Abstract

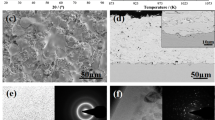

VN and VCN coatings were prepared using multi-arc ion plating technique on 316L stainless steel and single silicon substrates. Microstructures, mechanical performances, corrosion behaviors and tribology properties of VN and VCN coatings in the atmosphere, distilled water and seawater were contrastively tested. It was confirmed that the VCN coating had a typical nanocystallite/amorphous structure. Moreover, the hardness increased from 30.5 to 36.5 GPa and the corrosion current density decreased from 2.16 × 10−6 to 0.82 × 10−6 A cm−2 after carbon was doped into the VN coating. Compared with the VN coating, the VCN coating had the lowest friction coefficient of 0.26 and wear rate of 0.68 × 10−6 mm3 Nm−1 in seawater, which could be ascribed to the lubrication of graphitization transfer film and improvement of the comprehensive performance.

Similar content being viewed by others

Change history

21 August 2021

A Correction to this paper has been published: https://doi.org/10.1007/s42864-021-00115-4

References

Wang WC. Application of a high temperature self-lubricating composite coating on steam turbine components. Surf Coat Technol. 2004;177–178:12.

Liu C, Revilla RI, Zhang DW, Liu ZY, Lutz A, Zhang F, Zhao TL, Ma HC, Li XG, Terryn H. Role of Al2O3 inclusions on the localized corrosion of Q460NH weathering steel in marine environment. Corros Sci. 2018;138:96.

Liu C, Revilla RI, Liu ZY, Zhang DW, Li XG, Terryn H. Effect of inclusions modified by rare earth elements (Ce, La) on localized marine corrosion in Q460NH weathering steel. Corros Sci. 2017;129:82.

Voevodin AA, Zabinski JS. Nanocomposite and nanostructured tribological materials for space applications. Compos Sci Technol. 2005;65(5):741.

Ye YW, Zhang DW, Liu T, Liu ZY, Pu JB, Liu W, Zhao HC, Li XG, Wang LP. Superior corrosion resistance and self-healable epoxy coating pigmented with silanzied trianiline-intercalated graphene. Carbon. 2019;142:164.

Liu EY, Bai YP, Gao YM, Yi GW, Jia JH. Tribological properties of NiAl-based composites containing Ag3VO4 nanoparticles at elevated temperatures. Tribol Int. 2014;80:25.

Wang JJ, Pu JB, Zhang GA, Wang LP. Architecture of superthick diamond-like carbon films with excellent high temperature wear resistance. Tribol Int. 2015;81:129.

Aouadi SM, Gao H, Martini A, Scharf TW, Muratore C. Lubricious oxide coatings for extreme temperature applications: a review. Surf Coat Technol. 2014;257:266.

Ye YW, Wang YX, Ma XL, Zhang DW, Wang LP, Li XG. Tribocorrosion behaviors of multilayer PVD DLC coated 304L stainless steel in seawater. Diam Relat Mater. 2017;79:70.

Luster B, Stone D, Singh DP, Baben MT, Schneider JM, Polychronopoulou K, Rebholz C, Kohli P. Aouadi SM. Textured VN coatings with Ag3VO4 solid lubricant reservoirs. Surf Coat Technol. 2011;206(7):1932.

Luo Q. Temperature dependent friction and wear of magnetron sputtered coating TiAlN/VN. Wear. 2011;271(9–10):2058.

Su Q, Liu XQ, Ma HL, Guo YP, Wang YY. Raman spectroscopic characterization of the microstructure of V2O5 films. J Solid State Electr. 2008;12(7–8):919.

Ge FF, Zhu P, Meng FP, Xue QJ, Huang F. Achieving very low wear rates in binary transition-metal nitrides: the case of magnetron sputtered dense and highly oriented VN coatings. Surf Coat Technol. 2014;248:81.

Mu YT, Liu M, Zhao YQ. Carbon doping to improve the high temperature tribological properties of VN coating. Tribol Int. 2016;97:327.

Escobar C, Villarreal M, Caicedo JC, Aperador M, Prieto P. Tribological and wear behavior of HfN/VN nano-multilayer coated cutting tools. Ingeniería E Investigación. 2014;34:22.

Aouadi SM, Singh DP, Stone DS, Polychronopoulou K, Nahif F, Rebholz C, Muratore C, Voevodin AA. Adaptive VN/Ag nanocomposite coatings with lubricious behavior from 25 to 1000 °C. Acta Mater. 2010;58(16):5326.

Antonik MD, Lad RJ, Christensen TM. Clean surface and oxidation behavior of vanadium carbide, VC0.75(100). Surf Interface Anal. 1996;24(10):681.

Dai W, Ke PL, Wang AY. Microstructure and property evolution of Cr-DLC films with different Cr content deposited by a hybrid beam technique. Vacuum. 2011;85(8):792.

Zhou F, Adachi K, Kato K. Friction and wear property of a-CNx coatings sliding against ceramic and steel balls in water. Diam Relat Mater. 2005;14(10):1711.

Bismarck A, Tahhan R, Springer J, Schulz A, Klapotke TM, Zell H. Influence of fluorination on the properties of carbon fibres. J Fluor Chem. 1997;84(2):127.

Zhao ZW, Liu Y, Cao H, Gao SJ, Tu MJ. Synthesis of VN nanopowders via thermal processing of the precursor in N2 atmosphere. Int J Refract Met H. 2008;26(5):429.

Dang CQ, Li JL, Wang YX, Chen JM. Structure, mechanical and tribological properties of self-toughening TiSiN/Ag multilayer coatings on Ti6Al4V prepared by arc ion plating. Appl Surf Sci. 2016;386:224.

Ye YW, Wang YX, Wang CT, Li JL, Yao YR. An analysis on tribological performance of CrCN coatings with different carbon contents in seawater. Tribol Int. 2015;91:131.

Ye YW, Liu ZY, Liu W, Zhang DW, Wang YX, Zhao HC, Wang LP, Li XG. Bias design of amorphous/nanocrystalline Cr-Al-Si-N films for remarkable anti-corrosion and anti-wear performances in seawater. Tribol Int. 2018;121:410.

Ye YW, Wang YX, Chen H, Li JL, Zhou SG, Xue QJ. Influences of bias voltage on the microstructures and tribological performances of Cr-C-N coatings in seawater. Surf Coat Technol. 2015;270:305.

Ye YW, Wang YX, Chen H, Li JL, Yao YR, Wang CT. Doping carbon to improve the tribological performance of CrN coatings in seawater. Tribol Int. 2015;90:362.

Ye YW, Zhang DW, Li JL, Liu T, Pu JB, Zhao HC, Wang LP. One-step synthesis of superhydrophobic polyhedral oligomeric silsesquioxane-graphene oxide and its application in anti-corrosion and anti-wear fields. Corro Sci. 2019;147:9.

Ye YW, Wang CT, Wang YX, Liu W, Liu ZY, Li XG. The influence of different metallic counterparts on the tribological performance of nc-CrC/GLC in seawater. Surf Coat Technol. 2017;325:689.

Ye YW, Liu ZY, Liu W, Zhang DW, Wang YX, Zhao HC, Li XG. Effect of interlayer design on friction and wear behaviors of CrAlSiN coating under high load in seawater. RSC Adv. 2018;8(10):5596.

Wang YX, Wang LP, Zhang GA, Wang SC, Wood RJK, Xue QJ. Effect of bias voltage on microstructure and properties of Ti-doped graphite-like carbon films synthesized by magnetron sputtering. Surf Coat Technol. 2010;205:793.

Zhang HS. Comparative surface and nano-tribological characteristics of nanocomposite diamond-like carbon thin films doped by silver. Appl Surf Sci. 2008;255:2551.

Holmberg K, Ronkainen H, Laukkanen A, Wallin K. Friction and wear of coated surfaces-scales, modeling and simulation of tribomechanisms. Surf Coat Technol. 2007;202:1034.

Suzuki M, Tanaka A, Ohana T, Zhang W. Frictional behavior of DLC films in a water environment. Diam Relat Mater. 2004;13(4–8):1464.

Sánchez-López JC, Erdemir A, Donnet C, Rojas TC. Friction-induced structural transformations of diamond like carbon coatings under various atmospheres. Surf Coat Technol. 2002;163–164:444.

Acknowledgements

This work was supported by the Program of Qingjiang Excellent Young Talents, Jiangxi University of Science and Technology, Natural Science Foundation of Jiangxi Province (Grant 20181BBE58001) and Natural Science Foundation of Jiangxi Education Department (Grant GJJ180431).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chen, H., Xie, X., Wang, Y. et al. Understanding corrosion and tribology behaviors of VN and VCN coatings in seawater. Tungsten 1, 110–119 (2019). https://doi.org/10.1007/s42864-019-00002-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42864-019-00002-z