Abstract

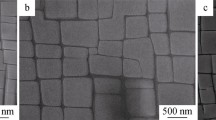

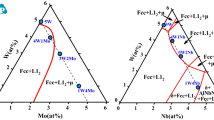

Microstructural features, including γ′ volume fraction and size, γ-γ′ lattice misfit, γ channel width, and dislocation substructure, are known to significantly influence the creep performance in Ni-base single-crystal superalloys. In this study, the microstructural characteristics of Ru-containing single-crystal superalloys with different levels of Co, Mo, and Ru additions were quantitatively investigated after ruptured and interrupted creep tests conducted at 1223 K (950 °C) and 400 MPa. The creep lifetime was slightly increased with the high level of Co addition and significantly increased with the coadditions of Mo and Ru. A minor effect of Co content on the γ channel width and γ′ volume fraction was found in experimental alloys. The alloy with high levels of Mo and Ru additions was determined to possess a more negative γ-γ′ lattice misfit, and a high density of stacking faults (SFs) was formed in the γ channels during creep. The combined effects of the SFs in the γ matrix serving as the barriers to dislocation movement, as well as the dense interfacial dislocation networks preventing dislocation to shear the γ′ phase, were considered as the main mechanism responsible for the improvement of creep resistance. Results from this study are helpful to understand the effect of microstructural features on creep performance and contribute to the knowledge of physical metallurgy in Ru-containing single-crystal superalloys.

Similar content being viewed by others

References

R.C. Reed: The Superalloys: Fundamentals and Applications, Cambridge University Press, Cambridge, United Kingdom, 2006.

T.M. Pollock and S. Tin: J. Propul. Power, 2006, vol. 22, pp. 361–74.

S Walston, A Cetel, R MacKay, K O’Hara, D Duhl, and R Dreshfield: Superalloys 2004, Champion, PA, 2004, KA Green, TM Pollock, H Harada, TE Howson, RC Reed, JJ Schirra, and S Walston, eds., TMS, Warrendale, PA, 2004, pp. 15–24.

GL Erickson: Superalloys 1996, Champion, PA, 1996, RD Kissinger, DJ Deye, DL Anton, AD Cetel, MV Nathal, TM Pollock, and DA Woodford, eds., TMS, Warrendale, PA, 1996, pp. 35–44.

R Bürgel, J Grossmann, O Lusebrink, H Mughrabi, F Pyczak, RF Singer, and A Volek: Superalloys 2004, KA Green, TM Pollock, H Harada, TE Howson, RC Reed, JJ Schirra, and S Walston, eds., Champion, PA, 2004, TMS, Warrendale, PA, 2004, pp. 25–34.

M. Nathal and L. Ebert: Metall. Trans. A, 1985, vol. 16A, pp. 1863–70.

L.J. Carroll, Q. Feng, and T.M. Pollock: Metall. Mater. Trans. A, 2008, vol. 39A, pp. 1290–1307.

RA Hobbs, GJ Brewster, CMF Rae, and S Tin: Superalloys 2008, RC Reed, KA Green, P Caron, TP Gabb, MG Fahrmann, and ES Huron, eds., Champion, PA, 2008, TMS, Warrendale, PA, pp. 171–80.

TM Pollock and RD Field: in Dislocations in Solids, FRN Nabarro and MS Duesbery, eds., Elsevier, New York, NY, 2002, pp. 547–618.

S. Ma, L. Carroll, and T.M. Pollock: Acta Mater., 2007, vol. 55, pp. 5802–12.

Y. Yuan, Y. Gu, C. Cui, T. Osada, Z. Zhong, T. Tetsui, T. Yokokawa, and H. Harada: J. Mater. Res., 2011, vol. 26, pp. 2833–37.

F. Xue, H.J. Zhou, Q.Y. Shi, X.H. Chen, H. Chang, M.L. Wang, and Q. Feng: Scripta Mater., 2015, vol. 97, pp. 37–40.

M.S. Titus, A. Mottura, G. Babu Viswanathan, A. Suzuki, M.J. Mills, and T.M. Pollock: Acta Mater., 2015, vol. 89, pp. 423–37.

JX Zhang, T Murakumo, H Harada, Y Koizumi, and T Kobayashi: Superalloys 2004, KA Green, TM Pollock, H Harada, TE Howson, RC Reed, JJ Schirra, and S Walston, eds., Champion, PA, 2004, TMS, Warrendale, PA, pp. 189–95.

Q. Shi, J. Huo, Y. Zheng, and Q. Feng: Mater. Sci. Eng. A, 2018, vol. 725, pp. 148–59.

J. Zhang, J.G. Li, T. Jin, X.F. Sun, and Z.Q. Hu: Mater. Sci. Eng. A, 2010, vol. 527, pp. 3051–56.

T. Tiearney and N.J. Grant: Metall. Trans. A, 1982, vol. 13A, pp. 1827–36.

F. Pettinari, J. Douin, G. Saada, P. Caron, A. Coujou, and N. Clement: Mater. Sci. Eng. A, 2002, vol. 325, pp. 511–19.

R.A. Hobbs, L. Zhang, C.M.F. Rae, and S. Tin: Mater. Sci. Eng. A, 2008, vol. 489, pp. 65–76.

T.Y. Yang, W. Wen, and G.Z. Yin: Nucl. Sci. Technol., 2015, vol. 26, pp. 1–5.

A. Heckl, S. Neumeier, M. Göken, and R.F. Singer: Mater. Sci. Eng. A, 2011, vol. 528, pp. 3435–44.

R.A. MacKay, T.P. Gabb, A. Garg, R.B. Rogers, and M.V. Nathal: Mater. Charact., 2012, vol. 70, pp. 83–100.

R.A. MacKay, T.P. Gabb, and M.V. Nathal: Mater. Sci. Eng. A, 2013, vol. 582, pp. 397–408.

T. Murakumo, T. Kobayashi, Y. Koizumi, and H. Harada: Acta Mater., 2004, vol. 52, pp. 3737–44.

S Neumeier, F Pyczak, and M Göken: Superalloys 2008, RC Reed, KA Green, P Caron, TP Gabb, MG Fahrmann, ES Huron, and SA Woodard, eds., Champion, PA, 2008, TMS, Warrendale, PA, 2008, pp. 109–19.

N. Tsuno, K. Kakehi, C.M.F. Rae, and R. Hashizume: Metall. Mater. Trans. A, 2009, vol. 40A, pp. 269–72.

J.X. Zhang, T. Murakumo, Y. Koizumi, T. Kobayashi, H. Harada, and S. Masaki: Metall. Mater. Trans. A, 2002, vol. 33A, pp. 3741–46.

T.M. Pollock and A.S. Argon: Acta Metall. Mater., 1992, vol. 40, pp. 1–30.

L.J. Carroll, Q. Feng, J.F. Mansfield, and T.M. Pollock: Metall. Mater. Trans. A, 2006, vol. 37A, pp. 2927–38.

J.X. Zhang, J.C. Wang, H. Harada, and Y. Koizumi: Acta Mater., 2005, vol. 53, pp. 4623–33.

J.X. Zhang, T. Murakumo, Y. Koizumi, and H. Harada: J. Mater. Sci., 2003, vol. 38, pp. 4883–88.

A.C. Yeh, A. Sato, T. Kobayashi, and H. Harada: Mater. Sci. Eng. A, 2008, vol. 490, pp. 445–51.

O. Boualy, N. Clément, and M. Benyoucef: J. Mater. Sci., 2018, vol. 53, pp. 2892–2900.

W.R. Johnson, C.R. Barrett, and W.D. Nix: Metall. Trans., 1972, vol. 3, pp. 963–69.

C. Cui, C. Tian, Y. Zhou, T. Jin, and X. Sun: Superalloys 2012, R.C. Reed, K.A. Green, P. Caron, T.P. Gabb, M.G. Fahrmann, and E.S. Huron, eds., Champion, PA, 2008, TMS, Warrendale, PA, 2012, pp. 715–22.

Acknowledgments

The authors thank beamline BL14B1 (Shanghai Synchrotron Radiation Facility) for providing the beam time and help during the experiments. The financial support provided by the National Key Research and Development Program of China (Project No. 2016YFB0701403) and the National Natural Science Foundation of China (Grant Nos. 51271015 and 51631008) are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted December 13, 2017.

Rights and permissions

About this article

Cite this article

Huo, J.J., Shi, Q.Y., Tin, S. et al. Improvement of Creep Resistance at 950 °C and 400 MPa in Ru-Containing Single-Crystal Superalloys with a High Level of Co Addition. Metall Mater Trans A 49, 5298–5308 (2018). https://doi.org/10.1007/s11661-018-4842-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-018-4842-6