Abstract

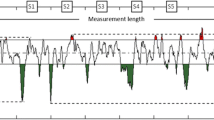

No recommendation was found in the literature with regard to which measuring resolution should be used when measuring wood surfaces and requirements in the general standard ISO 3274 (1996) appear too stringent. Due to its variability, wood requires longer evaluation length than recommended by ISO 4288 (1996) and combined with a high resolution will increase the matrix of data and so the time for scanning and data processing. A study was conducted on roughness profiles from sanded surfaces of oak, beech and spruce measured at different resolutions to see which is the lowest resolution that still allows accurate evaluation of the roughness parameters in real time. The effect of decreasing the resolution on roughness parameters was examined as compared with a resolution of 1 μm, which was taken as a reference. Results showed that a measuring resolution of 5 μm seems reliable for all species sanded with common grit sizes.

Zusammenfassung

In der Literatur gibt es keine Empfehlung, welche Messauflösung bei der Messung von Holzoberflächen verwendet werden soll. Die in der Norm ISO 3274 (1996) angegebenen Anforderungen erscheinen zu streng. Für Holz werden aufgrund seiner Variabilität längere Messstrecken benötigt als in ISO 4288 (1996) angegeben sind. Zusammen mit einer hohen Auflösung erhöht sich damit die Datenmatrix und somit die Zeit zum Scannen und zur Datenverarbeitung. Untersucht wurden Rauheitsprofile geschliffener Oberflächen aus Eichenholz, Buchenholz und Fichtenholz mit verschiedenen Messauflösungen. Dabei sollte die niedrigste Auflösung bestimmt werden, mit der eine genaue Bestimmung der Rauheitsparameter in Echtzeit noch möglich ist. Der Einfluss abnehmender Auflösung auf die Rauheitsparameter wurde im Vergleich zu einem Referenzwert von 1 μm untersucht. Die Ergebnisse zeigten, dass eine Messauflösung von 5 μm für alle Holzarten, die mit üblicher Körnung geschliffen werden, geeignet ist.

Similar content being viewed by others

References

ASME B46.1 (2009) Surface texture. Surface roughness, waviness, lay

Carrano AL (2000) Characterisation of wood surface preparation. Doctoral thesis. North Carolina State University

Dong WP, Mainsah E, Stout KJ (1996) Determination of appropriate sampling conditions for three-dimensional microtopography measurement. Int J Mach Tools Manuf 36(12):1347–1362

Faust TD, Rice JT (1986) Characterizing the roughness of southern pine veneer surfaces. For Prod J 37(11/12):75–81

Fujiwara Y, Fujii Y, Okumura S (2003) Effect of removal of deep valleys on the evaluation of machined surfaces of wood. For Prod J 53(2):58–62

Fujiwara Y, Fujii Y, Okumura S (2005) Relationship between roughness parameters based on material ratio curve and tactile roughness for sanded surfaces of two hardwoods. J Wood Sci 51:274–277

Funck JW, Forrer JB, Butler DA, Brunner CC, Maristany AG (1992) Measuring surface roughness on wood: a comparison of laser scatter and stylus tracing approaches. SPIE 1821:173–184

Gurau L (2004) The roughness of sanded wood surfaces. Doctoral thesis. Forest Products Research Centre, Buckinghamshire Chilterns University College, Brunel University

Gurau L, Mansfield-Williams H, Irle M (2001) A comparison of laser triangulation and stylus scanning for measuring the roughness of sanded wood surfaces. In: Bučar B (ed) Proceedings of the 5th international conference on the development of wood science, wood technology and forestry, 5th–7th September 2001, Ljubliana, Slovenia, pp 299–310, ISBN: 961-6144-13-8

Gurau L, Mansfield-Williams H, Irle M (2005) Processing roughness of sanded wood surfaces. Holz Roh-Werkst 63(1):43–52

Gurau L, Mansfield-Williams H, Irle M (2006) Filtering the roughness of a sanded wood surface. Holz Roh-Werkst 64(5):363–371

ISO 13565-2 (1996) + Cor 1 (1998) Geometrical product specifications (GPS)—surface texture: profile method. Surfaces having stratified functional properties. Part 2: height characterisation using the linear material ratio curve

ISO 3274 (1996) + Cor 1 (1998) Geometrical product specifications (GPS)—Surface texture. Profile method. Nominal characteristics of contact (stylus) instruments

ISO 4288 (1996) + Cor 1 (1998) Geometrical product specifications (GPS)—surface texture. Profile method. Rules and procedures for the assessment of surface texture

ISO 4287 (1997) + Amd1 (2009) Geometrical product specifications (GPS). Surface texture. Profile method. Terms. Definitions and surface texture parameters

ISO/TS 16610-31 (2010) Geometrical product specification (GPS)—filtration. Part 31: robust profile filters. Gaussian regression filters

Krisch J, Csiha C (1999) Analysing wood surface roughness using an S3P perthometer and computer based data processing. In: Proceedings of the XIII Sesja Naukowa “Badania dla Meblarstwa”, Poland

Magross E, Sitkei G (1999) Influence of wood structure on the surface roughness at milling operations. In: Proceedings of the 4th ICWSF, 1999. Missenden Abbey, FPRC, Buckinghamshire Chilterns University College, High Wycombe, UK, pp 290–296

Mathia TG, Pawlus P, Wieczorowski M (2011) Recent trends in surface metrology. Wear 271(3–4):494–508

Morris AS (1993) Principles of measurement and instrumentation. Prentice Hall International, UK. ISBN 0-13-489709-9

Sandak J, Tanaka C, Ohtani T (2004) Evaluation of surface smoothness by a laser displacement sensor II: comparison of lateral effect photodiode and multielement array. J Wood Sci 50:22–27

Schadoffsky O (2000) Topographiebewertung zur Prozeβbeurteilung beim Fräsen und Schleifen von Massivholz. Doctoral thesis. Technische Universität Braunschweig, IWF. Vulkan-Verlag, Essen 2000, ISBN: 3-8027-8652-1

Tan PL, Sharif S, Sudin I (2010) Roughness models for sanded wood surfaces. Wood Sci Technol 46:129–142

Usenius A (1975) Surface smoothness measurement of sawn timber. Paperi ja Puu 4:321–326. ISSN: 0031-1243

Westkämper E, Riegel A (1993) Qualitätskriterien für geschliffene Massivholzoberflächen. Holz Roh-Werkst 51(2):121–125

Westkämper E, Schadoffsky O (1995) Oberflächentopographie von Massivholz. Einflüsse und Verfahren bei der meβtechnischen Erfassung und Bewertung von Holzoberflächen. Teil 2. HOB Holzbearbeitung 4:50–54

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Gurau, L., Mansfield-Williams, H. & Irle, M. The influence of measuring resolution on the subsequent roughness parameters of sanded wood surfaces. Eur. J. Wood Prod. 71, 5–11 (2013). https://doi.org/10.1007/s00107-012-0645-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-012-0645-4