Abstract

In the present work, the two-dimensional analytical solution for Li diffusion in grains and grain boundaries of a polycrystalline film electrode is established with consideration of Li-segregation at the grain boundary. The stress field induced by the inhomogeneity of Li concentration, called chemical stress here for brevity, is analyzed via the finite element simulation. The effects of the grain boundary including its size, its diffusion coefficient as well as the segregation phenomenon on the solute concentration and the chemical stress are examined. It shows that grain boundaries can assist fast diffusion and significantly affect the stress profile in the whole film. It proves that tailoring the grain boundary size or other grain boundary-related parameters may provide an alternative strategy for improving the overall diffusivity and mechanical stability of battery electrodes.

Similar content being viewed by others

Change history

22 November 2018

In all the articles in Acta Mechanica Solida Sinica, Volume 31, Issues 1–4, the copyright is incorrectly displayed as “The Chinese Society of Theoretical and Applied Mechanics and Technology ” where it should be “The Chinese Society of Theoretical and Applied Mechanics”.

Abbreviations

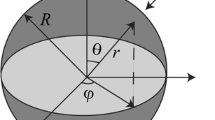

- x (\(x'\)) and y :

-

Coordinates

- t :

-

Time

- \(Y_{0}\) :

-

Film thickness

- L :

-

Half grain width

- a :

-

Half GB width

- C and \(C^\prime \) :

-

Li concentrations in grain and GB

- D and \(D^\prime \) :

-

Diffusion coefficients for grain and GB

- \(\Delta G\) :

-

Free energy of segregation

- K :

-

Segregation coefficient

- R :

-

Gas constant

- T :

-

Absolute temperature

- \(J_\mathrm{a}\) :

-

Apparent diffusion flux

- \(J_{0}\) and \(J_{0}^{\prime }\) :

-

Diffusion fluxes entering grain surface and GB surface

- \(\varDelta \) :

-

Ratio of diffusion coefficients

- \(\alpha _{mn}, {\alpha }_{mn}^{\prime }, \beta _n, A_{mn}, {A}_{mn}^{\prime }\) :

-

Coefficients in solutions of concentration

- \({\bar{x}} \, ({{\bar{x}}^{\prime }})\) and \({\bar{y}}\) :

-

Dimensionless coordinates

- \({\bar{t}}\) :

-

Dimensionless time

- \({\bar{a}}\) :

-

Dimensionless GB size

- \({\bar{\alpha }}_{mn}, {\bar{\alpha }}_{mn}^{\prime }, {\bar{\beta }}_n, {\bar{A}}_{mn}, {\bar{A}}_{mn}^{\prime }\) :

-

Dimensionless coefficients in solutions of concentration

- \({\bar{C}}\) and \({{\bar{C}}^{\prime }}\) :

-

Dimensionless concentration

- \(\sigma _{{\textit{ij}}}\) and \({\sigma }_{{\textit{ij}}}^{\prime }\) :

-

Stress components

- \(\varepsilon _{{\textit{ij}}}\) and \({\varepsilon }_{{\textit{ij}}}^{\prime }\) :

-

Strain components

- \(E (E^{\prime })\), \(\upsilon \, (\upsilon ^{\prime })\) and \({\varOmega }\, ({\varOmega }^{\prime })\) :

-

Young’s modulus, Poisson’s ratio and partial molar volume

- \(u_{i}\) :

-

Displacement components

- \({\bar{\sigma }}_{{\textit{ij}}}\) and \({\bar{\sigma }}_{{\textit{ij}}}^{\prime }\) :

-

Dimensionless stress

- \({\bar{{\varOmega }}}\) and \({\bar{{\varOmega }}}^{\prime }\) :

-

Dimensionless partial molar volume

- \(\gamma \) :

-

Ratio of Young’s moduli

References

Han SW, Park JH, Lu W, Sastry AM. Numerical study of grain boundary effect on \(\text{ Li }^{+}\) effective diffusivity and intercalation-induced stresses in Li-ion battery active materials. J Power Sources. 2013;240:155–67.

Kolobov YR, Grabovetskaya GP, Ivanov MB, Zhilyaev AP, Valiev RZ. Grain boundary diffusion characteristics of nanostructured nickel. Scr Mater. 2001;44(6):873–8.

Balke N, Jesse S, Morozovska AN, Eliseev E, Chung DW, Kim Y, Adamczyk L, Garcia RE, Dudney N, Kalinin SV. Nanoscale mapping of ion diffusion in a lithium-ion battery cathode. Nat Nanotechnol. 2010;5(10):749–54.

Lu B, Song YC, Zhang JQ. Selection of charge methods for lithium ion batteries by considering diffusion induced stress and charge time. J Power Sources. 2016;320:104–10.

Park MG, Zhang XC, Chung MD, Less GB, Sastry AM. A review of conduction phenomena in Li-ion batteries. J Power Sources. 2010;195(24):7904–29.

Deshpande R, Verbrugge M, Chen Y-T, Wang J, Liu P. Battery cycle life prediction with coupled chemical degradation and fatigue mechanics. J Electrochem Soc. 2012;159(10):A1730–8.

Vette J, Novak P, Wagner MR, Veit C, Moller M-C, Besenhard JO, Winter M, Wohlfahrt-Mehrens M, Vogler C, Hammouche A. Ageing mechanisms in lithium-ion batteries. J Power Sources. 2005;147(1–2):269–81.

Xiao X, Liu P, Verbruggea MW, Haftbaradaran H, Gao H. Improved cycling stability of silicon thin film electrodes through patterning for high energy density lithium batteries. J Power Sources. 2011;196(3):1409–16.

Haftbaradaran H. Solute segregation and stress intensity factors at the edge of elastic thin-film electrodes under chemical equilibrium. J Power Sources. 2015;288:278–87.

Kushima A, Liu XH, Zhu G, Wang ZL, Huang JY, Li J. Leapfrog cracking and nanoamorphization of ZnO nanowires during in situ electrochemical lithiation. Nano Lett. 2011;11(11):4535–41.

Liu XH, Zhong L, Huang S, Mao SX, Zhu T, Huang JY. Size-dependent fracture of silicon nanoparticles during lithiation. ACS Nano. 2012;6(2):1522–31.

Soni SK, Sheldon BW, Xiao XC, Tokranov A. Thickness effects on the lithiation of amorphous silicon thin films. Scr Mater. 2011;64(4):307–10.

Zhang TY, Ren H. Solute concentrations and strains in nanograined materials. Acta Mater. 2013;61(2):477–93.

Wang C, Wang S, He Y-B, Tang Y, Han CP, Yang C, Wagemaker M, Li BH, Yang Q-H, Kim J-K, Kang FY. Combining fast Li-ion battery cycling with large volumetric energy density: grain boundary induced high electronic and ionic conductivity in \(\text{ Li }_4\text{ Ti }_5\text{ O }_12\) spheres of densely packed nanocrystallites. Chem Mater. 2015;27(16):5647–56.

Diercks DR, Musselman M, Morgenstern A, Wilson T, Kumar M, Smith K, Kawase M, Gorman BP, Eberhart M, Packard CE. Evidence for anisotropic mechanical behavior and nanoscale chemical heterogeneity in cycled LiCoO\(_2\). J Electrochem Soc. 2014;161(11):F3039–45.

Fisher JC. Calculation of diffusion penetration curves for surface and grain boundary diffusion. J Appl Phys. 1951;22(1):74–7.

Whipple RTP. Concentration contours in grain boundary diffusion. Philos Mag. 1954;45(371):1225–36.

Gilmer GH, Farrell HH. Grain-boundary diffusion in thin films. I. The isolated grain boundary. J Appl Phys. 1976;47(9):3792.

Gilmer GH, Farrell HH. Grain-boundary diffusion in thin films. II. Multiple grain boundaries and surface diffusion. J Appl Phys. 1976;47(10):4373.

Preis W, Sitte W. Fast grain boundary diffusion and rate-limiting surface exchange reactions in polycrystalline materials. J Appl Phys. 2005;97(9):093504.

Preis W. Fast grain boundary diffusion and surface exchange reactions at active surface sites of polycrystalline material. Phys Chem Chem Phys. 2006;8(22):2629–34.

Liu LL, Zhang TY. Diffusion through a polycrystalline thin film. Appl Phys A Mater Sci Proc. 2009;96(2):515–20.

Amissah KB, Rickman JM, Chan HM, Harmer MP. Impact of microstructure on grain-boundary diffusion in polycrystals. J Appl Phys. 2005;98(6):063511.

Song YC, Shao XJ, Guo ZS, Zhang JQ. Role of material properties and mechanical constraint on stress-assisted diffusion in plate electrodes of lithium ion batteries. J Phys D Appl Phys. 2013;46(10):105307.

Crank J. The mathematics of diffusion. London: Oxford University Press; 1979.

Özisik MN. Heat conduction. New York: Wiley; 1993.

Lu B, Zhao YF, Song YC, Zhang JQ. Analytical model on lithiation-induced interfacial debonding of an active layer from a rigid substrate. J Appl Mech. 2016;83(12):121009.

Qi Y, Hector LG Jr, James C, Kim KJ. Lithium concentration dependent elastic properties of battery electrode materials from first principles calculations. J Electrochem Soc. 2014;161(11):F3010–8.

Zhang JQ, Lu B, Song YC, Ji X. Diffusion induced stress in layered Li-ion battery electrode plates. J Power Sources. 2012;209:220–7.

Wang DY, Wu XD, Wang ZX, Chen LQ. Cracking causing cyclic instability of \({\text{ LiFePO }}_{4}\) cathode material. J Power Source. 2005;140(1):125–8.

Watanabe T. The impact of grain boundary character distribution on fracture in polycrystals. Mater Sci Eng A. 1994;176(1–2):39–49.

Okumura T, Fukutsuka T, Uchimoto Y, Sakai N, Yamaji K, Yokokawa H. Determination of lithium ion diffusion in lithium-manganese-oxide-spinel thin films by secondary-ion mass spectrometry. J Power Sources. 2009;189(1):643–5.

Acknowledgements

We would like to acknowledge the support of National Natural Science Foundation of China under Grant Nos. 11702164, 11702166, 11672168 and 11332005, the Science and Technology Commission of Shanghai Municipality under Grant No. 14DZ2261200 and Shanghai Sailing Program No. 17YF1406000.

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix A

1.1 1. Derivation of the Characteristic Equation in Eq. (10b)

By substituting the solutions given by Eqs. (10a) and (10b) into the flux continuity condition in Eq. (3) and the segregation condition in Eq. (4), we can obtain the following two equations

By considering the orthogonal relation of

Equations (A1) and (A2) become

By combining Eqs. (A4) and (A5), the characteristic equation in Eq. (11b) can be obtained.

2. Derivation of Coefficients \(A_{{\textit{nm}}}\) for the Case When GB Size is Very Small

By considering the orthogonal relation in Eq. (A3), Eq. (12) becomes

for \(n \ne 0\) and

for \(n=0\).

It should be noted that \(X_{{\textit{nm}}} (x)\) in Eq. (10c) has no obvious orthogonal property, and we have to deal with it before moving on.

Technically, we have the relation of

By considering the relation in Eq. (A8), we have

for \(m \ne l\) and

for \(m=l\).

Coefficients \(A_{{\textit{nm}}}\) for the case of \(n \ne 0\) will be determined first. By substituting Eqs. (A9) and (A10) into Eq. (A6), we can obtain

By considering the characteristic equation in Eq. (13), we have

By substituting the obtained Eq. (A12) into Eq. (A11), we can get

From Eq. (A6), we have

By combining Eqs. (A13) and (A14), we can obtain the expression of \(A_{{nm}}\) for \(n \ne 0\) as given in Eq. (14a). Similarly, \(A_{{nm}}\) for \(n =0\) can be determined by Eq. (A7) instead of Eq. (A6). But it should be noted that when \(\alpha _{0m} =0\), the limit has to be taken for obtaining the expression in Eq. (14c).

Rights and permissions

About this article

Cite this article

Zhao, Y., Lu, B. & Zhang, J. Lithium Diffusion and Stress in a Polycrystalline Film Electrode. Acta Mech. Solida Sin. 31, 290–309 (2018). https://doi.org/10.1007/s10338-018-0018-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10338-018-0018-6