Abstract

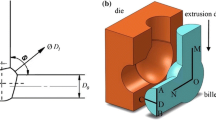

Aluminum has been deformed by equal channel angular extrusion (ECAE) to obtain submicron-grained structures under different deformation routes. The deformation routes were varied by rotating billets through 0, 90, and 180 deg between each extrusion pass, and were designated as route A, BC, and C, respectively. Based on quantitative microstructural analysis, the effectiveness of the deformation route is shown to depend upon the different definition used. The order of effectiveness is (a) A > BC > C for both 90 and 120 deg dies, in terms of the generation of high-angle grain boundaries (HAGBs); (b) BC > C > A for both 90 and 120 deg dies, in terms of the formation of equiaxed shape of grains; and (c) BC > A > C for 90 deg die and BC ∼ A > C for 120 die, in terms of reducing grain size. It is suggested that the generation of HAGBs can be related to the accumulation of nonredundant strain, while the shape and orientation of grains may be linked to the shearing patterns of the deformation route.

Similar content being viewed by others

References

A. Korbel and M. Richert: Acta Metall., 1985, vol. 33, pp. 1971–78.

R.Z. Valiev, R.K. Islamgaliev, and I.V. Alexandrov: Progr. Mater. Sci., 2000, vol. 45, pp. 103–89.

Y. Saito, N. Tsuji, H. Utsunomiya, T. Sakai, and R.G. Hong: Scripta Mater., 1998, vol. 39, pp. 1221–27.

V.M. Segal, V.L. Reznikov, A.E. Drobysheveskiy, and V.I. Kopylov: Russ. Metall., 1981, vol. 1, pp. 115–23.

V.M. Segal: Mater. Sci. Eng., 1995, vol. A197, pp. 157–64.

Y. Iwahashi, Z. Horita, M. Nemoto, and T.G. Langdon: Acta Mater., 1997, vol. 45, pp. 4733–41.

P.L. Sun, P.W. Kao, and C.P. Chang: Mater. Sci. Eng., 2000, vol. A283, pp. 82–85.

Y. Iwahashi, Z. Horita, M. Nemoto, and T.G. Langdon: Metall. Mater. Trans. A, 1998, vol. 29A, pp. 2503–10.

J.R. Bowen, P.B. Prangnell, and F.J. Humphreys: Mater. Sci. Forum, 2000, vols. 331–337, pp. 545–50.

A. Gholinia, P.B. Prangnell, and M.V. Markushev: Acta Mater., 2000, vol. 48, pp. 1115–30.

T.L. Tsai, P.L. Sun, P.W. Kao, and C.P. Chang: Mater. Sci. Eng., 2003, vol. A342, pp. 144–51.

P. Berbon, M. Furukawa, Z. Horita, M. Nemoto, N.K. Tsenev, R.Z. Valiev, and T.G. Langdon: Mater. Sci. Forum, 1996, vols. 217–222, pp. 1013–18.

S. Ferrasse, V.M. Segal, K.T. Hartwig, and R.E. Goforth: Metall. Mater. Trans. A, 1997, vol. 28A, pp. 1047–57.

P.B. Berbon and T.G. Langdon: in Ultrafine Grained Materials, R.S. Mishra, S.L. Semiatin, C. Suryanarayana, N.N. Thadhani, and T.C. Lowe, eds., TMS, Warrendale, PA, 2000, pp. 381–92.

Y. Iwahashi, J. Wang, Z. Horita, M. Nemoto, and T.G. Langdon: Scripta Mater., 1996, vol. 35, pp. 143–46.

M. Furukawa, Y. Iwahashi, Z. Horita, M. Nemoto, and T.G. Langdon: Mater. Sci. Eng., 1998, vol. A257, pp. 328–32.

P.B. Berbon, M. Furukawa, Z. Horita, M. Nemoto, and T.G. Langdon: Metall. Mater. Trans. A, 1999, vol. 30A, pp. 1989–97.

A. Yamashita, D. Yamaguchi, Z. Horita, and T.G. Langdon: Mater. Sci. Eng., 2000, vol. A287, pp. 100–06.

J.R. Bowen, A. Gholinia, S.M. Roberts, and P.B. Prangnell: Mater Sci. Eng., 2000, vol. A287, pp. 87–99.

Y. Iwahashi, Z. Horita, M. Nemoto, and T.G. Langdon: Acta Mater., 1998, vol. 46, pp. 3317–31.

T.R. McNelley, D.L. Swisher, Z. Horita, and T.G. Langdon: in Ultrafine Grained Materials II, Y.T. Zhu, T.G. Langdon, R.S. Mishra, S.L. Semiatin, M.J. Saran, and T.C. Lowe, eds., TMS, Warrendale, PA, 2002, pp. 15–24.

M. Furukawa, Z. Horita, and T.G. Langdon: Mater. Sci. Eng., 2002, vol. A332, pp. 97–109.

V.M. Segal: Mater. Sci. Eng., 2002, vol. A338, pp. 331–44.

V.M. Segal: Mater. Sci. Eng., 1999, vol. A271, pp. 322–33.

Y.T. Zhu and T.C. Lowe: Mater. Sci. Eng., 2000, vol. A291, pp. 46–53.

P.L. Sun, P.W. Kao, and C.P. Chang: in Ultrafine Grained Materials II, Y.T. Zhu, T.G. Langdon, R.S. Mishra, S.L. Semiatin, M.J. Saran, and T.C. Lowe, eds., TMS, Warrendale, PA, 2002, pp. 35–42.

I.J. Beyerlein, R.A. Lebensohn, and C.N. Tomé: Mater. Sci. Eng., 2003, vol. A345, pp. 122–38.

Q. Liu: J. Appl. Cryst., 1994, vol. 27, pp. 755–61.

Q. Liu: Ultramicroscopy, 1995, vol. 60, pp. 81–89.

S.J. Zaefferer: J. Appl. Cryst., 2000, vol. 33, pp. 10–25.

J.K. Mackenzie: Biometrica, 1958, vol. 45, pp. 229–40.

F.J. Humphreys, P.B. Prangnell, J.R. Bowen, A. Gholinia, and C. Harris: Phil. Trans. R. Soc. London A, 1999, vol. 357, pp. 1663–81.

D.A. Hughes and N. Hansen: Acta Mater, 1997, vol. 45, pp. 3871–86.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Sun, PL., Kao, PW. & Chang, CP. Effect of deformation route on microstructural development in aluminum processed by equal channel angular extrusion. Metall Mater Trans A 35, 1359–1368 (2004). https://doi.org/10.1007/s11661-004-0311-5

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-004-0311-5