Abstract

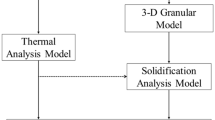

Residual stress of electron beam welding (EBW) is associated with the heat transfer, fluid flow, and keyhole dynamics occurred in the process. In engineering, it was commonly simulated by pure heat conduction-based thermomechanical modeling with an experimentally calibrated heat source model. This method, however, is difficult to be used to consider the effect of weld imperfections such as the spiking and porosity defect. In this study, we proposed a novel combined computational fluid dynamics and finite element method (CFD-FEM) model to predicate the residual stresses of EBW. This model allows us to include the integral effect of heat transfer, fluid flow, and keyhole dynamics as well as process defects on residual stresses for the first time. A phenomenological heat source model dependent on the dynamic keyhole was considered in the CFD model part. A mapping algorithm was developed to build a new heat source model of FEM modeling part from the CFD simulations. Parametrical simulations and experiments of EBW of a 10-mm-thickness Ti-6-Al-4-V alloy plate were carried out and good agreements were obtained by the comparisons. It was shown that for deep penetration EBW the keyhole oscillates in radial and depth directions and the spiking defect occurs, particularly under large heat input parameters. Interestingly, the equivalent and principle residual stresses exhibits strong oscillations in the bottom part of welds along the welding direction, in which the amplitudes are around 9 pct (73.69 MPa) of the equivalent stress and 24 pct (121.84 MPa) of the principle stress in penetration direction, respectively, when the power of electron beam is 1.5 kW. As the power of electron beam increases, the effect of spiking on the residual stress enhances. When the welding power increases to 2.25 kW, the amplitudes of equivalent residual stress increase to 12 pct (119.2 MPa). Our results provide a quantitative method connecting the weld pool dynamics and process defects with the residual stress of EBW, which previously could be understood only in a qualitative way, and demonstrate the possibility of residual stress predications only from the information of materials and process parameters before welding, without the knowledge of post-weld profiles.

Similar content being viewed by others

Abbreviations

- \( U \) :

-

Velocity

- \( \vec{U} \) :

-

Movement speed of the free surface interface

- \( T \) :

-

Temperature

- \( T_{\text{ref}} \) :

-

Reference temperature

- \( T_{\infty } \) :

-

Ambient temperature

- \( T_{i} \) :

-

Temperature of the CFD element

- \( p \) :

-

Pressure

- \( p_{\text{f}} \) :

-

Free surface

- \( p_{\text{r}} \) :

-

Recoil pressure

- \( g \) :

-

Gravitational vector

- \( c \) :

-

Specific heat

- \( C\rho \) :

-

Heat capacity

- \( K \) :

-

Heat conductivity

- \( k_{i} \) (i = x, y, z):

-

Thermal conductivity in the x, y, and z direction

- \( Q \) :

-

Volumetric energy generation

- \( Q_{\text{total}} \) :

-

Total energy input

- \( Q_{\text{d}} \) :

-

Dynamical keyhole-based heat source term

- \( Q_{i} \) :

-

Heat flux of each element of FEM model

- \( \vec{n} \) :

-

Unit normal vector

- \( \overrightarrow {{t_{1} }} \), \( \overrightarrow {{t_{2} }} \) :

-

Unit vector orthogonal cutting, \( \overrightarrow {{t_{1} }} \) is perpendicular to \( \overrightarrow {{t_{2} }} \)

- \( V_{i} \) :

-

Volume of the element of FEM model

- \( h_{\text{r}} \) :

-

Radiant heat transfer coefficient

- \( D^{P} \) :

-

Plastic matrix

- \( D^{e} \) :

-

Elastic matrix

- E :

-

Young’s modulus

- \( \mu \) :

-

Kinetic viscous coefficient

- \( \rho \) :

-

Density

- \( \beta \) :

-

Thermal expansion coefficient

- \( \phi \) :

-

Distant to the surface

- \( \sigma \) :

-

Surface tension coefficient

- \( \kappa \) :

-

Curvature

- \( \varepsilon_{\text{r}} \) :

-

Surface emissivity

- \( \sigma_{\text{s}} \) :

-

Stefan–Boltzmann constant

- \( \Omega \) :

-

Heat source zone

- \( d\sigma \) :

-

Stress increment

- \( d\varepsilon \) :

-

Strain increment

- \( \alpha \) :

-

Coefficient of liner expansion

References

J.W. Elmer, and W.H. Giedt, T.W. Eagar: Weld. J., 1990, vol. 69(5), pp. 167-176.

H. Hemmer, and Ø. Grong: Weld. Join., 1999, vol. 4(4), pp. 219-255.

D. Couedel, P. Rogeon, P. Lemasson, and M. Carin, J.C. Parpillon : Int. J. Heat Mass Transf., 2003, vol. 46(23), pp. 4553-4559.

S. Rouquette, J. Guo, and P. Le Masson: Int. J. Therm. Sci., 2007, vol. 46(2), pp. 128-138.

P. Lacki, and K. Adamus: Comput. Struct., 2011, vol. 89, pp. 977-985.

H.J. Stone, S.M. Roberts, and Reed R.C (2000) Metall. Mater. Trans. A, vol. 31A, pp. 2261–73.

C. Liu, B. Wu, and J.X. Zhang: Metall. Mater. Trans. B, 2010, vol. 41, pp. 1129-1138.

J.H. Cowles, M. Blanford, A.F. Giamei, and M.J. Bruskotter: in Proc. 7th Int. Conf. on Modeling of Casting, Welding and Advanced Solidification Processes, Minerals Metals & Materials Society, London, UK, 1995, pp. 347–54.

C.J. Rosen, A. Gumenyuk, H. Zhao, and U. Dilthey: Sci. Technol. Weld. Join., 2007, vol. 12, pp. 614-619.

H.Y. Zhao, P. Wang, and B. Wu: J. Tsinghua Univ. (Sic. & Technol.), 2013, vol. 53, pp. 1402–06.

P.S. Wei, and W.H. Giedt (1985) Weld. J., vol. 64(9), pp. 251-259.

R. Rai, S. Kelly, R. Martukanitz (2008) Metall Mater. Trans. A, Vol. 39A, pp. 98.

X. Hei, P.W. Fuerschbach, T. DebRoy (2003) J. Phys. D: Appl. Phys., Vol. 36, 1388

T. Zacharia, S.A. David, J.M. Vitek, T. Debroy: Weld. J., 1989, Vol. 68, pp. 269-79

T. Liu, L.J. Yang, H.L. Wei: Weld. J., 2017, Vol. 96, pp 258-70

P.S. Wei, and Y.T. Chow: Metall. Mater. Trans. B., 1992, vol. 23, pp. 81-90.

R. Rai, T.A. Palmer, and J.W. Elmer: Weld. J., 2009, vol. 88(3), pp. 54-61.

R. Rai, P. Burgradt, J.O. Milewski, and T. DebRoy (2008) J. Phys. D: Appl. Phys., vol. 42(2), p. 025503

A. Lundbäck, and H. Runnemalm: Sci. Technol. Weld. Join., 2005, vol. 10, pp. 717-724.

B. Huang, X. Chen, S. Pang, and R. Hu: Int. J. Heat Mass Transf., 2017, vol. 115, pp. 159-173.

J. Cheon J, D.V. Kiran, S.J. Na (2016) Mater. Des., 2016, Vol. 91, pp. 230-241.

M. Jamshidinia, F. Kong, R. Kovacevic: The Coupled CFD-FEM Model of Electron Beam Melting, 2013.

S. Pang, X. Chen, J. Zhou, X. Shao, and C. Wang: Opt. Laser. Eng., 2015, vol. 74, pp. 47-58.

S. Pang, X. Chen, X. Shao, S. Gong, and J. Xiao: Opt. Laser. Eng., 2016, vol. 82, pp. 28-40

S. Pang, L. Chen, J. Zhou, Y. Yin, and T. Chen (2011) J. Phys. D Appl. Phys, vol. 44(2), p. 025301

S. Osher, and J.A. Sethian (1988) J. Comput. Phys., vol. 79, pp. 12-49.

R.W. Lewis, P. Nithiarasu, and K.N. Seetharamu: Fundamentals of the Finite Element Method for Heat and Fluid Flow, 1st ed., John Wiley & Sons Ltd, Chichester, 2004.

A. Kermanpur, M. Shamanian, and V.E. Yeganeh: J. Mater. Process. Tech., 2008, vol. 199(1-3), pp. 295-303.

Y. Ueda, and Y. Yamakaw: Trans. Jpn. Weld. Soc., 1971.

Q. Tang, S. Pang, B. Chen, H. Suo, and J. Zhou (2014) Int. J. Heat Mass Transf., 2014, vol. 78, pp. 203-215.

D.A. Schaue, and W.H. Geidt: Prediction of electron beam welding spiking tendency. California Univ., 1978.

G.L. Mara, E.R. Funk, R.C. McMaster, and P.E. Pence (1974) Weld. J. vol. 53(6):246.

H. Tong and W.H. Giedt: Weld. J., 1970, vol. 49 (6), p. 259.

Y. Luo, J. Liu, and H. Ye: Vacuum., 2010, vol. 84(6), pp. 857-863.

K. Abderrazak, S. Bannour, H. Mhiri, G. Lepalec, M.Autric: Comp. Mater. Sci., 2009, Vol. 44, pp. 858-866,

X.Y. Li, L.J. Wang, L.J. Yang, J.F. Wang, K. Li: J. Mater. Process. Technol., 2014, Vol. 214, pp. 1844-1851.

S. Wu, H.Y. Zhao, Y. Wang, and X.H. Zhang: Trans. China Weld. Inst., 2004, vol. 25, pp. 91-94.

Acknowledgments

This research was supported by the Key R&D Projects (National Key projects) (Nos. 2017YFE0100100, 2018YFB1105300), the National Natural Science Foundation of China (NSFC) (No. 51675202), and the National Basic Research Program of China (973 Program, No. 2014CB046703).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted August 16, 2018.

Rights and permissions

About this article

Cite this article

Liang, L., Hu, R., Wang, J. et al. A CFD-FEM Model of Residual Stress for Electron Beam Welding Including the Weld Imperfection Effect. Metall Mater Trans A 50, 2246–2258 (2019). https://doi.org/10.1007/s11661-019-05154-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-019-05154-8