Abstract

We reconsider the notion of technological trajectories by means of a detailed case-study of the evolution of tank technology between 1915 and 1945. We use principal component analysis to analyze the distribution of technical characteristics and how they map into specific service characteristics. We find that, despite the existence of differences in technical leadership, tank designs of different countries show a high degree of overlap and closeness along a common technological trajectory. In the conclusions, we speculate on whether this pattern can be explained by common heuristics that influenced the rate and direction of design activities or by doctrinal viewpoints influencing the development and use of tanks in the battlefield.

Similar content being viewed by others

1 Introduction

The notions of technological paradigms and technological trajectories have exerted a wide appeal among economists and other social scientists working in the field of innovation studies.Footnote 1 Since the seminal contributions by Dosi (1982, 1988),Footnote 2 several authors have devoted substantial efforts to provide detailed empirical analyses of the process of technical change employing this framework (see, amongst others, Sahal 1985; and Saviotti 1996). Besides these authors, however, most of the literature has adopted the notions of paradigms and trajectories in a rather loose way, mainly as metaphors featuring in broad (‘appreciative’) reconstructions of the patterns of technological evolution. The main aim of this paper is to re-visit the original potentialities of Dosi’s framework in a detailed case-study of the evolution of a specific technology. In particular, we present an historical study of the evolution of tanks for the period 1915–1945. This is a period that has been singled out as particularly interesting both by historians of technology and by military historians. Tanks represent one of the major innovations in military technology introduced in the first half of the twentieth century, and the history of their development presents several points of interest in its own right (Hacker 2005). However, we contend that, from our case study, one could also draw implications with general bearings for the innovation studies literature.

The tank—at least in the period we consider—constituted a complex engineering product aimed at achieving certain performance results (in most general terms: mobility, firepower and protection). The task of tank designers was to search for technical solutions that translated into acceptable performance levels. In the case of tank technology, the relationship between the configuration of the various technical characteristics of the tank (road speed, armor, armament caliber, etc.) and the performance attributes is relatively straightforward. However, the existence of interdependencies among technical characteristics produced a number of trade-offs between performance attributes. In order to develop ‘good’ designs, engineers had to search for ‘satisfying’ solutions. Hence, the particularly clear-cut nature of the engineering trade-offs characteristics of this technology provides an ideal starting point for the study of the technological trajectories and of the underlying search processes. Second, in the period considered, for obvious strategic motives, all the major industrialized countries were engaged in the development of tanks. In this early phase, as stressed by the received historical accounts of the evolution of tank technology (Murray 1996), it was not at all clear what would have been the most effective way of employing tanks on the battlefield. Different countries held drastically different viewpoints on this topical issue. In the 1920s and 1930s, military establishments in France, UK and USA tended to regard the tank simply as a “gun with a certain degree mobility” to be primarily employed for infantry support. In Germany, mainly due to the influence of Heinz Guderian (Guderian 1999), tanks were considered as the backbone of new tactics based on speed and mobility. Therefore, it will be of particular interest to examine to what extent the debate among these different doctrinal viewpoints influenced the rate and direction of design activities.

The paper is structured as follows. In Section 2, we discuss the major theoretical and empirical issues related with both the identification and the mapping of technological trajectories. Section 3 provides a short historical account of the main trends in the evolution of tank technology. In Section 4, we present our data-set and, following Saviotti and Trickett (1992), we use principal component analysis to study the distributions of technical characteristics of the tank models contained in our data-set. In Section 5, we discuss the main findings of our exercise and conclude.

2 Background literature

Dosi (1982, 1988) proposed what may be called a paradigm/trajectory approach to the study of technical change. Dosi defines a technological paradigm as “model and a pattern of solution of selected technological problems, based on selected principles derived from natural sciences and on selected material technologies” (Dosi 1982: 152, emphasis in original). The term paradigm is clearly borrowed from Thomas Kuhn’s philosophy of science. In the case of technologies, the concept of paradigm refers to a framework, jointly adhered by a significant group of innovators, guiding the search for technical advances in particular historical contexts. In this way, a technological paradigm defines the boundaries of the domain in which future technological developments will take place. Dosi suggests that it should be possible to deconstruct each technological paradigm in a set of “heuristics”. These represent the prevailing accepted rules prescribing the procedures to be adopted in the search for innovations (for example: “in order to develop a more efficient steam engine, try to increase the rate of expansion”). It is interesting to note that the notions of technological paradigms and heuristics are intended to be broader in their scope than mere sets of engineering prescriptions. In Dosi’s view, technological heuristics are the product of the “amalgamation” of what might be termed the “autonomous drift” of a technology (i.e. the “compulsive sequences” of challenges and solutions identified by Rosenberg (1976) which are insensitive to market signals), with “inducement factors” of a genuine economic nature (i.e. current and expected factor prices). This means that local circumstances can, to a certain extent, shape the pattern of technological development.

The heuristic search process practised by the inventors’ community generates relatively ordered patterns of technical change, called “technological trajectories”, by channelling inventive activities in specific and finalized directions. These trajectories can, at least in principle, be mapped in both the space of input of coefficients and that of product characteristics (Dosi 1997: 1533).

The paradigm/trajectory view of technological evolution points to three essential features of the process of technical change:

-

1.

the local nature of technical progress: inventive activities are paradigm-bounded and, for this reason, they are highly selective and focused in rather precise directions;

-

2.

along a specific technological trajectory, technical advances are strongly cumulative, that is to say, they are strongly related to previous attainments;

-

3.

technological development is likely to display strong irreversibility. This means that techniques developed along particular trajectories are likely to become superior to old ones at every relative factor price level. As a consequence, once the movement along a particular technological trajectory has gained momentum, it becomes relatively unresponsive to changes in input prices.

One of the appealing features of the paradigm/trajectory view is that it could provide a theoretical explanation for a number of empirical findings (mostly going under the heading of ‘technological forecasting’) that, since the late 1970s and early 1980s, had introduced and developed quantitative indicators to describe the evolution of technologies.Footnote 3 These studies revealed that the evolution of technologies was characterized by relatively ordered dynamics of progress in the various characteristic spaces in which they could be mapped. Furthermore, these patterns were also punctuated by discontinuities and ruptures that could be linked to historical episodes of paradigm change. As Dosi puts it:

[T]here is no a priori economic reason why one should observe limited clusters of technological characteristics at one time and ordered trajectories over time. Indeed, given consumers with different preferences and equipment users with different technical requirements, if technology had the malleable attributes of information and if innovative search were a purely random search process, one would tend to observe sorts of “technological indifference curves” at any one time and, over time, random search all over the n-dimension characteristic space....[Rather,] the evidence surveyed suggests that one still observes “explorations” limited to some, smaller subsets of the notional characteristics space. It is precisely the paradigmatic cumulative nature of technological knowledge that accounts for the relatively ordered nature of the observed patterns of technological change. (Dosi 1988: 1129)

Somewhat paradoxically, however, precisely when the times seemed ripe for establishing an intriguing link between theoretical developments and empirical evidence, research efforts aimed at producing a detailed quantitative mapping of the long term evolution of technologies began to peter out. At the same time, since the late 1980s, growing concerns for providing ‘contextualized’ interpretations of technological evolution rendered the field of the history of technology almost impermeable to exercises in measurement and quantification.

One major exception is the stream of literature initiated by Saviotti and Metcalfe (1984). Saviotti and Metcalfe (1984) built an explicit link between the construction of technological output indicators and the mapping of trajectories in the evolution of technology. In their representation of technology, they draw an important distinction between ‘technical’ or design related characteristics and ‘service’ characteristics. Technical characteristics represent the internal structure of the artefact and, in most cases, are the dimensions that designers take into consideration (for example, in the case of the car, type of engine, type of suspensions, weight, etc). Service characteristics, by contrast, are the ‘services’ actually delivered by the artefact in which users are interested (in the case of the car, speed, reliability, comfort, etc.). Saviotti and Metcalfe (1984) note that, in general, there is no one-to-one mapping between technical and service characteristics. Rather, in most artefacts, one technical characteristic will typically affect several service characteristics through a complex pattern of correspondence.

This conceptual framework has obvious implications for the mapping of technological trajectories. Indeed, one has to be well aware whether observable modifications in the artefact result from changes in the technical characteristics, service characteristics or in transformations in the pattern of mapping between the two (Saviotti and Metcalfe 1984: 144–148). However, to date, only few technologies have been analyzed using the Saviotti–Metcalfe framework.Footnote 4 This paper expands on this research tradition. Its aim is twofold. First, it provides a new case study of a technology within the Saviotti and Metcalfe framework.Footnote 5 Second, relying on the distinction between service and technical characteristics, it aims at assessing the driving factors underlying the dynamics of technological trajectories as defined by Dosi. In particular, our purpose is to disentangle the role of what may be called “technological imperatives” stemming from the nature of the internal structure of the artefact, as distinguished from the influence of various contextual factors.

3 The development of tank technology: a short historical overview

This section provides a short account of the main technological events that characterized the history of tank technology in the period considered.Footnote 6

3.1 Milestones in the evolution of tank technology

Although the idea of armored fighting vehicles had been circulating for long timeFootnote 7, it was only during WWI that the three key mechanical constituents of the tank—bullet proof armor, internal combustion engine and caterpillar tracks—were available. Their combination turned out to be crucial for breaking the circumstances of the deadlocked trench warfare of attrition on the western front. Although early designs and prototyping began in 1915, the year 1917 can be considered the date of the birth of tank technology, when tanks were first employed on the battlefield in sizeable numbers. The early history of tank technology can be usefully sub-divided in four main periods: WWI (1915–1920), the 1920s (1921–1930), the 1930s (1931–1939) and WWII (1940–1945).

Tanks produced during WWI were characterized by a rather low degree of mobility—the maximum road speed was less than 10 km/h and the operative range was also fairly limited. The minimum requirement for the armor was to provide protection against machine-gun fire, whereas fire power capabilities were ensured by fitting into the vehicle guns of caliber comprised between 20 and 40 mm. The two most representative models are the British ‘Mother’ with its typical rhomboidal shape and the French Renault FT-17, which was the first tank with a rotating turret. During the war, these types of tanks proved capable of successfully piercing enemy trenches. However, low speed prevented them from achieving deep breakthroughs beyond enemy lines. In this first period, there were also experimental attempts of mounting heavy guns on tanks. This was done in the French Char 2C, mounting a 75 mm gun, and in the German K-Wagen, mounting 77 mm guns. Interestingly enough, such heavy guns would be fitted again into tanks only from the late 1930s. In fact, the sheer weight of these machines greatly limited their effectiveness. In the end, only 10 Char 2C and 2 K-Wagen were actually built.

Design efforts during the 1920s were aimed at solving a number of limitations related to the general operability (not least the extreme crew discomfort of WWI models) and to the overall mobility of the vehicle. Accordingly, in this period, some teething shortcomings were solved and the single rotating turret design emerged as the most effective solution. As shown in Table 1, Britain was the most active country in this phase. A particular noteworthy tank of this period was the Vickers 6-ton, which was produced by Vickers as a private venture. The tank was not adopted by the British Army, but a very similar design (the Vickers medium A6) was employed. However, the development of this tank led to a more favorable view of armor warfare in the military establishments of various countries (Habeck 2003). Indeed, the Vickers 6-ton was purchased by several countries and its design was copied in Russia, providing the basis for the early development of Soviet armor.

The 1930s witnessed a growth in the number of designs introduced, obviously linked with the rearmament race. The most successful tank of this period was probably the Russian BT-5, which employed the independent suspension system invented by the American engineer J. W. Christie. It also featured an unprecedented high power/weight ratio that provided a major breakthrough in road speed (65 km/h) and mobility. A 47 mm gun was fitted on the tank. Other tanks representative of this period are the French R-35 (a ‘light’ tank fitted with a 37 mm gun) and the British Matilda 2. This tank, although relatively slow (25 km/h), was endowed with thick armor (78 mm) and had a 76 mm gun. These figures show that many representative tank models introduced during WWII mounted similar calibers.

The WWII period was a phase in which design activities reflected the feedback stemming from the relative performance of various models in the battlefield. Many models displayed a gun caliber around 75 or 76 mm (the German Panzer 4, the Soviet T-34, the American M-4 Sherman, and the British Churchill). In a slightly later phase, there was a clear attempt to fit even higher gun calibers (88 mm for the German Tiger, 85 mm for the Soviet T-34 and 90 mm for the American M-26, up to the 122 mm of the Soviet JS). There was a somewhat wider dispersion in armor thickness, although it is evident in this case that tank models of different countries tended to converge towards similar values. This behavior could be plausibly interpreted by the need of matching the battlefield capabilities of enemy models. The most successful design of the WWII was the Soviet T-34, which represented an almost ideal combination in terms of speed, armor thickness and gun caliber. Compared to the Panzer 4, the dominant German tank, the T-34 was clearly superior in all three technical characteristics. The appearance of the T-34 stimulated the Germans to introduce the Panther and the Tiger, designs endowed with more powerful guns and thicker armor. However, it is worth noting that, although seemingly qualitatively superior, these tanks were produced in lower numbers. The most famous American tank of WWII was the M4-Sherman. Born as an attempt to match the caliber of the German Panzer 4, this tank was fitted with a 75 mm gun. The M4 did not match tanks such as the Tiger and the T-34 in armor thickness. Together with the T-34, the M4 is the tank that was produced in largest numbers during WWII.

Comparing tanks on the basis of their technical characteristics alone provides just a rough sketch of the historical developments in tank designs. Indeed, tanks are not simple bundles of technical characteristics. In each design, technical characteristics are inter-related with each other to form what Saviotti and Metcalfe (1984) define as the “internal structure of the technology”. The following section presents a conceptualization of tank technology based on the insights from the literature discussed above.

3.2 Conceptualizing tank technology

A tank is a technological system the design of which is a compromise between several technical characteristics (i.e. features that are manufactured by the designers) and service characteristics (i.e. features that result from the manipulation of technical characteristics). (Miller 2002: 6) identifies three main service dimensions: firepower, protection and mobility. Firepower and protection refer to the services tanks deliver on the battlefield. They both define the ‘battlefield capability’ of the artefact. Tank mobility instead is important in different contexts not only on the battlefield. Accordingly, (Ogorkiewicz 1991: 223) distinguishes between three different kinds of mobility: strategic mobility (i.e. the ability of tanks to be moved into the area of operation), operational mobility (i.e. the ability of tanks to move in the area of operation) and battlefield mobility (i.e. the ability of tank to move when in imminent contact with the target). Each of these services is usually influenced by more than one technical characteristic. Figure 1 provides a conceptualization of the relationship between technical and service characteristics largely based on Ogorkiewicz (1991).

Technical characteristics are listed on the right hand side, while service characteristics are summarized on the left hand side. Information on technical characteristics is available directly from our dataset. Information on the service dimensions are not directly available in the dataset, since changes in the service dimensions typically resulted from a manipulation and combination of several technical characteristics. As a result of this manipulation, there is no one-to-one mapping between the two spaces. To improve one specific service, designers could work on several technical characteristics. This is especially true in the case of mobility. For instance, strategic mobility involves travelling considerable distances to the fields of operation. The ease and speed at which distances can be covered by alternative means of transport (rail, ships and/or roads) depends inversely on the weight and size of the tanks.Footnote 8 Battlefield mobility instead involves the capability of tanks to move in quite different terrains, ranging from soft soil to hard ground. To the extent that mobility depends on the pressure exerted on the ground, battlefield mobility on soft soil depends inversely on weight. Battlefield mobility on hard ground depends instead on how the weight of tank is distributed, which in turn depends on the type of suspensions implemented and on the length of the tank. Suspensions can help reduce ground pressure. Increasing the length of the tank can help in distributing better its weight on the wheels. In both cases, mobility is increased. Finally, operational mobility involves the ability of tanks to move under their own power along roads as well as cross country. Cross country movement is inversely influenced by the weight of tanks. Heavy tanks are generally slower than light ones because they exert higher ground pressure. Road speed, range and engine power, by contrast, positively affect movement. Range, defined as the average distance a tank can cover without requiring logistic support, seems particularly important for operational mobility. The wider the range, the higher the freedom of movement becomes.

Understanding the link between technical and service characteristics does not exhaust all the issues involved in tank design. Indeed, the complexity of tank design is in part due to the presence of interdependence among the technical characteristics themselves. To improve performance, designers had, and still have today, to engineer around several technical trade-offs. Consider mobility, for instance. Increasing the length of the tank improves operational mobility. However, longer tanks become heavier and less manoeuvrable on the battlefield, which increases the probability of being hit. Finally, technical trade-offs very often translate into service trade-offs. For instance, better battlefield capability (i.e. better protection and greater fire power) achieved through an increase in armor thickness and higher armament caliber leads to an increase in the weight of the tank and a decrease in road speed. Battlefield capability is improved at the expense of mobility if it is not supported by an improvement in another characteristic, such as engine power, for instance.

The aim of the following section is to provide an assessment of the linkages between technical characteristics and of the patterns of mapping between these and service characteristics. This exercise will provide insights into the search process which characterized the historical evolution of tank technology.

4 The empirical analysis

In this section, we move forward in the analysis of the factors affecting the trajectory of tank technology. We first present our data source. We then employ principal component analysis to study the evolution of tank models over time.

4.1 The data

Our main source of information is the data contained in Hogg (2000), a directory of all tanks built between 1915 and 1999. The full data set contains information on more than 400 tank models built in 33 countries. For the purpose of our paper, we focus on 262 models manufactured between 1915 and 1945 in the five major industrialized countries of the time: France, Germany, USSR, UK and USA.Footnote 9 For each model, the dataset reports information on several technical characteristics of tanks, such as width, hull length, height, weight, armor thickness, road speed and range, armament caliber, as well as year of production and the manufacturer(s).Footnote 10 Additional information on quantity produced and the period of service of each tank model has been collected from various historical sources. Table 1 reports the number of tanks models present in our sample broken down by country and time period. The number of designs experienced a sharp rise towards the end of World War I (WWI), a decrease in the years that immediately followed the end of the conflict and a steady increase from 1923 onwards as a consequence of the proliferation of models that characterized the race toward rearmament.

It can be noted that, against an overall pattern of increase, various countries behaved differently. The UK is the country with the highest number of models manufactured, followed by the USA and Germany. UK, France and USA were the leaders during WWI while the USSR did not manufacture any tank until the 1920s. Between 1920 and 1930 Germany, introduced only one tank, a prototype that never went into full production. This was a consequence of the ban on army production imposed by the Versailles Treaty that delayed the diffusion of this new weapon in the country. This delay notwithstanding, Germany caught up very rapidly during the 1930s with the highest number of tank models among the countries in our sample. Model proliferation continued between 1940 and 1945 for all countries, with the obvious exception of occupied France.

As argued in Section 3, the evolution of tank technology between 1915 and 1945 was characterized by a common heuristics, entailing an increase in road speed as well as in armor thickness and caliber. Evidence on the major trade-offs between technical characteristics that accompanied the evolution of tanks is presented in Table 2, which reports the Spearman correlation ranks for selected pairs of technical characteristics.

As expected, the coefficient signs indicate that trade-off existed only for certain characteristics (notably road speed and armor, road speed and caliber). The trade-offs became particularly important during the 1940–1945 time period, when countries tried harder to tackle them. Coefficients show that certain countries, notably Germany, succeeded in solving the trade-offs better than others (USA). Armament caliber and armor thickness are positive correlated. This result confirms that pursuing greater fire power and looking for better protection occurred in parallel and became relevant during WWII when the armament race intensified. All in all, the size of the coefficients suggests that, despite the existence of a common heuristic, countries seemed to differ in its implementation.

4.2 A principal component analysis

Following Saviotti and Trickett (1992), we use principal component analysis to study the distribution of technical characteristics in our population of tank models. Principal component analysis is a widely used method of data reduction. When it is applied to an original set of variables, it creates a new set of variables that are correlated with the initial ones and that explain a reasonably high percentage of the variance of the original sample. In this way, the behavior of the initial set of variables may be usefully summarized by the behavior of the principal components. We consider only tanks produced in more than five exemplars, as a way to limit the influence of outliers and experimental designs in our reconstruction of the patterns of technical change Tables 3, 4 and 5 report the results of our principal component analysis.

The initial set of variables comprises: weight, road speed, range, engine power, armour, and armament caliber. Other important variables (i.e. width, hull length, height, type of fuel, type of suspensions, armor slope, etc.) were not included because they were not available for a sufficient number of models. Historical studies have pointed to the critical role of other characteristics, such as reliability or component standardization, in affecting the overall performance of the tank, but these are hard to pin down using quantitative indicators.Footnote 11

Eigenvalues are shown in Table 3. The so-called Kaiser criterion (Kaiser 1960) suggests retaining only those principal components with eigenvalue greater than 1. Accordingly, we consider only the first two principal components. Table 4 reports the eigenvectors of the components. The eigenvectors represent the weights of each initial variable in each principal component. We compute the values of the principal components also for models produced in less than five exemplars, in order to see their position with respect to the core of our technological population.

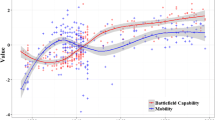

Table 3 shows that the first two principal components account for more than 80% of the total variance. Our first principal component (PC1) contains high contributions from weight, engine power, armor and armament caliber, whereas road speed and range contribute less. Our second principal component (PC2) is characterized by strong contributions of road speed and range and by small or even negative contributions from the other variables. In terms of interpretation, PC1 may be clearly understood as an indicator of the overall battlefield capability of the tank (in particular, PC1 may be viewed as a synthetic indicator of fire-power and protection), whereas PC2 appears as an indicator of mobility.

The estimated principal components can be used to evaluate the relative merits of alternative tank designs. Figure 2a–d represent the distribution of our tank population in terms of principal components in various sub-periods. Superior designs are located farther in the North–East region of the principal component space.

A similar cross-country pattern seems to emerge. In the early period 1915–1920, tank designs are concentrated in the South–West region and display negative values of both PC1 (battlefield capability) and PC2 (mobility). In the period 1921–1930, there is a movement towards the right, which can be interpreted as an attempt to improve the mobility of the tank. In the period 1931–1939, tank designs are mostly clustered on a diagonal around quadrant II and IV of the principal components space.Footnote 12 Finally, in the period 1940–1945, the cloud of designs moves in a North East direction, with several tank models characterized by positive values of both PC1 and PC2.Footnote 13 It is interesting to see that some experimental ‘super-heavy’ tank models, such as the German Maus and E-100 as well as the American T-28, are located far away from the region which contains the majority of tank designs. These models clearly represent ‘aberrations’ with respect to the normal pattern of technical progress.Footnote 14

As we noted in the previous section, it would be misleading to limit the consideration of the effectiveness of various tank models only to the evaluation of technical characteristics. During WWII, being able to mass produce tanks was, from a strategic viewpoint, at least as important as improving their quality. Table 5 shows the quantities and the principal component values of the main tank models used during the war.

While good designs could not always be easily mass produced, in some cases, notably the T-34 and the M-4 Sherman models, this was indeed possible.

4.3 Mapping the evolution of tank technology

The results of our principal component analysis provide insights into the nature of the search process that underlay the evolution of tank technology. Consistently with the paradigm/trajectory approach, our finding suggests that inventive activities were selective and finalized in rather specific directions. Figure 3 maps the unfolding of the technological trajectory in our space of Principal Components, by means of subsequent “Standard Deviational Ellipses” (SDE).

The construction of SDE is a technique for analysing dispersion in point patterns in two-dimensional space (see Ebdon 1977: 112–119, for a detailed overview).Footnote 15 We construct one SDE for each sub-period of our sample. The arrows connecting the centers of two subsequent ellipses provide a synthetic representation of design shifts and describe the unfolding of the trajectory. This technique seems to provide a rigorous implementation of the idea of representing the path of evolution of a product population through aptly defined clusters of points, as proposed by Saviotti (1996: 67–70).

Between the first and the second period, the ellipsis shifts horizontally, suggesting that there was an attempt at improving the mobility of the tank, somewhat neglecting the battlefield capability. Between the second and the third period, efforts to improve battlefield capability were carried out, without sacrificing too much mobility. This leads to a cluster of tank models stretched diagonally along region II and IV in the principal components space. The stretching of the cluster can also be interpreted as a process of specialization of tank designs. In this sense, engineers dealt with trade-offs not only by means of design improvements, but also by producing models with different capabilities aimed at different types of operations. This is the main motivation for the emergence of the differentiation between ‘light’, ‘medium’ and ‘heavy’ tanks. This is clearly captured by the increasing range of the ellipses for different periods, pointing to an increasing variety in designs. This result goes against the idea of convergence to a dominant design. Further analysis would need to investigate whether variety in the differentiated models decreased in the subsequent periods.

Between the third and the fourth period (i.e. during WWII), we see a further shift toward the North East area of the graph, with some particularly successful models capable of scoring good combinations in both mobility and battlefield capability. Not surprisingly, the war seems to have induced an acceleration of technical change. This development is not only related to the increase in the resources invested in development of new designs, but also to the feedback generated by the actual use of tanks on the battlefield (as well as to the reverse engineering on captured enemy models).

By looking at Figs. 2 and 3 together, another interesting finding emerges. Although there were particularly successful designs, there was also a rather high degree of closeness and even overlap between tanks produced in different countries. In this sense, no country seems to have ever gained a sizable and sustained technological leadership. In order to check for the existence of significant country effects, we run a multiple analysis of variance (MANOVA) on the two principal components for the last period. The results (reported in Table 6) of the multiple cross-country comparisons do not support the presence of significant differences.

In particular, the only difference emerges when we use the least conservative method to test differences in means of both principal components across countries, the LSD method (Least Significant Difference). In that case, Russian tanks show a higher value for the mobility component than German tanks. According to all other methods, the Bonferroni for example, countries do not differ significantly in terms of average components. This result contrasts with widespread beliefs in the superiority of German tanks that circulated in many Allied military circles in the initial phases of WWII. On the North African front, this belief even led to the formulation of a rule of thumb which stated that, in order to approach combat with some chance of victory, British tanks should have a numerical superiority of at least 3 to 2 (Griffith 1990: 74). As suggested by several historians (see Harris 1995 and the essays collected in Harris and Toase 1990), the successes achieved by German tanks in the first years of the war were due more to their effective use on the battlefield than to an intrinsic technological superiority. The same holds true for the Soviet achievements after 1942.

5 Discussion and conclusion

This paper has taken an empirical stance to study the notion of technological trajectories. By looking at the evolution of tank technology between 1915 and 1945, principal component analysis and Standard Deviational Ellipses techniques have been used to analyze the distribution of technical characteristics and to map them into specific service characteristics. Overall, we found the existence of a high degree of overlap among tank designs of different countries and we were able to identify a common technological trajectory.

One important issue related to the application of the paradigm/trajectory view in empirical studies of technology evolution concerns the interaction between different types of knowledge that shapes the trajectory. Dosi’s notion of paradigm is essentially restricted to a community of technological practitioners. However, in the case of tanks, doctrinal aspects (i.e. the theory of ‘blitzkrieg’ developed by Guderian and the analogous concept of ‘deep battle’ due to the Russian Tukhachevskii) mattered for the development of the technology.Footnote 16 Indeed, in the case of tanks, at least, two communities were interacting and potentially shaping the evolution of the trajectory. The first was the community of engineers involved in design activities. The second was the community of military establishments and strategists engaged in the formulation of the ‘principles’ as to the way in which tanks were to be used on the battlefield. Interestingly enough, historians have so far devoted most of their attention to the paradigmatic discussion taking place within this second community. In particular, several contributions have focused, on the one hand, on the failures of ‘innovative thinkers’ such as J.F.C. Fuller and Liddell Hart in transforming the views of the British military establishment on the role of tanks in future wars,Footnote 17 and, on the other hand, on the successes of Guderian and Tukhachevskii in developing successful principles of tank operation in Germany and the Soviet Union. To date, there has not been much research devoted to the engineering community. Interestingly, our result, that the pattern of technical change in the period 1915–1945 was broadly similar in all the countries considered, points to a relatively minor influence of doctrinal debates on actual tank designs, although not on their use in the battlefield.

This paper has shown how technological trajectories can be studied by using data on the technical characteristics of artefacts. A number of recent studies (Mina et al. 2007; Verspagen 2007) have attempted to map technological trajectories using publications and patent data. These contributions reconstruct the evolution of knowledge flows underlying the development of specific technologies. In this respect, this knowledge space can be regarded as a further dimension in which the dynamics of technical change takes place. In this sense, this approach is complementary to the mapping exercises on technical and service characteristics carried out in this paper. At the same time, attention must be paid to users and the communities in charge of prescribing the ‘code of use’ of a specific technology. In most cases, this means that it may be necessary to adopt broad narrative frames spanning beyond the study of the activities of the community of technological practitioners (Edgerton 1999; Staudenmaier 2002). Ultimately, combining such studies with quantitatively-based accounts of technological change that integrate the knowledge, technical and service characteristics space is a challenging research agenda for the future.

Notes

See the introduction to the Special Issue of Industrial and Corporate Change on ‘Technological Paradigms’, Von Tunzelmann et al. (2008).

These include Saviotti and Trickett (1992) for helicopters, Saviotti (1996) for aircraft, Frenken et al. (1999) for aircraft, helicopters, motorcycles and microcomputers, Frenken and Nuvolari (2004) for steam engines, Nguyen et al. (2005) for refinery processing, Windrum (2005) for cameras, and Frenken (2006) for desktop and laptop computers.

A specific property of tank technology is that its production is controlled by governments and not by private companies. This means that constraints related to efficiency in production are likely to play a less significant role.

This overview of the evolution of tank design draws heavily upon Ogorkiewicz (1991).

One could actually trace the concept of tank to the horse-drawn chariots launching spears and arrows that were employed in the Near East as far back as 2000 BC.

The width was particularly influential since transport occurred mainly by rail during WWI and WWII.

To be included in our analysis, the models had to possess certain minimal requirements, such as: a bullet proof armor, internal combustion engine and caterpillar tracks. To respect these requirements, we excluded from the analysis certain models which had to be towed to be moved on the battlefield or that were employed for very specific aims, such as the so called ‘tank destroyers’. This is a limitation of the present analysis.

Though, on the basis of the existing literature, there are valid reasons to consider the characteristics contained in the dataset as representative of the tank technology, it has to be noted that the list is far from being exhaustive. For instance, it may be argued that, under specific circumstances, muzzle velocity is a better indicator of fire power than armament caliber. Since information on these characteristics is generally not available for all the models, we did not take it into consideration.

Indeed, when this larger set of characteristics is taken into account, the assessment of the relative performance of tanks designs becomes much more difficult and debatable. See, for instance, the discussion in Johnson et al. (2000).

The few tank models in this period that are able to ‘score’ positive value of both PC1and PC2 are Soviet tank models.

Among these models, we find some of the most successful tanks, such as the Russian T-34 and the German Panther, together with the British Cromwell, which is not usually regarded as a particularly effective design because of the lack of slope armor, a feature not considered in our principal component analysis.

Indeed, in the case of Germany, the presence of such ‘aberrations’ is revealing of a general approach to tank design based on the idea of constructing the “miracle tank” (i.e. a tank endowed with unparallel armor and armament). The Tiger may be considered as a rather successful outcome of this approach (see Johnson et al. 2000: 247)

SDE are fitted by calculating: the center of the ellipsis, the orientation, and the length of the shortest and longest axes, which are always orthogonal to each other. The center of the ellipsis is simply the mean center of the point pattern, the orientation is given by the calculation of the direction of maximum dispersion, and the length of the two main axes reflect the dispersion of the points around the center along those dimensions.

Following the execution of Tukhachevskii in the 1930s, the concept of ‘deep battle’ was rejected by the high command of the Red Army. However, after the initial dramatic defeats, Soviet military establishments quickly returned to the concept.

The following statement by Sir Douglass Haig (commander of one of the two armies of the British force on the continent during WWI and one of the most enthusiastic supporters of mechanized warfare) in 1925 is revealing of the degree of doctrinal conservatism existing among British high command: “I believe that the value of the horse and the opportunity for the horse in the future are likely to be as great as ever...I am all for using aeroplanes and tanks, but they are only accessories to the man and the horse, and I feel sure that as time goes on you will find just as much use for the horse—the well-bred horse—as you have ever done in the past” (cited in Smithers 1986: 249–250).

References

Constant EW II (1973) A model for technological change applied to the turbojet revolution. Technol Cult 14:553–572

Dosi G (1982) Technological paradigms and technological trajectories: a suggested interpretation of the determinants and directions of technical change. Res Policy 11:147–162

Dosi G (1988) Sources, procedures and microeconomic effects of innovation. J Econ Lit 36:1120–1171

Dosi G (1997) Opportunities, incentives and the collective patterns of technological change. Econ J 107:1530–1547

Ebdon D (1977) Statistics in geography. Basil Blackwell, Oxford

Edgerton D (1999) From innovation to use: ten (eclectic) theses on the history of technology. Hist Technol 16:1–26

Frenken K (2006) Innovation, evolution and complexity theory. Edward Elgar, Cheltenham

Frenken K, Nuvolari A (2004) The early development of the steam engine: an evolutionary interpretation using complexity theory. Ind Corp Change 13:419–450

Frenken K, Saviotti PP, Trometter M (1999) Variety and niche creation in aircrafts, helicopters, motrocycles, and microcomputers. Res Policy 28(5):469–488

Gordon TJ, Munson TR (1980) Research into technology output measures. The Futures Group, Glastonbury

Griffith PG (1990) British armoured warfare in the western desert 1940–43. In: Harris JP, Toase FH (eds) Armoured warfare. St. Martin’s Press, New York

Guderian H (1999) Achtung Panzer! The development of tank warfare. Cassel, London (first German edition 1937)

Habeck MR (2003) Storm of Steel. The development of armor doctrine in Germany and the Soviet Union, 1919–1939. Cornell University Press, Ithaca

Hacker BC (2005) The machines of war: western military technology 1850–2000. Hist Technol 21:255–300

Harris JP (1995) Men, ideas and tanks. British military thought and armoured forces, 1903–1939. Manchester University Press, Manchester

Harris JP, Toase FH (1990) Armoured warfare. Batsford, London

Hogg IV (2000) The armoured fighting vehicles data book. Greenhill Books, London

Johnson DV II, Baily CM, Citino RM, Astore WJ (2000) Tanks: were American tanks inferior to their German and Soviet counterparts? In: Showalter D (ed) History in dispute volume 4. World War II. St. James Press, Detroit, MI, pp 238–252

Kaiser HF (1960) The application of electronic computers to factor analysis. Educ Psychol Meas 20:141–151

Miller D (2002) The great book of tanks. The world most important tanks from world war I to the present day. Motorbooks International, New York

Mina A, Ramlogan R, Tampubolon G, Metcalfe JS (2007) Mapping evolutionary trajectories: applications to the growth and transformation of medical knowledge. Res Policy 36(5):789–806

Murray W (1996) Armored warfare: the British, French, and German experiences. In: Murray W, Millett AR (eds) Military innovation in the interwar period. Cambridge University Press, Cambridge

Nelson RR, Winter SG (1977) In search of useful theory of innovation. Res Policy 6:36–76

Nguyen P, Saviotti PP, Trometter M, Bourgeois B (2005) Variety and the evolution of refinery processing. Ind Corp Change 14:469–500

Ogorkiewicz RM (1991) Technology of tanks. Jane’s, Coulsdon

Rosenberg N (1976) Perspectives on technology. Cambridge University Press, Cambridge

Sahal D (1981) Patterns of technological innovation. Addison-Wesley, London

Sahal D (1985) Technological guideposts and innovation avenues. Res Policy 14:61–82

Saviotti PP (1988) The measurement of changes in technological output. In: Van Raan AFJ (ed) Handbook of quantitative studies of science and technology. Elsevier, Den Haag

Saviotti PP (1996) Technological evolution, variety and the economy. Edward Elgar, Cheltenham

Saviotti PP, Metcalfe JS (1984) A theoretical approach to the construction of technological output indicators. Res Policy 13:141–151

Saviotti PP, Trickett A (1992) The evolution of helicopter technology, 1940–1986. Econ Innov New Technol 2:111–130

Smithers AJ (1986) A new excalibur. The development of the tank 1909–1939. Grafton Books, London

Staudenmaier J (2002) Rationality, agency, contingency: recent trends in the history of technology. Rev Am Hist 30:168–181

Verspagen B (2007) Mapping technological trajectories as patent citations networks. A study on the history of fuel cell research. Adv Complex systems 10:93–115

Von Tunzelmann N, Malerba F, Nightingale P, Metcalfe S (2008) Technological paradigms: past, present and future. Ind Corp Change 17:467–484

Windrum P (2005) Heterogenous preferences and new innovation cycles in mature industries: the amateur camera industry 1955–1974. Ind Corp Change 14(6):1043–1074

Acknowledgements

Earlier drafts of this paper were presented at the Workshop on Product Characteristics and Innovation, Jena, October, 2007, and at the Fourth European Meeting on Applied Evolutionary Economics (EMAEE), Utrecht, May 2005. We thank the participants at both meetings for the helpful comments. In particular, the paper has benefited from the suggestions of Koen Frenken, Jerry Silverberg, Marco Valente, Werner Holzl. We also thank Giovanni Dosi and Bart Verspagen for the encouraging words and useful discussions. The usual disclaimers apply.

Open Access

This article is distributed under the terms of the Creative Commons Attribution Noncommercial License which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This is an open access article distributed under the terms of the Creative Commons Attribution Noncommercial License (https://creativecommons.org/licenses/by-nc/2.0), which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

About this article

Cite this article

Castaldi, C., Fontana, R. & Nuvolari, A. ‘Chariots of fire’: the evolution of tank technology, 1915–1945. J Evol Econ 19, 545–566 (2009). https://doi.org/10.1007/s00191-009-0141-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00191-009-0141-0