Abstract

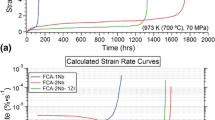

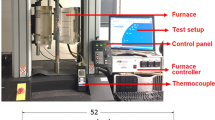

Understanding creep properties and microstructural evolution for candidate materials of the next-generation nuclear reactors is essential for design and safety considerations. In this work, creep tests were carried out at temperatures ranging from 973 to 1073 K and stresses 40 to 275 MPa followed by microstructural examinations of a Fe-20Cr-25Ni (mass pct) austenitic stainless steel (Alloy 709), a candidate structural material for the Sodium-cooled Fast Reactors. The apparent stress exponent and activation energy were found to be 6.8 ± 0.4 and 421 ± 38 kJ/mole, respectively. The higher activation energy relative to that of lattice self-diffusion together with the observation of dislocation-precipitate interactions in the crept specimens was rationalized based on the concept of threshold stress. The threshold stresses were estimated using a linear extrapolation method and found to decrease with increased temperature. By invoking the concept of threshold stresses, the true stress exponent and activation energy were found to be 4.9 ± 0.2 and 299 ± 15 kJ/mole, respectively. Together with the observation of subgrain boundary formation, the rate-controlling mechanism in the Alloy 709 was conclusively determined to be the high-temperature dislocation climb. Three types of precipitates were identified in the crept samples: Nb(C, N), Z-phases of sizes between 20 and 200 nm within the matrix and M23C6 with sizes between 200 and 700 nm within the matrix and on grain boundaries. Further, the analysis of creep rupture data at high stresses indicated that the Alloy 709 obeyed Monkman–Grant and modified Monkman–Grant relationships with creep damage tolerance factor of ~ 5. Using the Larson–Miller parameter, it was concluded that the Alloy 709 exhibited superior creep strengths relative to the other advanced austenitic steels.

Similar content being viewed by others

References

T.R. Allen, K. Sridharan, L. Tan, W.E. Windes, J.I. Cole, D.C. Crawford, G.S. Was: Nucl. Technol., 2008, vol. 162, pp. 342-357.

K.L. Murty, I. Charit: J. Nucl. Mater., 2008, vol. 383, pp. 189-195.

J.T. Busby: J. Nucl. Mater., 2009, vol. 392, pp. 301-306.

S.L.Mannan, S.C.Chetal, B. Raj, S.B.Bhoje: Transactions- Indian Institute of Metals, 2003, vol. 56, pp. 1-35.

J.D. Cook, D.R. Harries, A.C. Roberts: in Creep Strength in Steels and High Temperature alloys, The Metals Society, London, 1972, p. 91.

W. Corwin: Fiscal Year (FY) 2015 Annual Planning Webinar, DOE, 2014.

T.-L. Sham, L. Tan, Y. Yamamoto: in Fast Reactors and Related Fuel Cycles: Safe Technologies and Sustainable Scenarios (FR13), IAEA, Vienna, 2015, pp. 1-9.

T. Takahashi, M. Sakakibara, M. Kikuchi, T. Ogawa, H. Sakurai, S. Araki, K. Nagao, and H. Yasuda: Nippon Steel Corporation, 1988.

H.E. Evans, D.A. Hilton: Nucl. Energy, 1973, vol. 18, pp. 33-38.

G. Knowles: Met. Sci., 1977, vol. 11, pp. 117-122.

O.K. Chopra, K. Natesan: Metall. Trans. A, 1977, vol. 8, pp. 633-638.

J.S. Zhang, P.E. Li, J.Z. Jin: Acta Metall. Mater., 1991, vol. 39, pp. 3063-3070.

E. Evangelista, C. Guardamagna, L. Kloc, A. Rosen, S. Spigarelli: High Temp. Mater. Processes, 1995, vol. 14, pp. 151-161.

D.V.V. Satyanarayana, G. Malakondaiah, D.S. Sarma: Mater. Sci. Eng., A, 2002, vol. 323, pp. 119-128.

L.J. Meng, J. Sun, H. Xing: J. Nucl. Mater., 2012, vol. 427, pp. 116-120.

D.-B. Park, S.-M. Hong, K.-H. Lee, M.-Y. Huh, J.-Y. Suh, S.-C. Lee, W.-S. Jung: Mater. Charact., 2014, vol. 93, pp. 52-61.

P. Ou, L. Li, X.-F. Xie, J. Sun: Acta Metall. Sin. 2015, 28, 1336–43.

A.S. Alomari, N. Kumar, K.L. Murty: in Proceedings of the ASME 2017 Power and Engineering Conference, Charlotte, NC, USA, 2017.

J.K. Benz, L.J. Carroll, J.K. Wright, R.N. Wright, T.M. Lillo: Metall. Trans. A, 2014, vol. 45, pp. 3010-3022.

T. Sourmail, H.K.D.H. Bhadeshia: Metall. Trans. A, 2005, vol. 36, pp. 23-34.

B.K. Kim, L. Tan, C. Xu, Y. Yang, X. Zhang, M. Li: J. Nucl. Mater., 2016, vol. 470, pp. 229-235.

C. Degueldre, J. Fahy, O. Kolosov, R.J. Wilbraham, M. Döbeli, N. Renevier, J. Ball, S. Ritter: J. Mater. Eng. Perform., 2018, vol. 27, pp. 2081-2088.

T. Chen, L. Tan, Z. Lu, H. Xu: Acta Mater., 2017, vol. 138, pp. 83-91.

D.S. Smith, N.J. Lybeck, J.K. Wright, R.N. Wright: Nucl. Eng. Des., 2017, vol. 322, pp. 331-335.

A.S. Alomari, N. Kumar, K.L. Murty: Mater. Sci. Eng., A, 2018, vol. 729, pp. 157-160.

A.S. Alomari, N. Kumar, K.L. Murty: in International Congress on Advances in Nuclear Power Plants (ICAPP), American Nuclear Society, Charlotte, NC, USA, 2018.

S. Upadhayay, H. Li, P. Bowen, A. Rabiei: Mater. Sci. Eng., A, 2018, vol. 733, pp. 338-349.

K.L. Murty, F.A. Mohamed, J.E. Dorn: Acta Metall., 1972, vol. 20, pp. 1009-1018.

T.G. Langdon: in Dislocations and properties of real materials, The Institute of Metals, London, 1985, pp. 221-238.

K.L. Murty, G. Dentel, J. Britt: Mater. Sci. Eng., A, 2005, vol. 410-411, pp. 28-31.

J. Bird, A. Mukherjee, J. Dorn, in: Quantitative Relations between Properties and Microstructure, Israel Univ, 1969.

S. Latha, M.D. Mathew, P. Parameswaran, K. Sankara Rao, S.L. Mannan: Int. J. Press. Vessels Pip. 2008, 85, 866-870.

S. Latha, M.D. Mathew, P. Parameswaran, K. Bhanu Sankara Rao, S.L. Mannan: Mater. Sci. Eng., A, 2010, vol. 527, pp. 5167-5174.

A.F. Smith, G.B. Gibbs: Met. Sci. J., 1968, vol. 2, pp. 47-50.

R. Lagneborg, B. Bergman: Met. Sci., 1976, vol. 10, pp. 20-28.

R.S. Mishra, T.R. Bieler, A.K. Mukherjee: Acta Metall. Mater., 1995, vol. 43, pp. 877-891.

T. Shrestha, M. Basirat, I. Charit, G.P. Potirniche, K.K. Rink, U. Sahaym: J. Nucl. Mater., 2012, vol. 423, pp. 110-119.

A.F. Smith, G.B. Gibbs: Met. Sci. J., 1969, vol. 3, pp. 93-94.

A.F. Smith: CEGB-RD/B/N–2330, Central Electricity Generating Board, United Kingdom, 1972.

A.F. Smith: Zeitschrift für Metallkunde, 1975, vol. 66, pp. 692-696.

S.L. Robinson, O.D. Sherby: Acta Metall., 1969, vol. 17, pp. 109-125.

E.G. Wilson: in Creep strength in steel and high temperature alloys, The Metal Society, London, 1972, pp. 111-121.

J. Weertman: in Rate Processes in Plastic Deformation of Materials, ASM, Cleveland, Ohio, USA, 1972, pp. 315–336.

K.L. Murty: in Creep and fracture of engineering materials and structures, The Minerals, Metals & Materials Society, Irvine, USA, 1997, pp. 69-78.

S. Gollapudi, I. Charit, K.L. Murty: Acta Mater., 2008, vol. 56, pp. 2406-2419.

B. Kombaiah, K.L. Murty: Metall. Trans. A, 2015, vol. 46, pp. 4646-4660.

A. Horsewell: Metall. Trans. A, 1978, vol. 9, pp. 1843-1847.

M.D. Mathew, G. Sasikala, K. Bhanu Sankara Rao, S.L. Mannan: Mater. Sci. Eng., A, 1991, vol. 148, pp. 253-260.

N.D. Evans, P.J. Maziasz, J.P. Shingledecker, M.J. Pollard: Metall. Trans. A, 2010, vol. 41, pp. 3032-3041.

B. Peng, H. Zhang, J. Hong, J. Gao, H. Zhang, J. Li, Q. Wang: Mater. Sci. Eng., A, 2010, vol. 527, pp. 4424-4430.

V. Vodárek: Mater. Sci. Eng., A, 2011, vol. 528, pp. 4232-4238.

Y. Zhou, Y. Li, Y. Liu, Q. Guo, C. Liu, L. Yu, C. Li, H. Li: J. Mater. Res., 2015, vol. 30, pp. 3642-3652.

Z. Zhang, Z. Hu, H. Tu, S. Schmauder, G. Wu: Mater. Sci. Eng., A, 2017, vol. 681, pp. 74-84.

H.J. Kestenbach, T. Luiz Da Silvelra, S.N. Monteiro: Metall. Trans. A, 1976, vol. 7, pp. 155-158.

E.C.Monkman, N.J.Grant: Proc. Am. Soc. Test. Mater., 1956, vol. 56, pp. 593.

F. Dobeš, K. Milička: Met. Sci., 1976, vol. 10, pp. 382-384.

M.F. Ashby, B.F. Dyson: in Advances in Fracture Research, Pergamon Press, Oxford, 1984, pp. 3–30.

B. Wilshire, H. Burt: Int. J. Press. Vessels Pip., 2008, vol. 85, pp. 47-54.

European Technology Development, 2005.

Acknowledgments

The authors gratefully acknowledge the financial support from the Nuclear Energy University Programs (NEUP) of the Department of Energy, Office of Nuclear Energy for performing this research and Dr. Sam Sham of Argonne National Laboratory for various discussions and the experimental material. AA is thankful to KACST for funding his doctoral degree studies.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted September 20, 2018.

Rights and permissions

About this article

Cite this article

Alomari, A.S., Kumar, N. & Murty, K.L. Creep Behavior and Microstructural Evolution of a Fe-20Cr-25Ni (Mass Percent) Austenitic Stainless Steel (Alloy 709) at Elevated Temperatures. Metall Mater Trans A 50, 641–654 (2019). https://doi.org/10.1007/s11661-018-5044-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-018-5044-y