Abstract

This paper proposes a method for analyzing comprehensive theoretical digging performance of an excavator based on the convex polytope. The convex polytope is generated by using Newton–Euler’s equations to establish dynamic relationships between the digging capability of the bucket and the driving capability of hydraulic cylinders with the consideration of the excavator tipping and slipping constraints, and is used to identify the excavator’s output capability for digging forces and moments in the bucket force space. A set of indices for theoretically quantifying the digging capability, digging efficiency, as well as the matchability between the manipulator mechanism and the driving capability of hydraulic cylinders are proposed based on the polytope, and they are used to assess the digging trajectory characteristics and the dynamic digging performance of the entire excavator workspace. Two case studies for the excavator’s digging performance assessment and optimal digging trajectory generation are conducted to test and validate this method. The proposed method contributes to comprehensively and deeply understand the design principles of an excavator, and shows the promising application prospect for guiding the design and development of new excavators.

Similar content being viewed by others

References

Blouin, S., Hemami, A., Lipsett, M.: Review of resistive force models for earthmoving processes. J. Aerosp. Eng. 14, 102–111 (2001)

Wilkinson, A., De Gennaro, A.: Digging and pushing lunar regolith: classical soil mechanics and the forces needed for excavation and traction. J. Terramech. 44, 133–152 (2007)

Frimpong, S., Hu, Y., Inyang, H.: Dynamic Modeling of hydraulic shovel excavators for geomaterials. Int. J. Geomech. 8, 20–29 (2008)

SAE J1179: Hydraulic excavator and manipulator digging forces (2008)

ISO 6015: Earth-moving machinery—hydraulic excavators and manipulator loaders—methods of determining tool forces (2006)

Flores, F.G., Kecskeméthy, A., Pöttker, A.: Workspace analysis and maximal force calculation of a face-shovel excavator using kinematical transformers. In: 12th IFToMM World Congress, Besancon, pp. 1–6 (2007)

Chen, J., Qing, F., Pang, X.: Mechanism optimal design of backhoe hydraulic excavator working device based on digging paths. J. Mech. Sci. Technol. 28(1), 213–222 (2014)

Kim, J.W., Jung, S., Kim, J., Kim, J., Seo, T.W.: Optimal design of the front linkage of a hydraulic excavator for multi-objective function. J. Mech. Sci. Technol. 28(8), 3103–3111 (2014)

Hall, A.S., McAree, P.R.: A study of the interaction between operator style and machine capability for a hydraulic mining excavator. J. Mech. Eng. Sci. 219(5), 477–489 (2005)

Finotello, R., Grasso, T., Rossi, G., Tembile, A.: Computation of kinetostatic performances of robot manipulators with polytopes. In: Proceedings of the 1998 IEEE International Conference on Robotics and Automation, Leuven, Belgium, vol. 4, pp. 3241–3246 (1998)

Wei, B., Gao, F.: Output force capacity polytope approach for actuator forces selection of three degrees of freedom excavating manipulator. Proc. Inst. Mech. Eng., Part C, J. Mech. Eng. Sci. 228(11), 2007–2017 (2014)

Wei, B., Gao, F.: A method to calculate working capacity space of multi-DOF manipulator and the application in excavating mechanism. Front. Mech. Eng. 7(2), 109–119 (2012)

Janosevic, D., Mitrev, R., Andjelkovic, B., Petrov, P.: Quantitative measures for assessment of the hydraulic excavator digging efficiency. J. Zhejiang Univ. Sci. A 13(12), 926–942 (2012)

Chen, J., Zou, Z., Pang, X.: Digging performance characterization for hydraulic excavator considering uncertainty during digging operation. Proc. Inst. Mech. Eng., Part C, J. Mech. Eng. Sci. 232(5), 857–871 (2018)

Zou, Z., Chen, J., Pang, X.: Optimum dimensional synthesis for the working mechanism of a hydraulic excavator to improve the digging performance. Proc. Inst. Mech. Eng., Proc., Part K, J. Multi-Body Dyn. 232(3), 357–370 (2018)

Worley, M.D., La Saponara, V.: A simplified dynamic model for front-end loader design. Proc. Inst. Mech. Eng., Part C, J. Mech. Eng. Sci. 222(11), 2231–2249 (2008)

Crane, C., Duffy, J.: A dynamic analysis of a spatial manipulator to determine payload weight. J. Robot. Syst. 20(7), 355–371 (2003)

Šalinić, S., Bošković, G., Nikolić, M.: Dynamic modelling of hydraulic excavator motion using Kane’s equations. Autom. Constr. 44, 56–62 (2014)

Koivo, A.J., Thoma, M., Kocaoglan, E., Andrade-Cetto, J.: Modeling and control of excavator dynamics during digging operation. J. Aerosp. Eng. 9, 10–18 (1996)

Shabana, A.A.: Dynamics of Multibody Systems, 3rd edn. Cambridge University Press, New York (2005)

Chan, T.F., Dubey, R.V.: A weighted least-norm solution based scheme for avoiding joint limits for redundant joint manipulators. IEEE Trans. Robot. Autom. 11(2), 286–292 (1995)

Vahrenkamp, N., Asfour, T., Metta, G., Sandini, G., Dillmann, R.: Manipulability analysis. In: 2012 12th IEEE-RAS International Conference on Humanoid Robots (Humanoids), Osaka, Japan, pp. 568–573 (2012)

Yue, S., Tso, S.K., Xu, W.L.: Maximum-dynamic-payload trajectory for flexible robot manipulators with kinematic redundancy. Mech. Mach. Theory 36, 785–800 (2001)

Acknowledgement

This work is supported by the National Natural Science Foundation of China (grant no. 51475056). The support is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix A: Forward kinematics of the driving mechanisms of the manipulator

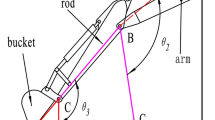

Figure 10 shows the schematics of the driving mechanisms of the manipulator. Considering the boom cylinder driving loop \(\Delta\mathit{AFC}\), one has

where \(\angle X_{1}\mathit{AF}\) is the angle that \(\overline{\mathit{AF}}\) makes with the \(x_{1}\)-axis. By the time derivative of Eq. (A.1), the joint velocity \(\dot{\theta }_{2}\) is obtained:

By further calculating the second derivative of joint angle \(\theta _{2}\) versus time, following equation can be derived:

After substituting the detailed representations of \(\alpha _{1}\) and \(\dot{\theta }_{2}\) into Eq. (A.3), joint acceleration \(\ddot{\theta }_{2}\) can be explicitly written as the function of \(r_{2}\), \(\dot{r}_{2}\) and \(\ddot{r}_{2}\). Equations (A.1)–(A.3) establish the forward kinematics of the boom cylinder driving mechanism.

For the stick cylinder loop \(\Delta\mathit{DBH}\), joint angle \(\theta _{3}\) is given by

The joint velocity \(\dot{\theta }_{3}\) is then given by differentiating the above expression, and it is written as

Further the time derivative of \(\dot{\theta }_{3}\) is given by

Thus, giving the length of stick cylinder and the ram velocity and acceleration, forward motion relations of stick cylinder driving loop can be determined by Eqs. (A.4)–(A.6).

Bucket cylinder driving mechanism includes loop \(\Delta \mathit{ENK}\) and a four-bar linkage \(\Box \mathit{KNGL}\). Based on the geometry of the mechanism, it can be obtained

where

According to the derivation rules of the function of functions, one has

where

Taking the derivative of Eq. (A.8) with respect to time, one obtains

Then the various variants in Eq. (A.9) are given by

Joint angle, angular velocity and acceleration of the bucket can be described by substituting above expressions of various variants into Eqs. (A.7)–(A.9), respectively.

Appendix B: Inverse kinematics of the driving mechanisms of the manipulator

Inverse kinematics equations of the driving mechanisms of the manipulator can be obtained by calculating the inverse functions of Eqs. (A.1)–(A.9). For the boom cylinder driving mechanism, the cylinder length, the ram velocity and acceleration are described in the following equations:

Thus, Eqs. (B.1)–(B.3) establish the inverse kinematics of the boom cylinder driving mechanism.

Similarly, the corresponding inverse kinematics equations of the stick cylinder driving mechanism are written

Equations (B.4)–(B.6) can specify \(r_{3}\), \(\dot{r}_{3}\) and \(\ddot{r}_{3}\), once the joint angle, angular velocity and acceleration are given.

Finally, for the bucket cylinder driving mechanism, the bucket cylinder length is determined by

where \(\alpha _{5}\) is the cosine of \(\angle \mathit{ENK}\), and \(\angle \mathit{ENK}\) is given by

Further, the ram velocity of the bucket cylinder can be calculated by

where

The ram acceleration of the bucket cylinder has the following expression:

where

Therefore, Eqs. (B.7)–(B.9) and the various variants included in them specify the inverse kinematics of the bucket cylinder driving mechanism.

Rights and permissions

About this article

Cite this article

Zou, Z., Pang, X. & Chen, J. Comprehensive theoretical digging performance analysis for hydraulic excavator using convex polytope method. Multibody Syst Dyn 47, 137–164 (2019). https://doi.org/10.1007/s11044-019-09686-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11044-019-09686-0