Abstract

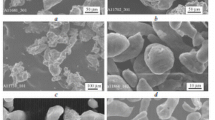

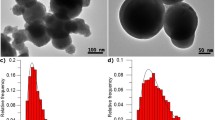

Amorphous spherical particles with diameters of 0.5 to 1.4 mm have been prepared by melt ejecting Ni-rich Ni-Pd-P alloys into stirred cold water with 1 vol pct surfactive agent. The sphericity of the amorphous particles defined by the difference in diameter was better than 98 pct. Particle diameters (d) are 2 to 3 times larger than the orifice diameter (2r) of the quartz nozzle. The size ratio has been interpreted by the Raplace’s relation (d = 4r) derived from the assumption that an internal pressure of molten alloy is equal between cylindrical stream and spherical droplet. From the result that no spherical amorphous particles are formed in the cold water without surfactive agent, a significant decrease in the surface tension of coolant by the addition of surfactive agent is essential in the formation of spherical liquid particles from the ejected melt stream. The amorphous particles with diameters below about 1.0 mm exhibit hardness, crystallization temperature, and heat of crys-tallization similar to those from the amorphous ribbon with about 40 μm thickness. However, the onset temperature and heat of relaxation are lower by 16 K (4.2 pct) and larger by 130 J/mol (13 pct), respectively, for the particles. It is thus concluded that the amorphous spherical particles have the same thermal stability as that of the amorphous ribbon and its structure is in a more disordered state as compared with the ribbon sample.

Similar content being viewed by others

References

A. Miller and R.J. Murphy:Scripta Met., 1979, vol. 13, p. 673.

N.J. Grant and P. K. Domalavaghe:J. Metals, 1983, vol. 1, p. 20.

T. Yamaguchi and K. Narita:IEEE Trans. Magn., 1977, vol. 13, p. 1621.

A. E. Berkowitz and J. L. Walter:Mater. Sci. Eng., 1982, vol. 55, p. 275.

H. Ishii, M. Naka, and T. Masumoto:Sci. Rep. Res. Inst. Tohoku Univ., 1981, vol. A-29, p. 343.

I. Ohnaka, Y. Tsutsumi, T. Daido, and T. Fukusako: private communication, Osaka Univ., Suita 565, Japan, Nov. 1981.

A. Inoue, M. Hagiwara, and T. Masumoto:J. Mater. Sci., 1982, vol. 17, p. 580.

M. R. Glickstein, R. J. Patterson, and N. E. Schockey:Rapid Solidification Processing, Principles and Technologies, R. Mehrabian, B. H. Kear, and M. Cohen, eds., Claitor's Publishing Division, Baton Rouge, LA, 1977, p. 46.

T. Sato, T. Ichiyama, T. Noda, and H. Kumai:Bull. Japan Inst. Metals, 1985, vol. 24, p. 509.

Y. Ishihara: private communication, Hitachi Research Laboratory, Hitachi Ltd., Hitachi 317, Japan, August 1981.

S. Ono:Surface Tension, Kyoritsu Pub. Co., Tokyo, 1980, p. 15.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Inoue, A., Ekimoto, T., Kimura, H.M. et al. Preparation of amorphous Ni-Pd-P particles by melt ejection into stirred water and their hardness and thermal stability. Metall Trans A 18, 377–383 (1987). https://doi.org/10.1007/BF02648797

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF02648797