Abstract

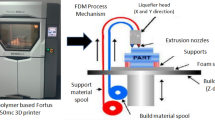

Open-source printing is a field where the cost of printing additive manufacturing products is cheaper due to more economical software and parts to construct a product including those of tissue engineering scaffolds. In this manuscript, fused deposition modeling (FDM) is used as the main avenue of open-source use in 3D printing of tissue engineering scaffolds. Additive manufacturing enables the researchers to build 3D products with interior and exterior architectures precisely defined and produced using open-access software which dictates the printer to print the models or the data obtained by various imaging techniques. In this way, implants to suit the dimensions and the mechanical and physicochemical properties needed for an artificial extracellular matrix can be produced. The main limitations are the limited number of printing materials and their unknown compositions which make their biocompatibility an issue. With the recent developments of in-house filament production, this limitation is also being overcome.

Similar content being viewed by others

References

R. Langer, J.P. Vacanti, Tissue engineering. Science. 260, 920–926 (1993)

F. Asghari, M. Samiei, K. Adibkia, A. Akbarzadeh, S. Davaran, Biodegradable and biocompatible polymers for tissue engineering application: a review. Artif. Cells Nanomed. Biotechnol. 45(2), 185–192 (2017)

C. Zhou, K. Yang, K. Wang, X. Pei, Z. Dong, Y. Hong, X. Zhang, Combination of fused deposition modeling and gas foaming technique to fabricated hierarchical macro/microporous polymer scaffolds. Mater. Des. 109, 415–424 (2016)

N.G. Rim, C.S. Shin, H. Shin, Current approaches to electrospun nanofibers for tissue engineering. Biomed. Mater. 8(1), 014102 (2013)

Y.F. Liu, X.T. Dong, F.D. Zhu, Adv. Mater. Res. 102–104, 550–554 (2010)

N. Mohan, P. Senthil, S. Vinodh, N. Jayanth, A review on composite materials and process parameters optimisation for the fused deposition modelling process. Virtual Phys. Prototyp. 12(1), 47–59 (2017)

K.S. Boparai, R. Singh, H. Singh, Development of rapid tooling using fused deposition modeling: a review. Rapid Prototyp. J. 22(2), 281–299 (2016)

B. Zhang, B. Seong, V.D. Nguyen, D. Byun, 3D printing of high-resolution PLA-based structures by hybrid electrohydrodynamic and fused deposition modeling techniques. J. Micromech. Microeng. 26(2), 025015 (2016)

J.M. Pearce, C. Morris Blair, K.J. Laciak, R. Andrews, A. Nosrat, I. Zelenika-Zovko, J. Sustain. Dev. 3(4), 17 (2012)

S. Bose, M. Roy, A. Bandyopadhyay, Recent advances in bone tissue engineering scaffolds. Trends Biotechnol. 30(10), 546–554 (2012)

U. Jammalamadaka, K. Tappa, Recent Advances in Biomaterials for 3D Printing and Tissue Engineering. J. Funct. Biomater. 9(1), 22 (2018)

C. Casavola, A. Cazzato, V. Moramarco, C. Pappalettere, Orthotropic mechanical properties of fused deposition modelling parts described by classical laminate theory. Mater. Des. 90, 453–458 (2016)

L.M. Galantucci, F. Lavecchia, G. Percoco, Quantitative analysis of a chemical treatment to reduce roughness of parts fabricated using fused deposition modeling. CIRP Ann. Manuf. Technol. 59(1), 247–250 (2010)

D. Pranzo, P. Larizza, D. Filippini, G. Percoco, Extrusion-based 3D printing of microfluidic devices for chemical and biomedical applications: a topical review. Micromachines 9(8), 374 (2018)

L.M. Galantucci, I. Bodi, J. Kacani, F. Lavecchia, Analysis of dimensional performance for a 3D open-source printer based on fused deposition modeling technique. Procedia CIRP 28, 82–87 (2015)

A. Brown, D. De Beer, P. Conradie, Development of a stereolithography (stl) input and computer numerical control (cnc) output algorithm for an entry-level 3-d printer. S. Afr. J. Ind. Eng 25, 39–47 (2014)

B.K. Gu, D.J. Choi, S.J. Park, M.S. Kim, C.M. Kang, C.H. Kim, 3-dimensional bioprinting for tissue engineering applications. Biomater. Res. 20(1), 12 (2016)

I. Abudayyeh, B. Gordon, M.M. Ansari, K. Jutzy, L. Stoletniy, A. Hilliard, J. Interv, Cardiol. 31(3), 375–383 (2018)

R. Singh, J.P. Davim, Additive Manufacturing: Applications and Innovations, 1st edn. (CRC Press, NW, 2018)

J. Torres, M. Cole, A. Owji, Z. DeMastry, A.P. Gordon, An approach for mechanical property optimization of fused deposition modeling with polylactic acid via design of experiments. Rapid Prototyp. J. 22(2), 387–404 (2016)

J. Suganuma, H. Alexander, J. Appl. Biomater. 4(1), 13–27 (2005)

M. Guvendiren, J. Molde, R.M.D. Soares, J. Kohn, Designing Biomaterials for 3D Printing. ACS Biomater. Sci. Eng. 2(10), 1679–1693 (2016)

E.J. McCullough, V.K. Yadavalli, Surface modification of fused deposition modeling ABS to enable rapid prototyping of biomedical microdevices. J. Mater. Process. Technol. 213(6), 947–954 (2013)

S. Chen, J. Lu, J. Feng, 3D-printable ABS blends with improved scratch resistance and balanced mechanical performance. Ind. Eng. Chem. Res. 57(11), 3923–3931 (2018)

F. Liu, C. Vyas, G. Poologasundarampillai, I. Pape, S. Hinduja, W. Mirihanage, P. Bartolo, Structural evolution of PCL during melt extrusion 3D printing. Macromol. Mater. Eng. 303(2), 1700494 (2018)

W. Wu, P. Geng, G. Li, D. Zhao, H. Zhang, J. Zhao, Influence of layer thickness and raster angle on the mechanical properties of 3D-printed PEEK and a comparative mechanical study between PEEK and ABS. Materials. 8(9), 5834–5846 (2015)

M. Vaezi, S. Yang, Extrusion-based additive manufacturing of PEEK for biomedical applications. Virtual Phys. Prototyp. 10(3), 123–135 (2015)

B.C. Tellis, J.A. Szivek, C.L. Bliss, D.S. Margolis, R.K. Vaidyanathan, P. Calvert, Trabecular scaffolds created using micro CT guided fused deposition modeling. Mater. Sci. Eng. C 28(1), 171–178 (2008)

F.S. Senatov, K.V. Niaza, M.Y. Zadorozhnyy, A.V. Maksimkin, S.D. Kaloshkin, Y.Z. Estrin, Mechanical properties and shape memory effect of 3D-printed PLA-based porous scaffolds. J. Mech. Behav. Biomed. Mater. 57, 139–148 (2016)

G.C. Anzalone, B. Wijnen, J.M. Pearce, Multi-material additive and subtractive prosumer digital fabrication with a free and open-source convertible delta RepRap 3-D printer. Rapid Prototyp. J. 21(5), 506–519 (2015)

A. Goyanes, J. Wang, A. Buanz, R. Martínez-Pacheco, R. Telford, S. Gaisford, A.W. Basit, 3D Printing of Medicines: Engineering Novel Oral Devices with Unique Design and Drug Release Characteristics. Mol. Pharm. 12(11), 4077–4084 (2015)

A.J.L. Morgan, L.H. San Jose, W.D. Jamieson, J.M. Wymant, B. Song, P. Stephens, D.A. Barrow, O.K. Castell, Simple and Versatile 3D Printed Microfluidics Using Fused Filament Fabrication. PLoS One 11(4), e0152023 (2016)

H.N. Chia, B.M. Wu, Recent advances in 3D printing of biomaterials. J. Biol. Eng. 9(1), 4 (2015)

L.D. Albrecht, S.W. Sawyer, P. Soman, 3D Print. Addit. Manuf. 3, 106–112 (2016)

J.E. Trachtenberg, P.M. Mountziaris, J.S. Miller, M. Wettergreen, F.K. Kasper, A.G. Mikos, Open-source three-dimensional printing of biodegradable polymer scaffolds for tissue engineering. J. Biomed. Mater. Res. A 102(12), 4326–4335 (2014)

J.P. Temple, D.L. Hutton, B.P. Hung, P.Y. Huri, C.A. Cook, R. Kondragunta, W.L. Grayson, Engineering anatomically shaped vascularized bone grafts with hASCs and 3D-printed PCL scaffolds. J. Biomed. Mater. Res. A 102(12), 4317–4325 (2014)

A. Liu, G.H. Xue, M. Sun, H.F. Shao, C.Y. Ma, Q. Gao, Z. Gou, S.G. Yan, Y.M. Liu, Y. He, Sci. Rep. 6, 1–13 (2016)

J. De Ciurana, L. Serenó, È. Vallès, Selecting process parameters in RepRap additive manufacturing system for PLA scaffolds manufacture. Procedia CIRP. 5, 152–157 (2013)

W. Kosorn, M. Sakulsumbat, P. Uppanan, P. Kaewkong, S. Chantaweroad, J. Jitsaard, K. Sitthiseripratip, W. Janvikul, J Biomed Mater Res B Appl Biomater 105, 1141–1150 (2016)

U. Ritz, R. Gerke, H. Götz, S. Stein, P.M. Rommens, Int. J. Mol. Sci. 18(12), 2596 (2017)

A. Grémare, V. Guduric, R. Bareille, V. Heroguez, S. Latour, N. L’heureux, J.C. Fricain, S. Catros, D. Le Nihouannen, Characterization of printed PLA scaffolds for bone tissue engineering. J. Biomed. Mater. Res. A 106(4), 887–894 (2018)

G.S. Diogo, V.M. Gaspar, I.R. Serra, R. Fradique, I.J. Correia, Manufacture of β-TCP/alginate scaffolds through a Fab@home model for application in bone tissue engineering. Biofabrication 6, 25001 (2014)

J.C. Boga, S.P. Miguel, D. de Melo-Diogo, A.G. Mendonça, R.O. Louro, I.J. Correia, In vitro characterization of 3D printed scaffolds aimed at bone tissue regeneration. Colloids Surf. B: Biointerfaces 165, 207–218 (2018)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Alagoz, A.S., Hasirci, V. 3D printing of polymeric tissue engineering scaffolds using open-source fused deposition modeling. emergent mater. 3, 429–439 (2020). https://doi.org/10.1007/s42247-019-00048-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42247-019-00048-2