Abstract

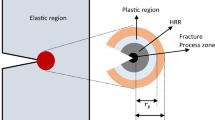

Defects in terms of three-dimensional voids are commonly encountered at bi-material interfaces. In the current study, the singular stress field near the circumferential corner line of a three-dimensional axisymmetric interfacial void is analyzed using our newly established singular interface edge elements. Under the premise that \(\rho {\ll }R\), the proposed singular element method does not depend on the size of the element; thereby, it is not necessary to use refined elements at the interface corner line. The numerical results reveal the intensity of the stress singularity at the interface line of the three-dimensional axisymmetric voids. The obtained stress intensity parameters can be used to judge the local fatigue crack initiation. The geometry effect of the void on the singular stress field at the circumferential interface corner line is studied and discussed in detail.

Similar content being viewed by others

References

Mehdikhani, M., Straumita, I., Gorbatikh, L., Lomov, S.V.: Detailed characterization of voids in multidirectional carbon fiber/epoxy composite laminates using X-ray micro-computed tomography. Composites. Part. A. 125, 105532 (2019)

Sinchuk, Y., Pannier, Y., Antoranz-Gonzalez, R., Gigliotti, M.: Analysis of moisture diffusion induced stress in carbon/epoxy 3D textile composite materials with voids by \(\mu \) -CT based Finite Element Models. Compos. Struct. 212, 561–570 (2019)

Wang, M., Beyerlein, I.J., Zhang, J., Han, W.Z.: Defect-interface interactions in irradiated Cu/Ag nanocomposites. Acta. Mater. 160, 211–223 (2018)

Wang, M., Beyerlein, I.J., Zhang, J., Han, W.Z.: Bi-metal interface-mediated defects distribution in neon ion bombarded Cu/Ag nanocomposites. Scr. Mater. 171, 1–5 (2019)

Hsu, H.L., Lee, H., Wang, C.W., Liang, C., Chen, C.M.: Impurity evaporation and void formation in Sn/Cu solder joints. Mater. Chem. Phys. 225, 153–158 (2019)

Song, R.W., Fleshman, C.J., Chen, H., Duh, J.G.: Suppressing interfacial voids in Cu/In/Cu microbump with Sn and Cu addition. Mater. Lett. 259, 126855 (2020)

Sun, L.X., Li, M.Q.: Interfacial voids, microstructure and shear strength of TC4/TC17 bond. J. Mater. Process. Tech. 270, 265–273 (2019)

Li, H.L., An, R., Wang, C.Q., Tian, Y.H., Jiang, Z.: Effect of Cu grain size on the voiding propensity at the interface of SnAgCu/Cu solder joints. Mater. Lett. 144, 97–99 (2015)

Tavoosi, M.: The Kirkendall void formation in Al/Ti interface during solid-state reactive diffusion between Al and Ti. Surf. Interfaces 9, 196–200 (2017)

Juluri, R.R., Gaiduk, P., Hansen, J.L., Larsen, A.N., Julsgaard, B.: Impact of a SiGe interfacial layer on the growth of a SiC layer on Si with voids at the interface. Thin. Solid. Films. 662, 103–109 (2018)

Asim, U.B., Siddiq, M.A., Kartal, M.E.: Representative volume element (RVE) based crystal plasticity study of void growth on phase boundary in titanium alloys. Comput. Mater. Sci. 161, 346–350 (2019)

Wang, H., Li, Z.H.: The three-dimensional analysis for diffusive shrinkage of a grain-boundary void in stressed solid. J. Mater. Sci. 39(10), 3425–3432 (2004)

Chu, K., Wang, J., Liu, Y.P.: Graphene defect engineering for optimizing the interface and mechanical properties of graphene/copper composites. Carbon. 140, 112–123 (2018)

Guo, J.X., Luo, J., Xiao, Z.M.: On the opening profile and near tip fields of an interface crack between a polymeric hydrogel and a rigid substrate. Eng. Fract. Mech. 153, 91–102 (2016)

Ayhan, A.O., Kaya, A.C., Nied, H.F.: Analysis of three-dimensional interface cracks using enriched finite elements. Int. J. Fract. 142(3–4), 255–276 (2006)

Begley, M.R., Ambrico, J.M.: Delamination of Thin Films From Two-Dimensional Interface Flaws at Corners and Edges. Int. J. Fract. 112(3), 205–222 (2001)

Chiu, T.C., Lin, H.C.: Analysis of stress intensity factors for three-dimensional interface crack problems in electronic packages using the virtual crack closure technique. Int. J. Fract. 156(1), 75–96 (2009)

Greco, F., Sgambitterra, G.: Validation of Homogenization Techniques for Locally Periodic Fiber-Reinforced Composites with Interfacial Debonding. Mech. Adv. Mater. Struct. 20, 638–651 (2013)

Veluri, B., Jensen, H.M.: Steady-state propagation of interface corner crack. Int. J. Solids. Struct. 50(10), 1613–1620 (2013)

Shiah, Y.C., Hwu, C., Yao, J.J.: Boundary element analysis of the stress intensity factors of plane interface cracks between dissimilarly adjoined anisotropic materials. Eng. Anal. Bound. Elem. 106, 68–74 (2019)

Okumura, M., Hasebe, N., Nakamura, T.: Bimaterial plane with elliptic hole under uniform tension normal to the interface. Int. J. Fract. 71, 293–310 (1995)

Pahn, L.O., Earmme, Y.Y.: Analysis of a short interfacial crack from the corner of a rectangular inclusion. Int. J. Fract. 106(4), 341–356 (2000)

Oda, K., Takahata, Y., Kasamura, K., Noda, N.A.: Stress intensity factor solution for edge interface crack based on the crack tip stress without the crack. Eng. Fract. Mech. 219, 106612 (2019)

Petrova, V., Schmauder, S., Ordyan, M., Shashkin, A.: Revisit of antiplane shear problems for an interface crack. Does the stress intensity factor for the interface Mode III crack depend on the bimaterial modulus? Eng. Fract. Mech. 216, 106524 (2019)

Tvergaard, V.: Effect of residual stresses on interface crack growth by void expansion mechanism. Int. J. Fract. 142(1–2), 43–50 (2006)

Yu, Q.M.: Influence of the stress state on void nucleation and subsequent growth around inclusion in ductile material. Int. J. Fract. 193(1), 43–57 (2015)

Koguchi, H., Yokoyama, K.: Stress analysis in three-dimensional joints with a crack at the vertex of the interface-In case of mode II. Acta. Mech. 228, 2759–2773 (2017)

Ping, X.C., Chen, M.C., Wang, C.G., Cheng, L.P.: A super crack front element for three-dimensional fracture mechanics analysis. Eng. Fract. Mech. 196, 1–27 (2018)

Sze, K.Y., Wang, H.T.: A simple finite element formulation for computing stress singularities at bimaterial interfaces. Finite. Elem. Anal. Des. 35, 97–118 (2000)

Chaudhuri, R.A.: An eigenfunction expansion solution for three-dimensional stress field in the vicinity of the circumferential line of intersection of a bimaterial interface and a hole. Int. J. Fract. 29(4), 361–384 (2004)

Chaudhuri, R.A.: Three-dimensional singular stress fields near the circumferential junction corner line of an island/substrate system either free-standing or fully/partially bonded to a rigid block. Eng. Fract. Mech. 107, 80–97 (2013)

Khanna, A., Kotousov, A., Yakubovich, S., Zakavi, B.: Asymptotic analysis of out-of-plane strain and displacement fields at angular corners. Int. J. Solids. Struct. 170, 111–122 (2019)

Labossiere, P.E.W., Dunn, M.L.: Fracture initiation at three-dimensional bimaterial interface corners. J. Mech. Phys. Solids. 49(3), 609–634 (2001)

Hasebe, N., Keer, L.M.: Anti-plane shear stress problem of two bonded dissimilar half spaces with an elliptical hole or rigid inclusion on the interface. Acta. Mech. 203(1–2), 97–111 (2009)

Hwu, C., Kuo, T.L.: Interface corners in piezoelectric materials. Acta. Mech. 214, 95–110 (2010)

Hwu, C., Huang, H.Y.: Investigation of the stress intensity factors for interface corners. Eng. Fract. Mech. 93, 204–224 (2012)

Kuo, T.L., Hwu, C.: Interface corners in linear anisotropic viscoelastic materials. Int. J. Solids. Struct. 50(3), 710–724 (2013)

Hwu, C.: A Unified Definition of Stress Intensity Factors for Cracks/ Corners/Interface Cracks/Interface Corners in Anisotropic/Piezoelectric/Viscoelastic Materials. Proc. Mat. Sci. 3, 257–263 (2014)

Abe, M., Ikeda, T., Koganemaru, M., Miyazaki, N.: Stress intensity factor analysis of a Three-dimensional Interfacial Corner between Anisotropic Piezoelectric Multi-materials under Several Boundary Conditions on the Corner Surfaces. Eng. Fract. Mech. 171, 1–21 (2016)

Scherzer, M., Kuna, M.: Combined analytical and numerical solution of 2D interface corner configurations between dissimilar piezoelectric materials. Int. J. Fract. 127(1), 61–99 (2004)

Ricotta, M., Zappalorto, M., Marchiori, M., Campagnolo, A., Meneghetti, G.: The peak stress method applied to bi-material corners. Proc. Struct. Integrity 13, 1560–1565 (2018)

Yuan, Y., Hao, W., Ma, Y.: Stress field at V-notch tip in polymer materials using digital gradient sensing. Mech. Adv. Mater. Struct. 24(4), 350–356 (2016)

Han, Z.L., Cheng, C.Z., Yao, S.L., Niu, Z.R.: Determination of stress intensity factors of V-notch structures by characteristic analysis coupled with isogeometric boundary element method. Eng. Fract. Mech. 222, 106717 (2019)

Tan, M.A., Meguid, S.A.: Analysis of bimaterial wedges using a new singular finite element. Int. J. Fract. 88(4), 373–391 (1997)

Ping, X.C., Chen, M.C., Ying, S.J.: Effects of thermomechanical properties on interface edge singular thermal stresses of Quad Flat Package solder joints. Sens. Lett. 11(6–7), 1326–1331 (2013)

Ping, X.C., Chen, M.C.: Computations of singular stresses along three-dimensional corner fronts by a super singular element method. Int. J. Comput. Methods. 14(4), 1750065 (2017)

British Standards Institution. Guide to Methods for Assessing the Acceptability of Flaws in Metallic Structures. Bs7910 British Standards (2013)

Zhang, Y.M., Fan, M., Xiao, Z.M., Zhang, W.G.: Fatigue analysis on offshore pipelines with embedded cracks. Ocean. Eng. 117, 45–56 (2016)

Ping, X.C., Zhang, Y.X., Guo, Y.B., Xiao, Z.M., Jalde, J., Chen, M.C.: Intensity of stress singularity for the circumferential V-shape corner front of a three-dimensional diamond-like defect. Fatigue. Fract. Eng. Mater. Struct. 43, 802–817 (2020)

Washizu, K.: Variational Methods in Elasticity and Plasticity, 3rd edn. Pergamon Press, Oxford (1982)

Sneddon, I.N.: The distribution of stress in the neighbourhood of a crack in an elastic solid. P. Roy. Soc. London. 187(1009), 229–260 (1946)

Rice, J.R., Sih, G.C.: Plane problems of cracks in dissimilar media. J. Appl. Mech. 32(2), 418–423 (1965)

Acknowledgements

The National Natural Science Foundation of China (Grant Nos. 51975411 and 51365013), the Tianjin Natural Science Foundation of China (Grant No. 18JCYBJC88500), and the Personnel Training Plan for Young and Middle-aged Innovation Talents in Universities in Tianjin, China, are acknowledged. The support of Singapore A*STAR SERC AME Programmatic Fund for the “Structural Metal Alloys Programme” (Project WBS M4070307.051) is also acknowledged.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

Similar to the interface crack problem, the orders of stress singularities for the singular stress terms in the interface corner domain may also be complex numbers, and the angular variations of singular stress fields change with the material mismatch. If one assumes \(\rho {\ll }R\), the displacement field \(u_{i} (\rho ,\phi ,\theta )\) including the components \(u_{\rho }\), \(u_{\phi }\) and \(u_{\theta }\) in the vicinity of the interface corner in the local coordinate system can be expressed as [30, 31]

in which \(\hbox {Re}\{\}\) represents the real part of an expression. \(\beta ^{(n)}\) is a stress intensity coefficient related to the external boundary conditions and loads, and is a function of \(\theta \), while N and M denotes the number of complex numbers and real numbers intercepted, respectively, from the asymptotic series expressions. \(\lambda _{n}\) is an order of the stress singularity, and the tensor \(u_{i}^{(n)} (\phi ,\theta )\) contains the angular variation of the displacement components corresponding to the nth terms. The third-order tensor \(u_{i}^{(n)} (\rho ,\phi ,\theta )\) is defined by \(\rho ^{\lambda _{n} +1}u_{i}^{(n)} (\phi ,\theta )\). Only the terms corresponding to \(\hbox {Re}(\lambda _{n} )>-1\) are included in the present asymptotic expressions.

The strain tensor \(\varepsilon _{ij} (\rho ,\phi ,\theta )\) including \(\varepsilon _{\rho } \), \(\varepsilon _{\phi } \), \(\varepsilon _{\theta }\), \(\varepsilon _{\rho \phi }\), \(\varepsilon _{\rho \theta }\) and \(\varepsilon _{\phi \theta }\) components with respect to the displacement components in Eq. (A1) can then be obtained from the strain–displacement relations in local coordinates \(\rho \), \(\phi \) and \(\theta \), and is expressed as follows:

where \(\varepsilon _{ij}^{(n)} (\phi ,\theta )\) is a tensor containing the angular variations of the strain components. The stress tensor \(\sigma _{ij} (\rho ,\phi ,\theta )\) with components \(\sigma _{\rho }\), \(\sigma _{\phi }\), \(\sigma _{\theta }\), \(\tau _{\rho \phi }\), \(\tau _{\rho \theta }\) and \(\tau _{\phi \theta }\) can be expressed by the strain tensor \(\varepsilon _{ij} (\rho ,\phi ,\theta )\) according to the constitutive relation, i.e.,

in which \(D_{ijkl}\) is the stiffness tensor of a linear elastic material.

A simple FEM for a 3D sectorial domain (Sze and Wang [29]) can be used to solve the 3D asymptotic singular stress fields in the vicinity of an interface corner herein. The eigenpair (i.e., the order of stress singularity \(\lambda _{n} \) and the corresponding angular variation functions) in Eqs. (A1)–(A3) can be solved numerically using this FEM.

When \(n\le N\), \(\lambda _{n} \) and \(\beta _{n} \) are both complex numbers, and \(u_{i}^{(n)} (\rho ,\phi ,\theta )\) and \(\varepsilon _{ij}^{(n)} (\rho ,\phi ,\theta )\) are both the tensors of displacement and strain including complex numbers. In order to obtain the real variable expressions of the displacement, strain and stress, we first define a matrix containing intermediate variables as follows:

where Im\(\{\}\) denotes the imaginary part of a complex number.

Next, we further establish two matrixes and a vector in terms of \({{\hat{{{\varvec{u}}}}}}_{i}^{(n)},\) \({{\hat{{{\varvec{\varepsilon }} }}}}_{ij}^{(n)}\) and \({{\hat{{{\varvec{\beta }}}}}}^{(n)},\) respectively, as follows:

Thus, the real variable expression of displacement and stress in Eqs. (A1) and (A3) can be rewritten as:

in which the vectors \({{{\varvec{u}}}}(\rho ,\phi ,\theta )\) and \({{ {\varvec{\sigma }} }}(\rho ,\phi ,\theta )\), and the matrixes \({{{\varvec{U}}}}\) and \({{{\varvec{E}}}}\) are defined as

and \({{{\varvec{D}}}}\) is the stiffness matrix of a linear elastic material.

The displacement \({{{\varvec{u}}}}(x,y,z)\) and stress \({{{\varvec{\sigma }} }}(x,y,z)\) in the Cartesian coordinate system (x, y, z) can be directly represented by those in the local coordinate system (\(\rho , \phi , \theta )\) through the coordinate transformation (refer to Fig. 2a)

in which \({{{\varvec{u}}}}(x,y,z)\) contains the components \(u_{x}, u_{y}\) and \(u_{\mathrm {z}}\), and \({{{\varvec{\sigma }}}}(x,y,z)\) includes the components \(\sigma _{x}\), \(\sigma _{y}\), \(\sigma _{z}\), \(\tau _{xy}\), \(\sigma _{xz}\) and \(\sigma _{yz}\). \({{{\varvec{T}}}}_{\mathrm{u}}\) and \({{{\varvec{T}}}}_{\mathrm{s}}\) are the coordinate transformation matrixes for the displacement and strain vectors from the local coordinate system (\(\rho , \phi , \theta \)) to the Cartesian coordinate system (x, y, z). Numerical solutions of U and E in Eqs. (A16) and (A17) can be obtained by using the FEM of Sze and Wang [29], i.e., they can be discretized using a natural coordinate \(\xi \) with respect to the angular coordinate \(\phi \). The unknown stress intensity parameters, \({{{\varvec{\beta }}}}\), need to be solved according to the external loads and boundary conditions.

Rights and permissions

About this article

Cite this article

Zhang, Y., Ping, X., Wang, C. et al. A new computational approach for three-dimensional singular stress analysis of interface voids. Acta Mech 232, 639–660 (2021). https://doi.org/10.1007/s00707-020-02842-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00707-020-02842-0