Abstract

Polyester resins are important raw materials for a myriad of applications especially in the field of coatings and radical curing polymers, such as wood and powder coatings, molding compounds, and UV-curing applications. In addition, polyols derived from polyester resins are precursors for the synthesis of polyurethanes and polycarbonates. Besides dicarboxylic acid, diols are used as monomers in these polyesters. To date most of the diols utilized are derived from petrochemical feedstock. To increase the bio-based content of polyester resins, novel diols derived from renewable resources are of special interest. In this respect, 1,3-propanediol has drawn considerable attention over the last years. It is accessible via microbial fermentation of glucose from starch at a competitive price in sufficient amounts. Therefore, 1,3-propanediol could be a valuable alternative to petrochemical diols, such as 1,6-hexanediol and neopentylglycol, which are currently used as diols in most resin applications. This article gives a brief overview over the utilization of 1,3-propanediol in high molecular weight polyesters for plastic application followed by a more detailed discussion of the most relevant work in the field of polyester resins derived from 1,3-propanediol.

Similar content being viewed by others

References

World Economic Forum, Ellen MacArthur Foundation and McKinsey & Company (2016) The new plastics economy—Rethinking the future of plastics. https://www.ellenmacarthurfoundation.org/publications/the-new-plastics-economy-rethinking-the-future-of-plastics

Fakirov S (ed) (2015) Biodegradable polyesters. Wiley, Weinheim

Auras RA, Lim LT, Selke SEM, Tsuji H (2010) Poly (lactic acid): synthesis, structures, properties, processing, and applications. Wiley, Hoboken

Endres H-J, Siebert-Raths A (2011) Engineering biopolymers: markets, manufacturing, properties and applications. Hanser, Munich

Hamad K, Kaseem M, Ayyoob M, Joo J, Deri F (2018) Polylactic acid blends: the future of green, light and tough. Prog Polym Sci 85:83–127

Li Z, Yang J, Loh XJ (2016) Polyhydroxyalkanoates: opening doors for a sustainable future. NPG Asia Mater 8:e265

Philip S, Keshavarz T, Roy I (2007) Polyhydroxyalkanoates: biodegradable polymers with a range of applications. J Chem Technol Biotechnol 82:233–247

Możejko-Ciesielska J, Kiewisz R (2016) Bacterial polyhydroxyalkanoates: still fabulous? Microbiol Res 192:271–282

Anjum A, Zuber M, Zia KM, Noreen A, Anjum MN, Tabasum S (2016) Microbial production of polyhydroxyalkanoates (PHAs) and its copolymers: a review of recent advancements. Int J Biol Macromol 89:161–174

Muller J, González-Martínez C, Chiralt A (2017) Combination Of Poly(lactic) acid and starch for biodegradable food packaging. Materials 10:952

Murariu M, Dubois P (2016) PLA composites: from production to properties. Adv Drug Deliv Rev 107:17–46

Narayanan G, Vernekar VN, Kuyinu EL, Laurencin CT (2016) Poly (lactic acid)-based biomaterials for orthopaedic regenerative engineering. Adv Drug Deliv Rev 107:247–276

Rabnawaz M, Wyman I, Auras R, Cheng S (2017) A roadmap towards green packaging: the current status and future outlook for polyesters in the packaging industry. Green Chem 19:4737–4753

Jain A, Kunduru KR, Basu A, Mizrahi B, Domb AJ, Khan W (2016) Injectable formulations of poly(lactic acid) and its copolymers in clinical use. Adv Drug Deliv Rev 107:213–227

Gandini A, Lacerda TM (2015) From monomers to polymers from renewable resources: recent advances. Prog Polym Sci 48:1–39

Gandini A, Lacerda TM, Carvalho AJF, Trovatti E (2016) Progress of polymers from renewable resources: furans, vegetable oils, and polysaccharides. Chem Rev 116:1637–1669

Gandini A (2008) Polymers from renewable resources: a challenge for the future of macromolecular materials. Macromolecules 41:9491–9504

Mathers RT, Meier MAR (2011) Green polymerization methods: renewable starting materials, catalysis and waste reduction. Wiley, Weinheim

Papageorgiou GZ, Papageorgiou DG, Terzopoulou Z, Bikiaris DN (2016) Production of bio-based 2,5-furan dicarboxylate polyesters: recent progress and critical aspects in their synthesis and thermal properties. Eur Polym J 83:202–229

Vilela C, Sousa AF, Fonseca AC, Serra AC, Coelho JFJ, Freire CSR, Silvestre AJD (2014) The quest for sustainable polyesters–insights into the future. Polym Chem 5:3119–3141

Zhu Y, Romain C, Williams CK (2016) Sustainable polymers from renewable resources. Nature 540:354

Zia KM, Noreen A, Zuber M, Tabasum S, Mujahid M (2016) Recent developments and future prospects on bio-based polyesters derived from renewable resources: a review. Int J Biol Macromol 82:1028–1040

Arntz D, Haas T, Müller A, Wiegand N (1991) Kinetische untersuchung zur hydratisierung von acrolein. Chem Ing Tech 63:733–735

Slaugh LH, Powell JB, Forschner TC, Semple TC, Weider PR (1995) Process for preparing 1,3-propandiol, US Patent 5,463,346.

Nakamura CE, Whited GM (2003) Metabolic engineering for the microbial production of 1,3-propanediol. Curr Opin Biotechnol 14:454–459

Saltzberg MA, Byrne AM, Jackson EN, Miller ES, Nelson MJ, Tyreus BD, Zhu Q (2016) DuPont: biorenewables at E.I. DU Pont DE Nemours & Co. In: Domínguez de María P (ed) Industrial biorenewables: a practical viewpoint. Wiley, Hoboken, pp 175–217

Whinfield JR, Dickson JT (1941) Improvements Relating to the Manufacture of Highly Polymeric Substances, US Patent 2,465,319.

Desborough IJ, Hall IH, Neisser JZ (1979) Structure of Poly (trimethylene terephthalate). Polymer 20:545–552

Roupakias CP, Bikiaris DN, Karayannidis GP (2005) Synthesis, thermal characterization, and tensile properties of alipharomatic polyesters derived from 1,3-propanediol and terephthalic, isophthalic, and 2,6-naphthalenedicarboxylic acid. J Polym Sci Part A Polym Chem 43:3998–4011

Fehrenbacher U, Grosshardt O, Kowollik K, Tübke B, Dingenouts N, Wilhelm M (2009) Synthese und charakterisierung von polyestern und polyamiden auf der basis von furan-2,5-dicarbonsäure. Chem Ing Tech 81:1829–1835

Gomes M, Gandini A, Silvestre AJD, Reis B (2011) Synthesis and characterization of poly(2,5-furan dicarboxylate)s based on a variety of diols. J Polym Sci Part A Polym Chem 49:3759–3768

Papageorgiou GZ, Papageorgiou DG, Tsanaktsis V, Bikiaris DN (2015) Synthesis of the bio-based polyester poly(propylene 2,5-furan dicarboxylate). Comparison of thermal behavior and solid state structure with its terephthalate and naphthalate homologues. Polymer 62:28–38

Ward IM, Wilding MA, Brody H (1976) The mechanical properties and structure of poly(m-methylene terephthalate) fibers. J Polym Sci Polym Phys Edit 14:263–274

Vannini M, Marchese P, Celli A, Lorenzetti C (2015) Fully biobased poly(propylene 2,5-furandicarboxylate) for packaging applications: excellent barrier properties as a function of crystallinity. Green Chem 17:4162–4166

Hbaieb S, Kammoun W, Delaite C, Abid M, Abid S, El Gharbi R (2015) New copolyesters containing aliphatic and bio-based furanic units by bulk copolycondensation. J Macromol Sci Part A 52:365–373

Bikiaris DN, Papageorgiou GZ, Achilias DS (2006) Synthesis and comparative biodegradability studies of three poly(alkylene succinate)s. Polym Degrad Stab 91:31–43

Bikiaris DN, Papageorgiou GZ, Giliopoulos DJ, Stergiou CA (2008) Correlation between chemical and solid-state structures and enzymatic hydrolysis in novel biodegradable polyesters. The case of Poly(propylene alkanedicarboxylate)s. Macromol Biosci 8:728–740

Debuissy T, Pollet E, Averous L (2017) Synthesis and characterization of fully biobased Poly(propylene succinate-ran-propylene adipate). Analysis of the Architecture-Dependent Physicochemical Behavior. J Polym Sci Part A Polym Chem 55:2738–2748

Debuissy T, Sangwan P, Pollet E, Averous L (2017) Study on the structure-properties relationship of biodegradable and biobased aliphatic copolyesters based on 1,3-propanediol, 1,4-butanediol, succinic and adipic acids. Polymer 122:105–116

Umare SS, Chandure AS, Pandey RA (2007) Synthesis, characterization and biodegradable studies of 1,3-propanediol based polyesters. Polym Degrad Stab 92:464–479

Liu H, Ou X, Zhou S, Liu D (2010) Microbial 1,3-propanediol, its copolymerization with terephthalate, and applications. In: Chen G-Q (ed) Plastics from bacteria: natural functions and applications. Springer, Berlin, pp 405–425

Liu H, Xu Y, Zheng Z, Liu D (2010) 1,3-Propanediol and its copolymers: research, development and industrialization. Biotechnol J 5:1137–1148

Sousa AF, Vilela C, Fonseca AC, Matos M, Freire CSR, Gruter G-JM, Coelho JFJ, Silvestre AJD (2015) Biobased polyesters and other polymers from 2,5-furandicarboxylic acid: a tribute to furan excellency. Polym Chem 6:5961–5983

Achilias DS, Bikiaris DN (2015) Synthesis, properties, and mathematical modeling of biodegradable aliphatic polyesters based on 1,3-propanediol and dicarboxylic acids. Biodegradable polyesters. Wiley, Weinheim, pp 73–108

Papageorgiou GZ, Bikiaris DN (2008) Biodegradable aliphatic polyesters derived from 1,3-propanediol: current status and promises. In: Yamashita H, Nakano Y (eds) Polyester: properties, preparation and applications. Nova Science Publishers, New York, pp 147–173

Liu Y, Söderqvist Lindblad M, Ranucci E, Albertsson A-C (2001) New segmented poly(ester-urethane)s from renewable resources. J Polym Sci Part A Polym Chem 39:630–639

Ranucci E, Liu Y, Söderqvist Lindblad M, Albertsson A-C (2000) New biodegradable polymers from renewable sources: High molecular weight poly(ester carbonate)s from succinic acid and 1,3-propanediol. Macromol Rapid Commun 21:680–684

Liu Y, Ranucci E, Söderqvist Lindblad M, Albertsson A-C (2001) New biodegradable polymers from renewable sources: Polyester-carbonates based on 1,3-propylene-co-1,4-cyclohexanedimethylene succinate. J Polym Sci Part A Polym Chem 39:2508–2519

Li C, Sablong RJ, Koning CE (2015) Synthesis and characterization of fully-biobased α, ω-dihydroxyl poly(limonene carbonate)s and their initial evaluation in coating applications. Eur Polymer J 67:449–458

Li C, van Berkel S, Sablong RJ, Koning CE (2016) Post-functionalization of fully biobased poly(limonene carbonate)s: synthesis, characterization and coating evaluation. Eur Polym J 85:466–477

Daniliuc A, Deppe B, Deppe O, Friebel S, Kruse D, Philipp C (2012) New trends in wood coatings and fire retardants. Eur Coat J 7/8:20–25

Philipp C, Eschig S (2012) Waterborne polyurethane wood coatings based on rapeseed fatty acid methyl esters. Prog Org Coat 74:705–711

García González MN, Börjesson P, Levi M, Turri S (2018) Development and life cycle assessment of polyester binders containing 2,5-Furandicarboxylic acid and their polyurethane coatings. J Polym Environ 26:3626–3637

Gao C, Han S, Zhang D, Wang B, Wang C, Wu Y, Liu Y (2018) A facile preparation of UV-cured films from waterborne unsaturated polyester via click reaction. Prog Org Coat 124:232–239

Akgün N, Büyükyonga ÖN, Acar I, Güçlü G (2016) Synthesis of novel acrylic modified water reducible alkyd resin: investigation of acrylic copolymer ratio effect on film properties and thermal behaviors. Polym Eng Sci 56:947–954

Büyükyonga ÖN, Akgün N, Acar I, Güçlü G (2017) Synthesis of four-component acrylic-modified water-reducible alkyd resin: investigation of dilution ratio effect on film properties and thermal behaviors. J Coat Technol Res 14:117–128

Lomelí-Rodríguez M, Corpas-Martínez J, Willis S, Mulholland R, Lopez-Sanchez J (2018) Synthesis and characterization of renewable polyester coil coatings from biomass-derived Isosorbide, FDCA, 1,5-pentanediol, succinic acid, and 1,3-propanediol. Polymers 10:600

Thames SF, Zhou L, Smith OW, Boon WH, Forschner TC (2000) Polyester powder coatings based on 1,3-propanediol. Abstr Pap Am Chem Soc 219:U481–U481

Noordover BAJ, van Staalduinen VG, Duchateau R, Koning CE, van Benthem R, Mak M, Heise A, Frissen AE, van Haveren J (2006) Co- and terpolyesters based on isosorbide and succinic acid for coating applications: synthesis and characterization. Biomacromol 7:3406–3416

Guo B, Chen Y, Lei Y, Zhang L, Zhou WY, Rabie ABM, Zhao J (2011) Biobased poly(propylene sebacate) as shape memory polymer with tunable switching temperature for potential biomedical applications. Biomacromol 12:1312–1321

Fonseca AC, Costa CSMF, Marques TMP, Coelho JFJ, Serra AC (2017) The impact of a designed lactic acid-based crosslinker in the thermochemical properties of unsaturated polyester resins/nanoprecipitated calcium carbonate composites. J Mater Sci 52:1272–1284

Farmer T, Castle R, Clark J, Macquarrie D (2015) Synthesis of unsaturated polyester resins from various bio-derived platform molecules. Int J Mol Sci 16:14912

Ordelt VZ (1963) Über die Reaktion von Glykolen mit der olefinischen Doppelbindung bei der Darstellung von ungesättigten Polyestern durch Schmelzkondensation. Die Makromolekulare Chemie 63:153–161

Ordelt Z, Krátký B (1969) Aufgabe der Reaktionssteuerung bei der Synthese von ungesättigten Polyestern aus Maleinsäureanhydrid. Farbe und Lack 6:523–531

Lehtonen J, Salmi T, Immonen K, Paatero E, Nyholm P (1996) Kinetic model for the homogeneously catalyzed polyesterification of dicarboxylic acids with diols. Ind Eng Chem Res 35:3951–3963

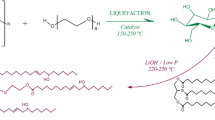

Schoon I, Kluge M, Eschig S, Robert T (2017) Catalyst influence on undesired side reactions in the polycondensation of fully bio-based polyester itaconates. Polymers 9:693

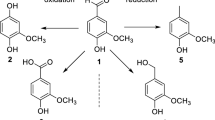

Robert T, Friebel S (2016) Itaconic acid—a versatile building block for renewable polyesters with enhanced functionality. Green Chem 18:2922–2934

Robert T, Eschig S, Biemans T, Scheifler F (2018) Bio-based polyester itaconates as binder resins for UV-curing offset printing inks. J Coat Technol Res. https://doi.org/10.1007/s11998-018-0146-4

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Rights and permissions

About this article

Cite this article

Kluge, M., Pérocheau Arnaud, S. & Robert, T. 1,3-Propanediol and its Application in Bio-Based Polyesters for Resin Applications. Chemistry Africa 2, 215–221 (2019). https://doi.org/10.1007/s42250-018-0026-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42250-018-0026-4