Abstract

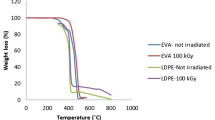

While materials sustainability is mostly considered in terms of their long-time aging, fires are more important—while polymers are flammable. We have developed flame retardants (FRs) for polypropylene (PP) with varied FR concentrations since PP is a very widely used polymer. Stearic acid (SA) has been added to increase filler–matrix interactions and filler dispersion in the matrix. Effects of filler types, particle size, and their concentrations on fire resistibility of different composite samples have been determined via limiting oxygen index tests and burning times. As expected, the oxygen index increases with increasing concentration of either FR. The highest value of the index is seen for 10 wt% 50 nm Al (OH)3 sample. Mixing the two hydroxides does not provide a synergy effect. The longest burning time is seen for 5 wt% 50 nm Al (OH)3 + 7 wt% SA, longer than the time for pure PP sample by 137%. Neat PP has a relatively high dynamic friction value, while addition of 5% SA results in the lowest friction value of all. The highest tensile modulus is seen for PP with 7.5 wt% 15 nm Al (OH)3 particle addition. Thermogravimetric analysis shows high thermal stability for PP with 5% each of Al (OH)3 and Mg (OH)2. Scanning electron microscopy shows that the surfaces of Al (OH)3-containing samples are slightly rougher than those with Mg (OH)2. Energy dispersive X-ray spectroscopy shows uniform distribution of both Al and Mg atoms in the composites.

Similar content being viewed by others

References

W.-Y. Chiang, C.H. Hu, Eur. Polym. J. 32, 385 (1996), The improvements in flame retardance and mechanical properties of polypropylene/FR blends by acrylic acid graft copolymerization, 390

Q.T. Shubhra, A.K.M.M. Alam, M.A. Quaiyyum, J. Thermo, Compos. Mater 26, 362 (2011)

M. Bugajny, M. Le Bras, S. Bourbigot, F. Poutch, J.-M. Lefevbre, Thermoplastic polyurethanes as carbonization agents in intumescent blends. Part 1: fire retardancy of polypropylene/thermoplastic polyurethane/ammonium polyphosphate blends. J. Fire Sci. 17, 494–513 (1999)

L. Techawinyutham, A. Frick, S. Siengchin, Adv. Mech. Eng 8 (2016). https://doi.org/10.1177/1687814016645446

L. Sun, Q. Wu, Y. Xie, R. Cueto, S. Lee, Q. Wang, J. Fire Sci. 34, 228 (2016)

B.M. Braune, M.L. Mallory, H.G. Gilchrist, R.J. Letcher, K.G. Drouillard, Levels and trends of organochlorines and brominated flame retardants in Ivory Gull eggs from the Canadian Arctic, 1976 to 2004. Sci. Total Environ. 378, 403–417 (2007)

K. Langfeld, A. Wilke, A. Sut, S. Greiser, B. Ulmer, V. Andrievici, P. Limbach, M. Bastian, B. Schartel, Halogen-free fire retardant styrene–ethylene–butylene–styrene-based thermoplastic elastomers using synergistic aluminum diethylphosphinate–based combinations. J. Fire Sci. 33, 157–177 (2015)

S.K. Li, Inorg. Chem. Ind 35, 3 (2003)

W.C.J. Zuiderduin, C. Westzaan, J. Huetink et al.: Polym 44, 261 (2003)

K. Kim, J.L. White, S. Shim, et al., Effects of stearic acid coated talc, CaCO3, and mixed talc/CaCO3 particles on the rheological properties of polypropylene compounds. J. Appl. Polym. Sci. 93, 2105–2113 (2004)

M. Avella, S. Cosco, M.L.D. Lorenzo, et al., Nucleation activity of nanosized CaCO3 on crystallization of isotactic polypropylene, in dependence on crystal modification, particle shape, and coating. Eur. Polym. J. 42, 1548–1557 (2006)

N. Kiattipanich, N. Kreua-Ongarjnukool, T. Pongpayoon, et al., J. Polym. Eng. 27, 411 (2007)

C.D. Angel, A.B. Morales, F.N. Pardo, T. Lozano, P.G. Lafleur, S.S.G.M. Colunga, E.R. Vargas, S. Alonso, R. Zitzumbo, J. Appl. Polym. Sci. 132, 42264 (2015)

US ASTM Standard No. D2862

US ASTM Standard No. D882

W. Brostow, J.-L. Deborde, M. Jaklewicz, P. Olszynski, J. Mater. Ed. 25, 119 (2003)

W. Brostow, V. Kovacevic, D. Vrsaljko, J. Whitworth, J. Mater. Ed. 32, 273 (2010)

W. Brostow, H.E. Hagg Lobland, N. Hnatchuk, J.M. Perez, Nano 7, 66 (2017)

W. Brostow, H.E. Hagg Lobland: Materials: introduction and applications, John Wiley & Sons (2017)

M. Barczewski, D. Chmielewska, M. Dobrzynska-Mizera, B. Dudziec, T. Sterzynski, Thermal stability and flammability of polypropylene-silsesquioxane nanocomposites. Internat. J. Polym. Anal. & Char. 19, 500–509 (2014)

G. Martinez-Barrera, F. Ureña-Nuñez, O. Gencel, W. Brostow, Mechanical properties of polypropylene-fiber reinforced concrete after gamma irradiation. Composites A 42, 567–572 (2011)

O. Gencel, C. Ozel, W. Brostow, G. Martinez-Barrera, Mechanical properties of self-compacting concrete reinforced with polypropylene fibres. Mater. Res. Innovat. 15, 216–225 (2011)

J. Andrzejewski, M. Szostak, M. Barczewski, J. Krasucki, T. Sterzynski, J. Appl. Polym. Sci. 131, 41180 (2014)

J. Karger-Kocsis, editor: Polypropylene structure, blends and composites, volumes 1 - 3, Springer Science (2012)

A. Wolska, M. Gozdzikiewicz, J. Ryszkowska, Thermal and mechanical behaviour of flexible polyurethane foams modified with graphite and phosphorous fillers. J. Mater. Sci. 47, 5627–5634 (2012)

C.P.R. Hoppel, R.N. Pangborn, R.W. Thomson, Damage accumulation during multiple stress level fatigue of short-glass-fiber reinforced styrene-maleic anhydride. J. Thermoplast. Compos. Mater. 14, 84–94 (2001)

D.R. Kelsey, B.M. Scardino, J.S. Grebowicz, H.H. Huah, High impact, amorphous terephthalate copolyesters of rigid 2,2,4,4-tetramethyl-1,3-cyclobutanediol with flexible diols. Macromolecules 33, 5810–5818 (2000)

C. Velasco-Santos, A.L. Martinez-Hernandez, F.T. Fisher, R. Ruoff, V.M. Castaño, Improvement of thermal and mechanical properties of carbon nanotube composites through chemical functionalization. Chem. Mater. 15, 4470–4475 (2003)

C. Zeppa, F. Gouanvé, E. Espuche, Effect of a plasticizer on the structure of biodegradable starch/clay nanocomposites: thermal, water-sorption, and oxygen-barrier properties. J. Appl. Polym. Sci. 112, 2044–2056 (2009)

W. Brostow, H.E. Hagg Lobland, S. Lohse, A.T. Osmanson, R. Ravi, S. Sayana, V. Shi, A. Singh, Proc. BALTTRIB Conf. 9, 57 (2017)

R. Levinskas, R. Kėželis, K. Brinkienė, V. Grigaitienė, V. Valinčius, I. Lukošiūtė, Ž. Kavaliauskas, A. Baltušnikas, High temperature ablation of composite material under plasma jet impact. Mater. Sci. Medžiagotyra 17, 423–427 (2011). https://doi.org/10.5755/j01.ms.17.4.781

R. Levinskas, I. Lukosiute, A. Baltusnikas, A. Kuoga, A. Luobikiene, J. Rodriguez, I. Cañadas, W. Brostow, Modified xonotlite–type calcium silicate hydrate slabs for fire doors. J. Fire Sci. 36, 83–96 (2018)

J. Broda, C. Slusarczyk, J. Fabia, A. Demsar, Formation and properties of polypropylene/stearic acid composite fibers. Textile Res. J. 86, 64–71 (2016)

Acknowledgements

Some financial as well as technical support for this project has been provided by the Encore Wire Corp., McKinney, TX, and are gratefully acknowledged. Several colleagues have provided useful comments on our work and on this manuscript including Ray H. Pahler and Andrew Hull. Anonymous reviewer comments have been taken into consideration and are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Brostow, W., Lohse, S., Lu, X. et al. Nano-Al (OH)3 and Mg (OH)2 as flame retardants for polypropylene used on wires and cables. emergent mater. 2, 23–34 (2019). https://doi.org/10.1007/s42247-018-0019-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42247-018-0019-8