Abstract

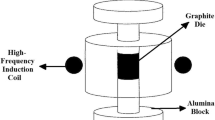

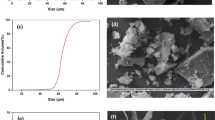

Silicon carbide (SiC) nanoparticles (NP) and/or graphene nanoplatelets (GNP) were incorporated into the aluminum matrix through colloidal dispersion and mixing of the powders, followed by consolidation using a high-frequency induction heat sintering process. All the nanocomposite samples exhibited high densification (> 96 pct) with a maximum increase in Vickers microhardness by 92 pct relative to that of pure aluminum. The tribological properties of the samples were determined at the normal frictional forces of 10 and 50 N. At relatively low load of 10 N, the adhesive wear was found to be the predominant wear mechanism, whereas in the case of a 50 N normal load, there was significant contribution from abrasive wear possibly by hard SiC NP. From wear tests, the values for the coefficient of friction (COF) and the normalized wear rate were determined. The improvement in hardness and wear resistance may be attributed to multiple factors, including high relative density, uniform SiC and GNP dispersion in the aluminum matrix, grain refinement through GNP pinning, as well as inhibition of dislocation movement by SiC NP. The nanocomposite sample containing 10 SiC and 0.5 GNP (by wt pct) yielded the maximum wear resistance at 10 N normal load. Microstructural characterization of the nanocomposite surfaces and wear debris was performed using scanning electron microscope (SEM) and transmission electron microscope (TEM). The synergistic effect of the GNP and SiC nanostructures accounts for superior wear resistance in the aluminum matrix nanocomposites.

Similar content being viewed by others

References

N. Chawla, and K.K. Chawla: Metal Matrix Composites, Springer, New York (2013).

Rawal, S.: JOM, 2001, vol. 53(4), pp. 14-17.

P. Stoyanov, D. Linsler, T. Schlarb, M. Scherg, R. Schwaiger: J. Mater. Sci., 2015, vol. 50, pp. 5524-32.

M.O. Bodunrina, K.K. Alaneme, L.H. Chown: J. Mater. Res. Technol., 2015, vol. 4(4), pp. 434-45.

K. Ma, E.J. Lavernia, J.M. Schoenung: Rev. Adv. Mater. Sci., 2017, vol. 48(2), pp. 91-104.

Z. Li, G. Fan, Q. Guo, Z. Li, Y. Su, D. Zhang: Carbon, 2015, vol. 95, 419-427.

C.-L. Chen, C.-H. Lin: Metall. Mater. Trans. A, 2015, vol. 46A, pp. 3687-3695.

L. Xin, W. Yang, Q. Zhao, R. Dong, X. Liang, Z. Xiu, M. Hussain, G. Wu: Mater. Sci. Eng. A, 2017, vol. 682, pp. 38-44.

Y. Uematsu, K. Tokaji, M. Kawamura: Compos. Sci. Technol., 2008, vol. 68, pp. 2785-91.

S. Mahdavi, F. Akhlaghi: J. Mater. Sci., 2011, vol. 46, pp. 7883-94.

Z.G. Wang, C.P. Li, H.Y. Wang, J.N. Zhu, C. Wang, Q.C. Jiang: J. Mater. Eng. Perform., 2017, vol. 26(2), 729-35.

S. Zhang, F. Wang: J. Mater. Processing. Technol., 2007, vol. 182, pp. 122–27.

K.M. Shorowordi, A.S.M.A. Haseeb, J.P. Celis: Wear, 2004, vol. 256, pp. 1176-81.

Gracio JJ, Picu CR, Vincze G, Mathew N, Schubert T, Lopes A, Buchheim C (2013) Metall Mater Trans 44: 5259-69.

A. Doraisamy and S. Thiagarajan: Adv. Tribol., 2014, vol. 273738, 8 pp.

J. Wang, Z. Li, G. Fan, H. Pan, Z. Chen, D. Zhang: Scripta Mater., 2012, vol. 66, pp. 594-7.

A. El-Ghazaly, G. Anis, H.G. Salem: Compos. A, 2017, vol. 95, pp. 325-36.

S.F. Bartolucci, J. Paras, M.A. Rafiee, J. Rafiee, S. Lee: Mater. Sci. Eng., 2011, vol. 528(27), pp. 7933-37.

T. Etter, P. Schulz, M. Weber, J. Metz, M. Wimmler, J.F. Loffler, P.J. Uggowitzer: Mater. Sci. Eng. A, 2007, vol. 448, pp. 1-6.

T. Sritharan, L.S. Chan, L.K. Tan, N.P. Hung: Mater. Character., 2001, vol. 47, pp. 75-77.

W.M. Tian, S.M. Li, B. Wang, X. Chen, J.H. Liu, M. Yu: Int. J. Miner. Metall. Mater., 2016, vol. 23(6), pp. 723-9.

B. Hekner, J. Myalski, N. Valle, A.B. Probierz, M.S. Lizer, J. Wieczorek: Compos. B, 2017, vol. 108, pp. 291–300.

A.F. Boostani, S. Yazdani, R.T. Mousavian, S. Tahamtanc, R.A. Khosroshahi, D. Wei, D. Brabazon, J.Z. Xu, X.M. Zhang, Z.Y. Jiang: Mater. Des., 2015, vol. 88, pp. 983-89.

I. Ahmad, M. Islam, T. Subhani, and Y. Zhu: Nanotechnology, 2016, vol. 27(42), pp. 425704, 13 pp.

I. Ahmad, M. Islam, H.S. Abdo, T. Subhani, K.A. Khalil, A.A. Almajid, B. Yazdani, Y. Zhu: Mater. Des., 2015, vol. 88, pp. 1234-43.

S. Mahdavi, F. Akhlaghi: Tribol. Lett., 2011, vol. 44(1), pp. 1-12.

H.C. Schniepp, J.L. Li, M.J. McAllister, H. Sai, M.H. Alonso, D.H. Adamson, I.A. Aksay: J. Phys. Chem. B., 2006, vol. 110, pp. 8535-39.

H.Y. Nan, Z.H. Ni, J. Wang, Z. Zafar, Z.X. Shi, Y.Y. Wang: J. Raman Spectrosc., 2013, vol. 44(7), pp. 1018-21.

I. Ahmad, M. Islam, T. Subhani, and Y. Zhu: J. Mater. Eng. Perform. 2015, vol. 24(11), pp. 4236-43.

Y. Zhang, C. Pan: Diam. Relat. Mater. 2012, vol. 24, pp. 1-5.

M. Kostecki, J. Wozniak, T. Cygan, M. Petrus, A. Olszyna: Materials, 2017, vol. 10, pp. 928.

P. Ravindran, K. Manisekar, R. Narayanasamy, P. Narayanasamy: Ceram. Int., 2013, vol. 39, pp. 1169-82.

M. Walczak, D. Pieniak, M. Zwierzchowski: Arch. Civ. Mech. Eng., 2015, vol. 15, pp. 116-23.

M. Djafri, M. Bouchetara, C. Busch, S. Weber: Wear, 2014, vol. 321, pp. 8-15.

A. Daoud, M.T.A. El-khair: Tribol. Int., 2010, vol. 43, pp. 544-53.

J.B. Yang, C.B. Lin, T.C. Wang, H.Y. Chu: Wear, 2004, vol. 257, pp. 941-52.

A. Baradeswaran, A.E. Perumal: Compos. B, 2014, vol. 56, pp. 472-76.

F. Akhlaghi, A.Z. Bidaki: Wear, 2009, vol. 266, pp. 37-45.

M.T. Khorshid, E. Omrani, P.L. Menezes, P.K. Rohatgi: Eng. Sci. Technol., 2016, vol. 19, pp. 463-9.

X.M. Du, R.Q. Chen, F.G. Liu: Dig. J. Nanomater. Biostruct., 2017, vol. 12(1), pp. 37-45.

M. Alipour, R.E. Farsani: Mater. Sci. Eng. A, 2017, vol. 706, pp. 71–82.

L. Jinfeng, J. Longtao, W. Gaohui, T. Shoufu, C. Guoqin: Rare. Metal. Mater. Eng., 2009, vol. 38(11), pp. 1894-98.

P. Kumar, A. Xavior: Mater. Manuf. Process., 2017. https://doi.org/10.1080/10426914.2017.1279320.

A.D. Moghadam, E. Omrani, P.L. Menezes, P.K. Rohatgi: Compos. B., 2015, vol. 77, pp. 402-20.

K. Rajkumar, S. Aravindan: Tribol. Int., 2013, vol. 57, pp. 282-96.

H.J. Choi, S.M. Lee, D.H. Bae: Wear, 2010, vol. 270(1-2), pp. 12-18.

Acknowledgment

The authors would like to extend their sincere appreciation to the Deanship of Scientific Research at King Saud University for its funding of this research through the Research Group Project No. RGP-283.

Conflict of interest

The authors express no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted December 1, 2017.

Rights and permissions

About this article

Cite this article

Islam, M., Khalid, Y., Ahmad, I. et al. Microstructural Evaluation of Inductively Sintered Aluminum Matrix Nanocomposites Reinforced with Silicon Carbide and/or Graphene Nanoplatelets for Tribological Applications. Metall Mater Trans A 49, 2963–2976 (2018). https://doi.org/10.1007/s11661-018-4625-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-018-4625-0