Abstract

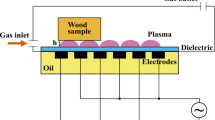

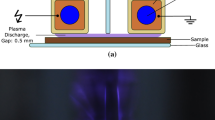

Radial cuts of Pedunculate oak (Quercus robur L.) heartwood was activated by Diffuse Coplanar Surface Barrier Discharge (DCSBD) plasma. The plasma treatment resulted in a considerable increase of free surface energy and in the substantial reduction of 50 μl water droplet uptake time. FTIR analysis confirmed the formation of additional polar functional groups on the wood surface due to the plasma treatment. This is consistent with the shift of wood surface pH level towards more acidic values. The energy efficiency of the DCSBD plasma treatment is better comparing to the known volume dielectric barrier discharge treatment method.

Similar content being viewed by others

References

Charles R, Frihart R (2004) In: Rowell RM (ed) Handbook of wood chemistry and wood composites, chap. 9. CRC Press, pp 215–278

Sernek M, Kamke FA, Glasser WG (2004) Holzforschung 58:22–31

Sakata I, Morita M et al (1993) J Appl Polym Sci 49:1251–1258

Podgorski L, Chevet B et al (2000) Int J Adhes Adhes 20(2):103–111

Rehn P, Wolkenhauer A et al (2003) Surf Coat Technol 174–175:515–518

Bente M, Avramidis G et al (2004) Holz Roh Werkst 62:157–163

Mertens M, Wolkenhauer A, Viol W (2006) Laser Phys Lett 3:380–384

Mahlberg R, Niemi HEM et al (1999) Langmuir 15:2985–2992

Blantocas GQ, Ramos HJ, Wada M (2006) Jpn J Appl Phys 45:8498–8501

Simor M, Rahel J et al (2002) Appl Phys Lett 81(15):2716–2718

Bursikova V, Stahel P et al (2004) Surface energy evaluation of plasma treated materials by contact angle measurement. MU, Brno, ISBN 80-210-3563-3

Liu CF, Xu F et al (2006) Carbohydr Res 341(16):2677–2687

Acknowledgment

The research was supported in part by the Slovak Research and Development Agency, Project No. APVT-20-033004 and the Czech Science Foundation, Grant No. 202/05/0777.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Odrášková, M., Ráhel’, J., Zahoranová, A. et al. Plasma Activation of Wood Surface by Diffuse Coplanar Surface Barrier Discharge. Plasma Chem Plasma Process 28, 203–211 (2008). https://doi.org/10.1007/s11090-007-9117-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11090-007-9117-8