Abstract

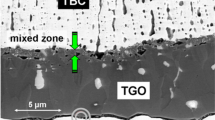

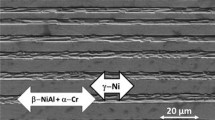

The lifetime at 1100 °C of furnace oxidation tested TBC samples having YSZ (ZrO2-7 wt.% Y2O3) and CeSZ (ZrO2-25 wt.% CeO2-2.5 wt.% Y2O3) topcoats on four Ni-base alloys including a no-bond coat NiCrAl alloy were studied. The thermally grown oxide (TGO) was investigated by energy-dispersive spectroscopy. The outer zone of the TGO revealed preferred enrichment of Zr and of rare earth elements Ce and Y in dependence of the stage of life. The oxygen potential gradients in the TGO have been rated; they are stronger for the YSZ TBC systems than for the CeSZ systems and cause a more intensive interaction of the outer zone alias mixed zone with the metal substrate than with the ceramic topcoat. When comparing the chemical composition data of the mixed zone as a function of the test period, the average lifetime as well as the particular composition of the two topcoats and the refractory element content of the substrates allowed conclusions to be drawn about the mechanisms which influence the lifetime.

Similar content being viewed by others

Notes

The expertise of T. Reetz, Reetz GmbH Berlin for optimal coating process management with CeSZ has been appreciatively employed.

References

N. P. Padture, M. Gell and E. H. Jordan, Science 269, (5566), 2002 (280–284).

J.-S. Wang, S.-L. Zhang, T. Liu, C.-J. Li, C.-X. Li and G.-J. Yang, Journal of the European Ceramic Society 17, 2017 (1577–1585).

U. Schulz, K. Fritscher, C. Leyens, M. Peters and W. A. Kaysser, Journal of Metals e-JOM 49, 1992 (1–10).

K. Fritscher, C.-J. Kröder and U. Schulz, Oxidation of Metals 86, 2016 (279–298).

K. Fritscher, W. Braue and U. Schulz, Metallurgical and Materials Transactions A 44, 2013 (2070–2082).

U. Kaden, Ph.D. thesis, RWTH Aachen, Werkstoffwissenschaftliche Schriftenreihe, 56 (2003) ISBN 3-86130-094-X.

K. Fritscher, unpublished results 2003.

J. A. Ruud, A. Bartz, M. P. Borom and C. A. Johnson, Journal of the American Ceramic Society 84, 2001 (1545–1552).

D. Zimmermann, M. Bobeth, M. Rühle and D. R. Clarke, Zeitschrift für Metallkunde 95, 2004 (84–90).

J. C. Yang, K. Nadarzinski, E. Schumann and M. Rühle, Scripta Metallurgica et Materialia 33, 1995 (1043–1048).

H. Schmalzried, Solid State Reactions, 2nd ed, (Verlag Chemie, Weinheim, 1981).

P. Saltykov, O. Fabrichnaya, J. Goczewski and F. Aldinger, Journal of Alloys and Compounds 381, 2004 (99–113).

D. Naumenko, V. Kochubey, L. Niewolak, A. Dymiati, L. Mayer, L. Singheiser and W. J. Quadakkers, Journal of Materials Science 43, 2008 (4550–4560).

U. Kolitsch, H. J. Seifert, T. Ludwig and F. Aldinger, Journal of Materials Research 14, 1999 (447–455).

J. Balmain and A. M. Huntz, Oxidation of Metals 46, 1996 (213–234).

G. J. Santoro, D. L. Deadmore, and C. E. Lowell, Oxidation of alloys in nickel–aluminum system with third-element additions of chromium, silicon, and titanium at 1100 °C, NASA TN D-6414, 1971.

M. W. Brumm and H. J. Grabke, Corrosion Science 33, 1992 (1677–1690).

B. A. Pint, B. A. Nagaraj, and M. A. Rosenzweig, Evaluation of TBC-Coated β-NiAl Substrates Without a Bond Coat, published in High Temperature Coatings II, eds.: N. Dahorte, J. M. Hampikian, and J. J. Stiglich, TMS, Warrendale, Pa. 1996, p. 163–74.

B. Pint, in Proceedings of the John Stringer Symposium on High Temperature Corrosion (5–8 Nov. 2001) pp. 9–19.

K. Bedu-Amissah, J. M. Rickman, H. M. Chan and M. P. Harmer, Journal of the American Ceramic Society 90, 2007 (1551–1555).

E. Wessel, V. Kochubey, D. Naumenko, L. Niewolak, L. Singheiser and W. J. Quadakkers, Scripta Materialia 51, 2004 (987–992).

W. J. Quadakkers and M. J. Bennett, Materials Science and Technology 10, 1994 (126–131).

A. Cuneyt Tas and M. Akine, Journal of the American Ceramic Society 77, 1994 (2961–2967).

C. G. Levi, E. Sommer, S. G. Terry, A. Catanoiu and M. Rühle, Journal of the American Ceramic Society 86, 2003 (676–685).

H. Lau, unpublished result 2013.

A. V. Sherchenko, E. V. Dudnik, A. K. Ruban, V. P. Redko and L. M. Lopato, Powder Metallurgy and Metal Ceramics 49, 2010 (42–49).

T. Shishido, Y. Zheng, A. Saito, H. Horiuchi, K. Kudou, S. Okada and T. Fukuda, Journal of Alloys and Compounds 260, 1997 (88–92).

M. Zinkevich, D. Djurovic and F. Aldinger, Solid State Ionics 177, 2006 (989–1001).

S. Humbert, A. Colin, I. Menceaux, F. Oudet, and P. Courtine, Simultaneous atmosphere and temperature cycling of three-way automotive exhaust catalysts, A. Frennet, J.-M. Bastin (Eds.) Catalysis and Automotive Pollution Control III, Studies in: Surface Science and Catalysis, Vol. 96 (1995) Elsevier Science.

M. M. Wada, T. Matsudaira and S. Kitaoka, Journal of the Ceramic Society of Japan 119, 2011 (832–839).

K. Fritscher, O. Schubert, C. Leyens and U. Schulz, Oxidation of Metals 78, 2012 (63–82).

Acknowledgements

Without the inspiring insightful discussions with Wolfgang Braue and his advantageous proofreading, this work would not have been created. The author also thanks Uwe Schulz for many years of fruitful cooperation.

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

Feasibility of EBPVD YSZ and CeSZ Topcoats

The favorable feasibility of YSZ topcoats via reactive electron beam evaporation, which has become a prominent industrially established technology, can be above all ascribed to particular material properties of the YSZ layer materials:

-

1.

Y2O3 and ZrO2 are part of a eutectic system that shows limited mixed crystal regions of appropriate tetragonal phase.

-

2.

Their ranges of stoichiometry are sufficiently stable at all typical temperatures and oxygen pressures of relevance.

-

3.

The boiling points and vapor pressures of both oxides are almost the same.

Therefore, a mixture of powders of both oxides can simply be compacted and be used as source material for zirconia coating deposition. In this way, YSZ TBCs are advantageously produced via single-crucible reactive electron beam evaporation.

However, the feasibility of CeSZ TBCs (consisting of ZrO2-25CeO2-2.5Y2O3 in wt.%) by reactive electron beam evaporation is problematic. CeO2 and Y2O3 form mutually wide mixed crystal regions but homogeneous phase regions depend on the temperature and the oxygen pressure. The vapor pressure of ceria differs by > four orders of magnitude from that of yttria and zirconia. Hence, the layers obtainable by single-crucible evaporation from a Ce-Y-Zr oxide source show a high scattering of the composition; as a consequence, a step-wise loss and degradation of those layers is observed in service. The step-wise loss is due to the fluctuations of the composition across the thickness of the TBC which cause alternating interlayers of weak and stronger phases, e.g., m-, c-and most appropriate t’-phase zirconia [2].

This problem has been circumvented at DLR by applying the “jumping beam method” using the simultaneous evaporation of two different source compositions put in two adjacent crucibles. One of the crucibles is charged with an appropriate ZrO2-Y2O3 ingot. The other crucible should be loaded with the “right” Ce containing ingot; in case of a ceria ingot, however, there arise fundamental questions about the feasibility of reproducible and homogeneous CeSZ TBCs: These relate to diverse equilibria required between various phases to be expected. These are two cerium oxide phases which can be liquid or solid or both (CeO2 melting point 2400 °C, Ce2O3 ≤ 2210 °C, and a low-melting eutectic at 795 °C of both ceria phases). They may evaporate and/or sublimate, depending on the temperature and the oxygen pressure in the coater. With respect to the Gibbs phase rule, the number of phases involved in this scenery is too high.

Reactive EBPVD processing of CeSZ coatings compliant with the Gibbs phase rule can well be achieved by means of dual-crucible jumping beam evaporation, e.g., in the following way: a ceramic ZrO2-Y2O3 ingot of appropriate composition is evaporated from the one crucible as just mentioned; simultaneously pure cerium—instead of a Ce2O3 source that cannot be provided as a storable ingotFootnote 1—is acting as the supplementary vapor source in the twin crucible. Meanwhile the oxygen partial pressure in the coater serves as a decisive “manipulated variable,” which has to be controlled during the reactive coating processing.

It should be noted that the lifetime results in this study are based on FCT experiments in calm air in a laboratory environment. If the use of CeSZ TBC systems under hot gas conditions for turbine blade applications should be considered, then the influence of the relatively high vapor pressure of ceria should be kept in mind.

Rights and permissions

About this article

Cite this article

Fritscher, K. Life and FCT Failure of Yttria- and Ceria-Stabilized EBPVD TBC Systems on Ni-Base Substrates. Oxid Met 91, 131–157 (2019). https://doi.org/10.1007/s11085-018-9870-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-018-9870-5