Abstract

This paper presents a theoretical approach to determine the dynamic fatigue strength characteristics of ceramics under variable loading rates on the basis of the slow crack growth (SCG) concept. First, a probabilistic effective inert strength model was derived on the basis of the SCG concept in conjunction with the Weibull distribution for ceramics subjected to multi-stage loading. Second, a four-point bending test was conducted on \(\hbox {Al}_{{2}}\hbox {O}_{{3}}\) under constant and two-stage variable loading rates, and the fracture surface was then observed. The experimental data that depend on loading rates can be unifiedly evaluated after converting the data to the effective inert strength, obeying the three-parameter Weibull distribution. In addition, the Weibull plots of the inert strength, which were calculated from the inclusion size on the fracture surface using the grain fracture model, showed good agreement with the three-parameter Weibull distribution for the converted effective inert strength. These analytical results theoretically indicate that dynamic fatigue under variable loading rates occurs by obeying SCG at the inclusion. Further, the inert strength and its scatter depend on the size and distribution of inclusions.

Similar content being viewed by others

References

Breder K (1995) Time-dependent strength degradation of a siliconized silicon carbide determined by dynamic fatigue. J Am Ceram Soc 78(10):2680–2684

Choi G, Horibe S (1993) The influence of variable-amplitude loading on cyclic-fatigue crack growth in silicon nitride. J Mater Sci Lett 12(24):1886–1887

Choi SR, Nemeth NN, Gyekenyesi JP (2005) Exponential slow crack growth of glass and advanced ceramics-dynamic fatigue. Fatigue Fract Eng Mater Struct 28(5):489–497

Evans AG (1980) Fatigue in ceramics. Int J Fract 16(6):485–498

Evans AG, Fuller ER (1974) Crack propagation in ceramic materials under cyclic loading conditions. Metall Trans 5:27–33

Evans AG, Johnson H (1975) The fracture stress and its dependence on slow crack growth. J Mater Sci 10(2):214–222

Evans AG, Lange FF (1975) Crack propagation and fracture in silicon carbide. J Mater Sci 10(10):1659–1664

Evans AG, Wiederhorn SM (1974a) Proof testing of ceramic materials-an analytical basis for failure prediction. Int J Fract 10(3):379–392

Evans AG, Wiederhorn SM (1974b) Crack propagation and failure prediction in silicon nitride at elevated temperature. J Mater Sci 9(2):270–278

Evans AG, Russell LR, Richerson DW (1975) Slow crack growth in ceramic materials at elevated temperatures. Metall Mater Trans A 6:707–716

Gilberta CJ, Ritchiea RO (1998) Transient fatigue-crack growth behavior following variable-amplitude loading in a monolithic silicon nitride ceramic. Eng Fract Mech 60(3):303–313

Guiu F, Reece MJ, Vaughan DAJ (1991) Cyclic fatigue of ceramics. J Mater Sci 26:3275–3286

Hasselman DPH, Chen EP, Ammann CL, Doherty JE, Nessler CG (1975) Failure prediction of the thermal fatigue of silicon nitride. J Am Ceram Soc 58(11–12):513–516

Hoshide T, Hiramatsu H (1999) A microstructural approach to flaw size dependence of strength in engineering ceramics. Fatig Fract Eng Mater Struct 22(12):1029–1039

Hoshide T, Ohara T, Yamada T (1988) Fatigue behavior of ceramic materials under variable stress amplitude. Eng Fract Mech 31(2):339–347

Kamiya N, Kamigaito O (1982) Thermal fatigue life of ceramics under mechanical load. J Mater Sci 17(11):3149–3157

Matsuda S (2016) Fracture characteristics of silicon nitride ceramic ball subjected to thermal shock. J Mater Sci 51(11):5502–5513

Matsuda S, Ogi K (2017) Effect analysis of loading rate on relationship between strength and flaw size of ceramics using probabilistic model on the basis of SCG concept. Trans JSME 83(847):16–00369

Matsuda S, Watanabe R (2011) Estimation of dynamic fatigue strengths in brittle materials under a wide range of stress rates. J Mater Sci 46(15):5056–5063

Ogi K, Ito K (2011) A probabilistic approach for thermal shock fatigue life of glass. Fatigue Fract Eng Mater Struct 34(9):643–653

Ogi K, Yashiro S, Niimi K (2010) A probabilistic approach for transverse crack evolution in a composite laminate under variable amplitude cyclic loading. Compos A 41(3):383–390

Okabe N, Ikeda T (1991) Strength evaluation method and design optimization for ceramic gas turbine blades. Mater Sci Eng A 143(1–2):11–19

Pan LS, Matsuzawa M, Horibe S (1998) Stress rate dependence of fracture strength in pre-cracked zirconia ceramics. Mater Sci Eng A 244(2):199–206

Pfingsten T, Glien K (2006) Statistical analysis of slow crack growth experiments. J Eur Ceram Soc 26(15):3061–3065

Phani KK (1988) Analysis of static and dynamic fatigue of polycrystalline alumina. J Mater Sci 23(11):3864–3868

Quinn GD, Salem J, Bar-on I, Cho K, Foley M, Fang H (1992) Fracture toughness of advanced ceramics at room temperature. J Res Natl Inst Stand Technol 97(5):579–607

Ritter JE (1995) Predicting lifetimes of materials and material structures. Dent Mater 11(2):142–146

Ritter JE Jr, Humenik JN (1979) Static and dynamic fatigue of polycrystalline alumina. J Mater Sci 14(3):626–632

Sakai T, Tanaka T (1980) Estimation of three parameters of Weibull distribution in relation to parameter estimation of fatigue life distribution: continued report. J Soc Mater Sci Jpn 29(316):17–23

Seshadri SG, Srinivasan M, Weber GW (1982) Evaluation of slow crack growth parameters for silicon carbide ceramics. J Mater Sci 17(5):1297–1302

Siegmund T (2004) A numerical study of transient fatigue crack growth by use of an irreversible cohesive zone model. Int J Fatigue 26(9):929–939

Tanaka T, Nakayama H, Okabe N, Yamamoto S, Fukui S (2002) Creep rupture map of engineering fine ceramics. In: Bradt RC et al (eds) Fracture mechanics of ceramics, vol 10. Plenum Press, New York, pp II-308–II-326

Teixeira EC, Piascik JR, Stoner BR, Thompson JY (2007) Dynamic fatigue and strength characterization of three ceramic materials. J Mater Sci Mater M 18(6):1219–1224

To T, Célarié F, Roux-Langlois C, Bazin A, Gueguen Y, Orain H, Le Fur M, Burgaud V, Rouxel T (2018) Fracture toughness, fracture energy and slow crack growth of glass as investigated by the single-edge precracked beam (SEPB) and chevron-notched beam (CNB) methods. Acta Mater 146:1–11

Usami S, Kimoto H, Takahashi I, Shida S (1986) Strength of ceramic materials containing small flaws. Eng Fract Mech 23(4):745–761

Wiederhorn SW, Bolz LH (1970) Stress corrosion and static fatigue of glass. J Am Ceram Soc 53(10):543–548

Zhu P, Lin Z, Chen G, Ikeda K (2004) The predictions and applications of fatigue lifetime in alumina and zirconia ceramics. Int J Fatigue 26(10):1109–1114

Acknowledgements

I would like to show my greatest appreciation to Prof. K. Ogi (Ehime University, Japan) whose comments and advice were highly valuable throughout the course of my study.

Funding

This work was supported by JSPS KAKENHI [Grant Number 17K14563].

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix: Determination of SCG parameters

Appendix: Determination of SCG parameters

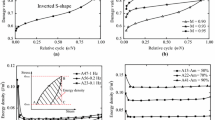

The SCG parameters n and \(g_{\mathrm{o}} \) were determined using the \(\sigma _{\mathrm {max}} -\dot{\sigma }\) plots (loading rate \(\dot{\sigma })\) in the CLR test shown in Fig. 6a by rewriting Eq. (9) as follows:

The ratio \(S_{\mathrm{i}}^*/\sigma _{\mathrm {max}} \) on the left-hand side of Eq. (18) was plotted against \(x=\sigma _{\mathrm {max}} ^{2}t_{\mathrm {eff}} \). Here, the effective inert strength \(S_{\mathrm{i}}^*\) was assumed to be the average of \(\sigma _{\mathrm {max}} \) in the CLR test under \(\hbox {CHS} = 200\,\hbox {mm}\,\hbox {min}^{-1}\) , which converges to the inert strength as shown in Fig. 6a, and the effective loading time \(t_{\mathrm {eff}} \) was calculated using Eq. (4) and the applied stress \(\sigma \left( t \right) =\dot{\sigma }t\) (period stress \(\sigma _{\mathrm {max}} =\dot{\sigma }t_{\mathrm{f}} )\) as \(\sigma _{\mathrm {max}}/\left\{ {\dot{\sigma }\left( {n+1} \right) } \right\} \). Then, n and \(g_{\mathrm{o}} \) were obtained by curve fitting these plots to the equation \(y=1/\left( {n-2} \right) \ln \left( {1+g_{\mathrm{o}} x} \right) \) using the least squares method, as shown in Fig. 6b. The values of n and \(g_{\mathrm{o}}\) were obtained as 21.1 and \(2.54\times 10^{-3}\,\hbox {MPa}^{-2}\,\hbox {s}^{-1}\), respectively. The value of n was smaller than \(n = 37.5\), which was obtained by Ritter and Humenik (1979). They conducted the CLR test under the loading rate region from 1/10 to 1/100 of the lowest loading rate of the CLR test in this study. Then, n was analyzed by curve fitting the obtained \(\sigma _{\mathrm {max}} -\dot{\sigma }\) plots to the equation \(\sigma _{\mathrm {max}} \propto \dot{\sigma }^{1/\left( {n+1} \right) }\), which is obtained on the basis of the SCG concept. On the other hand, on analyzing the S–N diagram in the cyclic fatigue test and the S–t diagram in the static fatigue test, the value of n varied between 21–25 and 36–54, respectively (Guiu et al. 1991). The value of n obtained from the S–N diagram almost agrees with this experimental result. The value of n differs depending on the loading method and the loading rate region.

Rights and permissions

About this article

Cite this article

Matsuda, S. Theoretical approach to determine dynamic fatigue strength characteristics of ceramics under variable loading rates on the basis of SCG concept. Int J Fract 215, 175–182 (2019). https://doi.org/10.1007/s10704-018-00337-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10704-018-00337-7