Abstract

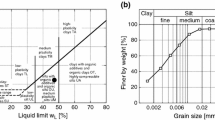

The flow rule used in the high-cycle accumulation (HCA) model proposed by Niemunis et al. (Comput Geotech 32: 245, 2005) is examined on the basis of the data from approximately 350 drained long-term cyclic triaxial tests (N = 105 cycles) performed on 22 different grain-size distribution curves of a clean quartz sand. In accordance with (Wichtmann et al. in Acta Geotechnica 1: 59, 2006), for all tested materials, the “high-cyclic flow rule (HCFR)”, i.e., the ratio of the volumetric and deviatoric strain accumulation rates \(\dot{\varepsilon}_{\rm{v}}^{{\rm acc}}/\dot{\varepsilon}_{\rm{q}}^{{\rm acc}}\), was found dependent primarily on the average stress ratio η av = q av/p av and independent of amplitude, soil density and average mean pressure. The experimental HCFR can be fairly well approximated by the flow rule of the modified Cam-clay (MCC) model. Instead of the critical friction angle \(\varphi_{\rm{c}}\) which enters the flow rule for monotonic loading, the HCA model uses the MCC flow rule expression with a slightly different parameter \(\varphi_{\rm{cc}}\). It should be determined from cyclic tests. \(\varphi_{\rm{cc}}\) and \(\varphi_{\rm{c}}\) are of similar magnitude but not always identical, because they are calibrated from different types of tests. For a simplified calibration in the absence of cyclic test data, \(\varphi_{\rm{cc}}\) may be estimated from the angle of repose \(\varphi_{\rm{r}}\) determined from a pluviated cone of sand (Wichtmann et al. in Acta Geotechnica 1: 59, 2006). However, the paper demonstrates that the MCC flow rule with \(\varphi_{\rm{r}}\) does not fit well the experimentally observed HCFR in the case of coarse or well-graded sands. For an improved simplified calibration procedure, correlations between \(\varphi_{\rm{cc}}\) and parameters of the grain-size distribution curve (d 50, C u) have been developed on the basis of the present data set. The approximation of the experimental HCFR by the generalized flow rule equations proposed in (Wichtmann et al. in J Geotech Geoenviron Eng ASCE 136: 728, 2010), considering anisotropy, is also discussed in the paper.

Similar content being viewed by others

References

Chang C, Whitman R (1988) Drained permanent deformation of sand due to cyclic loading. J Geotechn Eng ASCE 114(10):1164

Herle I (1997) Hypoplastizität und Granulometrie einfacher Korngerüste. Promotion, Institut für Bodenmechanik und Felsmechanik der Universität Fridericiana in Karlsruhe, Heft Nr. 142

Herle I, Gudehus G (1999) Determination of parameters of a hypoplastic constitutive model from properties of grain assemblies. Mech Cohes Frict Mater 4(5):461

Luong M (1982) Mechanical aspects and thermal effects of cohesionless soils under cyclic and transient loading. In: Proceedings of IUTAM Conference on deformation and failure of granular materials, Delft, pp. 239–246

Niemunis A (2003) Extended hypoplastic models for soils. Habilitation, Veröffentlichungen des Institutes für Grundbau und Bodenmechanik, Ruhr-Universität Bochum, Heft Nr. 34. http://www.pg.gda.pl/~aniem/an-liter.html

Niemunis A, Wichtmann T, Triantafyllidis T (2005) A high-cycle accumulation model for sand. Comput Geotech 32(4):245

Roscoe K, Burland J (1968) On the generalized stress-strain behaviour of wet clay. In: Engineering plasticity. ed. by J. Heyman, F. Leckie, Cambridge University Press, Cambridge, pp. 535–609

Wichtmann T, Niemunis A, Triantafyllidis T (2006) Experimental evidence of a unique flow rule of non-cohesive soils under high-cyclic loading. Acta Geotechnica 1(1):59

Wichtmann T, Niemunis A, Triantafyllidis T (2009) Validation and calibration of a high-cycle accumulation model based on cyclic triaxial tests on eight sands. Soils Found 49(5):711

Wichtmann T, Rondón H, Niemunis A, Triantafyllidis T, Lizcano A (2010) Prediction of permanent deformations in pavements using a high-cycle accumulation model. J Geotech Geoenviron Eng ASCE 136(5):728

Wichtmann T, Niemunis A, Triantafyllidis T (2010) On the determination of a set of material constants for a high-cycle accumulation model for non-cohesive soils. Int J Numer Anal Meth Geomech 34(4):409

Wichtmann T, Niemunis A, Triantafyllidis T (2010) Simplified calibration procedure for a high-cycle accumulation model based on cyclic triaxial tests on 22 sands. In: International Symposium: Frontiers in Offshore Geotechnics, Perth, Australia, pp. 383–388

Acknowledgements

The experiments analyzed in the paper have been performed in the framework of the project A8 “Influence of the fabric changes in soil on the lifetime of structures” of SFB 398 “Lifetime oriented design concepts” during the former work of the authors at Ruhr-University Bochum (RUB), Germany. The authors are grateful to DFG (German Research Council) for the financial support. The cyclic triaxial tests have been performed by M. Skubisch in the RUB soil mechanics laboratory.

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix 1: Generalized flow rule

In [10], the direction of accumulation m ij of the HCA model has been generalized in order to describe (inherent or induced) anisotropy. A second-order structure tensor

has been introduced with \(\breve{\sigma}_{ij}\) lying on a stress line for which the flow rule is assumed purely volumetric, i.e., \(m_{ij}(a_{ij}) = (\delta_{ij})^{\rightarrow} \cdot \breve{\sigma}_{ij}^{*}\) is the deviatoric part of \(\breve{\sigma}_{ij}\) and \(\breve{p}\) is the corresponding mean pressure. The isotropic flow rule can be recovered by setting a ij = 0. For the critical state, the flow rule is purely deviatoric. For an intermediate stress σ ij , an interpolation is used. Given a ij , the stress σ ij is projected radially onto the deviatoric plane expressed by p = 1. Next, the projected stress σ ij /p is decomposed as follows (Fig. 10a):

The so-called conjugated stress t ij is found from

It should lie on the critical surface at p = 1 (Fig. 10b). For that purpose, the scalar multiplier λ must be determined from the condition that the conjugated stress t ij satisfies

Having found λ, the generalized flow rule is calculated from

wherein n g is an interpolation parameter (a material constant). Linear interpolation is obtained with n g = 1.

As an example, the flow rule m ij for an axisymmetric stress with diagonal components

and for a transversal isotropy

is derived. The parameter a and the stress ratio η iso for which the accumulation is purely volumetric are interrelated via

Furthermore,

holds. From two solutions of Eq. (17) ,

the positive one is chosen as λ. Finally, the strain rate ratio ω is calculated from

for triaxial compression and extension, respectively. For an isotropic material (η iso = a = 0) Eq. (23) simplifies to

Appendix 2: Notation

- δ ij :

-

Kronecker delta (1 for i = j, 0 for i ≠ j)

- e :

-

Void ratio

- \(\varepsilon_1\) :

-

Axial strain

- \(\varepsilon_{3}\) :

-

Lateral strain

- \(\varepsilon_v\) :

-

Volumetric strain (\(= \varepsilon_{1} + 2 \varepsilon_{3}\) for triaxial tests)

- \(\varepsilon_{\rm{q}}\) :

-

Deviatoric strain (\(= 2/3 (\varepsilon_{1} - \varepsilon_{3}\)) for triaxial tests)

- \(\varepsilon^{{\rm ampl}}\) :

-

Strain amplitude

- \(\varepsilon^{{\rm acc}}\) :

-

Residual (accumulated) strain

- \(\varepsilon_{\rm{v}}^{{\rm acc}}\) :

-

Accumulated volumetric strain

- \(\varepsilon_{\rm{q}}^{{\rm acc}}\) :

-

Accumulated deviatoric strain

- \(\dot{\varepsilon}^{{\rm acc}}\) :

-

Intensity of strain accumulation

- \(\dot{\varepsilon}_{\rm{v}}^{{\rm acc}}\) :

-

Rate of volumetric strain accumulation

- \(\dot{\varepsilon}_{\rm{q}}^{{\rm acc}}\) :

-

Rate of deviatoric strain accumulation

- \(\varepsilon_{ij}^{{\rm av}}\) :

-

Average strain tensor

- \(\dot{\varepsilon}_{ij}^{{\rm av}}\) :

-

Trend of average strain

- \(\dot{\varepsilon}_{ij}^{{\rm acc}}\) :

-

Rate of strain accumulation

- \(\dot{\varepsilon}_{ij}^{{\rm pl}}\) :

-

Plastic strain rate

- E ijkl :

-

“Elastic stiffness” of HCA model

- \(\varphi_{\rm{c}}\) :

-

Critical friction angle

- \(\varphi_{\rm{cc}}\) :

-

MCC flow rule parameter calibrated from cyclic tests

- \(\varphi_{\rm{ccg}}\) :

-

Parameter of generalized flow rule

- \(\varphi_{\rm{r}}\) :

-

Angle of repose

- F :

-

Correction factor for M

- η :

-

Stress ratio =q/p

- η av :

-

Average stress ratio

- I D :

-

Relative density

- I D0 :

-

Initial value of relative density

- m v :

-

Volumetric part of flow rule (=m ii )

- m q :

-

Deviatoric part of flow rule (\(=\sqrt{2/3}\|m_{ij}^*\|\))

- M :

-

Critical stress ratio / Stress ratio with \(\dot{\varepsilon}_{\rm{v}}^{{\rm acc}} = 0\)

- M c :

-

Critical stress ratio for triaxial compression

- M cc :

-

Stress ratio with \(\dot{\varepsilon}_{\rm{v}}^{{\rm acc}} = 0\) for triaxial compression

- M ec :

-

Stress ratio with \(\dot{\varepsilon}_{\rm{v}}^{{\rm acc}} = 0\) for triaxial extension

- m ij :

-

Direction of strain accumulation (high-cyclic flow rule, HCFR)

- n g :

-

Parameter of generalized flow rule

- N :

-

Number of cycles

- p :

-

Effective mean pressure (=(σ 1 + 2 σ 3)/3 in triaxial tests)

- p av :

-

Average effective mean pressure

- q :

-

Deviatoric stress (=σ 1 − σ 3 in triaxial tests)

- q ampl :

-

Deviatoric stress amplitude

- σ 1 :

-

Effective axial stress

- σ 3 :

-

Effective lateral stress

- σ ij :

-

Effective Cauchy stress tensor

- σ av ij :

-

Average effective stress tensor

- \(\dot{\sigma}_{ij}^{{\rm av}}\) :

-

Trend of average effective stress

- \(\breve{\sigma}_{ij}\) :

-

Stress for which flow rule is purely volumetric

- ω :

-

Strain rate ratio (= \(\dot{\varepsilon}_v^{{\rm acc}}/\dot{\varepsilon}_q^{{\rm acc}}\))

- \(\bar{\omega}\) :

-

Average strain rate ratio of a test

- \(\zeta\) :

-

Amplitude-pressure ratio

- \(\|\sqcup\|\) :

-

Norm of \(\sqcup\)

- \(\sqcup^{*}\) :

-

Deviatoric part of \(\sqcup\)

- \(\sqcup^{\rightarrow}\) :

-

Normalization, i.e., \(\sqcup/\|\sqcup\|\)

Rights and permissions

About this article

Cite this article

Wichtmann, T., Niemunis, A. & Triantafyllidis, T. Flow rule in a high-cycle accumulation model backed by cyclic test data of 22 sands. Acta Geotech. 9, 695–709 (2014). https://doi.org/10.1007/s11440-014-0302-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11440-014-0302-7