ABSTRACT

Purpose

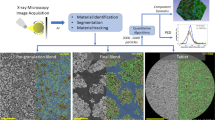

The aim of this work was to develop a quantification method based on image analysis, able to characterize sticking during pharmaceutical tableting. Relationship between image analysis features and relevant mechanical parameters recorded on an instrumented tablet press simulator were investigated.

Methods

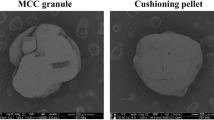

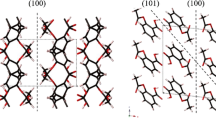

Image analysis, based on gray levels co-occurrence matrices (GLCM), generated textural features of the tablet surface. The tableting simulator (Stylcam® 200R, Medelpharm), instrumented with force and displacement transducers, provided accurate records. The tablet defects and compaction process parameters were studied using three pharmaceutical powders (Fast-Flo® lactose, anhydrous Emcompress® and Avicel® PH200 microcrystalline cellulose), five compression pressures (60 to 250 MPa), five lubricating levels, and three types of punches (standard steel, amorphous hard carbon and anti-sticking punches).

Results

Texture parameters made it possible to quantify with precision tablets’ aspect. The selected parameter IC2 (Information on Correlation 2) plotted versus the ratio between the ejection shear stress (Esh) and the compression pressure (Cp) let appear a relevant knowledge space where it was possible to identify a normal and a degraded tableting mode. A positive link between those two parameters was shown.

Conclusion

Since the Esh/Cp ratio was related to image analysis results, it proved to be an interesting defect tag.

Similar content being viewed by others

Notes

Some series have not been represented because their attached result did not make sense. For instance, low pressures series of Emcompress® had high values of IC2, not because the tablets were degraded, but because the individual particles of powder were still visible due to the low pressure, mimicking a kind of roughness, not linked to a defect (27). Indeed, Emcompress® had big, and brittle particles. This phenomenon appeared for some Avicel® series too (see Table I).

Abbreviations

- AHC:

-

amorphous hard carbon

- API:

-

active pharmaceutical ingredient

- AS:

-

anti sticking

- Cp:

-

compression pressure

- Ent:

-

entropy parameter

- Esh:

-

ejection shear stress

- GLCM:

-

gray level co-occurrence matrix

- IC2:

-

information on correlation 2

- StdStl:

-

standard steel

- WTA:

-

wavelet texture analysis

REFERENCES

Robert J-L. ASEAN training on ICH Q8/Q9/Q10 Guidelines: ICH [Internet]. ICH; 2010 [cited 2012 Mar 27]. Available from: http://www.ich.org/fileadmin/Public_Web_Site/Training/ICH_Endorsed_Training_Events/ASEAN_training_on_Q8_Q9_Q10_Guidelines/Q8_Pharma_development_JL.Robert.pdf

Tousey MD. Sticking and picking: some causes and remedies. Tablets and Capsules. 2003 October.

Brisson J, Genin M, Tabib N. Les défauts de fabrication des comprimés. Pharmaterm MD. 2006;17(2):1–6.

Wang JJ, Li T, Bateman SD, Erck R, Morris KR. Modeling of adhesion in tablet compression—I. Atomic force microscopy and molecular simulation. J Pharm Sci. 2003;92(4):798–814.

Wang JJ, Guillot MA, Bateman SD, Morris KR. Modeling of adhesion in tablet compression. II. Compaction studies using a compaction simulator and an instrumented tablet press. J Pharm Sci. 2004;93(2):407–17.

Waimer F, Krumme M, Danz P, Tenter U, Schmidt PC. A novel method for the detection of sticking of tablets. Pharm Dev Technol. 1999;4(3):359–67.

Danjo K, Kojima S, Chen CY, Sunada H, Otsuka A. Effect of water content on sticking during compression. Chem Pharm Bull. 1997;45(4):706–9.

Imbert C, Tchoreloff P, Leclerc B, Couarraze G. Indices of tableting performance and application of percolation theory to powder compaction. Eur J Pharm Biopharm. 1997;44(3):273–82.

Vezin WR, Pang HM, Khan KA, Malkowska S. The effect of precompression in a rotary machine on tablet strength. Drug Dev Ind Pharm. 1983;9(8):1465–74.

Kakimi K, Niwa T, Danjo K. Influence of compression pressure and velocity on tablet sticking. Chem Pharm Bull. 2010;58(12):1565–8.

Toyoshima K, Yasumura M, Ohnishi N, Ueda Y. Quantitative evaluation of tablet sticking by surface roughness measurement. Int J Pharm. 1988;46(3):211–5.

Danjo K, Kamiya K, Otsuka A. Effect of temperature on the sticking of low melting point materials. Chem Pharm Bull. 1993;41(8):1423–7.

Svensson O, Abrahamsson K, Engelbrektsson J, Nicholas M, Wikström H, Josefson M. An evaluation of 2D-wavelet filters for estimation of differences in textures of pharmaceutical tablets. Chemom Intell Lab Syst. 2006;84(1–2 SPEC. ISS):3–8.

García-Muñoz S, Carmody A. Multivariate wavelet texture analysis for pharmaceutical solid product characterization. Int J Pharm. 2010;398(1–2):97–106.

Levin M. Encyclopedia of pharmaceutical technology. 3rd ed. New York: Marcel Dekker; 2006.

Patel S, Kaushal AM, Bansal AK. Compression physics in the formulation development of tablets. Crit Rev Ther Drug Carrier Syst. 2006;23(1):1–65.

Wang J, Wen H, Desai D. Lubrication in tablet formulations. Eur J Pharm Biopharm. 2010;75(1):1–15.

Moody G, Rubinstein MH, FitzSimmons RA. Tablet lubricants I. Theory and modes of action. Int J Pharm. 1981;9(2):75–80.

Rowley FA. Tooling preparation practices and their effect on tablet picking. Pharm Technol Eur. 2005;17(10):42–8.

Roberts M, Ford JL, MacLeod GS, Fell JT, Smith GW, Rowe PH. Effects of surface roughness and chrome plating of punch tips on the sticking tendencies of model ibuprofen formulations. J Pharm Pharmacol. 2003;55(9):1223–8.

Pépin X. Évaluation de l'aptitude de pulvérulents aux transformations par granulation. Châtenay Malabry; 2000.

Porion P, Busignies V, Mazel V, Leclerc B, Evesque P, Tchoreloff P. Anisotropic porous structure of pharmaceutical compacts evaluated by PGSTE-NMR in relation to mechanical property anisotropy. Pharm Res. 2010;27(10):2221–33.

Busignies V, Leclerc B, Truchon S, Tchoreloff P. Changes in the specific surface area of tablets composed of pharmaceutical materials with various deformation behaviors. Drug Development and Industrial Pharmacy. 2011;37(2):225–33.

Yu LX. Pharmaceutical quality by design: Product and process development, understanding, and control (Pharmaceutical Research doi:10.1007/s11095-007-9511-1). Pharm Res. 2008;25(10):2463.

Michaut F, Busignies V, Fouquereau C, Huet De Barochez B, Leclerc B, Tchoreloff P. Evaluation of a rotary tablet press simulator as a tool for the characterization of compaction properties of pharmaceutical products. J Pharm Sci. 2010;99(6):2874–85.

Haralick RM, Shanmugam K, Dinstein I. Textural features for image classification. IEEE Trans Syst Man Cybern. 1973;smc 3(6):610–21.

Mazel V, Busignies V, Diarra H, Reiche I, Tchoreloff P. The surface layer of pharmaceutical compacts: the role of the punch surface and its impact on the mechanical properties of the compacts. Int J Pharm. 2013;442(1–2):42–8.

ACKNOWLEDGMENTS AND DISCLOSURES

The authors gratefully acknowledge Louis Henrion and Yves Collenot from Sanofi for image analysis and photography assistance, Cécile Gagaude from Sanofi for reviewing.

The authors would like to thank EPMO and SFOB for supplying free punches, Noesis for efficient support and updating of the image analysis software Visilog 6.8, Medelpharm for tableting assistance and Sanofi where experiments have been carried out, for their financial support.

The authors wish to thank Mrs Stella Ghouti Baxter for proof reading and grammar correction of the document.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mollereau, G., Mazel, V., Busignies, V. et al. Image Analysis Quantification of Sticking and Picking Events of Pharmaceutical Powders Compressed on a Rotary Tablet Press Simulator. Pharm Res 30, 2303–2314 (2013). https://doi.org/10.1007/s11095-013-1074-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11095-013-1074-8