Abstract

The adsorption behaviour of copper(II) ions in acidic streams using different polymeric adsorbents (Lewatit MonoPlus TP 220, Lewatit MonoPlus SR 7, Lewatit AF 5, Purolite A 830, Purolite S 984, Purolite A 400 TL, Dowex PSR 2, Dowex PSR 3) was studied, and the results were compared. The adsorbents were characterized by determination of the point of zero charge and the Fourier transform infrared spectroscopy method. The kinetic (effects of phases contact time) and equilibrium (effect of initial Cu(II) concentration) studies were also carried out. The effects of hydrochloric and nitric(V) acids on adsorption behaviour of Cu(II) were examined. The FTIR spectra after the Cu(II) adsorption were also obtained, and the mechanism of Cu(II) sorption was proposed. Of eight adsorbents, the best one was chosen and applied in further studies (column adsorption, column and batch desorption, reuse of adsorbent in cycles of sorption–desorption, selectivity in two-component solutions Pd(II)–Cu(II)). Cu(II) sorption efficiency was the highest using Lewatit MonoPlus TP 220. Its sorption is well described by the pseudo-second-order kinetic equation and the Langmuir isotherm model. Ion exchangers show also high affinity for noble metals, especially for gold(III): Au(III) > Pd(II) > Pt(IV) (the column test) from single- and two- or three-component solutions (the batch test).

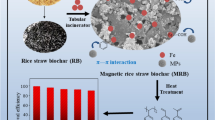

Graphic abstract

Similar content being viewed by others

Introduction

Copper is metal of unique and beneficial properties (mechanical, physical and chemical ones), and it is highly valued in the world today [1]. Copper possesses excellent thermal and electrical conductivity, is ductile, in 100% recyclable and can be used many times without decreasing its quality. Moreover, copper can be combined with other metals forms alloys of much better properties than individual metals (about 570 of different copper alloys are known). Copper has a unique hue makes this metal also so attractive [1,2,3].

Copper found wide application in numerous branches of industry which is difficult to enumerate, among others such as: air-conditioning and refrigeration market, fish cages production, architecture, building construction market, art, coins, design and manufacture, electrical system, energy and renewables, agriculture and farming, healthcare, interior design, pipe systems, transportation, etc. [2,3,4,5,6]. 15% of copper is consumed in industrial machinery, 5% in alloy production, 20% in plumbing and roofing and 60% in electrical wires production.

Due to numerous uses of copper, various wastewaters containing this metal are produced during the metallurgical treatment of copper concentrates, during copper refining, electrolyte regeneration steps and from sulphuric acid, zinc and noble metal plants, etc. Such wastewaters are characterized by high concentration of acids and they usually contain not only copper but also other heavy metal ions such as nickel, cobalt, zinc, lead, iron, etc. [7, 8]. Copper content in such wastewaters is usually lower than 1000 mg/L, and according to the World Health Organization (WHO) the maximum acceptable concentration of Cu(II) in water is equal to 1.5 mg/L [9]; therefore, due to the high outflows of such wastewaters many valuable as well as toxic metals are potentially lost and discharged. One sustainable option to decrease potential environmental pollution as well as to reuse heavy metal ions is recovery of valuable metals from polymetallic acidic streams. Recycling of copper saves resources and also helps save energy. Many different methods have been studied for heavy metal ions removal from industrial waters and wastewaters [10,11,12,13,14,15]. These treatment methods can be divided into three categories such as chemical, physical as well as biological. Physicochemical treatment methods (Fig. S1) such as chemical precipitation (hydroxide, sulphide precipitation, combined methods, chelating precipitation), ion exchange, adsorption, bioadsorption, coagulation, flocculation, flotation, membrane filtration [ultrafiltration (UF), micellar-enhanced ultrafiltration (MEUF) and polymer enhanced ultrafiltration (PEUF), reverse osmosis (RO), nanofiltration (NF), electrodialysis (ED), polymer inclusion membranes (PIMs)] and electrochemical treatment are the most suitable for the removal of heavy metal ions as well as copper(II) ions from industrial wastewaters [10,11,12,13,14,15,16]. As can be seen from Table S1 all physicochemical methods possess advantages and limitations. Chemical precipitation is applied for heavy metal ions removal from wastewaters of their high concentration due to its simplicity and inexpensive capital cost, but this method is ineffective when heavy metal ions concentration is low. Moreover, this method is not economical and produced large amount of sludge. Ion exchange method has been widely applied for the removal of heavy metal ions, but ion exchange resins need regeneration after exhausting by chemical reagents and secondary pollution is produced. Method is not recommended for large scale due to its high capital cost when a large amount of wastewaters containing heavy metal ions of low concentration needs to be treated. On the other hand, coagulation and flocculation produce sludge of good sludge settling and dewatering, but due to high consumption of chemicals and production of sludge of big volume this method did not play the most significant role in heavy metal ions removal. The main advantage of membrane filtration is high efficiency for heavy metal ions removal, but its high cost, complexity of process, fouling of membrane and low permeate flux result in its limited application. High selectivity and metals removal efficiency, low operating cost, generation of more concentrated sludge, high overflow rates are the main advantages of flotation, but this method is characterized by high initial capital and maintenance costs. Electrochemical treatment method possesses drawbacks such as capital cost, high energy consumption, and despite less production of sludge compared to filtration and lower consumption of chemicals, this technology has restricted application for heavy metal ions removal [10,11,12,13,14,15,16]. Adsorption is a technique of well-established position for copper and other heavy metal ions removal [10,11,12, 14]. It is one of the most economical methods and is characterized by many advantages compared to the other treatment techniques. Advantages of this method involve low investment cost, simplicity and flexibility in design and operation, produce high-quality treated effluent, wide range of commercially available adsorbents of good mechanical and kinetics properties, high efficiency and selectivity towards heavy metal ions of different concentrations. The efficiency of this method depends on the type of adsorbents, and due to the fact that adsorption could be reversible, the regeneration step is possible when the adsorbent is exhausted. On the other hand, the regeneration step could result in secondary pollutant production, but quantitative desorption ensures reuse of adsorbent results in cost reduction [10, 12].

Copper is an element essential for proper organisms growth and development. It takes part in oxidative-reduction processes, where it occurs as a coenzyme, regulates metabolism and transports oxygen for cells as well as stimulates the amount and activity of haemoglobin, etc. On the other hand, excess or deficiency of copper causes disorders manifested in various disease syndromes e.g. anaemia, growth and fertility restrictions, nervous system disorders, and cardiovascular diseases. Excess of this element may cause liver and kidney damage and even death. The most toxic is copper sulphate(VI) as well as copper oxides result in chronic poisoning. Copper compounds act on intact skin, causing inflammation, itching, ulceration of the mucosa, conjunctivitis, nasal septum and pharynx, etc. Additionally, negative effects of copper on humans and plants are shown in Fig. 1. Higher concentration of copper (> 100 µg/dm3) inhibits the growth of green plants, whereas concentrations in the range from 80 to 800 μg/dm3 is very dangerous for fish. Self-cleaning processes is inhibited at concentrations of copper equal to 10 μg/dm3, and the bitter taste of water appears at copper concentration above 1000 μg/dm3. Toxicity of cooper is higher in soft water of higher pH [4, 17,18,19,20].

Based on the toxic, ecological and economical aspects, the aim of this paper was the study of copper(II) removal from acidic streams by different types of ion exchangers. Ion exchange method and adsorption overcome many drawbacks of other methods applied for polymetallic wastewaters treatment and are able to meet strict discharge requirements. In the present study, copper(II) removal from acidic streams by eight different types of ion exchangers was investigated. The effects of phases contact time and acids concentration on copper(II) efficiency removal were studied. Moreover, both pHPZC and isotherms were obtained for the ion exchangers under discussion. For the most efficient sorbent for copper(II) removal, additional studies were carried out. The kinetic and equilibrium studies were modelled using the pseudo-first (PFO), pseudo-second (PSO) kinetic order as well as the Langmuir and Freundlich models. Additionally, possibility of Lewatit MonoPlus TP 220 regeneration and reuse (3 cycles of sorption–desorption) were analysed using different eluting agents and the static method. For full characteristics of copper(II) removal by Lewatit MonoPlus TP 220, both the fixed bed adsorption and desorption as well as the ion exchange resin reuse by the column method were presented and compared with noble metals such as palladium(II), platinum(IV) and gold(III) removal efficiency. The attenuated total reflectance Fourier transform infrared spectroscopy (ATR-FTIR) spectra for Lewatit MonoPlus TP220 after copper(II) sorption and binary containing palladium(II) and copper(II) and tertiary components solutions containing noble metal ions were also discussed.

Experimental

Sorbate and ion exchange resins characteristics

Copper(II) working solutions of 100 mg/L concentration were prepared from the stock solutions (10000 mg/L, CuCl2·2H2O in 0.1 M HCl) by dilution with HCl or HCl–HNO3 addition to obtain different acid concentrations. The solutions possess the following composition: 0.1–6.0 M HCl–100 mg Cu(II)/L; 0.1–0.9 M HCl–0.9–0.1 M HNO3–100 mg Cu(II)/L. Other multicomponent solutions were prepared in a similar way using PdCl2, H2PtCl6, HAuCl4 compounds. Salts, acids, bases of analytical grade used in the studies were purchased from POCH S.A. Gliwice.

The composition (HCl, HCl–HNO3) and concentration of heavy metal ions were selected in such a way that they reflect real solutions derived from hydrometallurgical leaching of waste materials containing precious metals and basic ones, e.g. copper ions. Noble and base metals from waste materials such as anodic slimes or spent automobile catalyst can be separated by pyrometallurgical or hydrometallurgical as well as mixed processes. Waste materials (catalyst) are treated (leaching process) using a suitable agent or a mixture of agents. These metals can be brought to the solutions using, e.g. mixture of nitric(V) acid, sulphuric(VI) acid or hydrochloric acid (HCl, HNO3 and H2SO4), aqua regia (HCl–HNO3), mixture of hydrochloric acid and chlorine (HCl–Cl2) or mixture of hydrochloric acid and sodium chloride (HCl–NaCl), etc. [21,22,23]. Hydrometallurgical methods are also employed to enrich noble metals and to recover base metals from anodic slimes. Most of the base metals, e.g. copper, is treated by acids like sulphuric(VI) acid, 4 M nitric(V) acid, 4 M hydrochloric acid, etc. [24, 25].

The ion exchanger under discussion was selected from commercially available resins supplied by resin manufacturing companies. After their pre-preparation according to the standard procedure [26], they were applied for copper(II) removal from acidic solutions. These functional resins belong to different types such as chelating, anionic ion exchangers or sorbent without functional groups. They are polyacrylic, styrene–divinylbenzene or carbonaceous functional resins with micro- or macroporous structure. The more detailed characteristics of functional resins (based on their product data sheets) are presented in Fig. 2. Ion exchangers were selected on the basis of their availability, price, physicochemical properties, type of functional groups as well as due to the type and composition of the solutions tested. Metals occur in solutions under discussion usually in the form of metal-chlorocomplexes or mixed complexes; therefore, the application of weakly and strongly basic and chelating resins is a promising way to recovered them. In addition, new generation of ion exchangers were applied here whose sorption properties towards copper and precious metal ions have not been discussed in the literature.

Sorption studies by the batch test

The batch test was applied in copper(II) removal from acidic solutions on the functional resins such as Lewatit MonoPlus TP 220, Lewatit MonoPlus SR 7, Lewatit AF 5, Purolite A 830, Purolite S 984, Purolite A 400 TL, Dowex PSR 2, Dowex PSR 3 and amount of copper(II) sorbed at time t (qt, mg/g), sorption capacities (qe, mg/g) and percentage removal efficiency (%R) were determined. Not only efficiency of copper(II) ions removal but also rate of its removal is a very important factor; therefore, the effects of phases contact time on copper(II) removal were also investigated. The procedure of the batch test is as follows: (1) sorbate and sorbent phases preparation, (2) both phases contacted in the 100 mL Erlenmeyer flask at room temperature by shaking 0.5 (± 0.0005) g of functional resin with 0.05 L of 100 mg Cu(II)/L solutions (shaking parameters: amplitude 8, agitation speed 180 stock/min, shaking time was in the range 1–240 min, the mechanical shaker Elphin +, type 357, Lubawa, Poland), (3) phases separation by filtration (filter paper), (4) determination of copper concentration in solution after the sorption process by the atomic absorption spectrometry method (AAS) (spectrometer Varian AA240FS, Australia) using copper standard solutions and calibration curve, (5) amount of copper(II) sorbed at time t (qt, mg/g) and sorption capacity, amount of copper(II) ions sorbed at equilibrium time (qe, mg/g) as well as percentage efficiency removal (%R) calculation using the following equations:

-

Amount of copper(II) ions sorbed at time t (qt, mg/g):

$$q_{\text{t}} = \left( {C_{0} - C_{\text{t}} } \right)V/m_{j}$$(1) -

Amount of copper(II) ions sorption at equilibrium time, sorption capacity (qe, mg/g):

$$q_{\text{e}} = \left( {C_{0} - C_{\text{e}} } \right)V/m_{j}$$(2)where Co is the initial concentration of copper(II) ions before the sorption process, Ce is the copper(II) ions concentration at equilibrium (mg/L), V is the volume of solution (0.05 L), mj is the mass of functional resin (g) [27],

-

Percentage removal efficiency of copper(II), (R, %):

$$R = \frac{{\left( {C_{0} - C_{\text{e}} } \right)}}{{C_{0} }} \times 100\%$$(3)where Co is the initial copper(II) ions concentration (mg/L) and Ce is the equilibrium copper(II) ions concentration (mg/L) [28].

The Cu(II) adsorption on examined sorbents was performed in triplicate, and the arithmetic mean values were obtained and presented in figures. The calculated standard deviation did not exceed 5% in all cases.

The point of zero charge (pHPZC) of sorbents under discussion was performed according to the solid addition method using the following parameters (mass of sorbent—0.5 g; volume of the solution of different pH—50 mL; agitation speed—180 spm; time of shaking—24 h) [29].

Equilibrium studies were carried out using the above described static procedure. The initial copper(II) concentration was in the range 100–10000 mg/L, and the shaking time was equal to 24 h.

Desorption efficiency using different eluting agents and reuse studies (three sorption -desorption cycles) for the most efficient sorbent was determined.

The removal efficiency of copper(II) using ion exchangers under discussion was also analysed in the two-component solutions Pd(II)–Cu(II). Moreover, removal efficiency of noble metals Pd(II), Pt(IV) and Au(III) from tertiary components solutions on Lewatit MonoPlus TP 220 was also discussed.

Sorption studies by the column test

Metal ions removal by the batch method was used for preliminary screening of the systems resulting in maximum uptake, effectiveness of sorbents determination, but the practical utility of a sorbent is judged from the column operation. Therefore, Cu(II) removal by the column studies was carried out. In the dynamic studies, Lewatit MonoPlus TP 220 (10 cm3 of swollen ion exchanger) was placed in the glass column of 1 cm diameter and 25 cm high and contacted continuously with fresh solutions of the initial solute concentration of 100 mg/L (flow rate was 0.4 cm3/min). The efficiency of column could be judged by means of the breakthrough curve obtained by plotting C/C0 (ratio of effluent concentration to the initial concentration of solution) versus the volume of the effluent collected from the column. The volumes of the effluents to reach the breakthrough point and shape of the breakthrough curve are very important characteristics for determining the working ion exchange capacity (Cw), mass (Dm) and bed (Db) distribution coefficients. These parameters were calculated based on Eqs. 4–6 presented in Table 1 and compared to the others obtained for noble metal ions.

Results and discussion

The point of zero charge determination of the resins under discussion

The point of zero charge (pHPZC) of the sorbents under discussion was determined using the solid addition method [29]. The solutions of 0.01 M KNO3 of different pH values were prepared applying 1 M NaOH and 1 M HCl solutions to adjusted pH, and then 50 ml of solutions was contacted with 0.5 ± 0.0005 g of sorbent for 24 h. After that, the pH was measured again (final pH, pHf) using the pH meter CP-411 (Elmetron, Zabrze) and the plot pHo (initial pH of the solutions) versus the difference between the initial (pHo) and the final (pHf) ones was obtained. pH is a very important factor in metal ions sorption because it influences on chemical speciation of the metal ions in solution and, on the other hand, on the ionization of active sites on the sorbent. Sorbent surface charge might play a crucial role in sorption processes efficiency, and sorbents functionality (protonation–deprotonation behaviour) in aqueous acidic media could be helpful in sorption mechanism explanation [30]. Point of zero charge (pHPZC) is the pH at which the sorbent surface charge is neutral that means that there are equal amounts of positive and negative surface sites. These values were determined from the above-mentioned plot: pH0 versus ∆pH = pH0 − pHf in the place where such curves cross the x axis. Table 2 collects the values of pHPZC of the sorbents under discussion and presents chosen examples of experimentally obtained plots. In the case of the SBA resin, the pHPZC is close to 1–1.5, whereas for the WBA and adsorbent without functional groups this value is higher.

As it was known, copper(II) interaction with the sorbents under discussion depends on the form in which metal exists as well as on the surface charge. In the acidic solutions 0.1–6 M HCl, Cu(II) exists in the cation form Cu2+ as well as in the form of chlorocomplexes of different charges. The copper(II) species in the HCl system was previously described in [31]. At the solution pH higher than pHPZC, the negatively charged sorbent surface results in possible interactions with copper positive species (electrostatic interactions), while at pH lower than pHPZC the positively charged surface results in electrostatic interactions with anionic copper species and repulsions with copper cations.

Selection of the best ion exchangers for copper(II) removal

Effects of phases contact time (1 min–4 h) as well as acids (HCl and HCl–HNO3) concentration and solutions composition on copper(II) removal efficiency using eight ion exchangers under discussion were studied previously [31,32,33,34] and in this paper according to the procedure described in Subchapter “Sorption studies by the batch test”. The results of adsorption from the solutions of the initial concentration equal to 100 mg Cu(II)/L are presented in Fig. 3. Figure 3a–d presents the amount of copper(II) sorbed versus the phases contact time depending of the HCl concentration (0.1–6.0 M HCl). Due to the fact that the copper(II) removal efficiency was much lower from the HCl–HNO3 systems, only chosen results are presented for this system. Figure 3e shows the results obtained during copper(II) removal from 0.9 M HCl–0.1 M HNO3 solutions in which the qt and qe values were the highest, whereas Fig. 3f presents the results obtained from the HCl- HNO3 system for Lewatit MonoPlus TP 220.

Comparison of the amount of copper(II) sorbed from a–d HCl and e–f HCl–HNO3 systems (chosen example) (experimental conditions: mass of the ion exchanger: mj = 0.5 ± 0.0005 g, volume of the Cu(II) solution: V = 0.05 L, initial Cu(II) concentration: Co = 100 mg/L, shaking rate: Vas = 180 spm, amplitude: A = 8, temperature: T = ambient, shaking time: t = 1 min–4 h)

The obtained results lead to the following conclusions:

-

Lewatit MonoPlus TP 220 shows the highest affinity for Cu(II) ions compared to the other ion exchangers under discussion in all examined HCl and HCl–HNO3 systems.

-

The highest sorption capacity in the dilute acid solutions as well as quantitative Cu(II) removal was obtained for the Lewatit MonoPlus TP 220 ion exchanger from 0.1, 1.0 M HCl as well as from 0.9 M HCl–0.1 M HNO3 solutions. In this case, the %R is equal to 100%, whereas for other acid concentrations the %R is close or slightly lower than 100% (91–99%). Sorption is not quantitative in the case of other ion exchangers (Dowex PSR 2, Dowex PSR 3, Lewatit MonoPlus SR 7, Purolite A 400 TL, Lewatit AF 5, Purolite S 984, Purolit A 830). For these ion exchangers, %R is in the range from 0 to 35% (HCl systems) and from 0 to 15%.

-

The effect of phases contact time on the amount of sorbed Cu(II) ions is clearly marked in the case of Lewatit MonoPlus TP 220 in the HCl and HCl–HNO3 systems as well as to a lesser extent for Purolite A 830 and Purolite S 984 in the systems of 6 M hydrochloric acid concentration. The time required to achieve the system equilibrium for Lewatit MonoPlus TP 220 was > 120 min (HCl systems) and > 60 min (HCl–HNO3 systems). For the other ion exchangers under discussion, the Cu(II) sorption was not strongly time dependent; therefore, in contrast to Lewatit MonoPlus TP 220 the qt values do not significantly increase with the phases contact time increase.

The Cu(II) sorption efficiency depends mainly on the ion exchange resin types, presence and types of functional groups, physical and chemical properties of the ion exchange resin as well as bead size [35]. Diversifying copper(II) ions removal effectiveness using the ion exchangers under discussion from acidic streams is caused by several factors: (1) ion exchangers possess a different matrix—usually they are polystyrene, polyacrylic cross-linked with divinylbenzene or carbonaceous matrices (Fig. 2), (2) the ion exchangers structure is macroporous or microporous, (3) ion exchangers possess different functional groups (Fig. 4), (4) the sorption uptake of Cu(II) ions depends on the acidic conditions which affect the ion exchangers functionality, (5) different mechanisms of Cu(II) sorption could proceed.

Moreover, the difference in copper(II) removal in solutions of different acids concentrations could be caused by competition of the chloride ions with the Cu(II) ions. The behaviour of the anion exchange resins: weakly (WBA) and strongly basic (SBA) types in the HCl system are pH and total chloride ions concentration dependent as well as depend on the form in which Cu(II) ions exist under acidic conditions. The SBA resins are ionized in a wide pH range from 0 to 13, whereas the WBA ones are efficient in the acidic pH region in which the WBA functional groups are protonated which results in anions removal [31,32,33]. Ion exchangers of chelating types show higher selectivity towards the Cu(II) metal ions and can remove Cu(II) ions more effectively by means of a mixed mechanism. In this case combination of ionic interactions, electrostatic interactions and coordination could take place. Chelating ion exchange resins of the functional groups containing one, two or more donor atoms, e.g. N, S, O, can interact with the Lewis acids therefore such as Lewis bases; they can form coordinating bonds with the Lewis acids such as the Cu(II) ions, which results in extremely high selectivity for Cu(II) [31, 35,36,37,38]. Lewatit MonoPlus TP 220 as the ion exchange resin possesses three nitrogen donor atoms (two of them are in the aromatic pyridyl groups and tertiary amine) [39]. Electron-withdrawing effects of the aromatic group cause that pKa (negative logarithm of the acid dissociation constant) values are quite low, resulting in nitrogen atoms deprotonation even at pH of 1.5. The bis-picolylamine functional groups pKa values and those in the HCl system indicate that the behaviour of these functional groups depends on pH and the chloride ions [7, 31, 38, 39]. Large copper(II) removal is caused by the following factors: (1) at acidic pH two pyridyl nitrogen donor atoms are available and therefore the bidentate complex with Cu(II) can be formed, (2) Cu(II) possesses greater affinity compared to other transition metals (first stability constants for Cu(II) is equal to log Ks = 14.4, whereas for Ni(II)—log Ks = 8.7, Zn(II)—log Ks = 7.57 etc. [40]), (3) Lewis acid–base interactions of bis-picolylamine and Cu(II) without electrostatic interactions take place. As reported in the literature and was proved in this paper, the chelating resins with bis-picolylamine are efficient for Cu(II) removal from acidic solutions [31, 35, 39]; therefore, such ion exchange resin was chosen in the additional studies.

Equilibrium studies

The selection of ion exchangers was also made on the basis of the equilibrium studies which allow to determine the maximum sorption capacities for copper(II) ions. The static procedure described in the Experimental part was applied, and the initial concentration of copper(II) solutions was in the range from 100 to 10000 mg/L. Due to the fact that in this case the concentration of copper(II) ions was much higher than 100 mg/L, the phases contact time extended to 24 h to be sure that the system equilibrium was achieved. The curves qe (mg/g) versus Ce (mg/L) are presented in Fig. 5 (different axis scales were applied for the results to be better observed).

Based on the obtained experimental values capacities, the ion exchangers were placed in the following selectivity series: Lewatit MonoPlus TP 220 (230.2 mg/g) ≫ Dowex PSR 3 (140 mg/g) > Purolite S 984 (133.5 mg/g) ≈ Purolite A 830 (132 mg/g) ≈ Dowex PSR 2 (131 mg/g) > Purolite A 400 TL (123.2 mg/g) > Lewatit SR 7 (118.3 mg/g) ≈ Lewatit AF 5 (117.8 mg/g). As it was found, Lewatit MonoPlus TP 220 was the most efficient for copper(II) ions removal; therefore, for this ion exchanger the two most commonly used isotherm models such as Freundlich and Langmuir ones were applied. Description of these models together with the graphical presentation of isotherm curves as well as the values of calculated parameters is shown in Table 3 [41, 42]. The adsorption parameters were obtained using the linear regression technique and were calculated from the slope and intercept of the plots of log qe versus log Ce (Langmuir isotherm) and Ce/qe versus Ce (Freundlich isotherm).

Comparing the values of determination coefficients of both models, the higher values were obtained using the Langmuir model (R2 = 0.949) than the Freundlich one. The experimental maximum sorption capacity calculated from Langmuir model is high (Q0 = 221.43 mg/g) and close to the experimental one (230.2 mg/g) indicating favourable sorption and good fitting of the experimental results with the Langmuir model (see fitting plot located in Table 3). The nature of the sorption (favourable, unfavourable, irreversible) was considered by the shape of the isotherm curve and by the dimensionless constant, RL (\(R_{L} = 1/(1 + bC_{o} )\)). Based on the RL parameter which was equal to 0.825 and the following conditions: RL = 0–1—favourable, RL > 1—unfavourable, RL = 1—the linear isotherm, RL = 0—the irreversible can be concluded that the Cu(II) sorption on Lewatit MonoPlus TP220 is favourable. The obtained results are in agreement with the literature ones [10, 43,44,45] which also indicate that the Cu(II) sorption on the other sorbents is well described by the Langmuir isotherm and/or Freundlich models and the favourable sorption is observed, e.g.: Cu(II) sorption on brushite calcium phosphate—the Langmuir isotherm, R2 = 0.999, Q0 = 343.64 mg/g [43] or Cu(II) sorption on marine macro green algae, Halimeda gracilis—the Langmuir isotherm, R2 = 0.998, Q0 = 38.46 mg/g [44], etc. As was mentioned by Buracov et al. [45] in the review paper concerning sorption of heavy metal ions on conventional and nanostructures materials, the adsorption of heavy metal ions can be described by the Langmuir and Freundlich isotherm models but for heavy metal cations sorption the Freundlich model has frequently proved superior to the Langmuir one. On the other hand, in another review [46], the cited examples show that the Langmuir isotherm is more suitable for Cu(II) sorption description. The analysis of the sorption capacities values presented in the literature, e.g. review papers [10, 45, 46], shows that Lewatit MonoPlus TP 220 possesses higher or much higher capacity compared to that of the other ion exchangers (this paper), low cost adsorbents [10] and carbon adsorbents [46].

Sorption of heavy metal ions from two- or three-component solutions

Heavy metal ions sorption on eight ion exchangers was performed, and the results were published e.g. in [31,32,33,34, 47,48,49] and are presented in this paper. As it was proved Lewatit MonoPlus TP 220 is an efficient sorbent for noble metal ions removal (Pd(II), Pt(IV) and Au(III)), particularly for Pd(II) as well as for Cu(II), Co(II), Ni(II), Zn(II) removal, especially for Cu(II). Due to this fact sorption was also carried out from the two-component solutions containing Pd(II) and Cu(II) (Pd(II)–Cu(II), eight ion exchangers) and three-component solutions (Pd(II), Pt(IV), Au(III); Lewatit MonoPlus TP 220).

The results of Cu(II) sorption from two-component solutions and their comparison to those obtained from single solutions were analysed and are depicted in Fig. 6 (chosen examples) and Table 4.

The presented results lead to the following observation:

-

the effectiveness of Cu(II) and Pd(II) ions removal from the single and two-component solutions is slightly (Lewatit MonoPlus TP 220) or significantly different for the remaining tested ion exchangers,

-

in the case of the ion exchanger Lewatit MonoPlus TP 220 (Fig. 6a) for which the Pd(II) and Cu(II) removal efficiency from single solutions is high (removal efficiency is equal to 100% or slightly lower, qt values in the range 9.1–10 mg/g) no significant changes of this efficiency in the two-component solutions are observed. The competitive effect of these heavy metal ions is not pointed out, and the coordination mechanism using N donor atoms of the bis-picolylamine functional groups takes place [31],

-

in all other cases Pd(II) sorption efficiency or amount of Pd(II) sorbed from single solutions is high, quantitative removal from the diluted acidic solution is observed, and then the values of qt decrease with the hydrochloric acid increase; opposite situation is observed in the case of Cu(II) sorption from single solutions (qt values usually increase with the hydrochloric acid concentration increase) [31,32,33,34, 47,48,49]. The diversified effectiveness of the Cu(II) and Pd(II) removal process is related to the form in which these metals exist in the solution under discussion which is dependent on the acidity of the medium, the total concentration of the chloride ions and temperature. In acidic solutions (0.1–6 M HCl), various forms of Cu(II) and Pd(II) chlorocomplexes can be formed or they can exist in the form of cations or inert chlorocomplexes [31, 50,51,52,53]:

-

Cu(II): [CuCl4]2−—exists when HCl concentration is in the range 1–4 mol/L; [Cu2Cl6]2−—exists when HCl concentration is in the range 5–10 mol/L; decrease in acidity results in [Cu(H2O)6]2+ formation; in the Cl− ions presence (0.5–1 mol/L)—weaker acidic media the following reaction takes place: 2[CuCl2] ↔ [CuCl3]− + [CuCl]+ [31, 50,51,52],

-

Pd(II): [PdCl4]2−—exists when HCl concentration is higher than 0.1 mol/L [31]; with the decreasing acidity of the solution, [PdCl4]2− ions are aquatized to [Pd(H2O)Cl3]−, [Pd(H2O)2Cl2] and [Pd(H2O)3Cl]+ forms [54].

-

More details of such sorption behaviour in the single solutions can be found in the previously published papers [31,32,33,34, 47,48,49]. It is known that the removal efficiency is also strongly dependent on the functional groups of the ion exchangers that means types of the ion exchangers. Due to this fact, the mechanism of sorption is different (see Fig. 7).

-

In the binary solutions, Pd(II)–Cu(II) qt values of Pd(II) usually remain unchangeable or decrease compared to the single solutions, whereas the qt values of Cu(II) usually slightly or significantly increase (except for Lewatit MonoPlus SR 7—in this case both Pd(II) and Cu(II) ions sorption efficiency increases). During the simultaneous sorption of Pd(II) and Cu(II) ions from the weak and strong acidic solutions, the presence of Pd(II) results in the Cu(II) removal efficiency increase that means that the joint action of simultaneously sorbed Pd(II) and Cu(II) ions results in increased selectivity of ion exchange resins towards copper(II) ions. Such behaviour may result from the acidic effect, affecting the ion exchange resin phase and facilitating the sorption of more stable anion complexes. Kononova et al. [51] also examined ion exchangers selectivity towards heavy metal ions such as Cu(II) and Zn(II) (binary acidic solutions—HCl solutions). As it was found Cu(II), sorption efficiency as well as selectivity of anion exchange resins increases in the presence of Zn(II) ions in the case of weak acidic solutions and strong acidic solutions for strongly basic anion exchanger, which was explained by the acidic effect and complex mechanism.

Lewatit MonoPlus TP 220 was also applied in sorption of noble metal ions Pd(II), Pt(IV) and Au(III) from three-component solutions in which the metal concentration was in the range from 5 to 100 mg/L. The results are presented in Fig S2 (Supplementary Materials). As can be seen from the results in the system of the same concentrations of all heavy metal ions, the selectivity series is as follows: Au(III) ≥ Pt(IV) ≥ Pd(II), but the differences between the qt values are not so high. The high affinity of Lewatit TP MonoPlus TP 220 towards gold complexes could be attributed to high mobility of AuCl4− through the resin network and the presence of free electron pairs on the ligand (ion exchangers possess three nitrogen donor atoms). The smallest charge density of Au(III) causes that the functional groups of ion exchanger resin favoured interaction with gold chlorocomplexes [55]. Moreover, the qt values increase with the metal ions concentration increase (the initial metal concentration provides an important driving force). The percentage removal efficiency (%R) is in the range from 93.4 to 99.6% for Pt(IV), from 90 to 99.1% for Pd(II) and from 95.4 to 100% for Au(III). In the case of an excess of one heavy metal ions during the sorption on Lewatit MonoPlus TP 220, a slight decrease in qt values for Pt(IV) with the Pd(II) and Au(III) ions concentration increase was observed. The %R values decrease from 99% (100 mg Pt(IV)/L; 5 mg Pd(II)/L; 5 mg Au(III)/L) to 97.2% (100 mg Pt(IV)/L; 80 mg Pd(II)/L; 80 mg Au(III)/L), whereas in the case of solutions with an excess of two heavy metal ions %R values of Pt(IV) slightly increase with the Pd(II) concentration increase; %R values increase from 97.7% (100 mg Pt(IV)/L; 5 mg Pd(II)/L; 100 mg Au(III)/L) to 99.1% (100 mg Pt(IV)/L; 80 mg Pd(II)/L; 100 mg Au(III)/L). The changes of qt and %R values indicate that the competitive effect between heavy metal ions of sorption sites could take place but does not influence significantly the sorption yield and could be neglected. As it was mentioned in the paper [31], Lewitit MonoPlus TP 220 ion exchanger preference towards specific heavy metal ion from the mixture is not observed. For Pd(II)–Pt(IV)–Au(III) solutions of the same heavy metal ions concentration (concentration of each heavy metal ions from 5 to 80 g/L) sorption and desorption cycles (three repetitions) used as the eluting agents, the mixture of thiourea with 0.1 M HCl, sodium hydroxide and ammonium hydroxide selected by the desorption efficiency (%D) from the single solutions [31] indicates that using NaOH solutions Pt(IV) desorption was observed (e.g. %D1 for Pt(IV) was from 39.6% to 66.5% and a decrease in the third desorption step), whereas that for Pd(II) and Au(III) was equal to 0 or was very low (% D1, D2, D3 from 0 to 2.8%), which indicates that Pt(IV) separation could be possible. The other mentioned above eluting agents give %D1 in the range: 95.8–32.9% (0.1 M thiourea + 0.1 M HCl) and 50.2–14% (3 M NH4OH) for all heavy metal ions present in the solutions. High desorption efficiency of gold is related to the displacement principle. Introducing an anion with higher affinity to resin compared with the adsorbed gold chlorocomplex results in adsorption equilibrium shifting to the left. The complex of gold of positive charge with thiourea starts to form Au[CS(NH2)2]+2 . The resin has weak affinity to the newly formed species; thus, it is able to efficiently strip gold from ion exchange resin in the presence of the weak eluent, e.g. HCl [55]. The sorption efficiency in the second and third steps (%S2, %S3) sometimes decreases, but the highest sorption yield decrease in %S2 and %S3 was observed for Au(III) (desorption 0.1 M thiourea + 0.1 M HCl). The %S2, %S3 decrease is related to the fact that desorption after first cycle is not quantitative and some heavy metal ions remained on the resins and the adsorption sites are occupied. The reduction in sorption ability of gold could be also related to osmotic shock produced by repeated elution in acidic media (breakage of the resin beads), but this hypothesis needs additional analysis. Moreover, the decomposition of thiourea in acid solutions occurs which makes the desorption less efficient [56].

Copper(II) sorption by Lewatit MonoPlus TP 220 using the batch method: kinetic studies

The kinetic investigations are very important due to possible prediction of the rate at which toxic copper metal ions are removed from aqueous, acidic solutions and are helpful for understanding the mechanism of Cu(II) sorption reactions. Kinetic sorption experiments were performed to establish the effect of phase contact time on the sorption of copper(II) ions on Lewatit MonoPlus TP 220. The pseudo-first-order (PFO) and pseudo-second-order (PSO) kinetic equations were used to describe the kinetic curves whose characteristics are presented in Fig. 8. The plots of log(qe − qt) versus t (PFO model) and the plots t/qt versus t (PSO model) were obtained and are presented in Fig. 3S. As can be seen, PFO equation fails at the data matching stage; instead of a straight line, a bent curve is obtained. The applicability of these models (error analysis to evaluate the best fitted model for Cu(II) sorption) was assessed based on the normalized standard deviation Δq(%), Chi-square test (χ2) and the coefficient of determination R2. The best-fit model is the one which possesses the lowest value of Δq%, χ2 and the highest values of R2 which is closer to unity. The normalized standard deviation (Δq%) and Chi square (χ2) parameters were calculated using the following mathematical expressions [54]:

where qt,exp and qt,cal are the experimental and calculated (predicted) amounts of Cu(II) sorbed, and n is the number of data points.

The results of kinetic models with their parameters, determination coefficient, normalized standard deviation values and the fitting plots of predicted and experimental qt values are given in Table 5 for PSO and in Table S2 for PFO. As can be seen from Table 5 and Table S2, the kinetic rate of PFO k1 decreases with the hydrochloric acid concentration increase, whereas in the case of PSO model these values first increase with the hydrochloric acid increase up to 1 M and then decrease. The initial sorption rate h changes with the hydrochloric acid concentration similar to k2 values, at first increases up to 1 M and then decreases. Changes of k1 and k2 parameters with hydrochloric acid concentration increase are related to the fact that at the beginning of the sorption due to a high number of empty active sites the adsorption is fast in the dilute solutions and the h parameter increase. Then with the increase in HCl concentration the total concentration of ions in the solution also increases, whereas the number of adsorption sites decreases resulting in that the solution is more crowded and the speed of diffusion decreases. After that, the initial sorption rate and k2 values decrease. Shape of kinetic curves indicates that the time required to reach system equilibrium is short. This fact suggests that rather surface adsorption takes place than the surface diffusion of adsorbed particles into the pores of the adsorbent, but additional analysis and applications of so-called Boyd plot (qt vs. t1/2) which has physical sense only for low surface coverings for qt < qe/3 is needed to prove this hypothesis [55]. The pseudo-second-order kinetic model has much higher determination coefficient values (R2 > 0.999) compared to the values obtained using the PFO model (R2 > 0.902). Moreover, the sorption capacity value obtained experimentally for different hydrochloric acid concentrations, qe,exp was in a good agreement with the calculated one, qe,cal obtained by the PSO model e.g. qe,exp = 9.98 mg/g, qe,cal = 10.38 mg/g (0.1 M HCl, PSO), qe,cal = 5.58 mg/g (0.1 M HCl, PFO) or qe,exp = 9.95 mg/g, qe,cal = 10.14 mg/g (1 M HCl, PSO), qe,cal = 3.39 mg/g (1 M HCl, PFO) and was much higher than that obtained from PFO model. The smaller values of calculated qt in the case of PFO could result from random experimental errors and properties of the linear representation used. The impact of random experimental errors is crucial in the case of PFO equations, whereas that in the case of PSO is negligible, which results in limitation in PFO applicability. Taking into account the linear representation of PFO model—log(qe − qt) the difference between qe and qt during the adsorption progress decreases, whereas the value of log(qe − qt) increases. The impact of random errors will increase proportionally to the inverse (qe − qt) results that the good fitting of PFO with the experimental point close to the equilibrium could not be observed [55]. Based on the error analysis of PFO and PSO models that means the normalized standard deviation Δq(%) and Chi-square test (χ2), these parameters are lower in the case of PSO model, Δq was in the range from 4.78 to 12.53% (0.1 M HCl, PSO) and in the range from 43.19 to 57.56% (0.1 M HCl, PFO), whereas the χ2 values were in the range from 0.09 to 0.22 (0.1 M HCl, PSO) and in the range from 13.01 to 48.18 (0.1 M HCl, PFO). Thus, it can be concluded that the Cu(II) ions sorption on Lewatit MonoPlus TP 220 follows the pseudo-second-order kinetics. A similar conclusion was also obtained by other researchers who applied different types of sorbents for Cu(II) removal, e.g. Dada et al. [57] who examined sorption of Cu(II) onto a novel manganese nano-adsorbent, Faghihian et al. [58] who examined sorption of Cu(II) onto silica aerogel modified with amino propyl triethoxysilane, Samadi et al. [59] who examined sorption of Cu(II) onto the chelating resins CSMA-M, CSMA-MO and CSMA-MB, Cho et al. [60] who examined a novel chitosan/clay/magnetite composite for adsorption of Cu(II) and As(V) ions, Ngah et al. [61] who examined sorption of Cu(II) ions by three types of chitosan–zeolite composites, etc.

Attenuated total reflectance Fourier transform infrared spectroscopy (ATR-FTIR) analysis for Lewatit MonoPlus TP 220 applied for copper(II) sorption

ATR-FTIR spectra of Lewatit MonoPlus TP 220 before and after copper(II) sorption were recorded to confirm the presence of functional groups of ion exchange resin and to provide some information about Cu(II) sorption mechanism. The spectra of non-loaded Lewatit MonoPlus TP 220 and after Cu(II) sorption process (loaded ion exchange resin) are presented in Fig. 9.

From the presented ATR-FT-IR spectra, the peaks related to the resin matrix and their functional groups can be distinguished. As was observed in the higher-frequency region at 3350–3450 cm−1, the broad and intense peak was assigned to the stretching vibrations of the –OH group (maximum of peak can be found at 3346.1 cm−1 (%T 88.59)—before sorption and at 3353.56 cm−1 (%T 87)—after Cu(II) sorption. Moreover, stretching vibrations of the N–H groups, symmetric and asymmetric stretching bonds of –CH2 groups (before sorption—νs –CH2 2840–2850 cm−1, νas –CH2 2905–2930 cm−1, after sorption shifted to the higher-frequency region—νs –CH2 2850-2870 cm−1, νas –CH2 2915–2925 cm−1) and the peak related to cross-linked polystyrene (before sorption—at 1585–1595 cm−1 and after sorption—1598–1612 cm−1) can be found. Additionally, the peak related to the vibrations of C=N of pyridine groups as well as the asymmetric scissoring vibrations of the methylene groups δas at 1425–1455 cm−1 (after sorption at 1438–1450 cm−1), adsorption peaks of C–H at 750–770 cm−1 (after sorption at 760–770 cm−1) and peaks related to the amine groups at 950–1250 cm−1 are present. The spectra showed also stretching vibrations of C=C and C=N characteristic of the functional groups at the wavelength 1650–1400 cm−1 and the bands from the stretching vibrations of the C–N groups in aliphatic and aromatic amines. After copper sorption, a significant drop of some band intensity and their shift to the higher-frequency region were found, particularly in the region 950–1250 cm−1, 1400–1500 cm−1, 1550–1650 cm−1 in the case of band corresponding to the stretching vibrations of the O–H and N–H groups and stretching vibrations of the C–N groups present in aromatic and aliphatic amines. Such changes could be due to the coordination bands formation with Cu(II) ions sorbed on the ion exchanger (coordinating mechanism) [7, 31, 62].

Copper(II) desorption from Lewatit MonoPlus TP 220 and ion exchange resin reuse: batch method

Three sorption/desorption cycles of Cu(II) on/from Lewatit MonoPlus TP 220 using the batch method were carried out in order to check the desorption possibilities of Cu(II) ions from the loaded ion exchanger and its reused possibility. Different eluting agents were applied such as acids: HNO3, HCl, H2SO4, base: NaOH and ammonium hydroxide: NH4OH of concentration equal to 1 and 2 M. The eluting agents were selected based on the literature data concerning the desorption studies of copper(II) from different sorbents and ion exchangers taking into account its efficiency, types and concentration. (More information can be found in Supplementary Materials.) The other experimental conditions were following: mass of the sorbent applied for sorption and desorption studies, mj = 0.5 ± 0.0005 g, volume of the solutions containing Cu(II)/L (S1, S2, S3) and volume of the eluting agents applied for desorption (D1, D2, D3) V = 0.05 L, initial concentration of copper Co = 100 mg Cu(II)/L—sorption studies, initial concentration of eluting agents, Co = 1 or 2 M—desorption studies, agitation speed, Vas = 180 spm, amplitude, A = 8, time of sorption and desorption, t = 2 h, temperature, T = room temperature. Desorption studies using various types of eluents (Fig. 10) have shown that copper ions can be desorbed with different efficiencies. The use of mineral acids for removal of Cu(II) ions from the Lewatit MonoPlus TP 220 ion exchanger does not give satisfactory results (the effectiveness of desorption with acids was in the range from 0.34–10.46% (D1) and increases with the increasing acid concentration, e.g. from 2.96%—1 M HNO3 to 9.43%—2 M HNO3 or from 4.11%—1 M H2SO4 to 10.53%—2 M H2SO4 (D1)). Slightly better results were obtained using NaOH solutions (9.84%—1 M NaOH, 14.24%—2 M NaOH). The most effective eluting agent was 2 M NH4OH, for which the desorption efficiency was 54.38%—1 M NH4OH and 76.41%—2 M NH4OH. The obtained percentage desorption efficiency in the first cycle (%D1) causes that NaOH and NH4OH were selected for the second and third sorption/desorption studies whose yields are presented in Fig. 10 b. In %D2 and %D3, the amount of Cu(II) remaining on the ion exchanger after the previous step was taken into account, e.g. the amount of Cu(II) remaining on Lewatit MonoPlus TP 220 in the D1 step was included in %D2 calculations, whereas in %D3 calculations the amount of Cu(II) remaining on the ion exchanger after D1 and D2 was included. The most appropriate eluting agent for copper(II) desorption from the ion exchange resin under discussion was ammonium hydroxide of 2 M concentrations resulting in 76.92% of Cu(II) desorption in the first cycle, 69.5% in the second and 45.9% in the third cycle. Despite not quantitative Cu(II) desorption, the ion exchanger could be reused again in the next cycle and still exhibit good sorption properties. After 3 cycles of sorption–desorption (static method), the ion exchange resin shows high sorption capacity in the 3rd cycle and is still as high as in cycle 1.

Sorption and desorption test for copper(II) on/from Lewatit MonoPlus TP 220 using the column studies

The goal of the column test is to quantify important parameters which are required to design industrial scale fixed bed adsorption columns. The sorption studies of metals by the column method were carried out from the chloride solutions ((Cu(II), Pd(II), Pt(IV), Au(III)) and chloride–nitrate(V) ones (Pd(II), Pt(IV), Au(III)) in order to obtain the breakthrough curves and calculate sorption parameters. In the case of copper(II) ions after the sorption process (S1), the desorption was performed (D1) and then the next two similar cycles. Some examples of the breakthrough curves are presented in Figs. 11, 12 and 13, whereas the obtained parameters are collected in Table 6.

The breakthrough curve is one of the most important results of a dynamic studies under gravitated flow conditions on a fixed bed—Lewatit MonoPlus TP 220. This curve shows relationships between changes of concentration (C/C0) versus time and results from different kinetic and thermodynamic effects. As shown in Figs. 11, 12 and 13, the breakthrough curves are characterized by midpoint, steepness and shape. The mentioned curves are not ideal, not symmetrical and not possess typical “S” shape. The sorption capacity, selectivity, the mass transfer of adsorptive molecules into the adsorbent particles, the sorption rate and inlet concentration play a key role during the dynamic sorption process and influence the position and shape of the breakthrough curve considerably. The position and shapes of breakthrough curve contain information about different scales involved in dynamic sorption and macro-, meso- and microscopic parameters influences: (a) macroscopic (shape and size of adsorber), (b) mesoscopic (bed porosity and nature of fixed bed, shape and size of particles), (c) microscopic (surface chemistry, textural properties and accessibility).

The volume of solution collected to the breakthrough point decreases with the HCl concentration increase, and then Lewatit MonoPlus TP 220 is characterized by a smaller working exchange capacity (presented curves moved to the left side and are closer to point (0,0)). The exceptionally large shift of the breakthrough curve is observed in the case of Au(III) when the concentration of HCl changes from 0.1 to 1 M. In this case the working capacity reduction is 36% (Cr changes from 0.164 g/cm3 to 0.105 g/cm3), whereas in the case of Cu(II) is 2.86%, Pd(II) 22% and Pt(IV) 22.2%. The highest sorption capacities are observed in the dilute acidic solution (0.1 M HCl), and the selectivity series is as follows: Au(III) (0.164 g/cm3) ≫ Pd(II) (0.104 g/cm3) > Pt(IV) (0.099 g/cm3) ≫ Cu(II) (0.0175 g/cm3). In the case of HCl–HNO3 systems, the values of Cr usually grow with the HCl concentration increase and HNO3 concentration decrease, e.g. from 0.004 g/cm3 (0.1 M HCl–0.9 M HNO3; Au(III)) to 0.102 g/cm3 (0.9 M HCl–0.1 M HNO3; Au(III)). The sorption capacity has significant impact on the position of the breakthrough curve. By increasing the sorption capacity (see e.g. Fig. 11 and breakthrough curve for Au(III)), the breakthrough curve is shifted to longer breakthrough times (curve moved to the right) because more Au(III) ions will be held back by Lewatit MonoPlus TP 220. On the other hand, the observed steep shape of breakthrough curve indicates that sorption kinetics is fast (spontaneous breakthrough occurs are not observed) (for faster kinetics the breakthrough curve becomes steeper). Short local equilibrium times are formed due to fast mass transfer results in smaller enlargement of the concentration front (compensation by other effects can be also observed). Additionally the asymmetric shape of breakthrough curve can be caused by the thermodynamic effect, by axial dispersion as well as heterogeneity of adsorbents [63, 64].

The bed and weight distribution coefficients in the chloride solutions decrease significantly with the HCl concentration increase as a results of competitive effect, whereas in the chloride–nitrate(V) solutions these parameters do not show clear trend in the changes with those of HCl and HNO3 concentrations.

After three cycles of sorption–desorption, the S1–D1–S2–D2–S3–D3 (Cu(II) sorption by Lewatit MonoPlus TP 220 from 0.1, 1, 3 and 6 M HCl) was observed that the working ion exchange capacities, the weight and bed distribution coefficients decrease in the second and third cycles, e.g. Cr (g/cm3) obtained during the Cu(II) sorption from 0.1 M HCl solutions was 0.0175 (S1), 0.0161 (S2) and 0.0133 (S3), respectively. The desorption curves (Cu(II) desorption using 2 M NH4OH) in all cases are characterized by a high desorption peak at the beginning (sharp increase in Cu(II) ions in the solutions after desorption), then the concentration of Cu(II) in solution after desorption slowly decreases, and tailing of the peak is observed. The maximum of peaks is observed after using 25–35 ml of desorbing solutions in all cases (Cu(II) sorption from 0.1, 1, 3, and 6 M HCl), and the height of the peaks decreases with the HCl concentration increase, e.g. the Cu(II) concentration decreases from 8136.4 mg/L (sorption from 0.1 M HCl) through 7459.0 mg/L (sorption from 1 M HCl), 6222.7 mg/L (sorption from 3 M HCl) to 1033.9 mg/L (sorption from 6 M HCl). Passing through the column even about 3 L (2985 to 3335 ml, 2555–3775 ml) or about 2 L (1660–2280 ml) of the desorbing solution (2 M NH4OH) due to the tailing of the peak gives in the solution a trace concentration of Cu(II) ions of 0.39–0.9 mg/L (desorption cycle 1, D1), 0.08–1.4 mg/L (desorption cycle 2, D2) or 1.65–1.96 mg/L (desorption cycle 3, D3). The desorption process could be observed visually because the solution after the desorption process changed its colour from colourless to heavily navy blue (desorption peak achieved the maximum, Cu(II) concentration in the eluate was the highest), and then the colour of the eluate decreased its intensity (increasingly paler blue), until colourless (trace concentration of Cu(II)). As the results show, Lewatit MonoPlus TP 220 is characterized very good sorption properties for noble metals, especially for Au(III) and among base metals, e.g. Cu(II), Co(II), Zn(II), Ni(II) good sorption properties for Cu(II). Lewatit MonoPlus TP 220 possesses still high sorption ability for Cu(II) even after 3 cycles of sorption–desorption [reduction of capacity is small and equal to 8% (Cw from S1 to S2) and 17.4% (Cw from S2 to S3) (0.1 M HCl)]. In the case of sorption from 1 M HCl solutions Cr capacity reduction from S1 to S2 and from S2 to S3 was 18.2% and 27.3%, whereas from 3 M HCl solutions it was 16.2% and 12.8%. Only in the more concentrated solutions of HCl (6 M HCl) the Cr reduction was very high and equal to 88.9% and 60%. As found by Yahorava et al. [65] during the Co(II) and Cu(II) sorption on the Fiban sorbents, Fiban AK-22(3) lost its capacity within only 10 cycles of adsorption and elution, whereas Fiban X-1 retained capacity over 20 cycles of adsorption and desorption and in this case the desorption from Fiban X-1 was quantitative. Desorption efficiency of Cu(II) from SCAM-1 (cellulose sorbent, surface area = 189.12 m2/g) was 62.1–100% using a HCl or NaOH solution, whereas using 2 M HCl almost 100% of the Cu(II) was removed. The sorbent SCAM-1 is a promising adsorbent for copper removal from copper-bearing wastewaters because after 10 replications of adsorption and desorption cycles adsorption capacity is still on a similar level whereas after 20 or 30 cycles the capacity values reduction was only 2.6% and 7.2% [66].

Conclusions

Eight sorbents were applied for copper(II) ions sorption from the chloride and chloride–nitrate(V) solutions. Sorption studies indicate that Lewatit MonoPlus TP 220 shows the highest affinity for Cu(II) ions compared to the other ion exchangers under discussion in all examined HCl and HCl–HNO3 systems and was selected for future studies. Moreover, the kinetic studies show that the amount of Cu(II) sorbed on Lewatit MonoPlus TP 220 depends on the time of agitation and the ion exchanger is characterized by moderately fast kinetics, the time required to reach equilibrium was higher than 120 min (HCl systems) and higher than 60 min (HCl–HNO3 systems). Additionally, the sorption of Cu(II) on Lewatit MonoPlus TP 220 could be described by the pseudo-second-order kinetic equation (Δq = 4.78–12.53%, χ2 = 0.09–0.22). High sorption ability for copper(II) was also confirmed by the equilibrium studies [sorption capacity of Lewatit MonoPlus TP 220 towards Cu(II) = 230.2 mg/g and was much higher for the other sorbents (sorption capacities from 140 to 117.8 mg/g)]. The maximum sorption capacity calculated from the Langmuir model (Q0 = 221.43 mg/g) was close to the experimental one indicating favourable sorption and good fitting of experimental results. The FTIR studies confirmed the coordinated binding mechanism during the Cu(II) sorption on Lewatit MonoPlus TP 220 and on all examined sorbents is anion exchange, coordinate, electrostatic interaction or mixed. Selectivity of ion exchange resins towards copper(II) ions during the simultaneous sorption of Pd(II) and Cu(II) ions from the acidic solutions increases in the presence of Pd(II) increase. Lewatit MonoPlus TP 220 shows also a high sorption ability for noble metals from single and three-component solutions, particularly for Au(III)—column test). Desorption of Cu(II) from Lewatit MonoPlus TP 220 was the highest using 2 M NH4OH (it was not quantitative), but the additional sorption–desorption tests show that this ion exchanger is a promising candidate for Cu(II) removal from the model and real acidic streams.

References

Beatty R (2001) The element copper. Marshall Cavendish, New York

Modrogan C, Miron AR, Orbulet OD, Costache C, Apostol G (2015) Ion exchange process on weak acid resins for wastewater containing copper ions treatment. Environ Eng Manag J. 14:449–454

Davis JR (ed) (2001) Copper and copper alloys. ASM International, Cleveland

Piontek M, Fedyczak Z, Łuszczyńska K, Lechów H (2014) Toksyczność miedzi, cynku oraz kadmu, rtęci i ołowiu dla człowieka, kręgowców i organizmów wodnych. Inżynieria środowiska 35:70–83 (in Polish)

Günter J, Kundig KJA (1999) Copper: its trade, manufacture, use, and environmental status. ASM International, Cleveland

Anyadike N (2002) Copper: a material for the new millennium. Woodhead Publishing Ltd., Cambridge

Kołodyńska D, Sofińska-Chmiel W, Mendyk E, Hubicki Z (2014) Dowex M4195 and Lewatit MonoPlus TP220 in heavy metal ions removal from acidic streams. Sep Sci Technol 49:2003–2015. https://doi.org/10.1080/01496395.2014.908920

Giannopoulou I, Panias D (2007) Copper and nickel recovery from acidic polymetallic aqueous solutions. Min Eng 20:753–760. https://doi.org/10.1016/j.mineng.2007.02.009

Nguyen NV, Lee J, Jha MK, Yoo K, Jeong J (2009) Copper recovery from low concentration waste solutions using Dowex G-26 resin. Hydrometallurgy 97:237–242. https://doi.org/10.1016/j.hydromet.2009.03.003

Al-Saydeh SAA, El-Naas MH, Zaidi SJ (2017) Copper removal from industrial wastewater: a comprehensive review. J Ind Eng Chem 56:35–44. https://doi.org/10.1016/j.jiec.2017.07.026

Sharma S, Bhattacharya A (2017) Drinking water contamination and treatment techniques. Appl Water Sci 7:1043–1067. https://doi.org/10.1007/s13201-016-0455-7

Crini G, Lichtfouse E (2019) Advantages and disadvantages of techniques used for wastewater treatment. Environ Chem Lett 17(1):145–155. https://doi.org/10.1007/s10311-018-0785-9

Kanamarlapudi SLRK, Chintalpudi VK, Muddada S (2018) Application of biosorption for removal of heavy metals from wastewater. InTech 4:69–116. https://doi.org/10.5772/intechopen.77315

Fu F, Wang Q (2011) Removal of heavy metal ions from wastewaters: a review. J Environ Manag 92(3):407–418. https://doi.org/10.1016/j.jenvman.2010.11.011

Fonseca Couto C, Lange LC, Santos Amaral MC (2018) A critical review on membrane separation processes applied to remove pharmaceutically active compounds from water and wastewater. J Water Process Eng 26:156–175. https://doi.org/10.1016/j.jwpe.2018.10.010

Rubio J, Souza ML, Smith RW (2002) Overview of flotation as a wastewater treatment technique. Miner Eng 15:139–155. https://doi.org/10.1016/s0892-6875(01)00216-3

Ingle AP, Paralikar P, Shende S, Gupta I, Biswas JK, da Silva Martins LH, Rai M (2018) Copper in medicine: Perspectives and toxicity, chapter 4. In: Rai M, Ingle AP, Medici S (eds) Biomedical applications of metals. Springer, Cham, pp 95–112. https://doi.org/10.1007/978-3-319-74814-6_4

Senczuk W (2005) Toksykologia współczesna. PZWL, Warszawa (in Polish)

Yruela I (2009) Copper in plants: acquisition, transport and interactions. Funct Plant Biol 36:409–430. https://doi.org/10.1590/s1677-04202005000100012

Demayo A, Taylor MC, Taylor KW, Wiersma GB (1982) Effects of copper on humans, laboratory and farm animals, terrestrial plants, and aquatic life. J Crit Rev Environ Control 12(3):183–255. https://doi.org/10.1080/10643388209381697

Rao CRM, Reddi GS (2000) Platinum group metals (PGM); occurrence, use and recent trends in their determination. Trends Anal Chem 19:565–586. https://doi.org/10.1016/S0165-9936(00)00031-5

Godlewska-Żyłkiewicz B (2004) Preconcentration and separation procedures for the spectrochemical determination of platinum and palladium. Microchim Acta 147:189–210. https://doi.org/10.1016/S0165-9936(00)00031-5

Gaita R, AlBazi SJ (1995) An ion-exchange method for selective separation of palladium, platinum and rhodium from solutions obtained by leaching automotive catalytic converters. Talanta 42:249–255. https://doi.org/10.1016/0039-9140(94)00246-O

Xing WD, Sohn SH, Lee MS (2020) A review on the recovery of noble metals from anode slimes. Mineral Process Extr Metall Rev 41(2):130–145. https://doi.org/10.1080/08827508.2019.1575211

Wang W, Xu Z, Huang ST, Yang LM, Cai LL, Ji ZG, Li Y (2014) Characteristics research and selective leaching of anode slime with high content of copper and stannum. Adv Mater Res 1010–1012:1594–1597. https://doi.org/10.4028/www.scientific.net/AMR.1010-1012.1594

Harland CE (1994) Ion exchange: theory and practice. Royal Society of Chemistry, Cambridge

Ciesielczyk F, Bartczak P, Klapiszewski Ł, Jesionowski T (2017) Treatment of model and galvanic waste solutions of copper(II) ions using a lignin/inorganic oxide hybrid as an effective sorbent. J Hazard Mater 328:150–159. https://doi.org/10.1016/j.jhazmat.2017.01.009

Samadi N, Ansari R, Khoavirdilo B (2017) Removal of Copper ions from aqueous solutions using polymer derivations of poly (styrene-alt-maleic anhydride). Egyptian J. Petrol. 26:375–389. https://doi.org/10.1016/j.ejpe.2016.05.010

Balistrieri LS, Murray JW (1981) The surface chemistry of goethite (α-FeOOH) in major ion seawater. Am J Sci 281:788–806. https://doi.org/10.2475/ajs.281.6.788

Fiol N, Villaescusa I (2009) Determination of sorbent point zero charge: usefulness in sorption studies. Environ Chem Lett 7:79–84. https://doi.org/10.1007/s10311-008-0139-0

Wołowicz A, Hubicki Z (2012) The use of the chelating resin of a new generation Lewatit MonoPlus TP-220 with the bis-picolylamine functional groups in the removal of selected metal ions from acidic solutions. Chem Eng J 197:493–508. https://doi.org/10.1016/j.cej.2012.05.047

Wołowicz A, Hubicki Z (2014) Polyacrylate ion exchangers in sorption of noble and base metal ions from single and tertiary component solutions. Solv Extr Ion Exch 32:189–205. https://doi.org/10.1080/07366299.2013.838494

Wołowicz A, Hubicki Z (2016) Sorption behavior of Dowex PSR-2 and Dowex PSR-3 resins of different structures for metal(II) removal. Solvent Extr Ion Exch 34:375–397. https://doi.org/10.1080/07366299.2016.1187983

Wołowicz A, Hubicki Z (2016) Carbon-based microporous adsorber Lewatit AF 5 applicability in metal ion recovery. Micropor Mesopor Mater 224:400–414. https://doi.org/10.1016/j.micromeso.2015.12.051

Edebali S, Pehlivan E (2016) Evaluation of chelate and cation exchange resins to remove copper ions. Powder Technol 301:520–525. https://doi.org/10.1016/j.powtec.2016.06.011

Hubicki Z, Kołodyńska D (2012) Selective removal of heavy metal ions from waters and waste waters using ion exchange methods, Chapter 8. In: Kilislioğlu A (ed) Ion exchange technologies. In Tech, London, pp 193–240

Kołodyńska D (2009) Chelating ion exchange resins in removal of heavy metal ions from waters and wastewaters in presence of a complexing agent. Przem Chem 88:182–189 (in Polish)

Sengupta AK, Zhu Y, Hauze D (1991) Metal(II) in binding onto chelating exchangers with nitrogen donor atoms: some new observations and related implications. Environ Sci Technol 25:481–488. https://doi.org/10.1021/es00015a016

Zonga L, Liua F, Chena D, Zhanga X, Linga Ch, Lia A (2018) A novel pyridine based polymer for highly efficient separation of nickel from high-acidity and high-concentration cobalt solutions. Chem Eng J 334:995–1005. https://doi.org/10.1016/j.cej.2017.10.127

Chatterjee PK, SenGupta AK (2011) Interference-free detection of trace copper in the presence of EDTA and other metals using two complementary chelating polymers. Colloids Surf A Physicochem Eng Aspects 384:432–441. https://doi.org/10.1016/j.colsurfa.2011.04.031

Langmuir I (1918) The adsorption of gases on plane surfaces of glass, mica and platinum. J Am Chem Soc 40:1361–1368

Freundlich HMF (1906) Over the adsorption in solution. J Phys Chem 57:385–470

Hamidi A, Arsalane S, Halim M (2012) Kinetics and isotherm studies of copper removal by brushite calcium phosphate: linear and non-linear regression comparison. E-J Chem 9:1532–1542

Jayakumar R, Rajasimman M, Karthikeyan C (2015) Optimization, equilibrium, kinetic, thermodynamic and desorption studies on the sorption of Cu(II) from an aqueous solution using marine green algae: Halimeda gracilis. Ecotoxicol Environ Saf 21:199–210. https://doi.org/10.1016/j.ecoenv.2015.03.040

Burakov AE, Galunin EV, Burakova IV, Kucherova AE, Agarwal S, Tkachev AG, Gupta VK (2018) Adsorption of heavy metals on conventional and nanostructured materials for wastewater treatment purposes: a review. Ecotoxicol Environ Saf 148:702–712. https://doi.org/10.1016/j.ecoenv.2017.11.034

Ihsanullah, Abbas A, Al-Amer AM, Laoui T, Al-Marri MJ, Nasser MS, Khraisheh M, Atieh MA (2016) Heavy metal removal from aqueous solution by advanced carbon nanotubes: critical review of adsorption applications. Sep Purif Technol 157:141–161. https://doi.org/10.1016/j.seppur.2015.11.039

Wołowicz A, Hubicki Z (2012) Ion exchange recovery of palladium(II) from acidic solutions using monodisperse Lewatit SR-7. Ind Eng Chem Res 51:16688–16696. https://doi.org/10.1021/ie302304c

Wołowicz A, Hubicki Z (2014) Adsorption characteristics of noble metals on the strongly basic anion exchanger Purolite A 400 TL. J Mater Sci 49:6191–6202. https://doi.org/10.1007/s10853-014-8333-x

Wołowicz A, Hubicki Z (2012) Applicability of new acrylic, weakly basic anion exchanger Purolite A-830 of very high capacity in removal of palladium(II) chlorocomplexes. Ind Eng Chem Res 51:6191–6202. https://doi.org/10.1021/ie202859n

Kononova ON, Karplakova NS, Duba EV (2015) Sorption recovery of platinum(II, IV) in presence of copper(II) and zinc(II) from chloride solutions. J Serb Chem Soc 80:1149–1160. https://doi.org/10.2298/JSC141217018K

Kononova ON, Kuznetsova MA, Melnikov AM, Karplakova NS, Kononov YS (2014) Sorption recovery of copper(II) and zinc(II) from aqueous chloride solutions. J Serb Chem Soc 79:1037–1049. https://doi.org/10.2298/JSC130911033K

Zhao H, Chang J, Boika A, Bard AJ (2013) Electrochemistry of high concentration copper chloride complexes. Anal Chem 85:7696–7703. https://doi.org/10.1021/ac4016769

Kononova ON, Duba EV, Shnaider NI, Pozdnyakov IA (2017) Ion exchange extraction of platinum(IV) and palladium(II) from hydrochloric acid solutions. Russ J Appl Chem 90:1239–1245. https://doi.org/10.1134/S1070427217080080

Dada OA, Adekola FA, Odebunmi EO (2017) A novel zerovalent manganese for removal of copper ions: synthesis, characterization and adsorption studies. Appl Water Sci 7:1409–1427. https://doi.org/10.1007/s13201-015-0360-5

Mohebbi A, AbolghasemiMahani A, Izadi A (2019) Ion exchange resin technology in recovery of precious and noble metals. Appl Ion Exch Mater Chem Food Ind 9:193–258. https://doi.org/10.1007/978-3-030-06085-5_9

Salter RS, Wyslouzil DM, McDonald GW (eds) (1987) Proceedings of the international symposium of gold metallurgy. Pergamon Press, Canada

Dada OA, Adekola FA, Odebunmi EO (2015) Kinetics and equilibrium models for sorption of Cu(II) onto a novel manganese nano-adsorbent. J Dispers Sci Technol 37:119–133. https://doi.org/10.1080/01932691.2015.1034361

Faghihian H, Nourmoradi H, Shokouh M (2014) Removal of copper (II) and nickel (II) from aqueous media using silica aerogel modified with amino propyl triethoxysilane as an adsorbent: equilibrium, kinetic, and isotherms study. Desalin Water Treat 54:305–313. https://doi.org/10.1080/19443994.2013.785367

Samadi N, Ansari R, Khodavirdilo B (2017) Removal of Copper ions from aqueous solutions using polymer derivations of poly (styrene-alt-maleic anhydride). Egypt J Pet 26:375–389. https://doi.org/10.1016/j.ejpe.2016.05.010

Cho DW, Jeon BH, Chon ChM, Kim Y, Schwartz FW, Lee ES, Song H (2012) A novel chitosan/clay/magnetite composite for adsorption of Cu(II) and As(V). Chem Eng J 200–202:654–662. https://doi.org/10.1016/j.cej.2012.06.126

Wan Ngah WS, Teong LC, Toh RH, Hanafiah MAKM (2013) Comparative study on adsorption and desorption of Cu(II) ions by three types of chitosan–zeolite composites. Chem Eng J 223:231–238. https://doi.org/10.1016/j.cej.2013.02.090

Sofińska-Chmiel W, Kołodyńska D (2018) Application of ion exchangers for the purification of galvanic wastewater from heavy metals. Sep Sci Technol 53:1097–1106. https://doi.org/10.1080/01496395.2017.1330350

Yahorava V, Kotze M, Auerswald D (2013) Evaluation of different adsorbents for copper removal from cobalt electrolyte. In: The Southern African Institute of Mining and Metallurgy Base Metals Conference 2013, pp 283–297

Da’na E, Sayari A (2013) Modeling adsorption of copper on amine-functionalized SBA-15: predicting breakthrough curves. J Environ Eng 139(1):95–103. https://doi.org/10.1061/(ASCE)EE.1943-7870.0000602

Marsh H, Rodriguez F (2006) Activated carbon. Elsevier, Edinburgh

Liu M, Deng Y, Zhan H, Zhang X (2002) Adsorption and desorption of copper(II) from solutions on new spherical cellulose adsorbent. J Appl Polym Sci 84:478–485. https://doi.org/10.1002/app.10114

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Wołowicz, A., Hubicki, Z. Enhanced removal of copper(II) from acidic streams using functional resins: batch and column studies. J Mater Sci 55, 13687–13715 (2020). https://doi.org/10.1007/s10853-020-04982-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-04982-z