Abstract

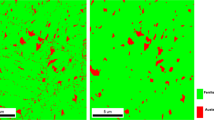

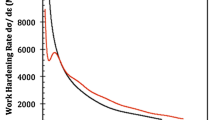

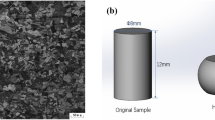

The microstructural evolution of hot-deformed austenite during recrystallization was studied in a non-microalloyed low carbon steel and a low carbon steel, microalloyed with niobium and titanium. Double-hit compression tests were carried out to evaluate the isothermal recrystallization behavior. Specific deformation temperatures and interpass times were combined to produce characteristic recrystallization states by quenching the samples to a martensitic microstructure. The reconstruction software Merengue 2 was used to determine the prior austenite microstructure and evaluate the recrystallized fraction in the microstructure. The reconstruction is based on EBSD measurements of the martensitic microstructure. The determination of the recrystallized fraction was realized by evaluating the grain orientation spread. This work compares the results of both methods and estimates their uncertainties. It shows the potential of EBSD reconstruction methods to characterize different recrystallization states of low carbon steels out of EBSD data.

Similar content being viewed by others

References

L Bäcke (2010) ISIJ Int. 50(2):239–247.

B Dutta, CM Sellars (1987) Am. J. Mater. Sci. Technol. 3(3):197-206.

FJ Humphreys (1997) Acta Mater. 45(12):5031-5039.

H Watanabe, YE Smith, RD Pehlke (1997) The Hot Deformation of Austenite. Metallurgical Society, AIME, New York, pp. 140-168.

S Vervynckt, K Verbeken, B Lopez, JJ Jonas (2012) Int. Mater. Rev. 57(4):187-207.

S Bechet, L Beaujard (1955) Rev. Metall. (Paris) 52(10):830–836

S Weyand, D Britz, D Rupp, F Mücklich (2015) Mater. Perform. Charact. 4(3):322-340.

G. Nolze: Cryst. Res. Technol., 2006, 41(1):72-77.

C Cayron (2007) J. Appl. Crystallogr. 40(6):1183-1188.

L. Germain, P. Blaineau, N. Gey, M. Humbert: Mater. Sci. Forum, 2011, vol. 702, pp. 846-849.

M. Humbert, L. Germain, N. Gey, E. Boucard: Acta Mater., 2015, vol. 82, pp. 137-144.

M. Kubota, K. Ushioda, G. Miyamoto, T. Furuhara: Scr. Mater., 2016, vol. 112, :92-95.

G Miyamoto, N Takayama, T Furuhara (2009) Scr. Mater. 60(12):1113-1116.

JS Perttula, LP Karjalainen (1998) Mater. Sci. Technol. 14(7):626-630.

AI Fernández, B López, JM Rodríguez-Ibabe (1999) Scr. Mater. 40(5):543-549.

CN Homsher, CJ Van Tyne (2015) Mater. Perform. Charact. 4(3):293-306.

M. Humbert, P. Blaineau, L. Germain, N. Gey: Scr. Mater., 2011, vol. 64, :114-117.

DP Field, LT Bradford, MM Nowell, TM Lillo (2007) Acta Mater. 55(12):4233-4241.

H. Mirzadeh, A. Najafizadeh, J. M. Cabrera, P. Rodriguez-Calvillo: Mater. Sci. Eng. A, 2012, vol. 538, pp. 236-245.

H. Sato, S. Zaefferer: Acta Mater., 2009, vol. 57, pp. 1931–1937

L. Eisenhut, D. Rupp, and C. Motz: Assoc. Ital. Metall., Conference Proceeding, 5th International Conference on Thermomechanical Processing, Milan, 2016

AIZ Farahat (2008) J. Mater. Process. Technol. 204(1):365-369.

Y Huang, FJ Humphreys (2012) Mater. Chem. Phys. 132(1):166-174.

P. Uranga, A. I. Fernández, B. López, J. M. Rodríguez-Ibabe: Mater. Sci. Eng. A, 2003, vol. 345, :319-327.

SF Medina (1997) J. Mater. Sci. 32(6):1487-1492.

S Vervynckt, K Verbeken, P Thibaux, M Liebeherr (2009) ISIJ Int. 49(6):911-920.

S. Vervynckt, K. Verbeken, P. Thibaux, Y. Houbaert: Mater. Sci. Eng. A, 2011, vol. 528, :5519-5528.

D. P. Field: Ultramicroscopy, 1997, vol. 67, :1-9.

L. Germain: Habilitation dissertation, 2014, http://lionelgermain.free.fr/HDR%20Lionel%20Germain.pdf.

P. Blaineau, L. Germain, M. Humbert, N. Gey: Solid State Phenom., 2010, vol. 160, pp. 203-210.

N. Bernier, L. Bracke, L. Malet, S. Godet: Mater. Charact., 2014, vol. 89, pp. 23-32.

K. Radwanski: Steel Res. Int., 2015, vol.86, pp. 1379–1390.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted September 28, 2017.

Rights and permissions

About this article

Cite this article

Krämer, T., Eisenhut, L., Germain, L. et al. Assessment of EBSD Analysis and Reconstruction Methods as a Tool for the Determination of Recrystallized Fractions in Hot-Deformed Austenitic Microstructures. Metall Mater Trans A 49, 2795–2802 (2018). https://doi.org/10.1007/s11661-018-4593-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-018-4593-4