 143–54.

25.L. Maddi, G.S. Deshmukh, A.R. Ballal, D.R. Peshwe, R.K. Paretkar, K. Laha, and M.D. Mathew: Mater. Sci. Eng. A, 2016, vol. 668, pp. 215–23.

26.S. Zhu, M. Yang, X.L. Song, S. Tang, and Z.D. Xiang: Mater. Charact., 2014, vol. 98, pp. 60–65.

27.G. Dimmler, P. Weinert, E. Kozeschnik, and H. Cerjak: Mater. Charact., 2003, vol. 51, pp. 341–52.

28.O. Prat, J. Garcia, D. Rojas, G. Suauthoff, and G. Inden: Intermetallics, 2013, vol. 32, pp. 362–72.

29.Z.F. Peng, S. Liu, C. Yang, F.Y. Chen, and F.F. Peng: Acta Mater., 2018, vol. 143, pp. 141–55.

30.S.K. Rai, A. Kumar, V. Shankar, T. Jayakumar, and K.B.S. Rao: Scripta Mater., 2004, vol. 51, pp. 59–63.

31.Ö. Özgün, H.Ö. Gülsoy, R. Yilmaz, and F. Findik: J. Alloy. Compd., 2013, vol. 546, pp. 192–207.

32.A. Mostafaei, Y. Behnamian, Y.L. Krimer, E.L. Stevens, J.L. Luo, and M. Chmielus: Mater. Des., 2016, vol. 111, pp. 482–91.

33.L.M. Suave, J. Cormier, P. Villechaise, S. Aurélie, H. Zéline, and D. Bertheau: Metall. Mater. Trans. A, 2014, vol. 45A, pp. 2963–82.

34.P.H. Wang, J.M. Chen, H.Y. Fu, S. Liu, H.W. Li, and Z.Y. Xu: J. Nucl. Mater., 2013, vol. 442, pp. S9–S12.

35.I.J. Moore, M.G. Burke, and E.J. Palmiere: Acta Mater., 2016, vol. 119, pp. 157–66.

36.Z.X. Xia, C. Zhang, H. Lan, Z.G. Yang, P.H. Wang, J.M. Chen, Z.Y. Xu, X.W. Li, and S. Liu: Mater. Sci. Eng. A, 2010, vol. 528, pp. 657–62.

37.K. Ding, P. Wang, X. Liu, X.H. Li, B.G. Zhao, and Y.L. Gao: J. Mater. Eng. Perform., 2018, vol. 27 pp. 6027–39.

38.Q. Guo, F.G. Lu, X. Liu, R.J. Yang, H.C. Cui, and Y.L. Gao: Mater. Sci. Eng. A, 2015, vol. 638, pp. 240–50.

39.Q.J. Wu, F.G. Lu, H.C. Cui, Y.M. Ding, X. Liu, and Y.L. Gao: Mater. Sci. Eng. A, 2014, vol. 615, pp. 98–106.

40.H.G. Dong, P.X. Wang, X.H. Hao, S. Li, P. Li, Y.L. Gao, B.G. Zhao, and D.J. Yan: Mater. Lett., 2018, vol. 228, pp. 407–10.

41.K. Ding, H.J. Ji, X. Liu, P. Wang, Q.L. Zhang, X.H. Li, and Y.L. Gao: J. Iron Steel Res. Int., 2018, vol. 25 pp. 847–53.

42.K. Ding, H.J. Ji, Q.L. Zhang, X. Liu, P. Wang, X.H. Li, L. Zhang, and Y.L. Gao: J. Iron Steel Res. Int., 2018, vol. 25, pp. 839–46.

43.Q.J. Wu, F.G. Lu, H.C. Cui, X. Liu, P. Wang, and Y.L. Gao: Mater. Lett., 2015, vol. 141, pp. 242–44.

44.H.K. Ji, Y.J. Oh, I.S. Hwang, J.K. Dong, and J.T. Kim: J. Nucl. Mater., 2001, vol. 299, pp. 132–39.

A. Laha, K.S. Chandrevathi, P. Parameswaran, K. BhanuSankaraRao, and S.L. Mannan: Metall. Mater. Trans. A, 2007, vol. 38A, pp. 58–68.

46.T. Watanabe, M. Tabuchi, M. Yamazaki, H. Hongo, and T. Tanabe: Int. J. Press. Vessel. Pip., 2006, vol. 83, pp. 63–71.

47.Y.H. Wei, S.F. Qiao, F.G. Lu, and W. Liu: Mater. Des., 2016, vol. 97, pp. 268–78.

48.P. Dahlman, F. Gunnberg, and M. Jacobson: J. Mater. Process. Technol., 2004, vol. 147, pp. 181–84.

49.J. Hua, R. Shivpuri, X.M. Cheng, V. Bedekar, Y. Matsumoto, F. Hashimoto, and T.R. Watkins: Mater. Sci. Eng. A, 2005, vol. 394, pp. 238–48.

50.W. Liu, X. Liu, F.G. Lu, X.H. Tang, H.C. Cui, and Y.L. Gao: Mater. Sci. Eng. A, 2015, vol. 644, pp. 337–46.

51.P. Liu, F.G. Lu, X. Liu, H.J. Ji, and Y.L. Gao: J. Alloys Compd., 2014, vol. 584, pp. 430–37.

52.A. Elrefaey, Y. Javadi, J.A. Francis, M.D. Callaghan, and A.J. Leonard: Int. J. Press. Vessel. Pip., 2018, vol. 165 pp. 20–28.

53.C.G. Panait, W. Bendick, A. Fuchsmann, A.F. Gourgues-Lorenzon, and J. Besson: Int. J. Press. Vessel. Pip., 2010, vol. 87, pp. 326–35.

54.H.G. Armaki, R. Chen, K. Maruyama, and M. Igarashi: Metall. Mater. Trans. A, 2011, vol. 42A, pp. 3084–94.

55.X. Wang, X. Wang, H.J. Li, H.L. Wu, Y.Y. Ren, H.W. Liu, and H. Liu: Weld. World, 2017, vol. 61 pp. 231–39.

56.J.S. Lee, H.G. Armaki, K. Maruyama, T. Muraki, and H. Asahi: Mater. Sci. Eng. A, 2006, vol. 428, pp. 270–75.

57.D. Rojas, J. Garcia, O. Prat, L. Agudo, and C. Carrasco: Mater. Sci. Eng. A, 2011, vol. 528, pp. 1372–81.

58.K. Shinozaki, L.I. De-Jun, H. Kuroki, H. Harada, and K. Ohishi: ISIJ Int., 2002, vol. 42, pp. 1578–84.

59.Y.T. Xu, Y.H. Nie, M.J. Wang, W. Li, and X.J. Jin: Acta Mater., 2017, vol. 131, pp. 110–22.

60.M.I. Isik, A. Kostka, and G. Enggeler: Acta Mater., 2014, vol. 81, pp. 230–40.

Acknowledgments

The authors gratefully acknowledge the National Natural Science Foundation of China (Grant No. U1760102), the financial support from the Program for Professor of Special Appointment (Eastern Scholar), the Shanghai Institutions of Higher Learning (Grant No. TP2014042), and the Shanghai Science and Technology Committee (Grant No. 13DZ1101502).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted December 25, 2018.

Rights and permissions

About this article

Cite this article

Ding, K., Qiao, S., Liu, S. et al. Failure Transition Mechanism of Stress Rupture Performance of the Inconel 625/9 Pct Cr Steel Dissimilar Welded Joint. Metall Mater Trans A 50, 4652–4664 (2019). https://doi.org/10.1007/s11661-019-05372-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-019-05372-0