Abstract

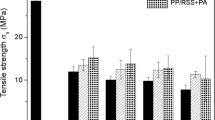

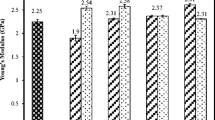

Pollen grains have the potential to be effective plant-based biorenewable fillers in polymer matrices due to their high modulus, strength, chemical stability, and unique nanoscale architectures. In this work, we present evidence for the effectiveness of pollen as a reinforcing filler in epoxy matrices, characterized as a function of pollen loading and surface treatment. Composites prepared with unmodified native defatted ragweed pollen (D) displayed decreased mechanical properties and increasing glass transition temperatures (Tg) with increasing pollen loading. A soft interphase was observed to form around native pollen that is likely due to incompletely cured epoxy, resulting in decreased mechanical properties. However, pollen treated via a common base-acid (BA) surface preparation was a load-bearing, toughening filler in epoxy composites, displaying simultaneously increased tensile strength (by 47%) and strain at break (by 70%), improving interfacial morphology (absence of soft interphase), and increasing Tg at 10 wt% pollen loading. Elastic modulus improves by 14% with 10 wt% BA pollen loading, and fitting of the modulus with the Halpin-Tsai and Counto models results in an estimated pollen exine modulus of 8 GPa, the first reported pollen modulus measurement from composite studies. Improvements in mechanical properties in BA pollen versus D pollen likely result due to crosslinks with the epoxy matrix due to the presence of protic functional groups (hydroxyls or carboxyls) on the BA surface. BA-treated ragweed pollen shows promise as a toughening filler for imparting higher strength to polymers without increasing mass.

Similar content being viewed by others

References

S.-Y. Fu, X.-Q. Feng, B. Lauke, Y.-W. Mai, Effects of particle size, particle/matrix interface adhesion and particle loading on mechanical properties of particulate–polymer composites. Compos. Part B 39, 933–961 (2008)

G. Wypych, Handbook of fillers, 3 edn (ChemTec, 2010)

B.J. Ash, D.F. Rogers, C.J. Wiegand, L.S. Schadler, R.W. Siegel, B.C. Benicewicz, T. Apple, Mechanical properties of Al2O3/polymethylmethacrylate nanocomposites. Polym. Compos. 23, 1014–1025 (2002)

Z. Spitalsky, D. Tasis, K. Papagelis, C. Galiotis, Carbon nanotube–polymer composites: chemistry, processing, mechanical and electrical properties. Prog. Polym. Sci. 35, 357–401 (2010)

S. Barrier, Physical and chemical properties of sporopollenin exine particles, Ph.D. Thesis, University of Hull, (2008)

O.O. Fadiran, J.C. Meredith, Surface treated pollen performance as a renewable reinforcing filler for poly(vinyl acetate). J. Mater. Chem. A 2, 17031–17040 (2014)

J.H. Lee, B.M. Suttle, H.J. Kim, J.C. Meredith, Pollen: a novel, biorenewable filler for polymer composites. Macromol. Mater. Eng. 296, 1055–1062 (2011)

T. Liu, Z. Zhang, Mechanical properties of desiccated ragweed pollen grains determined by micromanipulation and theoretical modelling. Biotechnol. Bioeng. 85, 770–775 (2004)

B. Goodwin, I. Gomez, Y. Fang, J.C. Meredith, K.J. Sandhage, Conversion of pollen particles into three-dimensional ceramic replicas tailored for multimodal adhesion. Chem. Mater. 25, 4529–4536 (2013)

W.B. Goodwin, D. Shin, D. Sabo, S. Hwang, Z.J. Zhang, J.C. Meredith, K.H. Sandhage, Bioinspiration & Biomimetics 12, 066009 (2017)

Y. Wang, Z.M. Liu, B.X. Han, Y. Huang, G.Y. Yang, Carbon microspheres with supported silver nanoparticles prepared from pollen grains. Langmuir 21, 10846–10849 (2005)

Y. Wang, Z.M. Liu, B.X. Han, Z.Y. Sun, J.M. Du, J.L. Zhang, T. Jiang, W.Z. Wu, Z.J. Miao, Chemical communications, 2948–2950 (2005)

H.S. Lin, M.C. Allen, J. Wu, B.M. DeGlee, D. Shin, Y. Cai, K.H. Sandhage, D.D. Deheyn, J.C. Meredith, Chem Mater 27, 7321–7330 (2015)

S.U. Atwe, Y.Z. Ma, H.S. Gill, Pollen grains for oral vaccination. J. Control. Release 194, 45–52 (2014)

I. Sargin, L. Akyuz, M. Kaya, G. Tan, T. Ceter, K. Yildirim, S. Ertosun, G.H. Aydin, M. Topal, Controlled release and anti-proliferative effect of imatinib mesylate loaded sporopollenin microcapsules extracted from pollens of Betula pendula. Int. J. Biol. Macromol. 105, 749–756 (2017)

P. Piffanelli, J.H.E. Ross, D.J. Murphy, Biogenesis and function of the lipidic structures of pollen grains. Sex. Plant Reprod. 11, 65–80 (1998)

R. Wiermann, S. Gubatz, Pollen wall and sporopollenin. Int. Rev. Cytol. 140, 35–72 (1992)

S. Blackmore, A.H. Wortley, J.J. Skvarla, J.R. Rowley, Pollen wall development in flowering plants. New Phytol. 174, 483–498 (2007)

E. Dominguez, J.A. Mercado, M.A. Quesada, A. Heredia, Sex. Plant Reprod. 12, 171–178 (1999)

E.M. Petrie, Epoxy adhesive formulations (McGraw-Hill, 2006)

H. Lin, I. Gomez, J.C. Meredith, Pollenkitt wetting mechanism enables species-specific tunable pollen adhesion. Langmuir 29, 3012–3023 (2013)

B.J.R. Thio, J.H. Lee, J.C. Meredith, Characterization of ragweed pollen adhesion to polyamides and polystyrene using atomic force microscopy. Environ. Sci Technol. 43, 4308–4313 (2009)

F. Zetzsche, H. Vicari, Untersuchungen über die Membran der Sporen und Pollen II. Lycopodium clavatum L. 2. Helv Chim Acta 14, 58–78 (1931)

J.L. Sormana, S. Chattopadhyay, J.C. Meredith, Rev. Sci. Instrum. 76 (2005)

E. Dominguez, J.A. Mercado, M.A. Quesada, A. Heredia, Isolation of intact pollen exine using anhydrous hydrogen fluoride. Grana 37, 93–96 (1998)

G. Shaw, D.C. Apperley, 13C-NMR spectra ofLycopodium clavatumsporopollenin and oxidatively polymerised β-carotene. Grana 35, 125–127 (1996)

J.C.C. Maria González González, J.C. Cabanelas, J. Baselga, in Infrared spectroscopy - materials science, engineering and technology, ed. by T. Theophile. (InTech, 2012), pp. 261–284

V. Cecen, Y. Seki, M. Sarikanat, I.H. Tavman, FTIR and SEM analysis of polyester- and epoxy-based composites manufactured by VARTM process. J. Appl. Polym. Sci. 108, 2163–2170 (2008)

S.H. Xu, N. Girouard, G. Schueneman, M.L. Shofner, J.C. Meredith, Mechanical and thermal properties of waterborne epoxy composites containing cellulose nanocrystals. Polymer 54, 6589–6598 (2013)

J.I. Yang, Part I: synthesis of aromatic polyketones via soluble precursors derived from bis(A-amininitrile)s Part II: modifications of epoxy resins with functional hyperbranched poly(areylene ester)s, Ph.D. Thesis, Virginia Tech, (1998)

M. Amato, F. Barbato, P. Morrica, F. Quaglia, M.I. La Rotonda, Helv Chim Acta 83, 2836–2847 (2000)

J.Y.C. Ma, J.K.H. Ma, K.C. Weber, Fluorescence studies of the binding of amphiphilic amines with phospholipids. J. Lipid Res. 26, 735–744 (1985)

B. Tadolini, G. Hakim, Ital. J. Biochem. 37, A184–A185 (1988)

J.C. Halpin, J.L. Kardos, Polym. Eng. Sci. 16, 344–352 (1976)

S. Ahmed, F.R. Jones, A review of particulate reinforcement theories for polymer composites. J. Mater. Sci. 25, 4933–4942 (1990)

U.J. Counto, The effect of the elastic modulus of the aggregate on the elastic modulus, creep and creep recovery of concrete. Mag. Concr. Res. 16, 129–138 (1964)

H.B. Lu, S. Nutt, Restricted relaxation in polymer nanocomposites near the glass transition. Macromolecules 36, 4010–4016 (2003)

A. Yim, R.S. Chahal, L.E. Stpierre, The effect of polymer—filler interaction energy on the T′g of filled polymers. J. Colloid Interface Sci. 43, 583–590 (1973)

A. Yasmin, J.L. Abot, I.M. Daniel, Processing of clay/epoxy nanocomposites by shear mixing. Scr. Mater. 49, 81–86 (2003)

Funding

We would like to thank the Renewable Bioproducts Institute (Georgia Institute of Technology) and the Air Force Office of Scientific Research (Grant # FA9550-10-1-0555) for financial support of this research.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

ESM 1

Electronic supplementary material is available, which includes SEM images (pollen recovered from solution and fracture surfaces), photographs (color changes in amines and epoxy films), uniaxial mechanical properties and modeling, AFM force modulation images of fracture surfaces. (DOCX 7898 kb)

Rights and permissions

About this article

Cite this article

Fadiran, O.O., Girouard, N. & Meredith, J.C. Pollen fillers for reinforcing and strengthening of epoxy composites. emergent mater. 1, 95–103 (2018). https://doi.org/10.1007/s42247-018-0009-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42247-018-0009-x