Abstract

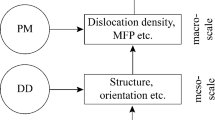

Martensitic steels are widely used as a structural material in critical components of fossil fuel and nuclear power plants, such as boilers, pipes, and fittings. Martensitic steels are known to have a hierarchical microstructure that follows the Kurdjumov–Sachs (K–S) orientation relationship, where a prior austenite grain is composed of packets separated by high angle grain boundaries or packet boundaries, which are, in turn, divided into blocks or variants segregated by high angle grain boundaries called block boundaries. Blocks themselves are an agglomeration of laths divided by low angle grain boundaries named lath boundaries which have precipitates scattered on them. This work seeks to examine, using a couple dislocation dynamics—continuum mechanics approach called multiscale dislocation dynamics plasticity (MDDP), the interactions between dislocations and packet, block, lath boundaries, and precipitates under uniaxial tension loading and their effect on the mechanical response of the material. The simulations are conducted at a strain rate of 105 s−1 at room temperature. The main crystallographic features that arise during the deformation process were extracted and analyzed in terms of their contribution to the mechanical response of the material. The orientation relationship governing the microstructure of martensitic steels, namely, the K–S orientation relationship, was incorporated in MDDP in an effort to accurately capture the deformation behavior of the material in question. The strength of lath martensitic steel was analyzed as a function of the lath width, block size, and packet size to determine the appropriate effective grain size.

Similar content being viewed by others

Data and code availability

All data can be made available to interest readers upon request.

References

An W, Zeng Z, Xiong Q, Huang M, Li Z (2023) Crystal plasticity study of stress overshoot during high-strain rate deformation. Meccanica 58:193–215. https://doi.org/10.1007/s11012-022-01632-3

Azeem MM, Wang Q, Li Z, Zhang Y (2020) Dislocation-oxide interaction in Y2O3 embedded Fe: a molecular dynamics simulation study. Nucl Eng Technol 52:337–343. https://doi.org/10.1016/J.NET.2019.07.011

Bailey JE, Hirsch PB (1960) The dislocation distribution, flow stress, and stored energy in cold-worked polycrystalline silver. Philos Mag A J Theor Exp Appl Phys 5:485–497. https://doi.org/10.1080/14786436008238300

Bakó B, Weygand D, Samaras M, Chen J, Pouchon MA, Gumbsch P, Hoffelner W (2007) Discrete dislocation dynamics simulations of dislocation interactions with Y2O3 particles in PM2000 single crystals. Philos Mag 87:3645–3656. https://doi.org/10.1080/14786430701383085

Barrett RA, O’Donoghue PE, Leen SB (2014) A dislocation-based model for high temperature cyclic viscoplasticity of 9–12Cr steels. Comput Mater Sci 92:286–297. https://doi.org/10.1016/j.commatsci.2014.05.034

Berecz T, Jenei P, Csóré A, Lábár J, Gubicza J, Szabó PJ (2016) Determination of dislocation density by electron backscatter diffraction and X-ray line profile analysis in ferrous lath martensite. Mater Charact 113:117–124. https://doi.org/10.1016/j.matchar.2015.11.014

Deschênes PA, Wheeler R, Paquet D, Lanteigne J, Serventi AM, Tôn-Thât L, Champliaud H (2022) Micromechanical properties of low-carbon martensitic stainless steel by microtensile experiments. Mater Sci Eng A 858:144030. https://doi.org/10.1016/J.MSEA.2022.144030

Du C, Hoefnagels JPM, Vaes R, Geers MGD (2016) Block and sub-block boundary strengthening in lath martensite. Scr Mater 116:117–121. https://doi.org/10.1016/j.scriptamat.2016.01.043

El Ters P, Shehadeh MA (2023) On the investigation of size effect in bcc α-iron under high strain rate and high temperature: multiscale dislocations dynamics simulations. Eur J Mech-A/Solids 97:104779. https://doi.org/10.1016/j.euromechsol.2022.104779

El Ters P, Shehadeh MA (2020) On the strain rate sensitivity of size-dependent plasticity in BCC iron at elevated temperatures: discrete dislocation dynamics investigation. Mech Mater 148:103494. https://doi.org/10.1016/j.mechmat.2020.103494

El Ters P, Shehadeh MA (2019) Modeling the temperature and high strain rate sensitivity in BCC iron: atomistically informed multiscale dislocation dynamics simulations. Int J Plast 112:257–277. https://doi.org/10.1016/j.ijplas.2018.09.002

Gao Y, Zhuang Z, You X (2011) A hierarchical dislocation-grain boundary interaction model based on 3D discrete dislocation dynamics and molecular dynamics. Sci China Phys Mech Astron 54:625–632. https://doi.org/10.1007/s11433-011-4298-9

Ghaffarian H, Na YE, Jang D (2022) Interfacial plasticity mediated by lath boundaries in reduced-activation ferritic/martensitic steels. J Nucl Mater 559:153439. https://doi.org/10.1016/j.jnucmat.2021.153439

Ghassemi-Armaki H, Maaß R, Bhat SP, Sriram S, Greer JR, Kumar KS (2014) Deformation response of ferrite and martensite in a dual-phase steel. Acta Mater 62:197–211. https://doi.org/10.1016/j.actamat.2013.10.001

Golden BJ, Tiernan P, Scully S, (2016) PVP2015–45487 pp 1–9

Gurrutxaga-Lerma B (2016) The role of the mobility law of dislocations in the plastic response of shock loaded pure metals. Model Simul Mater Sci Eng 24:065006. https://doi.org/10.1088/0965-0393/24/6/065006

Gurrutxaga-Lerma B, Shehadeh MA, Balint DS, Dini D, Chen L, Eakins DE (2017) The effect of temperature on the elastic precursor decay in shock loaded FCC aluminium and BCC iron. Int J Plast 96:135–155. https://doi.org/10.1016/j.ijplas.2017.05.001

HajyAkbary F, Sietsma J, Böttger AJ, Santofimia MJ (2015) An improved X-ray diffraction analysis method to characterize dislocation density in lath martensitic structures. Mater Sci Eng A 639:208–218. https://doi.org/10.1016/j.msea.2015.05.003

Hatem TM, Zikry MA (2009) Dislocation density crystalline plasticity modeling of lath martensitic microstructures in steel alloys. Philos Mag 89:3087–3109. https://doi.org/10.1080/14786430903185999

Hutchinson B, Hagström J, Karlsson O, Lindell D, Tornberg M, Lindberg F, Thuvander M (2011) Microstructures and hardness of as-quenched martensites (0.1–0.5%C). Acta Mater 59:5845–5858. https://doi.org/10.1016/J.ACTAMAT.2011.05.061

Jiang M, Monnet G, Devincre B (2021) On the origin of the Hall–Petch law: a 3D-dislocation dynamics simulation investigation. Acta Mater 209:116783. https://doi.org/10.1016/j.actamat.2021.116783

Khan SMA, Zbib HM, Hughes DA (2004) Modeling planar dislocation boundaries using multi-scale dislocation dynamics plasticity. Int J Plast 20:1059–1092. https://doi.org/10.1016/j.ijplas.2003.10.004

Kitahara H, Ueji R, Tsuji N, Minamino Y (2006) Crystallographic features of lath martensite in low-carbon steel. Acta Mater 54:1279–1288. https://doi.org/10.1016/j.actamat.2005.11.001

Kitahara H, Ueji R, Ueda M, Tsuji N, Minamino Y (2005) Crystallographic analysis of plate martensite in Fe-28.5 at% Ni by FE-SEM/EBSD. Mater Charact 54:378–386. https://doi.org/10.1016/j.matchar.2004.12.015

Klueh RL (2005) Elevated temperature ferritic and martensitic steels and their application to future nuclear reactors. Int Mater Rev 50:287–310. https://doi.org/10.1179/174328005X41140

Kondo S, Mitsuma T, Shibata N, Ikuhara Y (2016) Direct observation of individual dislocation interaction processes with grain boundaries. Sci Adv 2:1–8. https://doi.org/10.1126/sciadv.1501926

Kurdjumow G, Sachs G (1930) Der Mechanismus der Stahlhärtung Naturwissenschaften 18:534. https://doi.org/10.1007/BF01513427

Li DF, Golden BJ, O’Dowd NP (2014) Multiscale modelling of mechanical response in a martensitic steel: a micromechanical and length-scale-dependent framework for precipitate hardening. Acta Mater 80:445–456. https://doi.org/10.1016/j.actamat.2014.08.012

Li J, Liu B, Fang QH, Huang ZW, Liu YW (2017) Atomic-scale strengthening mechanism of dislocation-obstacle interaction in silicon carbide particle-reinforced copper matrix nanocomposites. Ceram Int 43:3839–3846. https://doi.org/10.1016/J.CERAMINT.2016.12.040

Li S, Zhu G, Kang Y (2016) Effect of substructure on mechanical properties and fracture behavior of lath martensite in 0.1C-1.1Si-1.7Mn steel. J Alloys Compd 675:104–115. https://doi.org/10.1016/j.jallcom.2016.03.100

Li Z, Hou C, Huang M, Ouyang C (2009) Strengthening mechanism in micro-polycrystals with penetrable grain boundaries by discrete dislocation dynamics simulation and Hall–Petch effect. Comput Mater Sci 46:1124–1134. https://doi.org/10.1016/j.commatsci.2009.05.021

Luo H, Wang X, Liu Z, Yang Z (2020) Influence of refined hierarchical martensitic microstructures on yield strength and impact toughness of ultra-high strength stainless steel. J Mater Sci Technol 51:130–136. https://doi.org/10.1016/j.jmst.2020.04.001

Maki T, Tsuzaki K, Tamura I (1980) The Morphology of Microstructure Composed of Lath Martensites in Steels. Trans Iron Steel Inst Japan 20:207–214. https://doi.org/10.2355/isijinternational1966.20.207

Meade ED, Sun F, Tiernan P, O’Dowd NP (2018) Experimental study and multiscale modelling of the high temperature deformation of tempered martensite under multiaxial loading. Mater Sci Eng A 737:383–392. https://doi.org/10.1016/j.msea.2018.09.040

Michiuchi M, Nambu S, Ishimoto Y, Inoue J, Koseki T (2009) Relationship between local deformation behavior and crystallographic features of as-quenched lath martensite during uniaxial tensile deformation. Acta Mater 57:5283–5291. https://doi.org/10.1016/J.ACTAMAT.2009.06.021

Mine Y, Hirashita K, Takashima H, Matsuda M, Takashima K (2013) Micro-tension behaviour of lath martensite structures of carbon steel. Mater Sci Eng A 560:535–544. https://doi.org/10.1016/j.msea.2012.09.099

Morito S, Tanaka H, Konishi R, Furuhara T, Maki T (2003) The morphology and crystallography of lath martensite in Fe–C alloys. Acta Mater 51:1789–1799. https://doi.org/10.1016/S1359-6454(02)00577-3

Morito S, Yoshida H, Maki T, Huang X (2006) Effect of block size on the strength of lath martensite in low carbon steels. Mater Sci Eng A 438–440:237–240. https://doi.org/10.1016/j.msea.2005.12.048

Na H, Nambu S, Ojima M, Inoue J, Koseki T (2014) Crystallographic and microstructural studies of lath martensitic steel during tensile deformation. Metall. Mater Trans A Phys Metall Mater Sci 45:5029–5043. https://doi.org/10.1007/s11661-014-2461-4

Ohashi T, Kawamukai M, Zbib H (2007) A multiscale approach for modeling scale-dependent yield stress in polycrystalline metals. Int J Plast 23:897–914. https://doi.org/10.1016/J.IJPLAS.2006.10.002

Pešička J, Kužel R, Dronhofer A, Eggeler G (2003) The evolution of dislocation density during heat treatment and creep of tempered martensite ferritic steels. Acta Mater 51:4847–4862. https://doi.org/10.1016/S1359-6454(03)00324-0

Shamsujjoha M (2020) Evolution of microstructures, dislocation density and arrangement during deformation of low carbon lath martensitic steels. Mater Sci Eng A 776:139039. https://doi.org/10.1016/J.MSEA.2020.139039

Shehadeh* MA, Zbib HM, Diaz De La Rubia T (2005) Modelling the dynamic deformation and patterning in fcc single crystals at high strain rates: dislocation dynamics plasticity analysis, Philos Mag, 85, 1667–1685. https://doi.org/10.1080/14786430500036470

Shehadeh MA (2012) Multiscale dislocation dynamics simulations of shock-induced plasticity in small volumes. Philos Mag 92:1173–1197. https://doi.org/10.1080/14786435.2011.637988

Shehadeh MA, El Ters P, Armstrong RW, Arnold W (2021) Dislocation mechanics of extremely high rate deformations in iron and tantalum. J Eng Mater Technol. https://doi.org/10.1115/1.4052104

Shehadeh MA, Zbib HM, Diaz de la Rubia T (2005) Multiscale dislocation dynamics simulations of shock compression in copper single crystal. Int J Plast 21:2369–2390. https://doi.org/10.1016/j.ijplas.2004.12.004

Shibata A, Nagoshi T, Sone M, Morito S, Higo Y (2010) Evaluation of the block boundary and sub-block boundary strengths of ferrous lath martensite using a micro-bending test. Mater Sci Eng A 527:7538–7544. https://doi.org/10.1016/j.msea.2010.08.026

Shin CS, Fivel MC, Verdier M, Oh KH (2003) Dislocation–impenetrable precipitate interaction: a three-dimensional discrete dislocation dynamics analysis. Philos Mag 83:3691–3704. https://doi.org/10.1080/14786430310001599379

Singh J, Nath SK (2020) Effects of cyclic heat treatment on microstructure and mechanical properties of 13%Cr–4%Ni Martensitic stainless steel. J Mater Eng Perform 29:2478–2490. https://doi.org/10.1007/s11665-020-04787-w

Sridharan N, Gussev MN, Field KG (2019) Performance of a ferritic/martensitic steel for nuclear reactor applications fabricated using additive manufacturing. J Nucl Mater 521:45–55. https://doi.org/10.1016/j.jnucmat.2019.04.020

Sun F, Meade ED, O’Dowd NP (2019) Strain gradient crystal plasticity modelling of size effects in a hierarchical martensitic steel using the Voronoi tessellation method. Int J Plast 119:215–229. https://doi.org/10.1016/j.ijplas.2019.03.009

Sun F, Meade ED, O’Dowd NP (2018) Microscale modelling of the deformation of a martensitic steel using the Voronoi tessellation method. J Mech Phys Solids 113:35–55. https://doi.org/10.1016/j.jmps.2018.01.009

Vaid A, Guénolé J, Prakash A, Korte-Kerzel S, Bitzek E (2019) Atomistic simulations of basal dislocations in Mg interacting with Mg17Al12 precipitates. Materialia 7:100355. https://doi.org/10.1016/J.MTLA.2019.100355

Yamashita T, Onzawa T (1980) Martensites in austenitic stainless steel welded explosively. J Electron Microsc (Tokyo) 29:32–37. https://doi.org/10.1093/oxfordjournals.jmicro.a050205

Zbib HM, Diaz de la Rubia T (2002) A multiscale model of plasticity. Int J Plast 18:1133–1163. https://doi.org/10.1016/S0749-6419(01)00044-4

Zhang X, Lu S, Zhang B, Tian X, Kan Q, Kang G (2021) Dislocation–grain boundary interaction-based discrete dislocation dynamics modeling and its application to bicrystals with different misorientations. Acta Mater 202:88–98. https://doi.org/10.1016/j.actamat.2020.10.052

Zhao J, Jiang Z (2018) Thermomechanical processing of advanced high strength steels. Prog Mater Sci 94:174–242. https://doi.org/10.1016/J.PMATSCI.2018.01.006

Zhou X, Liu C, Yu L, Liu Y, Li H (2015) Phase transformation behavior and microstructural control of high-Cr martensitic/ferritic heat-resistant steels for power and nuclear plants: a review. J Mater Sci Technol 31:235–242. https://doi.org/10.1016/j.jmst.2014.12.001

Acknowledgements

Support from the Office or Research and Innovation at Alfaisal University and the Research Board at the American University of Beirut is greatly acknowledged. The authors would like to acknowledge the helpful discussion with Dr. Noel O’Dowd (University of Limerick).

Author information

Authors and Affiliations

Contributions

OAAM and MS have contributed equally to this work.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

Not applicable.

Additional information

Handling Editor: M. Grant Norton.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Abou Ali Modad, O., Shehadeh, M.A. Modeling dislocation interactions with grain boundaries in lath martensitic steels. J Mater Sci 59, 4829–4851 (2024). https://doi.org/10.1007/s10853-023-09084-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-023-09084-0