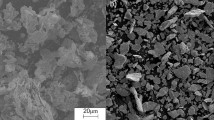

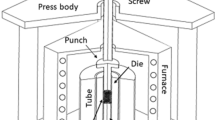

This paper is an attempt to understand the characteristics of Al + TiO2 + Gr hybrid ball-milled composite powders, which would probably have extensive applications in the near future. Aluminum with titanium dioxide (TiO2) and graphite (Gr) powders was ball-milled in order to get a composition like: Al + 0% TiO2, Al + 5% TiO2, Al + 5% TiO2 + 2% Gr, Al + 5% TiO2 + 4% Gr and Al + 5% TiO2 + 6% Gr. The grain size, lattice space, lattice constant, stress, strain, dislocation density, and volume of the unit cell were calculated according to the data of X-Ray diffraction analysis of milled powders. Compressibility tests were performed in a hardened steel die under pressures between 100 to 500 MPa to determine Al with 5 wt.% TiO2 and 2 & 4 wt.% of Gr powder mixtures. For understanding the compaction behavior of aluminum-based hybrid composites reinforced with TiO2 and Gr particles under various applied pressure conditions, the experimental research was realized by using several powder compaction equations. The microstructure analysis is reported for the Al + 5% TiO2 + 6% Gr composite.

Similar content being viewed by others

References

M. Rahimian, N. Parvin, and N. Ehsani, “The effect of production parameters on microstructure and wear resistance of powder metallurgy Al–Al2O3 composite,” Mater. Design, 32, 1031–1038 (2011).

S. Sivasankaran, K. Sivaprasad, R. Narayanasamy, and V. Kumar Iyer, “An investigation on flowability and compressibility of AA 6061 100−x-x wt.% TiO2 micro and nanocomposite powder prepared by blending and mechanical alloying,” Powder Technol., 201, 70–82 (2010).

P. Ravindran, K. Manisekar, P. Narayanasamy, N. Selvakumar, and R. Narayanasamy, “Application of factorial techniques to study the wear of Al hybrid composites with graphite addition,” Mater. Design, 39, 42–54 (2012).

F. Akhlaghi and S. A. Pelaseyyed, “Characterization of aluminum/graphite particulate composites synthesized using a novel method termed “in-situ powder metallurgy,” Mater. Sci. Eng. A, 385, 258–266 (2004).

M. Adamiak, “Mechanical alloying for fabrication of aluminum matrix composite powders with Ti–Al intermetallics reinforcement,” J. Arch. Mater. Manufact. Eng., 31, 191–196 (2008).

H. Z. Razavi, H. R. Hafizpour, and A. Simchi, “An investigation on the compressibility of aluminum/nanoalumina composite powder prepared by blending and mechanical milling,” Mater. Sci. Eng. A, 454–455, 89–98 (2007).

V. Viswanathan, T. Laha, K. Balani, A. Agarwal, and S. Seal, “Challenges and advances in nanocomposite processing techniques,” Mater. Sci. Eng. R, 54, 121–285 (2006).

J. B. Fogagnolo, F. Velasco, M. H. Robert, and J. M. Torralba, “Effect of mechanical alloying on the morphology, microstructure and properties of aluminum matrix composite powders,” Mater. Sci. Eng. A, 342, 131–143 (2003).

S. M. Zebarjad and S. A. Sajjadi, “Microstructure evaluation of Al–Al2O3 composite produced by mechanical alloying method,” Mater. Design, 27, 684–688 (2006).

B. Prabhu, C. Suryanarayana, L. Ana, and R. Vaidyanathan, “Synthesis and characterization of high volume fraction Al–Al2O3 nanocomposite powders by high-energy milling,” Mater. Sci. Eng. A, 425, No. 2, 192–200 (2006).

S. Sivasankaran, K. Sivaprasad, R. Narayanasamy, and P. V. Satyanarayana, “X-ray peak broadening analysis of AA 6061100−x−x wt. % Al2O3 nanocomposite prepared by mechanical alloying,” Mater. Charact., 62, 661–672 (2011).

M. Ravichandran, A. N. Sait, and V. Anandakrishnan, “Synthesis and forming behavior of aluminum-based hybrid powder metallurgic composites,” Int. J. Min. Met. Mater., 21, 181–189 (2014).

J. H. Shin, H. J. Choi, and D. H. Bae, “The structure and properties of 2024 aluminum composites reinforced with TiO2 nanoparticles,” Mater. Sci. Eng. A, 607, 605–610 (2014).

C. Ghia and I. N. Popescu, “Experimental research and compaction behavior modeling of aluminum based composites reinforced with silicon carbide particles,” Comp. Mater. Sci., 64, 136–140 (2012).

A. Hafeez and V. Senthilkumar, “Consolidation behavior of mechanically alloyed aluminum based nanocomposites reinforced with nanoscale Y2O3/Al2O3 particles,” Mater. Charact., 62, 1235–1249 (2011).

S. Romankov, Y. Hayasaka, I. V. Shchetinin, J.-M. Yoon, and S. V. Komarov, “Fabrication of Cu–SiC surface composite under ball collisions,” Appl. Surf. Sci., 257, 5032–5036 (2011).

Author information

Authors and Affiliations

Corresponding author

Additional information

Published in Fizyko-Khimichna Mekhanika Materialiv, Vol. 51, No. 4, pp. 136–143, July–August, 2015.

Rights and permissions

About this article

Cite this article

Ravichandran, M., Vidhya, V. & Anandakrishanan, V. Study of the Characteristics of AL + 5 wt.% TiO2 + 6 wt.% GR Hybrid P/M Composite Powders Prepared by the Process of Ball Milling. Mater Sci 51, 589–597 (2016). https://doi.org/10.1007/s11003-016-9880-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11003-016-9880-x