Abstract

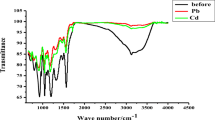

Converting of elemental mercury (Hg0) into oxidized mercury compounds is considered to be an effective method for prompting mercury removal of conventional flue gas treatment systems. The technology of non-thermal plasma (NTP) with CaCl2 treatment was utilized to oxidize Hg0 in this paper. The effects of input energy and different flue gas components like O2, NO and SO2 on Hg0 oxidation were investigated. The results showed that the Hg0 oxidation efficiency with CaCl2 treatment was increased obviously compare with single NTP treatment, and would be more than 90% when the input energy was 120 J/L. The O2 in simulated flue gas played an important role for mercury oxidation. The Hg0 oxidation efficiency and O3 outlet concentration were increased with the increase of O2 content. However, both NO and SO2 inhibited Hg0 oxidation due to their competitive consumption of O3 and O. Compare with single NTP technology, the effects of NO and SO2 on Hg0 oxidation under NTP with CaCl2 treatment were decreased obviously. The technology of Temperature-Programmed Decomposition and Desorption was utilized to analyze the mercury speciation adsorbed or deposited on AC and CaCl2 surface. The results concluded that the main Hg0 oxidation products by NTP with CaCl2 treatment were HgO, Hg2O and HgCl2, which indicated that the chlorine of CaCl2 surface was the main reason for enhancement of Hg0 oxidation.

Similar content being viewed by others

References

Sorensen JA, Glass GE, Schmidt KW et al (1990) Airborne mercury deposition and watershed characteristics in relation to mercury concentrations in water, sediments, plankton, and fish of eighty northern Minnesota lakes. Environ Sci Technol 24:1716–1727

Jensen RR, Karki S, Salehfar H (2004) Artificial neural network-based estimation of mercury speciation in combustion flue gases. Fuel Process Technol 85:451–462

Wang Q, Shen W, Ma Z (2000) Estimation of mercury emission from coal combustion in china. Environ Sci Technol 34:2711–2713

Hui ML, Zhang L, Wang ZG et al (2015) The mercury mass flow and emissions of coal-fired power plants in China. China Environ Sci 35:2241–2250 (in Chinese)

Carpi A (1997) Mercury from combustion sources: a review of the chemical species emitted and their transport in the atmosphere. Water Air Soil Pollut 98:241–254

Pavlish JH, Sondreal EA, Mann MD et al (2005) Status review of mercury control options for coal-fired power plants. Fuel Process Technol 82:89–165

Lee SJ, Seo YC, Jurng JS et al (2004) Mercury emissions from selected stationary combustion sources in Korea. Sci Total Environ 325:155–161

Streets DG, Hao J, Wu Y et al (2005) Anthropogenic mercury emissions in China. Atmos Environ 39:7789–7806

Hall B, Schager P, Lindqvist E (1991) Chemical reactions of mercury in combustion flue gases. Water Air Soil Pollut 56:3–14

Niksa S, Naik CV, Berry MS et al (2009) Interpreting enhanced Hg oxidation with Br addition at Plant Miller. Fuel Process Technol 90:1372–1377

Senior CL, Helble JJ, Sarofim AF (2000) Emissions of mercury, trace elements, and fine particles from stationary combustion sources. Fuel Process Technol 65–66:263–288

Zhang Y, Thompson JS, Zygarlicke CJ et al (2007) Impact of calcium chloride addition on mercury transformations and control in coal flue gas. Fuel 86:2351–2359

Zhou Q, Duan YF, Zhao SL et al (2015) Mercury transformation and NO emission of coal combustion with CaCl2 and NH4Cl additives in a 6 kW CFB combustor. Energy Fuel 29:5267–5273

Galbreath KC, Zygarlicke CJ (1996) Mercury speciation in coal combustion and gasification flue gases. Environ Sci Technol 30:2421–2426

Brown TD, Smith DN, Hargis RN et al (1999) Mercury measurement and its control: what we know, learned, and need to further investigate. J Air Waste Manag 49:628–640

Ko KB, Byun Y, Cho M, Namkung W, Hamilton LP, Shin DN, Koh DJ, Kim KT et al (2008) Influence of gas components on the oxidation of elemental mercury by positive pulsed corona discharge. Main Group Chem. 7:191–204

Yamamoto T, Okubo M, Nagaoka T et al (2002) Simultaneous removal of NOx, SOx and CO2 at elevated temperature using a plasma-chemical hybrid process. IEEE Trans Ind Appl 38:1168–1173

Yan P, Fujiwara M, Zhou Y, Ishida M et al (2001) Investigation on luminescence and NOx removal by pulse corona discharges. J Electrostat 51–52:266–271

Obradović BM, Sretenović GB, Kuraica MM (2011) A dual-use of DBD plasma for simultaneous NOx and SO2 removal from coal-combustion flue gas. J Hazard Mater 185:1280–1286

Chen Z, Mannava DP, Mathur VK (2006) Mercury oxidization in dielectric barrier discharge plasma system. Ind Eng Chem Res 45:6050–6055

Wang MY, Zhu TL, Luo HJ et al (2009) Oxidation of gaseous elemental mercury in a high voltage discharge reactor. J Environ Sci 21:1652–1657

An JT, Shang KF, Lu N et al (2014) Oxidation of elemental mercury by active species generated from a surface dielectric barrier discharge plasma reactor. Plasma Chem Plasma Process 34:217–228

Yang HM, Liu H, Wu H et al (2012) Photochemical removal of gaseous elemental mercury in a dielectric barrier discharge plasma rector. Plasma Chem Plasma Process 32:969–977

Wang ZH, Jiang SD, Zhu YQ et al (2010) Investigation on elemental mercury oxidation mechanism by non-thermal plasma treatment. Fuel Process Technol 91:1395–1400

Jeong J, Jurng J (2007) Removal of gaseous elemental mercury by dielectric barrier discharge. Chemosphere 68:2007–2010

Wang MY, Zhu TL, Luo HJ et al (2011) Effect of reaction conditions on elemental mercury oxidation in simulated flue gas by DC non-thermal plasma. Ind Eng Chem Res 50:5914–5919

Zhang J, Duan YF, Zhao WX et al (2016) Removal of elemental mercury from simulated flue gas by combining non-thermal plasma with calcium oxide. Plasma Chem Plasma Process 36:471–485

Byun Y, Ko KB, Cho M et al (2008) Oxidation of elemental mercury using atmospheric pressure non-thermal plasma. Chemosphere 72:652–658

YokoyamaT Asakura K, Matsuda H et al (2000) Mercury emissions from a coal fired power plant in Japan. Sci Total Environ 259:97–103

Calvert JG, Lindberg SE (2005) Mechanisms of mercury removal by O3 and OH in the atmosphere. Atmos Environ 39:3355–3367

Rumayor M, Lopez-Anton MA, Díaz-Somoano M et al (2015) A new approach to mercury speciation in solids using a thermal desorption technique. Fuel 160:525–530

Huggins FE, Yap N, Huffman GP et al (2003) XAFS characterization of mercury captured from combustion gases on sorbents at low temperatures. Fuel Process Technol 82:167–196

L’vov BV (1999) Kinetics and mechanism of thermal decomposition of mercuric oxide. Thermochim Acta 333:21–26

Martinez AI, Deshpande BK (2007) Kinetic modeling of H2O2-enhanced oxidation of flue gas elemental mercury. Fuel Process Technol 88:982–987

Xu MH, Qiao Y, Zheng CG et al (2003) Modeling of homogeneous mercury speciation using detailed chemical kinetics. Combust Flame 132:208–218

Ko KB, Byun Y, Cho M et al (2008) Influence of HCl on the oxidation of gaseous elemental mercury by dielectric barrier discharge process. Chemosphere 71:1674–1682

Acknowledgements

This work was supported by the Doctor Special Foundation of Nanjing College of Information Technology (YB20170301), National Nature Science Foundation of China (51376046, 51576044), Natural Science Foundation of Jiangsu Province High Education (16KJB430034).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, J., Duan, Y., Zhao, W. et al. Study on Elemental Mercury Oxidation by Non-thermal Plasma with Calcium Chloride Enhancement. Plasma Chem Plasma Process 38, 573–586 (2018). https://doi.org/10.1007/s11090-018-9878-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11090-018-9878-2