Abstract

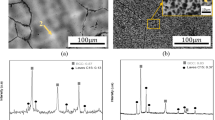

The growth kinetics of microarc oxidation TiO2 ceramic film on Ti6Al4V alloy in 0.1 M Na2B4O7·10H2O electrolyte were studied using scanning electron microscopy, transmission electron microscope, atomic force microscope, X-ray diffraction, and potentiodynamic polarization. It was found that the discharge sizes increased gradually from anodic oxidation, spark discharge, and microarc to arc discharges in the microarc oxidation process, and reached the maximum value without anymore increases. The microarc oxidation coating was mainly composed of nanocrystalline rutile TiO2 grains with very little amorphous titanium dioxide, and was made up of three layers, namely an inner dense thin layer, a middle dense thick layer, and a porous outer layer. The content of the rutile phase increased with the increasing discharge size, and when the discharge size reached a maximum, the increase rate decreased slightly. The surface roughness, Rv, and corrosion resistance of the coating increased with the increasing discharge size until the discharge size reached a maximum. It was concluded that the thickness of two dense layers depended on the discharge size, with any changes in it revealing the growth kinetics of the coating. A new method was developed to obtain the effective thickness of the coatings by measuring the thickness of the two dense layers. The results demonstrated that the growth kinetics of the two dense layers are linear during spark and microarc discharges, of which the growth trend is the same as that of the voltage. A linear relationship for the voltage and thickness of the two dense layers was obtained.

Similar content being viewed by others

References

X. Liu, P. K. Chu, C. Ding: Mater. Sci. Eng. R, vol. 47(3–4), pp. 49-121 (2004).

M. Popa, J. M. C. Moreno, C. Vasilescu, S. I. Drob, E. I. Neacsu, A. Coer, J. Hmeljak, G. Zerjav, and I. Milosev: Metall. Mater. Trans. A, 2014, vol. 45(7), pp. 3130-3143.

Y. Wang, H. Yu, C. Chen, Z. Zhao: Mater. Design, 2015, vol. 85, pp. 640-652.

R. Osman, M. Swain: Materials, 2015, vol. 8(3), pp. 932-958.

N. Hallab: J. Clin. Rheumatol., 2001, vol. 7(4), pp. 215-8.

S. Stojadinovic, R. Vasilic, J. Radic-Peric, M. Peric: Surf. Coating Technol., 2015, vol. 273, pp.1-11.

T. Mi, B. Jiang, Liu Z, L. Fan: Electrochim Acta, 2014, vol.123, pp.369-377.

R. F. Zhang, S. F. Zhang, Y. L. Shen, L.H. Zhang, T.Z. Liu, Y.Q. Zhang, S.B. Guo: Appl. Surf. Sci., 2012, vol. 258(17), pp.6602-6610.

T. S. N. S. Narayanan, M. H. Lee: J. Alloy Compd., 2016, vol. 687, pp.720-732.

D. Sreekanth, N. Rameshbabu, K. Venkateswarlu, CH. Subrahmanyam, L. R. Krishna, K. P. Rao: Surf. Coat. Technol., 2013, vol. 222(6), pp. 31-37.

H.X. Li, V.S. Rudnev, X.H. Zheng, T.P. Yarovaya, R.G. Song: J. Alloys Compd., vol. 462(1), pp. 99-102 (2008)

M. S. Joni, A. Fattah-Alhosseini: J. Alloy Compd., 2016, vol. 661, pp. 237-244.

S. Yagi, K. Kuwabara, Y. Fukuta, K. Kubota, E. Matsubara: Corros. Sci., 2013, vol. 73(13), pp. 188-195.

M. S. Vasil’Eva, V. S. Rudnev, L. M. Tyrina, I. Lukiyanchuk, N. B. Kondrikov, Pavel S Gordienko: Russ. J. Appl. Chem., 2002, vol. 75(4), pp. 569-572.

V. S. Rudnev, M. S. Vasilyeva, N. B. Kondrikov, L.M. Tyrina: Appl. Surf. Sci., 2005, vol. 252(5), pp. 1211-1220.

V. S. Rudnev, T. P. Yarovaya, V. S. Egorkin, S. Sinebryukhov, S. V. Gnedenkov: Russ. J. Appl. Chem., 2010, vol. 83(4), pp. 664-670.

F.C. Walsh, C.T.J. Low, R.J.K. Wood, K.T. Stevens, J. Archer, A.R. Poeton, A. Ryder: Trans. Inst. Met. Finish, 2009, vol. 87(3), pp. 122-135.

J.M. Albella, I. Montero, J.M. Martinez-Duart: J. Electrochem Soc., vol. 131(5), pp. 1101-1104 (1984).

X. P. Zhang, S. M. Xiong, Q. Xu, B. Liu: Mater. Prot., 2004, vol. 37(8), pp. 19-20.

G. Sundararajan, L. R. Krishna: Surf. Coat. Technol., 2003, vol. 167(2), pp. 269-277.

E. Erfanifar, M. Aliofkhazraei, H. F. Nabavi, H. Sharifi, A. S. R. Aghdam: Mater. Chem. Phys., 2017, vol. 185, pp. 162-175.

G. B. Darband, M. Aliofkhazraei, P. Hamghalam, N. Valizade: Journal of Magnesium and Alloys, 2017, vol. 5(1), pp. 74-132.

L. Chang: J. Alloys Compd., vol. 468(1-2), pp. 462-465 (2009).

T. H. Teh, A. Berkani, S. Mato, P. Skeldon, G. E. Thompson, H. Habazaki, K. Shimizu: Corros. Sci., 2003, vol. 45(12), pp. 2757-2768.

X. Jiang, C. Pan: Handbook of Nanoceramic and Nanocomposite Coatings and Materials. Elsevier, Amsterdam, 2015, pp. 257-276.

J. Zhao, X. Wang, R. Chen, L. Li: Solid State Commun., 2005, vol. 134(10), pp. 705-710.

M. Sowa, J. Worek, G. Dercz, D. Korotin, A. I. Kukharenko, E. Kurmaev, S. O. Cholakh, M. Basiaga, W. Simka: Electrochimica Acta, 2016, vol. 198, pp. 91-103.

Y. Cheng, J. Cao, M. Mao, H. Xie, P. Skeldon: Surf. Coating Technol., 2016, vol. 291, pp. 239-249.

Y. Leng: Materials Characterization: Introduction to Microscopic and Spectroscopic Methods. Wiley, New York, 2010.

M. Stern, A.L. Geary (1957) J. Electrochem. Soc., 104(1), 56

G. C. Wood, C. Pearson: Corros. Sci., 1967, vol. 7(2), pp. 119-125.

A. L. Yerokhin, X. Nie, A. Leyland, A. Matthews, S.J. Dowey: Surf. Coat. Technol., 1999, 122(2-3), 73-93.

X. Jiang, A. Shi, Y. Wang, Y. Li, C. Pan: Nanoscale, 2011, vol. 3(9), pp. 3573-3577.

A. Fattah-Alhosseini, M. K. Keshavarz, M. Molaei, and S. O. Gashti: Metall. Mater. Trans. A, 2018, vol. 49(10), pp. 4966-4979.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted November 18, 2018.

Rights and permissions

About this article

Cite this article

Zhai, D., Feng, K. & Yue, H. Growth Kinetics of Microarc Oxidation TiO2 Ceramic Film on Ti6Al4V Alloy in Tetraborate Electrolyte. Metall Mater Trans A 50, 2507–2518 (2019). https://doi.org/10.1007/s11661-019-05185-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-019-05185-1